Download Low power dissipation touch plane interface circuit

Transcript

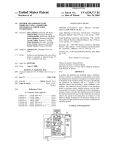

US007327354B2 (12) United States Patent (10) Patent N0.: (45) Date of Patent: Dotson (54) LOW POWER DISSIPATION TOUCH PLANE INTERFACE CIRCUIT (73) Assignee: Rockwell Automation Technologies, Inc., May?eld Heights, OH (US) Notice: Feb. 5, 2008 OTHER PUBLICATIONS Prentice Hall’s Illustrated Dictionary of Computing, 2nd Ed., 1985, (75) Inventor: Gary Dan Dotson, Muskego, WI (US) (*) US 7,327,354 B2 p. 59. (Continued) Primary ExamineriHenry N Tran (74) Attorney, Agent, or FirmiHimanshu S. Amin; Subject to any disclaimer, the term of this patent is extended or adjusted under 35 Alexander M. GerasimoW U.S.C. 154(b) by 512 days. (57) ABSTRACT A method of determining a type of touch plane operator (21) Appl. No.: 10/832,668 input device comprises sensing the impedance across ?rst (22) Filed: Apr. 27, 2004 (65) and second terminals of a touch plane operator input device to distinguish the touch plane operator input device as being Prior Publication Data US 2004/0196269 A1 one of at least tWo different types of touch plane operator input devices. A method of processing an input from a touch Oct. 7, 2004 plane operator input device comprises determining a ?rst location of a ?rst touch on the touch plane operator input Related US. Application Data device; determining a second location of a second touch on (63) Continuation of application No. 09/677,103, ?led on Sep. 29, 2000, noW Pat. No. 6,753,853. the touch plane operator input device; comparing the ?rst (51) Int. Cl. G09G 5/00 (2006.01) difference between the ?rst and second locations; and deter mining Whether the indication of the amount of difference exceeds a predetermined amount. These steps are performed (52) US. Cl. .............. .. 345/174; 178/1801; 178/1802; by discrete logic circuitry that provides an event noti?cation 178/2001 to a microprocessor When the indication of the amount of Field of Classi?cation Search ...... .. 345/173*179; difference exceeds the predetermined amount. An interface circuit for a touch plane operator input device comprises a digital signal processor that includes a data processing path along Which data from a touch plane operator input device (58) 178/18.01*18.07, 190141904, 200142004 See application ?le for complete search history. (56) References Cited U.S. PATENT DOCUMENTS 4,413,314 A 11/1983 Slater et al. (Continued) and second locations to obtain an indication of an amount of passes While being processed by the digital signal processor. The interface circuit is capable of processing data from ?rst and second different types of touch plane operator input devices. The data path is a common data processing path that is the same for input data for both of the ?rst and second types of touch plane operator input devices. FOREIGN PATENT DOCUMENTS WO WO98/49650 20 Claims, 11 Drawing Sheets 11/1998 TUUClLFREsS US 7,327,354 B2 Page 2 U.S. PATENT DOCUMENTS 6,292,181 B1 9/2001 Banerjee et al. 9/2002 Chambers et al. 8/2003 Dotson et al. 6/2004 Dotson ..................... .. 345/173 7/2004 Dotson ..................... .. 345/173 4908620 A 3/1990 Fujisawa 6,445,383 B1 6,611,257 B1 4942514 A 5,014,051 A 7/1990 Miyagaki er 915/1991 LiPPmaIm er 91- 6,753,853 Bl* 6,765,558 Bl* 5,053,758 A 10/1991 Cornett et al. 5,376,947 A 12/1994 Kuroda 5,867,665 A 5,880,411 A 2/1999 Butman et al. 3/ 1999 Gillespie et al. OTHER PUBLICATIONS The New IEEE Standard Dictionary of Electrical and Electronics 5,956,020 A 5,995,084 A * 9/1999 D’Amico et al. ......... .. 345/173 11/1999 Chan et al. ............... .. 345/173 Terms, 5th Ed., 1983, p. 1051. Setup and User Manual Hampshire TSHARC-8 Touch Screen 6,037,930 6,088,628 6,091,031 6,163,313 3/2000 7/2000 7/2000 12/2000 5/2001 Controller Board (Revision 1.6) pp. 3 & 7. “MDS 7121 Touch Screen Controller Data Sheet” Printed Nov. 16, 2000 (Revised Oct. 8, 1999). pp. 1-16. A A A A 6,229,472 B1 Wolfe 6t 81. Watanabe et a1~ Lee er a1 Aroyan et al. Nidhida * cited by examiner U.S. Patent Feb. 5, 2008 Sheet 1 0f 11 US 7,327,354 B2 32 Y+ X- _L_______ Y+ X. 2? / 14 5y, l T q '1; $Y 3X_ : a: . 