Download Solar PV systems Users` maintenance guide

Transcript

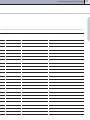

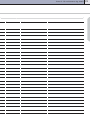

Solar PV systems Users’ maintenance guide Solar PV Systems: Users maintenance guide Produced by Australian Business Council for Sustainable Energy 60 Leicester Street Carlton Victoria 3053 Australia Phone: 03 9349 3077 Website: www.bcse.org.au Funded by Australian Greenhouse Office Major contributors Jeff Hoy, JP Energy Technologies Brad Shone, Alternative Technology Association (ATA) Geoff Stapleton, Global Sustainable Energy Solutions Mike Russell, Business Council for Sustainable Energy Nigel Wilmot, Research Institute for Sustainable Energy (RISE) ISBN: 978-0-9802806-9-2 The information in this guide has been provided as a guide to solar PV systems. While every effort has been made to ensure the content is useful and relevant, no responsibility for any purchasing decision based on this information is accepted by the Australian Business Council for Sustainable Energy or other contributors. Australian Government funding through the Australian Greenhouse Office in the Department of the Environment and Water Resources supports this project. The views expressed herein are not necessarily the views of the Commonwealth, and the Commonwealth does not accept responsibility for any information or advice contained herein. Solar PV Systems: Users maintenance guide Contents A: Introduction 1. About this guide Maintenance 2. Precautions and warnings 3 3 3 4 B: Stand-alone solar PV systems 1. Energy generation equipment 10 11 Solar array 11 Gensets 12 12 240 volt output 4 Wind generators Battery banks 5 Pico-hydro generators Wet lead-acid batteries 5 Sealed lead acid batteries 6 General installation requirements Solar modules 7 Safety first! 15 Gensets 7 Maintenance of battery banks 16 Wind generators 8 Checking your batteries 16 Pico-hydro generators 8 Charging your batteries 17 3. Maintenance schedules and logbooks 9 2. Battery bank 12 14 14 Checking the voltage 17 Typical battery maintenance tasks 18 Isolating the system for maintenance 18 Cleaning the cells 19 Checking the charge and condition of the battery bank 19 Voltage measurement 20 Specific gravity measurement 20 Using a hydrometer 20 Neutralising acid spills 21 Topping up the electrolyte 21 Cleaning the battery terminals 22 Differences for gel cell type batteries 22 1 2 Solar PV Systems: Users maintenance guide 3. Balance of Systems (BOS) The inverter 23 Annex 1: SPS maintenance log sheets 32 Regulator(s) 24 Switchboards and wiring 25 Solar array log sheet 32 Battery chargers 25 Battery bank log sheet 34 System wiring 25 Balance of systems log sheet 35 Genset log sheet 36 4. Interpretation of monitoring equipment 26 Solar array meter 26 Wind generator meter 26 Pico-hydro meter 26 System voltage meter 27 Other monitoring 27 C: Grid-connected solar PV systems 1. 2. 3. 4. 23 PV solar modules Inverters Balance of system How do I know my system is working? 28 29 30 30 31 Wind generator log sheet 36 Pico-hydro log sheet 37 Annex 2: GC maintenance log sheets Solar array log sheet 38 38 Inverter log sheet 40 BOS log sheet 40 Annex 3: Glossary 41 Annex 4: SPS maintenance at a glance 43 Safety First Annex 5: Information to be obtained from System Supplier or Manufacturers 43 44 A: Introduction A: Introduction 1. About this guide This guide will give you an overview of the maintenance required for a typical stand-alone solar power system (SPS)* and grid-connected solar power system (GC) including precautions and warnings on the hazards of working with solar power systems. SPS maintenance is covered in Section B and GC in Section C. For each section: • the first three chapters provide an overview of each of the individual components followed by a more detailed description of the maintenance required; • the final chapter describes how to monitor the operation of the system. Annexes 1 and 2 demonstrate sample log sheets for a system l o g b o o k. Annex 3 is the glossary of terms introduced in this guide. Annex 4 is an at-a-glance sheet. Annex 5 is information to check with system supplier or manufacturer Maintenance * A definition of all words or phrases in bold italics is provided in Annex 3, the glossary As with any piece of equipment, performing regular maintenance and inspection of components will help ensure system performance and minimise disruption due to component failure. If our described procedures differ from those suggested by your manufacturer and/or installer, follow the procedures outlined in the system user manual supplied with your system. This guide is designed for those already familiar with the basic components and configuration of solar power systems. More introductory information can be found in the Electricity From The Sun – Solar PV Systems Explained (ISBN: 978-09802806-7-8) available from your installer. There are many books available to provide further details about these systems and components. As part of the regular maintenance of a system, it is recommended that you keep a logbook recording all system maintenance and performance. In the logbook the type and frequency of maintenance and who performed it should be recorded. If kept up to date, it can be used to provide a history of the system which can then be used for fault diagnosis. With some standalone systems, a logbook is required to be kept in accordance with the battery warranty conditions. Check with the system supplier concerning any logbook requirements. 3 4 Solar PV Systems: Users maintenance guide 2. Precautions and warnings Solar power systems are safe when operating correctly however there are potentially dangerous hazards associated with some system components. These hazards can include: • 240V outputs and other dangerous voltages; • batteries; • solar modules; • gensets ; • wind generators; and • p i c o - h y d r o generators . 240 volt output Safety warnings The following symbols appear in this manual. Immediate SAFETY Hazard Failure to follow recommended procedure will result in serious injury. General SAFETY Warning Failure to follow recommended procedure could result in injury. A stand-alone power system (SPS) typically provides 240V AC power without being connected to the electricity grid. Electrical SAFETY Warning Failure to follow recommended procedure could result in injury. Work Safely Wear protective eyewear and appropriate clothing during maintenance. A grid-connected power system (GC) provides 240V AC power by being connected to the electricity grid, often referred to as power lines or mains power. A: Introduction Battery banks Although 240V AC power is dangerous and can cause death when live exposed wires/terminals are touched or cause fire, it is generally safe when kept in good working order. Low voltage (LV) is specified in the Australian Standards as any voltage equal to or higher than 50V AC or 120V DC. Any service requiring LV wiring must be undertaken by a suitably licensed electrical worker or contractor. The owner of the system MUST NOT undertake any maintenance to LV wiring systems or the output terminals of equipment that produces low voltage (LV). NOTE If the battery bank has a nominal voltage of 120V DC or above, maintenance can only be undertaken by a suitably licensed electrical worker or contractor. The owner of the system MUST NOT undertake any maintenance to battery banks 120V DC or above. The battery bank can include either wet lead-acid or sealed lead-acid cells. Wet lead-acid batteries The hazards related to a wet lead-acid battery bank include the risk of: • explosion due to hydr ogen gas; • burns caused by acid in the individual cells; • shor t i n g of ter minals on and between the individual cells; and • electrocution caused by an output voltage 120V DC or greater. To minimise the hazards the following precautions should be taken when undertaking any maintenance: • no maintenance should be undertaken if there is a strong smell of sulphuric acid in the vicinity of the battery bank; • no smoking or naked flames; • safety goggles MUST be worn; • acid resistant gloves MUST be worn; • acid resistant apron or clothing should also be worn; • clean water should be available near the batteries to wash any acid that comes in contact with skin; • bi-carbonate soda should also be available to be used, with water, to neutralise any acid that is spilled onto the ground; and • the end of spanners (or any other tools) that you will use near the battery bank should be insulated to avoid any accidental shorts between the terminals. 