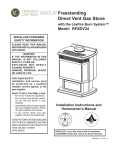

Download Vermont Castings RFSDV32 Specifications

Transcript