43 as . 1 ‘u a! . 41 2° 5 L16 s z / 2 2 "0 20 : C-____‘_'l 12 ~'; 2 ‘ "_ 12 T-k “ 3° 30 “Prior Art“ "Prior Art" F I G. 1A FIG. 1 B V+ V+ 24-!2Y4; Z51. 14+ 5a a: 56 ‘W is‘ as J r a: I“ ‘v T /5‘ 62 \ wiper so ,/ J wine: ‘on w 87/ / as 51 "Prior Art" FIG. 1C "Prior Al"?I FIG. 1D ‘ 6Q U.S. Patent Feb. 5, 2008 Sheet 4 0f 11 Touch screen connected? 152 8-wire touch screen connected? 4-wire touch screen connected‘? 5-wire touch screen connected Touch screen pressed? FIG. 4A US 7,327,354 B2 U.S. Patent Feb. 5, 2008 Sheet 5 0f 11 172 Touch screen connected? 174 180 176 4-wire or 8-wire 4-wire touch screen touch screen connected? connected? 5-wire or 7-wire touch screen Y connected 182 5-wire touch screen connected? 7-wire touch screen connected ouch screen operating properiy? Touch screen FIG. 4B pressed? US 7,327,354 B2 U.S. Patent Feb. 5, 2008 Sheet 6 0f 11 US 7,327,354 B2 .mEUm.GEOm .OE(mmm U.S. Patent Feb. 5, 2008 wmFomouca-l mass Sheet 7 0f 11 US 7,327,354 B2 m 224 SCAN Y-AXIS (TAKE 4, 8, 18. OR 32 SAMPLES STORING SCAN X-AXIS (TN<E4.a.1a.oRa2 smpms sromuem MIN. AND AVERAGE) 2°‘ MAX, MINrAND AVERAGE) ABS (MAX-MIN DEVIATIG‘J? X INT PENDING? 210 ABS (x-xusn XMIN? 212 SETXINT PENDING PA XLAST B X ABS LESS THAN N m? 216 214 Y SET X INT PENDING XLASTaX SET Y INT PENDNG WBY H6. 6 U.S. Patent Feb. 5, 2008 Sheet 9 0f 11 US 7,327,354 B2 .OEOw Ow W mw .QE<w U.S. Patent Feb. 5, 2008 Sheet 10 0f 11 mm US 7,327,354 B2 2 77 mm c 2%? FIG. 9 3‘? ‘\ 30o 4 30‘! / + 305 J 302 308/ FIG. 10 ' - l/O U.S. Patent Feb. 5,2008 1/ US 7,327,354 B2 Sheet 11 01 11 14/0 / H00 @102 / V0 V0 1 1 FIG. 11 V0 1 US 7,327,354 B2 1 2 LOW POWER DISSIPATION TOUCH PLANE INTERFACE CIRCUIT touch screens tend to be different because voltage feedback provisions are made to compensate for the effects of resis tance and temperature drift due to the larger screen siZe. Additionally, even Within the feedback/nonfeedback catego ries of touch screens, variations exist. As a result, it has been dif?cult to provide a system-on-chip that is usable in a Wide CROSS-REFERENCE TO RELATED APPLICATIONS This application is a continuation of US. application Ser. No. 09/677,103 ?led Sep. 29, 2000 now US. Pat. No. 6,753,853 and entitled “LOW POWER DISSIPATION TOUCH PLANE INTERFACE CIRCUIT,” the entirety of variety of touch screen applications because different touch screen applications tend to use different types of touch screens and different types of touch screens have different interface characteristics. FIGS. 1A-1D beloW shoW four different types of com Which is incorporated herein by reference. monly employed analog resistive touch screens. In general, BACKGROUND OF THE INVENTION most analog resistive touch screens comprise front and back resistive layers (often formed of indium tin oxide) that are pressed together When an operator touch is received. The 1. Field of the Invention This invention relates to interface circuits for touch screens. This invention also relates to methods of processing inputs from touch screens. This invention also relates to integrated circuits that include interfaces for touch screens. 2. Description of Related Art Touch plane operator input devices, such as touch screens and touch pads, are knoWn. Typically, a touch plane operator input device provides a generally planar surface that is sensitive to the touch of an operator and is operative to provide one or more output signals indicative of the location operator touch causes the tWo layers to establish an electrical contact at a particular location on each layer. Therefore, by applying a voltage to one layer and reading the voltage 20 characteristics of each layer. 