5 6 Solar PV Systems: Users maintenance guide Sealed lead acid batteries The hazards related to a sealed lead acid battery include the risk of: • explosion due to hydrogen gas (if covered); • shorting of terminals on and between the individual cells; and • electrocution caused by having a nominal output voltage 120V DC or greater. To minimise the hazards, the following precautions should be taken when undertaking any maintenance: • no smoking or naked flames • no maintenance should be undertaken if there is a strong smell of sulphuric acid in the vicinity of the battery bank; and • the end of spanners (or any other tools) that you will use near the battery bank should be insulated to avoid any accidental shorts between the terminals. A: Introduction Solar modules Gensets The hazards related to solar modules include the risk of: • electric shock due to array open-cir c u i t voltage greater than 120V d.c; and • falling from the roof when performing maintenance. The hazards related to gensets include the risk of: • electrocution due to 240V AC output; and • ignition of flammable and/or explosive fuels • inhaling of exhaust gases • combustion caused by exhaust sparks • burns from hot exhaust pipe • the presence of a battery (see above) • accidents from moving parts • ear damage due to noise. NOTE If the solar modules are connected in an array where the open circuit voltage is 120V DC or above, maintenance can only be undertaken by a suitably licensed electrical worker or contractor. The owner of the system MUST NOT undertake any maintenance to these solar modules other than simple cleaning. To minimise the hazards the following precautions should be taken when undertaking any maintenance: • when working on roofs there is always the risk of falling. NEVER climb onto a roof to perform any service on the solar modules (eg. clean them) unless there is a barrier (eg. scaffolding) to prevent you from falling or you are wearing an approved safety harness which is supported correctly. They also have rotating parts and these should be protected during operation. To minimise the hazards the following precautions should be taken when undertaking any maintenance: • follow all recommendations provided in the equipment manuals; or • use a qualified service technician. Any service required to the LV wiring must be undertaken by a suitably licensed electrical worker or contractor. 7 8 Solar PV Systems: Users maintenance guide Wind generators Pico-hydro generators The hazards related to wind generators can include the risk of: • electrocution due to dangerous voltages (either DC or AC LV) ; • falling from the top of a pole or structure; • damage caused by rotating and/or moving parts. • an accident while lowering or raising of tower • damage by stumbling into unfenced or unprotected guy wir es • being hit by tail in sudden wind gusts (if structure tower is suitable for climbing). The hazards related to pico-hydro generators can include the risk of: • electrocution due to dangerous voltages (either DC or AC LV) ; • falling whilst accessing pipes in steep and slippery locations; and • accidents caused by rotating and/or moving parts. To minimise the hazards the following precautions should be taken when undertaking any maintenance: • follow all recommendations provided in the equipment manuals; and • use a brake on turbine before lowering or raising tower; or • use a qualified service technician. To minimise the hazards, the following precautions should be taken when undertaking any maintenance: • follow all recommendations provided in the equipment manuals; and • turn off water source or • use a qualified service technician. Any service required to the LV wiring must be undertaken by a suitably licensed electrical worker or contractor. A: Introduction 3. Maintenance schedules and logbooks A maintenance schedule with an equipment logbook (or logbooks) should be provided as part of the documentation supplied to the system owner by the supplier at the completion of system installation and commissioning. Suggested maintenance intervals and records for major equipment components of an SPS or GC system are provided in sections B and C. A loose-leaf folder can be used as the system log book with individual sheets added for each item. Though having one folder might be ideal for an SPS, often you will have a couple of logbooks due to gensets requiring regular services like a car and can be supplied with their own logbook. Battery bank manufacturers can often supply battery logbooks, which must be completed to meet warranty conditions. If you do have separate logbooks, it is advisable to keep them together in a clean dry location. Annex 1 (SPS) and Annex 2 (GC) provide examples of sheets that can be used for each piece of equipment. When completing the log sheets, the date and name of person undertaking the maintenance or inspection should be recorded. Log books can be particularly useful because the historical information they contain can show changes over time, as well as abnormal variations from the usual, indicating a problem, or a potential problem. 9 10 Solar PV Systems: Users maintenance guide B: Stand-alone solar PV systems Prior to performing any maintenance, follow shut down procedures as specified in your system manual. The typical SPS will include: • PV array of modules; • battery bank; • balance of system (BOS) equipment—including inverter, regulator(s), battery charger, system wiring; and • a genset. These sections cover the maintenance requirements for these components which includes the complete system i n t e g r i t y. Since some systems include wind generators or pico-hydro generators, this chapter does finish with a summary of the maintenance requirements for these two items. B: Stand-alone solar PV systems 1. Energy generation equipment Energy generation equipment includes the solar photovoltaic array, gensets, wind generators, pico-hydro generators and is also considered to include associated equipment such as frames, trackers, towers, water pipes and regulators or controllers. The regulators and controllers are discussed in chapter B3. Solar array WARNING If modules are The solar array (a number of solar modules mounted together) is quite often referred to as being maintenance free. This can be the case in many situations, however, with occasional maintenance and inspection, the performance of all the solar modules in the array can be assured. The most common maintenance task for solar modules is the cleaning of the glass area to remove excessive dirt. An example of a PV panel maintenance log sheet is shown in Annex 2. located on the roof and there is a risk of falling during maintenance, then fall protection equipment (eg. harness or scaffolding) MUST be used. In most situations cleaning is only necessary during long dry periods when there is no rain to provide natural cleaning. To remove a layer of dust and dirt from the modules, simply wash the module with water. If the module has thick dirt or grime, which is harder to remove, wash with warm water and a sponge. Washing the modules is similar to washing glass windows but detergents should not be used. The modules should be cleaned when they are not excessively hot, typically early in the morning. After the modules have been cleaned, a visual inspection of the modules can be done to check for defects such as cracks, chips and discolouration. If any obvious defects are found, note their location in the system logbook, so these can be monitored in the future in case further deterioration affects the modules’ output. When inspecting the solar modules, the condition of the array mounting frame should also be noted. Items to observe should include the array mounting bolts (eg. bolts rusting) and checks to ensure that the frame and modules are firmly secured. 