Download 20151124 ~ FORBO-EUROCOL-NL ~ 022-euroblock-one-coat

Transcript

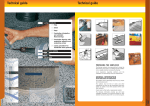

022 EUROBLOCK ONE COAT Two Component Epoxy Surface DPM. Basis : Component A: Epoxy Coating (7,6 kg). Component B: Epoxy Curing Agent (2,4 kg). Colour : Component A: Dark Grey. Component B: Offwhite Consistency : Thin liquid. l l l l l l Cost effective single coat application Allows the early installation of resilient floorcoverings British Standard 8203 / British Standard 5325 compliant Suitable for use with underfloor heating systems Pinhole resistant Low viscosity and easy to apply. Specific weight : Consumption : Part A = 7.6 Kg (4.2Lt) SG = 1.80 gr/ltr. Part B = 2.4 Kg (2.3Lt) SG = 1.03 gr/ltr l l l l l l Moisture vapour contents of up to 98% RH can be accommodated Depending on the moisture content of the base, different thicknesses can be applied Can be used where a damp proof membrane is not present or if it is deemed ineffective Adheres to a variety of damp substrates even at low temperatures Suitable for sealing cracks and seams in subfloors. Can be used in conjunction with under floor heating systems. Moisture Testing : Moisture testing should be undertaken in accordance with British Standard 8203. Layer thickness : 24 m2 = 250 microns thickness (Moisture Content Below 92% RH) * 20 m2 = 350 microns thickness (Moisture Content up to 98% RH) * Storage : Store in dry conditions between + 5° C and + 30° C Tools : 2 mm x 5 mm ‘V’ notched flooring grade trowel. Long handle, fluff free paint roller. Drying : + 20° C: 5 to 6 hours.* + 15° C: 8 to 11 hours.* + 10° C: 14 to 20 hours.* Shelf Life : 6 months, in unopened packaging. Potlife : + 20° C: 1 hour en 25 minutes.* + 15° C: 2 hours.* + 10° C: 2 hours en 30 minutes.* Application temperature : 20°C to +80°C * The mentioned values have been established in our laboratory and must be considered as guidelines in view of possible variations in climatic circumstances, subfloor compositions and layer thickness. Substrate: The subfloor must have a good tensile and compression strength and be smooth, clean, even, permanently dry and be free from any contaminant deemed liable to impede adhesion and be in accordance with the requirements set out within the BS 8203, the BS 5325, BS 8204 and the DIN 18365. l Subfloors such as powerfloated concrete and sand cement screeds should first be mechanically cleaned to provide an adequate key. We recommend shot blasting, grinding or machine scarifying. l The moisture content of the base must not exceed 98% RH l Should doubt exist regarding the products use or its application, always seek our technical advice. l User manual: Working conditions: Required surrounding temperature : 15° 25° C. Temperature for material and subfloor : min. 15° max. 20º C. Relative humidity : 40 70%. Directions for use: l l l l l l l l l Add the epoxy curing agent (part B) to the resin coating (part A) and thoroughly mix together with a mixing spindle (Eurocol no. 855) in a slow speed drill until a uniform colour and consistency has been reached. It is important to mix both components together for at least 45 minutes. Apply the mixed material immediately with a 2 mm x 5 mm ‘V’ notched flooring grade trowel. Whilst the product is still wet, flatten out the serration ridges with a long handled fluff free paint roller that has been prewetted with the mixed solution. It is essential that the applied coating is continuous, free of pinholes and any thin patches. Should issues be observed, patch like repairs will be necessary. In order to ensure that excess moisture vapour will not permeate the membrane, the products must not be less than 250 or 350 microns in thickness. For specific information, please read Technical Facts above. Allow to cure for 8 to 11 hours at +15° C. Once cured, the surface of the 022 Euroblock One Coat should be primed with 044 Europrimer Multi and allow to dry as per the products data sheet. Once sufficiently dry, apply a suitable Eurocol smoothing/levelling underlayment to a minimum thickness of 3mm and allow to dry as per the products data sheet. Secure the floorcovering with the approved Eurocol adhesive. Precautions: 022 Euroblock One Coat can be irritating to the eyes, respiratory system and skin, and may cause sensitisation by contact. Consult the relevant health and safety data sheets for full information. In case of accidents seek medical advice. Application Notes : The aforementioned systems are given as general guidance only. Please consult one of Forbo Eurocol’s Commercial Technical Advisors who will be more than happy to submit a tailormade written specification. Hazard Class : Component A: Xi (irritant), N (dangerous for the environment). Component B: C (corrosive). Safety and environment : Safety data sheets of Forbo Eurocol products according to EEGguideline 91/155. MSDS : Available on request. Article Definition Packaging 022 Epoxy Coating. Comp. A 7.6 kg EANcode 022 Epoxy Curing Agent. Comp. B 2.4 kg