25 of the touch on the plane. The output signals may be based either on the raW data from a touch screen sensor system, or 35 as Well as industrial applications such as operator interfaces 40 that connects to a Y+ terminal 28 of the touch screen, and a Y- bus bar 30 that connects to a Y- terminal 32 of the touch screen. The touch screen is scanned in the X-direction by applying a voltage across the X+ and X- bus bars 16 and 20, and then sensing the voltage that appears at one or both of the Y+ and Y- terminals 28 and 32. Assuming negligible current ?oW through the Y+ and Y- terminals, the voltage at the Y+ and Y- terminals 28 and 32 should be approximately the same and is determined by the X-coordinate of the point of electrical contact betWeen the X-axis and Y-axis layers 12 and 14, that is, by the X-coordinate of the touch. By comparing the voltage to values determined during calibra 45 on laptop computers to alloW operator control of a mouse pointer. Numerous other applications also exist. tion, the X-coordinate of the touch can be determined. The Y-coordinate of the touch is then determined in the same manner, except that a voltage is applied across the Y+ and Y- bus bars 26 and 30, and the resultant voltage that appears For convenience, the discussion Will noW focus on touch screens, it being understood that the discussion is equally applicable to touch pads and other touch plane operator terminal 18 of the touch screen, and an X- bus bar 20 that connects to an X- terminal 22 of the touch screen. Similarly, the Y-axis resistive layer further includes a Y+ bus bar 26 the operator. Touch screens have been put to use in a Wide in industrial control systems. In some applications, the operator touch is made by a stylus or other device held by the operator. In other applications, the operator touches the screen directly. Touch pads are similar in operation to touch screens, except that they are not used in connection With a display device. Touch pads are often placed adjacent the space bar screen comprises an X-axis resistive layer 12 and a Y-axis further includes an X+ bus bar 16 that connects to an X+ 30 device that include a touch plane operator input device. Touch screens are therefore capable not only of displaying information to an operator, but also of receiving inputs from variety of applications. Such applications include consumer applications such as personal digital assistants (PDAs), digital audio playback systems, internet devices, and so on, For example, FIG. 1A is a schematic diagram of a 4-Wire analog resistive touch screen. As shoWn therein, the touch resistive layer 14. The resistance of the layers 12 and 14 is shoWn schematically as four resistors. The X-axis layer 12 may be based on processed data that provides X-Y coordi nate information of the touch. Touch screens are an enhanced type of computer display established by electrical contact on the other layer, the location of the touch can be determined based on the knoWn 50 input devices. In many touch screen systems, a computer system is implemented using “system-on-hip” integrated at one or both of the X+ and X- terminals 18 and 22 is sensed. Of course, With all touch screens, X and Y axis de?nitions are arbitrary and different de?nitions can be coordinated With program code to determine screen position. circuits. In a single chip, these integrated circuits provide FIG. 1B is a schematic diagram of an 8-Wire analog many of the functions that used to be spread among many integrated circuits. For example, in addition to the main microprocessor, it is not uncommon to have other circuits such as specialiZed serial interfaces, UARTs, memory con resistive touch screen. The 8-Wire touch screen is the same 55 as the 4-Wire touch screen, except that four additional sX+, sX-, sY+ and sY- feedback terminals 40-43 are provided. Typically, both 4-Wire touch screens and 8-Wire touch trollers, DMA controllers, Ethernet interfaces, display inter screens use an analog-to-digital converter to sense the faces, USB (universal serial bus) interfaces, and so on, as voltages that appear at the X+ and Y+ terminals. In the case of a 4-Wire touch screen, the reference voltage inputs to the analog-to-digital converter are connected directly to the same positive and ground terminals of a poWer supply that also applies voltages to the