Download IR33 uni Manual

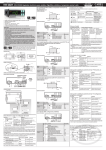

Transcript