11 12 Solar PV Systems: Users maintenance guide Gensets Wind generators WARNING Disable any remote or automatic start mechanisms for gensets before commencing servicing. Also remove any keys and disconnect any starter batteries. A petrol, LPG or diesel genset will require regular checks of the fuel and oil levels. These will need to be topped up as required. In addition, regular servicing including complete oil changes and filter changes will be required, at intervals specified in the system manual. It is recommended that all gensets do at least have an AC volt meter on the output so the output voltage can be monitored. If the genset is generating a voltage higher or lower than the typical 240V (230V), or operating faster or slower than the recommended speed, the genset could damage household appliances while the associated battery charger could also be damaged or not operate correctly. There should also be a run-hour meter to determine when maintenance is due. If you suspect that the genset is not operating correctly, call your system supplier/installer or your service mechanic. WARNING Gensets produce 240V AC. Do not open any enclosures on the genset that will expose LIVE terminals. Pico-hydro generators The basic components of a pico-hydro system are shown in the diagram below. With most pico-hydro generators, the maintenance required will be specific to the machine and pipe installed. The user manual should always be consulted before attempting any maintenance. The intake system should be designed to minimise the blocking of the inlet pipe by leaves, sticks or silting up. If this is a problem then the main maintenance on a pico-hydro system will be keeping the intake system clean and free of debris. B: Stand-alone solar PV systems With most wind generators the maintenance required will be specific to the machine and tower installed. • check that system regulators and dump loads are functioning in windy conditions, (refer to system supplier if things don’t look right). The wind generator is typically located on a tower. Most of the maintenance that will be required on the wind generator will require the tower to be lowered. The user manual should always be consulted before attempting any maintenance. Typical checks by the system owner: • inspection of guy wires on guyed tower— check for tension, and excessive fraying or corrosion of guy wires; • check the functioning of any manual furling mechanisms; • if a cable twist system is used, check the amount of twist and untwist if required; and WARNING Do not attempt to lower a turbine tower unless you have been trained in this procedure and never in windy conditions. W AT E R STORAGE I N TA K E SYSTEM The water flow can be controlled automatically PIPELINE CONTROLS To Load I S O L AT I N G VA LV E G E N E R AT O R To stream TURBINE SHUNT LOADS 13 14 Solar PV Systems: Users maintenance guide 2. Battery bank The battery bank usually consists of individual 2V cells connected together in series and sometimes in parallel to provide a battery bank with the required system DC voltage and energy storage. Sometimes 12V or 6V monoblock cells are used instead of the 2V cells. These systems should use batteries which are designed for deep cycling applications which are better suited to the charging and discharging regime. Car and truck batteries are not suitable. The battery bank should be housed in an enclosure accessible only to authorised people. An authorised person could be the system owner or an appointed person. In Australia there are two main types of batteries used in SPS systems: • Wet cell flooded batteries (vented cells)—in which the electr olyte level must be regularly checked. • Sealed or gel cell batteries—where there is no access to the electrolyte, a regulated valve is incorporated and the battery is completely sealed. Nickel cadmium (NiCad) and nickel iron (NiFe) batteries are rarely used for solar power systems in Australia. General installation requirements The batteries should be located in accordance with manufacturer’s recommendations. The battery bank must be protected by a suitable enclosure which is only accessible by appropriately authorised people (eg. system owner, installer, service person). In large sheds the battery bank should still be housed in either a separate room or battery box to prevent unauthorised access and to separate spark sources B: Stand-alone solar PV systems Safety first! Always remember that a battery is a form of energy storage which, under certain conditions, can release its energy instantaneously, with explosive consequences. The battery bank should only be accessible to people who understand its functioning and are responsible for its maintenance. It should be able to restrict access to other people, especially children. As far as possible, the area should be animal and vermin proof. Restricting access to the batteries will be the first and often the from explosive vented battery gases. All battery installations should be either naturally or for ced ventilated to prevent the build up of explosive gases. The battery enclosure should be clean, dry and lockable to prevent unauthorised access. It should also house only the batteries. Good access to the battery terminals and electrolyte filler caps is required. Generally, batteries are best safety measure. Suitable safety signs should caution people of the dangers (see example signage above.) The following safety equipment should always be available and ready to use. People who have access to the battery bank area should all be instructed in its use. • Bucket of clean water –for rinsing off acid splashes. installed on a battery rack or on timber to keep them off the floor and provide the required access to the batteries. There should not be shelves or any other equipment above the batteries because items falling from these shelves onto the batteries could cause a short circuit or the equipment itself could be spark generating. In addition, gases from the battery can corrode equipment. Avoid clutter around the battery enclosure to facilitate easy • Safety goggles or face shield – for face and eye protection. • Rubber gloves – for protection of hands. • Eyewash bottle – for rinsing acid splashes out of eyes. • Overalls or apron – for protection of body and clothing from acid splash. • Baking soda (Bicarbonate) – for neutralising acid spills. access. The battery enclosure must not be used as a storage area. Minimise the battery bank’s exposure to extremes of temperature because this can reduce performance and life. The battery bank should be installed so that each individual battery is exposed to the same temperature conditions. Provision should be made for the containment of any spilled electrolyte. 