touch screen. In the case of an 8-Wire touch screen, the reference voltage inputs are con nected to sX+ and sX- terminals 40 and 42 of the X+ and X- bus bars or to sY+ and sY- terminals 41 and 43 of the Well as a touch screen interface used to acquire data from a 60 touch screen. Aproblem that has been encountered With system-on-chip integrated circuits adapted for use With touch screens is that there are many different types of touch screens. For example, some touch screens are relatively small (e. g., three inches or less) Whereas other touch screens are much larger (e.g., tWenty inches or more). The interface characteristics of large 65 Y+ and Y- bus bars, respectively. The sX+, sX-, sY+ and US 7,327,354 B2 3 4 sY- terminals 40-43 are used for voltage feedback to eliminate the effects of resistance and temperature drift in SUMMARY OF THE INVENTION the circuit components. According to one aspect of the invention, the invention FIG. 1C is a schematic diagram of a 5-Wire analog resistive touch screen. The 5-Wire analog resistive touch screen includes a resistive layer 52 and a Wiper layer 54. The relates to a method of determining a type of a touch plane operator input device comprising sensing the impedance resistive layer includes V+, V—, Z+/—, and Z—/+ terminals across ?rst and second terminals of a touch plane operator input device to distinguish the touch screen as being one of 56-59 at the four opposing corners of the touch screen. A at least tWo different types of touch plane operator input constant voltage is applied to the V+ and V- terminals 56-57. The X and Y axes are scanned by applying a voltage at the Z+/Z— and Z—/Z+ terminals 58-59, and then reversing the polarity of the voltage to scan the other direction. The resulting tWo voltages produced at the Wiper terminal 60 are indicative of the X and Y-positions of the touch. FIG. 1D is a schematic diagram of a 7-Wire analog devices. According to another aspect of the invention, the inven tion relates to a method of processing an input from a touch plane operator input device comprising determining a ?rst location of a ?rst touch on the touch plane operator input device; determining a second location of a second touch on the touch plane operator input device; comparing the ?rst resistive touch screen. The 7-Wire touch screen is the same and second locations to obtain an indication of an amount of as the 5-Wire touch screen, except that tWo additional sV+ and sV- feedback terminals 61-62 are provided. As With the difference betWeen the ?rst and second locations; and deter mining Whether the indication of the amount of difference exceeds a predetermined amount. These steps are performed sX+, sX-, sY+ and sY- feedback terminals 40-43, the sV+ and sV- feedback terminals 61-62 are used for voltage feedback to eliminate the effects of resistance and tempera ture drift in the circuit components. Analog resistive touch screens are popular because they are inexpensive and reliable. HoWever, other types of touch 20 to a microprocessor When the indication of the amount of difference exceeds the predetermined amount. According to yet another aspect of the invention, the invention relates to an interface circuit for a touch plane screens are also common, such as capacitive touch screens 25 and electrostatic touch screens. In vieW of these different types of touch screens, a touch screen interface that is compatible With these multiple different types of touch screens Would be highly advanta geous. A touch screen interface that is capable of automati cally detecting the type of touch screen to Which it is 30 With touch screens is the processing overhead required to 35 The interface circuit is capable of processing data from at least ?rst and second different types of touch plane operator input devices. The data path is a common data processing path that is the same for input data regardless of Which type of touch plane operator input device is used. According to yet another aspect of the invention, the invention relates to a system that