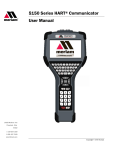

Download Extending ABB`s WirelessHART Tool

Transcript