15 16 Solar PV Systems: Users maintenance guide Maintenance of battery banks Generally maintenance of batteries will concentrate on correct charging regimes, electrolyte condition, battery terminals and overall battery safety. Before you start Before you start with your maintenance, ensure all safety equipment is at hand and ready to use. Listed below is typical equipment you will need for these maintenance tasks safely and correctly. Safety equipment See safety first! above • Hydr ometer – for checking specific gravity of electrolyte and hence battery charge. • Glass bulb type thermometer – for temperature measurement of electrolyte. • Container with clean water to rinse hydrometer and thermometer. • Handheld voltmeter or multimeter – for checking battery voltage. • Appropriate tools – correct size spanners and/or screwdrivers with insulated handles. Checking your batteries As part of regular maintenance, a thorough visual inspection of the battery bank is required. This inspection should include: • cleanliness of batteries; • level of electrolyte, (not required for gel cell batteries); • condition of battery terminals; • signs of any electrolyte in the safety trays (if provided) or on the floor, indicating a possible battery leak or overfilling; • condition of battery containers; and • battery voltage level. • Plastic type dishwashing scourer or similar – for cleaning battery terminals and connectors. • Anti oxidant coating – for coating battery terminals and connectors after cleaning. • Baking soda – for cleaning of batteries. B: Stand-alone solar PV systems Charging your batteries To maximise the life of a battery bank, it is best to ensure that it is regularly receiving a full charge and that its state of charge is not allowed to fall excessively. Please check the manufacturer’s recommendation with the system supplier—some solar lead acid batteries can go down to a maximum depth of dischar ge of 7080% while, for some deep cycle lead acid batteries, the recommended maximum depth of discharge is 50%. Each day, at around the same time, the battery voltage should be checked, as this will give you a regular indication of the battery charge condition. Decisions on energy use can be made based on this check to avoid over discharge of the battery. Such decisions may include delaying energy use or using backup generators to charge the batteries. When you become more familiar with the operation of your system, this battery check may occur less frequently. For flooded batteries, the battery bank also requires an equalisation charge to ensure that all individual cells in the bank are at a similar charge. This is achieved by charging the battery until bubbling (gassing) occurs. The period between equalisation charges is dependent upon manufacturer and typically vary from 7–28 days but some batteries can be as high as 90 days. Please check with your system supplier. If the equalisation charge is not achieved by the solar array then the genset will need to be run and the charging provided by the separate battery charger. Checking the voltage The table below lists typical voltage levels that indicate whether the state of charge is good or bad for the battery bank. This table is valid when the batteries are at rest, (ie. no charge or discharge is occurring). This table should only be used as Nominal Voltage 2V 12V 24V 48V Bad <1.9 <11.4 <22.8 <45.6 a guide and for accurate charge levels the specific gravity of each cell should be tested, where possible. The table below is typical of flooded wet cell batteries at 25oC. At higher or lower temperatures, correction should be made using temperature correction factors from your battery specifications. If you have gel cell batteries, you can only check the battery specifications from the manufacturer for an indication of state of charge for various voltage levels. Time to start economising or using backup charger Good 1.9-2.0 11.4-12 22.8-24 45.6-48 2-2.2 12-13.2 24-26.4 48-52.8 Caution (depending on battery – see note) >2.4 >14.4 >28.8 >57.6 Note: Some batteries have an equalisation or boost charge of 2.6V per 2V cell. 17 18 Solar PV Systems: Users maintenance guide Typical battery maintenance tasks Preparing the system for battery maintenance It is important to avoid clutter around the battery bank, so remove all unnecessary items, leaving only safety gear and equipment required for the maintenance of the battery bank. Before starting the battery bank maintenance, it is extremely important to isolate the battery bank from the system to shut the system down. Follow the specified shutdown procedure—you should see a sign on the wall near your equipment, spelling out this procedure. The user manual may provide further information. It is also best to wait for the solar regulator, wind generator dump load or picohydro dump load to have finished a boost char ge before switching to a float char ge mode. Ensure there is plenty of ventilation in the battery enclosure or room. If using forced ventilation, check that ventilation systems are functioning correctly and are clean and unobstructed. For consistency in the recording of specific gravity and voltage measurements, each cell should have a permanent number identification on it which is not easily erased by wear and maintenance. When recording specific gravity or voltage, these numbers can be used as a reference label. Before assessing the condition of a battery, it is best to have a fully charged battery. Isolating the system for maintenance A typical process in shutting down a system and isolating the battery bank to make it safe to perform the maintenance tasks would follow the following steps. WARNING Refer to system user manual provided by system supplier for exact procedures relevant to your system. 1. Shut down (turn off) all loads on the system starting from the household appliances and working back to the inverter. 2. Disconnect (turn off) all energy generation devices such as solar or wind generators. 3. Shut down the battery bank—this would involve either switching off cir cuit br eakers or removing any fuses on the battery bank. If fuses are used, the fuse on the negative terminal of the battery bank should be removed first followed by the fuse on the positive terminal. 4. If a switch-fuse is used, opening the switch fuse disconnects the fuses from the batteries. Remove the front mechanism to prevent it being closed while you are working. 5. When a circuit breaker is used, either place a ‘Do B: Stand-alone solar PV systems Cleaning the cells Each cell should be clean before removing any filler caps to perform maintenance or measurements. This will avoid contamination of the cell by dirt. To clean the cells, use either a brush to remove dry material and/or a rag dipped in a solution of baking soda and water and thoroughly squeezed out. Checking the charge and condition of the battery bank WARNING When cleaning batteries, avoid using excess water which may spill into the cell and always wipe away from electrolyte filler holes. Do not allow any baking soda to enter the cell— even a tiny amount of baking soda will permanently damage the cell. There are two methods for determining the state of charge and condition of the battery bank. They are: • measuring the voltage of each cell; • measuring the specific gravity of the electrolyte in each cell. The measuring of specific gravity is the more accurate measure of a cell’s state of charge when used in conjunction with manufacturer’s specifications and data. Frequent recording of the specific gravity of your cells can be part of their warranty requirements. have its own circuit breakers or switch-fuses, to isolate each parallel string, as described above. not operate tag’ on the circuit breaker or physically isolate the battery bank by removing the battery cabling, first from the negative terminal, then from the positive terminal. 6. If the battery bank contains more than one string of cells, each parallel string should The battery bank is now electrically isolated from all energy generating devices and loads. It can now be worked on for maintenance BUT remember each cell is an energy storage deviceshorting of any terminals is dangerous and can cause an explosion. 