automatically con?gures a touch screen interface for one of a plurality of touch screen across a touch screen in response to an operator touch that moves across the touch screen. It is desirable to have smooth types. The system comprises a ?rst component that utiliZes touch screen poWer signals to automatically determine a type of touch screen coupled to the interface and a second and responsive mouse pointer movement. Current tech niques for obtaining a satisfactory level of responsiveness operator input device, the interface circuit comprising a digital signal processor that includes a data processing path along Which data from a touch plane operator input device passes While being processed by the digital signal processor. connected Would also be highly desirable. Another problem that has been encountered in connection process information from touch screens. It is knoWn to emulate a hardWare mouse by moving a mouse pointer by discrete logic circuitry that provides an event noti?cation 40 component that con?gures the interface by Writing values require a signi?cant amount of processor overhead, hoW associated With the touch screen type to memory accessible ever, because the microprocessor scans the touch screen directly or because the microprocessor must monitor a to the interface. The ?rst component comprises an analog to-digital converter, an analog sWitch matrix, and at least one continuous stream of data from a separate scanning module or hardWare. For example, dragging a cursor around the register. The second component comprises a microproces 45 sor. screen in random directions on a Microsoft® WindoWsTM NT system that supports hardWare cursoring can register an BRIEF DESCRIPTION OF THE DRAWINGS additional 3% to 7% of the processing poWer of a 300 MHZ Pentium IITM system under the task monitor program. By comparison, major architectural or processor step changes usually provide only a 5% to 10% processing speed FIGS. 1A-1D are schematic diagrams of analog resistive 50 FIG. 2 is a block diagram of a system-on-hip integrated improvement. A touch screen interface that reduces the amount of microprocessor overhead required for hardWare mouse emulation Would be advantageous. This is especially important in embedded solutions and PDAs Where high circuit that includes a touch screen interface circuit; FIG. 3 is a schematic diagram of the touch screen inter 55 poWer processors are less cost effective. Therefore, a touch screen interface that minimiZes process or overhead Would face circuit of FIG. 2 shoWn in greater detail; FIGS. 4A-4B are How charts shoWing the operation of the touch screen interface circuit of FIG. 3 to determine a touch screen type; also be highly advantageous, especially if it is capable of detecting the type of touch screen to Which it is detected and/or is compatible With multiple different types of touch touch screens, appropriately labeled “prior art”; 60 FIGS. 5A-5D are schematic diagrams shoWing the con ?guration of the touch screen interface circuit of FIG. 3 screens. during different steps of the process of FIG. 4; Another ongoing challenge that has been encountered is trying to reduce poWer consumption to extend battery life in devices such as personal digital assistants, laptop computers, FIG. 6 is a How chart of a scanning process used by the touch screen interface circuit of FIG. 3; FIG. 7 is a block diagram ofa logic circuit that is used to portable intemet access devices, and so on. A touch screen 65 implement the process of FIG. 6; interface that decreases poWer consumption Would therefore be highly advantageous. FIGS. 8A-8D are schematic diagrams shoWing the con ?guration of the touch for a ?rst type of touch screen; US 7,327,354 B2 6 5 110-118 the con?guration of the analog sWitch matrix 104 during a different mode of operation. Di?ferent values may be stored in the registers 112-118 depending on Which type FIG. 9 is a representation of a minimum move noti?cation system embodied in the ?owchart of FIG. 6; FIG. 10 is a ?rst industrial control system having