19 20 Solar PV Systems: Users maintenance guide Voltage measurement Once the battery bank is isolated, use a volt meter to measure the voltage across the complete battery bank and across each cell and record in the logbook. If any cell is more than 10% higher or lower than the average cell voltage, an equalisation charge should be performed and the battery bank rechecked. Using a hydrometer to check the specific gravity of the electrolyte in a battery bank Before use, thoroughly rinse all components of the hydrometer to avoid contamination of the electrolyte by foreign materials. Also rinse and clean the thermometer. Choose one cell for the measurement of the electrolyte temperature. Insert the thermometer into a cell, being careful not to touch any plate or other internal battery structures. Leave the thermometer in the electrolyte while measuring the specific gravity of the other cells in the battery bank. Hydrometer Thermometer with stopper Completely deflate the bulb of the hydrometer and insert the tube into the electrolyte, releasing the bulb to draw up the electrolyte. Specific gravity measurement To measure specific gravity, a hydrometer is used. A glass thermometer is used to measure the cells’ temperatures. Generally the electrolyte is drawn up by the hydrometer and a specific gravity reading is taken from the float level. A typical deep cycle cell which is fully charged will have a specific gravity of approximately 1.250 at 25°C. (Confirm the value for your battery from the system supplier or battery manufacturer). A reading less than 1.250 indicates a lower state of charge within the battery. The thermometer is required because the specific gravity changes with temperature. A higher temperature decreases the specific gravity; a lower temperature increases the specific gravity of the electrolyte. To convert your actual measurement to a value at the standard temperature of 25°C, a correction factor must be applied. This information will be supplied in your battery manual. Some manufacturers supply graphs showing the relationship between specific gravity, temperature and effective state of charge Measure the specific gravity of electrolyte in each cell, (see above) and record in the logbook. Apply the temperature correction to the readings and check with battery data to estimate the state of charge. If the specific gravity measurement of any cell is more than 0.025 below the average specific gravity of the battery bank, then an equalisation charge should be applied and the battery bank rechecked. B: Stand-alone solar PV systems WARNING Use only distilled water for rinsing hydrometer and thermometer. Use of bore water may introduce contaminants which are damaging to batteries. Reading the electrolyte specific gravity Squeeze the bulb and deflate, squirting electrolyte carefully back into cell. Repeat this three to four times to ensure that the hydrometer is at the same temperature as the electrolyte. Now fill the hydrometer and hold it vertically, ensuring its float is floating in the electrolyte. Now read the electrolyte level off the float. Return the electrolyte to the cell. Record the reading in the logbook. Rinse the hydrometer in fresh water and test the next cell, following the same procedure until all cells are tested. Neutralising acid spills Topping up the electrolyte To neutralise an acid spill, use a solution of baking soda and water. Mix half a cup of baking soda in approximately 10 litres of water. For larger spills, use a mop to clean up the spill. This solution can also be used for cleaning the cells and battery terminals. When batteries are charging and gassing, the battery is losing water. To top up the electrolyte, use distilled water (or de-ionised water) and fill the battery via the electrolyte filler hole until the correct level is reached. There are several types of indicators to show the level is correct. These indicators vary from simple markings on the side of the battery case, indicating high and low levels to systems which use a float indicator. WARNING When neutralising acid spills do not allow any baking soda solution to enter the battery cells—even a tiny amount of baking soda will permanently damage the cell. Check the manufacturer’s instructions for the type of indicator used in your batteries. It is preferable to add distilled water when the battery charge is high as the addition of water will decrease the charge of the battery. 21 22 Solar PV Systems: Users maintenance guide Cleaning the battery terminals WARNING Do not use any metal files or other harsh abrasives (eg. sand paper) to remove corrosion or oxidisation from terminals or posts as this may cause a poor fit when terminals are reconnected. If the battery terminals are showing signs of corrosion, or have not had an antioxidising coating applied, they may require cleaning. This will involve disconnecting the battery leads and cleaning both the battery terminal posts and the battery lead connectors. It is important to ensure the battery bank has been isolated before attempting to disconnect any leads. Battery terminal corrosion is often seen as a white crystalline or powdery material around or on the battery terminals. A heavily oxidised terminal will have a very dark, almost black coating. If this is between mating surfaces of the connectors and posts it will need to be cleaned. Before disconnecting, carefully wipe most of the corrosion off using a brush or rag with the baking soda solution, then carefully disconnect the battery lead connector from the battery terminal post and clean both using a plastic scourer. Once clean, apply the antioxidising coating following the manufacturer’s recommended procedure and reconnect the battery lead connector onto the battery terminal post. Repeat this procedure for each terminal, as required, being careful not to contaminate the electrolyte with any foreign material. Differences for gel cell type batteries Gel cell batteries require special attention to the method used for charging as overcharging of a gel cell type battery may cause irreversible damage to the battery. Consult with system supplier for recommendations on charging of gel cell type batteries. Controllers and chargers should be set to the gel cell mode for best performance. NOTE Overcharging a gel battery can lead to battery gases escaping with a similar risk of explosion as for wet lead-acid batteries. Maintenance of gel cell batteries only relates to the battery terminals and connections. The maintenance required for these is the same as for wet cell flooded batteries. The state of charge of the battery can only be determined by measuring voltage of the battery, when there has been no discharging or charging of the battery for at least 1530 minutes, and referring to tables supplied by the manufacturer. B: Stand-alone solar PV systems 3. Balance of systems (BOS) Balance of systems include: • regulators (or controllers) for the solar array, wind generator and pico-hydro generator; • inverters; • all interconnecting power cables and control cables between the individual components to create the system; • all switchboards, protection equipment and metering/monitoring equipment. This equipment requires little maintenance. If this equipment requires any maintenance or repair it will generally need to be done by qualified personnel and the supplier should be contacted for advice. The inverter The inver ter should be installed in a clean, dry, and ventilated area which is separated from, and not directly above, the battery bank. While the system is operating the following operational checks can be made: • check that the inverter is functioning correctly by observing LED indicators, metering and/or other displays on the inverter • check to see if the inverter’s stand-by mode (if present) is functioning correctly. This can be done by turning off all loads and appliances operating on the system. Once in standby mode, switch an appliance on and the inverter should start almost immediately. • check that any control functions for r emote star ting of diesel genset (if installed) are operating. Ensure that the diesel genset is starting and stopping at correct battery voltage levels as specified by manufacturer (refer to system supplier or inverter operating manual). NOTE The third check can be difficult to undertake as it can require disconnecting all charging sources (eg. PV array) and turning on sufficient appliances to force the battery voltage to decrease to the set voltage for starting the genset. It could also be simulated by raising the voltage setting so checking that the generator does start at the higher voltage, which is close to the actual voltage of the battery bank. The exact testing method will depend on the actual set-up of the system and probably might only be able to be undertaken by a suitably qualified person eg. the system supplier/installer. Typically the system owner is only aware that the genset has not started when the batteries have reached a low voltage. When inspecting the inverter, remove any excess dust from the unit and especially from the heatsinks. This should only be done with a dry cloth or brush. Check that “vermin” have not infested the inverter eg. typical signs of this include spider webs on ventilation grills or wasps’ nests in heat sinks. Contact system suppliers if you suspect vermin are inside the inverter. 