an operator interface that incorporates the touch screen inter face circuit of FIG. 3; and FIG. 11 is a second industrial control system having an operator interface that incorporates the touch screen inter face circuit of FIG. 3. of touch screen is used. The analog sWitch matrix includes eight input/ output (I/O) terminals 120-134. The ?rst terminal 120 is labeled “X+ or V+”, indicating that the terminal 120 is adapted to be operably connected to the X+ terminal of 4-Wire and 8-Wire touch screens, and is adapted to be operably connected to the DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENT 1. Construction of Touch Screen Interface Circuit Referring noW to FIG. 2, FIG. 2 is a block diagram of an example of a system-on-chip integrated circuit 70 that includes a touch screen interface circuit 100 in accordance With a preferred embodiment of the present invention. The integrated circuit 70 includes a plurality of devices that are disposed on a peripheral bus 72 including-one or more universal asynchronous receiver-transmitters (UARTs) 73, 20 one or more serial interfaces 74 for interfacing to external devices (such as digital to analog converters (DACs), audio controllers, and so on), interrupt controller/timers 75, a keypad interface 76, one or more I/O ports 77, and a touch screen interface circuit 100 (described in greater detail beloW). The integrated circuit 70 also includes a plurality of 25 devices-that are disposed on a processor bus 80 including one or more universal serial bus (U SB) host interfaces 81 for connection to USB devices such as a keyboard, mouse, printer, and so on, an Ethernet port 82, DMA controllers 83, a microprocessor 86, a display interface 87 (for example, a raster engine), memory controllers such as a SRAM and ?ash interface 88 and a SDRAM interface 90, and boot ROM 89 for storing program code executed during a boot up sequence. Referring noW to FIG. 3, a portion of the preferred touch screen interface circuit 100 of FIG. 2 is illustrated in greater detail. The remainder of the preferred interface circuit is shoWn in FIG. 7, discussed in greater detail beloW. In FIG. 30 3, the interface circuit 100 comprises an analog-to-digital (A/D) converter 102, an analog sWitch matrix 104, and an 40 V+ terminal of 5-Wire and 7-Wire touch screens. The second terminal 122 is labeled “X- or V—”, indicating that the terminal 122 is adapted to be operably connected to the X terminal of 4-Wire and 8-Wire touch screens, and is adapted to be operably connected to the V- terminal of 5-Wire and 7-Wire touch screens. The third terminal 124 is labeled “Y+ or Z+/—”, indicating that the terminal 124 is adapted to be operably connected to the Y+ terminal of 4-Wire and 8-Wire touch screens, and is adapted to be operably connected to the Z+/— terminal of 5-Wire and 8-Wire touch screens. The fourth terminal 126 is labeled “Y- or Z—/+”, indicating that the terminal 126 is adapted to be operably connected to the Y- terminal of 4-Wire and 8-Wire touch screens and is adapted to be operably connected to the Z—/+ terminal of 5-Wire and 7-Wire touch screens. The ?fth terminal 128 is labeled “sX+ or sV+”, indicating that the terminal 128 is adapted to be operably connected to the sX+ terminal of 8-Wire touch screens and is adapted to be operably con nected to the sV+ terminal of 7-Wire touch screens. For 4-Wire and 5-Wire touch screens, the terminal 128 is not utiliZed. The sixth terminal 130 is labeled “sX- or sV-”, indicating that the terminal 130 is adapted to be operably 35 connected to the sX- terminal of 8-Wire touch screens and is adapted to be operably connected to the sV- terminal of 7-Wire touch screens. For 4-Wire and 5-Wire touch screens, the terminal 130 is not utiliZed. The seventh terminal 132 is labeled “sY+ or Wiper”, indicating that the terminal 132 is adapted to be operably connected to the sY+ terminal of 8-Wire touch screens and is adapted to be operably con nected to the Wiper terminal of 7-Wire touch screens. For 4-Wire and 5-Wire touch screens, the terminal 