23 24 Solar PV Systems: Users maintenance guide Regulator(s) Each of the renewable energy charging sources: PV array, wind generator and pico-hydro generator will require their own specific charge regulator (or controller). Any regulator should be installed in a clean, dry and ventilated area. The regulator is an electronic device that controls the voltage of the charging sources (solar, wind, hydro) energy output to charge the battery bank appropriately. The regulators are designed to disconnect or reduce the charge current when preset voltages are reached. Typically there are boost voltage settings and float voltage settings. Inspect and check the functioning of the regulator to ensure that any indicators or meters are correctly operating for the various regulator modes. In the case of a PV system, check that when the batteries are fully charged and it is sunny, that the solar regulator is changing into float mode. The wind generator and picohydro regulator do operate differently to the solar regulator. If you have a wind generator or pico-hydro generator the regulators used are known as shunt regulators and will require additional components known as dummy loads, typically a bank of resistive coils. When the battery bank reaches the preset voltage, the current from the generator source is “shunted” into the dummy load. WARNING These shunts can get very hot and should not be touched. During maintenance checks, inspect the functioning of the regulator to ensure that any indicators or meters are correctly operating for the various regulator modes. In general correct operation of the regulator(s) can only be observed in certain conditions. This is achieved by observing that the charge currents from the different sources (solar, wind or picohydro) are either removed or reduced when specified voltages are obtained. This could be observed when the voltage of the battery reaches a certain point, this indicates that the battery is fully charged and the regulators go from boost to float mode. Full operation tests might need to be undertaken by a suitably qualified person eg. the system supplier/installer. When inspecting the regulators: • look for any loose wiring on the terminal connections. If they are loose follow the shutdown procedures for the system before tightening the connections or contact your installer. NOTE Loose connections can cause hot joints and possibly fire. • remove any excess dust from the unit and especially from the heatsinks. This should only be done with a dry cloth or brush. B: Stand-alone solar PV systems Switchboards and wiring Correctly installed switchboards and wiring should not require maintenance. The licensed electrical contractor who installed the system should have checked all existing wiring and switchboards. As part of your system inspection, the switchboards and visible wiring can be visually inspected for signs of corrosion and/or burning. If either is apparent, consult a licensed electrical contractor to identify and rectify possible faults. All safety switches, r esidual c u r r ent devices (RCDs) which detect current leakage to earth should be tested by pressing the test button provided. Residual current device (RCD) Battery chargers The maintenance required for battery charging equipment is similar to that required for inverters. Check that the charger does charge the battery bank when the genset is operating. If it does not appear to be operating correctly check the output voltage of the genset. (if volt meter has been installed). If genset is not producing correct output voltage, then the battery charger will not operate correctly. If the genset is OK then contact system supplier/installer. Any battery charging equipment should be installed in a System wiring Check for any breaks or deterioration in exposed conduit and wiring. Also inspect connections for any signs of corrosion and/or burning. If any damage is noticed contact the system supplier/installer. Inspect the condition of the conduit and wiring from the: • charging source to its regulator; • • • • regulator to battery bank; inverter to battery bank; genset to battery charger battery charger to battery bank • inverter and genset to AC switchboard. An example of poorly wired, unprotected and unsupported cabling for a charger clean, dry and ventilated area. When inspecting the charging equipment remove any excess dust from the unit and especially from any heatsinks. This should only be done with a dry cloth or brush. 25 26 Solar PV Systems: Users maintenance guide 4. Interpretation of monitoring equipment Often a system owner is unaware of a problem until suddenly the inverter turns off and the house has no power. Typically the system will include a back-up genset so that this can be operated to provide power to the house but this will be noisy, expensive, environmentally unfriendly and inconvenient. As a minimum, the Australian Standard recommends that your system should include a volt meter for measuring the system DC voltage and a current meter from each of the charging sources (solar, wind and/or pico-hydro). Regularly monitoring these meters will help to identify a problem before the point is reached where the inverter switches off due to low battery state of charge (reflected by low battery voltage). Solar array meter If a system has metering for the solar array output, by observing the output current regularly any loss of performance may be noticed. There will be some variation in this current due to changes in ambient temperature, season of the year, angle of the sun and the level of solar radiation incident on the modules. To minimise these effects, this observation should be done on fine, cloud-free days at around noon. Any significant changes in output that are noticed can be investigated. The most common causes for loss of output would be excessive dirt on the modules or partial shading of the array. Other causes could include wiring problems and/or problems with system regulators – refer to the system supplier for advice if you suspect either of these problems. Wind generator meter If a system has metering for the wind generator output, by observing the output current regularly any loss of performance may be noticed. The current will be dependent on the amount of wind but through regular observation on windy days you will notice that the generator is produc- ing suitable current. Any significant changes in output which are noticed can be investigated. Causes could include wiring problems and/or problems with system regulators – refer to the system supplier for advice if you suspect either of these problems. Pico-hydro meter If a system has metering for the pico-hydro output, by observing the output current regularly, any loss of performance may be noticed. Typically the output of a picohydro generator is constant. Any significant changes in output which are noticed can be investigated. The most common causes for loss of output would be blockage of the inlet pipe thereby reducing the water flow or the water flow has reduced in the stream. Other causes could include: blocked jets in the turbine or wiring problems and/or problems with system regulators – refer to the system supplier for advice if you suspect either of these problems. B: Stand-alone solar PV systems System voltage meter Other monitoring If a system has metering for the system DC voltage (battery voltage), by observing the voltage regularly at a similar time of day any loss of performance might be noticed. The system voltage will be higher when being charged and lower when there is no charge and there are loads present. A good time to observe the voltage is first thing in the morning and at night time. If the voltage is lower than expected then this could indicate that: • the system is not being charged effectively; or • the energy usage has increased, thereby using more than the system is producing; or • battery cells are getting old and either losing efficiency or a cell might have failed. Many of the inverters and regulators on the market today are micr opr ocessor controlled and therefore allow other monitoring features. This can include the ability to data-log your system for a period of time and even allow for r emote monitoring via modems and phone lines. If you are unable to determine the problem contact your system supplier for advice. In particular monitoring the energy generated each day provides more information than simply observing the charge current. If this figure reduces substantially, it will indicate there is a problem in the charging of the system. These will typically include all the meters mentioned above but will often include measuring the amount of energy being produced and consumed daily. If your system includes this type of monitoring, logging the daily energy flow (in and out) will help determine whether your system is operating correctly and will often alert you to a problem before it causes a system failure. By observing the amount of energy used each day, you will then know if your energy consumption has increased. By comparing the amount of energy generated with the amount of energy consumed, you will then see whether you are: • under-using the system— that is, the system is producing more energy than you are using. (Note: due to system losses, you should always produce more than you use) • using more than the system is producing and therefore you may soon have flat batteries and a system failure. Alternatively, you may need to run the genset and battery charger to compensate. Your system supplier should train you to make effective use of the monitoring equipment. 27 28 Solar PV Systems: Users maintenance guide C: Grid-connected solar PV systems The typical GC system will include: • PV modules; • inverter; and • BOS equipment- including meters, switching equipment and system wiring. These sections provide an overview of the maintenance requirements for these pieces of equipment. In particularly, how do you know that your GC system is working? C: Grid-connected solar PV systems 1. PV solar modules The solar array (a number of solar modules mounted alongside each other) is often thought to be maintenance free. This can be the case in many situations, however, with occasional maintenance and inspection, the performance of all the solar modules in the array can be assured. The most common maintenance task for solar modules is the cleaning of the glass area of the module to remove excessive dirt. WARNING Typically modules are located on a roof hence there is a risk of falling. When performing maintenance, some form of fall protection equipment (eg. harness or scaffolding), MUST be used. In most situations cleaning is only necessary during long dry periods when there is no rain to provide natural cleaning. To remove a layer of dust and dirt from the modules, simply wash the panel with water. If the module has thick dirt or grime, which is harder to remove, wash with warm water and a sponge. Washing the modules is similar to washing glass windows but detergents should not be used. After the modules have been cleaned, a visual inspection of the modules can be done to check for defects in the modules such as cracks, chips and discolouration. If any obvious defects are found, note their location in the system logbook, so they can be monitored in the future in case further deterioration affects the modules’ output. In most cases the module output will not be affected. When inspecting the solar modules, the condition of the array mounting frame (if used) should also be noted. Items to observe should include the array mounting bolts (eg. bolts rusting) and checks to ensure that the frame and modules are firmly secured. An example of a PV panel maintenance log sheet is shown in Annex 2. 29 30 Solar PV Systems: Users maintenance guide 2. Inverters These items generally require very little maintenance but when maintenance is being performed on other parts of the system then the following should be undertaken: • keep the inverter clean and minimise the possibility of dust being blown over the equipment —clean with dry cloth when required; • ensure the unit is not “infested” by vermin; and • check that the inverter is functioning correctly by observing LED indicators, metering and/or other displays on the inverter. An example of an inverter log sheet is shown in Annex 2. 3. Balance of system These items generally require very little maintenance but when maintenance is being performed on other parts of the system then the following should be undertaken: • check that all interconnections and cables/conduits are mechanically secure; • check that all switches and circuit breakers are operating correctly; and • confirm any meters are operating correctly. Typically grid-connected PV systems are using “plug” cables between the solar modules in the array and when mounted on the roof these are often hidden behind the solar modules. Therefore the only cables that can be inspected will be the cables and/or conduits: • from the array to the inverter and • the inverter to the switchboard. An example of a BOS log sheet is shown in Annex 2. C: Grid-connected solar PV systems 4. How do I know my system is working? Power output display With a grid-connected PV system there are no moving parts. During the day, when the sun is shining on the modules, they are quietly producing electricity which is either being consumed in your house or exported to the grid. Since it’s so quiet, how do you know it’s working? It is recommended that as a minimum, your system should include a meter that records either the amount of energy being generated by the modules or the amount being exported to the grid. If it is only measuring the production then you could record the meter reading in the morning and then again that evening. The difference in the reading will determine the day’s production. If it is only measuring what is being supplied to the grid, and you are consuming all your generated power, then this meter will not move very often. In this case, turn off all appliances in the house and then observe whether that meter is moving. Some systems will include meters that indicate exactly what is being produced at any time, while other inverters will constantly monitor and record the energy generated. It is important that your system supplier explains to you how to know if your system is working. 31 32 Solar PV Systems: Users maintenance guide Annex 1: SPS maintenance log sheets components and the system. Those maintenance items that are shaded in grey are only to be The following log sheets specify all the maintenance that should be performed on each of the system undertaken by a trained service person. They have been included to ensure the log sheets are complete. Solar array log sheet Date Name Cleaned modules Array structure OK Array Array cabling cabling mechanical electrical I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I Array output voltage Array output current C: Grid-connected solar PV systems Time Weather Comments 33 34 Solar PV Systems: Users maintenance guide Battery bank log sheet Date Name Battery voltage Ambient temperature Cell 1 SG Electrolyte temperature Corrected SoC Cell volts Water used in litres …….. Cell x SG Electrolyte temperature Corrected SG Cell volts Water used in litres Interconnections OK? Battery cases OK? Comments Date Date Annex 1: SPS maintenance log sheets Balance of systems log sheet Date Date Date Name Battery voltage Regulator Item clean Insects removed Cables connections OK Functioning OK Inverter Item clean Insects removed Cables connections OK Functioning OK Battery Charger Item clean Insects removed Cable connections OK Functioning OK Control Board Item clean Insects removed Cable connections OK All switches/circuit breakers operate correctly OK? Cables/conduits mechanically OK? Electrical connections OK? Comments Note: Tick when OK Also if there are other generating items eg. wind generator then the log sheet should include space for all regulators. 