132 is not utiliZed. Finally, the eighth terminal 134 is labeled “sY-”, indicating that the terminal 134 is adapted to be operably inverting logic gate 106. The analog-to-digital converter 102 may be implemented using virtually any A/D conversion connected to the sY- terminal of 8-Wire touch screens. For technique. In the illustrated embodiment, the A/D converter 4-Wire, 5-Wire and 7-Wire touch screens, the terminal 134 is 102 is a successive approximation A/D converter or a delta 45 not utiliZed. sigma A/D converter. The analog sWitch matrix 104 alloWs the terminals 120 134 to be selectively connected to VDD and VSS poWer supply terminals, to an analog input of the A/D converter 102, and to the voltage reference inputs of the A/ D converter The analog sWitch matrix 104 comprises tWenty-eight analog sWitches, labeled SWO-SW27. The con?guration of the sWitch matrix 104 is controlled by a plurality of registers including a DIRECT register 110, a DETECT register 112, a DISCHARGE register 114, an XSAMPLE register 116, and a YSAMPLE register 118. Additional registers may also be utiliZed if it is desired to achieve additional functionality using the analog sWitch matrix 104. The registers 110-118 control the con?guration of the analog sWitch matrix. The con?guration of the sWitch matrix 104 as shoWn in FIG. 3 is characterized by the folloWing bit string: 0000 0100 0000 0000 0110 0010 0000. The bits in the 50 or by Way of a pull-up resistor (SW22). With the pull up resistor, the analog sWitch matrix 104 can supply the VDD 55 foregoing bit string correspond to the open/closed states of the sWitches SWO-SW27 in FIG. 3, With the number of the sWitch (0-27) indicating bit position and a “1” at a particular bit position indicating that a particular sWitch is closed. Di?ferent con?gurations of the analog sWitch matrix can be obtained With different bit strings. These bit strings may be stored in the registers 110-118 or, alternatively, may be 102. In the case of the terminal 120, the terminal 120 can receive the VDD poWer supply input either directly (SW11) 60 poWer supply input to an I/O terminal of a touch screen in a Way that alloWs the terminal 120 to be pulled loW if the touch screen I/O terminal is connected to ground (either directly or by Way of touch screen resistance), or to be left high if no connection to ground exists. A similar arrange ment is provided for the terminal 124. As Will be detailed beloW, this is one preferred Way of enabling the touch screen interface circuit to distinguish betWeen different types of touch screens. 2. Automatic Detection of Touch Screen Type Referring noW to FIGS. 4A-4B, tWo preferred methods of 65 determining a touch screen type is illustrated. The touch provided directly by the microprocessor. As Will be screen interface circuit 100 is capable of receiving input data described in greater detail beloW, each register controls from a variety of types of touch screens, and it is desirable US 7,327,354 B2 7 8 that the touch screen interface circuit 100 be able automati cally determine the touch screen type to Which it is con- _continued nected. This can be accomplished by sensing the impedance characteristics of the touch screen. FIGS. 4A-4B describe tWo exemplary methods that can be performed during a 5 boot-up sequence of a device that incorporates the interface circuit 100 to determine a touch screen type. Refemng ?rst to FIG- 4A’ at Step 150’ it is ?rst deter‘ STEP REGISTER EFFECT 154 0401601 X_ to vss circuit 100. FIG. 5A shoWs the con?guration of the analog 10 ~ ~ e opera ion 0 0408601 is low sX+ to VSS 1501 The e ana og sW1 c 0410601 Pull X+ high, Short check that X+ Operational 154 0804604 SX_ to VSS is low Piiii Y+ high, ShOit check that Y+ Y- to VSS 15 154 156 STEP REGISTER EFFECT 150 047F601 TEST RESULT LoW = Touch Piiii x+ high, ShOit ADC X—, Y+, Y—, sX+, conversion screen sX-, sY+, sY- to on X+ connected VSS op?rational is loW 154 ma nx dur1ng step 150: Wire touch Smut d gilliiiighai Pull X+ high, sholt ch?ck that X+ ' SWltCh 1.11am; 104 dlglng