35 36 Solar PV Systems: Users maintenance guide Genset log sheet Date Name Genset Oil total hours changed run Fuel filter Oil filter Air filter Comments Note: Ticked when changed Wind generator log sheet Date Name Integrity of tower structure Bearings Mechanical lubricated/ integrity changed of blades & tail Electrical wiring integrity I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I Comments Date Name I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I Bearings Wheel lubricated/ checked changed Intake filters cleaned I I I I I I I I I I I I I I I I I I I I I I Nozzles checked I I I I I I I I I I I I I I I I I I I I I I Pipes checked I I I I I I I I I I I I I I I I I I I I I I Electrical Comments connections Annex 1: SPS maintenance log sheets Pico-hydro log sheet 37 38 Solar PV Systems: Users maintenance guide Annex 2: GC maintenance log sheets Solar array log sheet Date Name Cleaned modules Array structure OK Array Array cabling cabling mechanical electrical I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I Array output voltage Array output current Annex 2: GC maintenance log sheets Time Weather Comments 39 40 Solar PV Systems: Users maintenance guide Inverter log sheet Date Name Cleaned inverter No insects Cable Inverter connections operating OK correctly I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I Comments I I I I I I I I I I BOS log sheet Date Name Cable All connections switches OK and CB’s operating Cable Meter connections operating OK correctly I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I Comments Annex 3: Glossary Annex 3: Glossary 240V 240 volts AC – a lethal voltage AC alternating current ambient surrounding array A number of PV modules electrically interconnected balance of systems includes regulators, inverters, cables, control board and protection equipment bi-carbonate soda baking soda – sodium bicarbonate boost charge A charging cycle that ensures the battery reaches close to fully charged also known as “topping up the battery” BOS Balance of System brake prevents the turbine from turning cable twist A mechanism in a wind turbine where the cables in the tower of the wind turbine can twist one way then another – working on the theory that the wind turbine will approximately turn equally clockwise and anticlockwise so that the cable does not twist too tight cells a single battery unit (usually 2 volts) circuit breakers an electrical protection device that automatically switches to off when overloaded DC direct current deep cycling suitable for large charge and discharge cycles depth of discharge percentage discharge of a battery. dump loads a load to prevent the current from overcharging the battery electrolyte solution in a battery that stores energy and allows the current to pass energy generation devices PVs, wind turbine, genset or pico-hydro generator equalisation overcharging to ensure all cells have equalised specific gravity and therefore each cell is fully charged exhaust gases contain noxious fumes exhaust sparks sparks in fumes which can cause fire float sealed cylinder inside hydrometer float charge intermittent charging of the battery at a voltage specified by manufacturer also known as intermittent topping up of the battery flooded A battery with wet electrolyte within the battery case and around the electrodes forced ventilated powered by a fan fuels usually diesel, LPG or petrol furling turning the blades to avoid the wind fuses protection devices that break the overload by burning a wire inside their casing—must be replaced when operated GC connected to the mains power grid gel the electrolyte in the battery is a gel as distinct to a liquid solution gensets a diesel, LPG or petrol 240V generator guy wires supports holding tower of wind tower in place heat-sinks finned steel to help dissipate heat hot exhaust pipe from a fuel genset and can cause burns hot joints poor electrical contact causing heating hydrogen a volatile gas given off during charging of batteries hydrometer device for measuring specific gravity incident striking insulated prevents electrical shorting integrity components working correctly and in harmony inverter converts DC current into 240 V AC isolate cut off electrically lead-acid the electrolytic compound and the electrodes LED light-emitting diode 41 42 Solar PV Systems: Users maintenance guide live carrying an electrical current loads appliances drawing electricity logbook book recording data sampled by the user low voltage (LV) 120V DC, 50V AC or greater pico-hydro generators converts kinetic energy in water to electrical energy microprocessor using computer chips modules photovoltaic cells connected in series and sometimes parralel to provide required power monoblock battery cells connected in series and located in one case – often provided as a 6V or 12V battery eg. same as in your car noise can damage ears open-circuit voltage across PV array when there’s no load parallel electrically connected side by side photovoltaic electricity produced from the sunlight RCD residual current device regulators controls the current to the batteries remote monitoring reading data in another location using a modem remote starting ability to start the genset from a remote switch residual current devices circuit breaker triggered by an electrical short to earth rusting can be caused by galvanic reaction between dissimilar metals series electrically connected in a line SG specific gravity shorting when two opposite charged terminals or cable (eg. + and –) are connected together shunt electrical current bypasses the load and is supplied to an alternative load specific gravity density relative to water SPS stand-alone power system – not connected to the grid stand-by mode inverter is switched on, waiting for a load terminals positive and negative battery connectors tower structure holding the wind turbine trackers follows the path of the sun vented open to the air wind generators converts wind energy into electrical energy Annex 4: SPS maintenance at a glance Annex 4: SPS maintenance at a glance Safety first DATE 1. Do not climb above 2 metres to maintain PV modules or wind turbines without safety rails or harness 2. Do not touch any component with a voltage 120V DC, 50V AC or greater 3. Wear personal protective clothing when maintaining batteries 4. Do not maintain batteries while there’s an acrid smell in the vicinity 5. No smoking, sparks or naked flames in battery enclosure 6. Ensure clean water is readily accessible while maintaining batteries 7. Ensure all tools are insulated while maintaining batteries PV Modules Balance of System Battery Genset I Cleaned I Battery voltage I Battery voltage I Run hours I Check structure I Switches/CBs I Interconnections I Oil change I Cabling mechanical Connections I Ambient temp I Fuel filter I Cabling electrical I Regulator I Log completed I Oil filter I Output voltage I Inverter I Output current I Charger I Log completed I Control board I Cleaned I Bugs removed I Cables I Working OK I Log completed for each cell I SG I Temperature I Air filter I Log completed I SoC Wind Generator I Voltage I Guys I Water I Case OK Pico-hydro I Intake cleaned 43 44 Solar PV Systems: Users maintenance guide Annex 5: Information to be obtained from system supplier or manufacturers • What is the manufacturer’s recommendation for a maximum depth of discharge of the batteries? • What is the recommended time between equalisation charges? • If using sealed batteries, obtain chart showing battery voltage in relation to state of charge. • Obtain tables or graphs that relate specific gravity readings and temperature to state of charge information. • What is the maximum charging current? Solar PV Systems: Users maintenance guide Printed on recycled paper

![[ENG] EVO DSP TM 10-30 kVA User Manual v. 2.0](http://vs1.manualzilla.com/store/data/005715238_1-26b73917878f712f842422018d03a475-150x150.png)