summarizes 154 RESULT LOW : g_ Pii11x+ high, Short check that x+ mined Whether a touch screen is connected to the interface ' TEST Operational is 10W 0820604 Pull Y+ high, Short check that Y+ 0402601 sY+ to VSS is 10W Pull X+ high, Short ADC Y+ to VSS Operational conv?rsion on LoW = touch Screen X+ Pmss?d or shlon?d 20 High : NO High : NO touch screen touch screen pmss connected If an 8-Wire touch screen is connected, then the Y+ . . . terminal 120 is ulled loW because the sY- terminal estab The value stored in the DIRECT reg1ster 110, Which changes 25 1- h throughout. the processes of FIGS 4A-4B controls the . ' . ’ . d F 11 h h 1S es, es ahcon?ecnon t-O glmun ' 0:1 aandother 19 U6 ?criegn+ t e s — term1na 1s unuse t ere ore t e con?guration of the analog sW1tch matr1x 104 during the typ - processes of FIGS. 4A-4B. The value stored in the DIRECT 33153205511132; a;gSHO€ViI?Hr;SIIg’SVI; i?etvghszvlgcat 3112?: register 110 during step 150 is 047F601 (hexadecimal) or - 1 1 - h- h g 1 b d h -' h - h B A/ - g 0000 0100. 0111 1111 0110 0000 0001 (binary) When the 30 tenénna 1.20 Cal‘: gmeasglre. “mg L escreen 1390mm“ 1212 . . . .' to eterm1ne W et er an -W1re touc is connecte . analog switch matrix 104 is programmed With this value, the . effect is to pull X+ high and to Short the X_ Y+ Y_ sX+ SX_ SY+ and SY_ terminals 122434 to V’ as’des’cribed in the table. The A/D converter 102 then performs an A/D s a proceeds to step 154, Where it is determined Whether the Pouch Screen 15 Operatmg properly‘ The Vanous Con?gure" SS: Conversion on the X+ terminal 120 - . ~ ~ 35 t1ons for the analog sW1tch matnx 104 are set forth in the If a touch Screen is Connected ‘then the touch Screen establishes a connection betWeen the X+ and X- terminals . . If an 8-W1re touch screen 1s connected, then the process . table above. If all the conditions in the table are met, then the touch Screen 15 Operanng properly; Otherwlse’ the touch . screen is not 0 120 and 122 (1.e., 1n the case of a 4-W1re or 8-W1re touch N screen, or the V+ and V- terminals in the case of a 5-Wire 40 eratin ro erl p 156 g_p_ pd y . _ d h h h h ext,’ at Stepd Th’i 1; 1S etermnge W f3; if t e mule or 7-Wire touch screen), causing the X+ terminal to be pulled loW. If no touch screen is connected, then no connection is Semen 1S presse ' S eajmre may e use 5‘ or efamp e’ to glve the Operator the opnon to proceed to 2.1 Setup Screen established betWeen the X+ and X- terminals 120 and 122, and the X+ terminal 120 remains pulled high. The X+ dumlg a bootfup Proces?‘ To perform thls tea’ the X_+ tenmnal 120 IS pulled hlgh and the Y+ ?qmmal 12,4 1S terminal 120 is also connected to the input of the A/D 45 co?mflctei t; the gfoulniizéémlllmil’ alnd It, IS degerhmmid converter 102 and, therefore, the voltage at the X+ terminal W et, er t e _ + termlna 15 1g or OW (1'e" W et erl e X-ax1s layer is touching the Y-ax1s layer). lfthe X+ term1nal 120 can be measured using the A/D converter 102 to determine Whether a touch screen is connected. If no touch 1120 15 low’ then the toglchhscreifn 1S plrlessed (althcilugh Zn screen is connected, then the auto detect process terminates, and for example the user may be noti?ed that no touch a temanve reaspn may . e t. at t e touc Screen 15 S 0.1% )' If the X+ terminal 120 is high, then the touch screen is not screen has been detected. 50 press_ed_' Assuming a tOuch Screen is Connected it is next detep _ _ If it is determined at step 152 that an 8-W1re touch screen mined at Step 152 Whether an 8_Wire tou’ch Screen is COn_ is not connected to the interface circuit 100, then the process nected or Whether another type of touch screen is connected. proceéds to Step 158' At Step 158’ it is determined Whether FIG. 5B shoWs the con?guration of the analog sWitch matrix 55 a 7'W1re touch sc_reen 15 Connected or Whether another type 104 during Step 152' The following table S arizes the operation of the analog Switch matrix 104 during Steps oftouch screen is connected. FIG. 5C shoWs the con?gu ration of the analog SWIIC'h matr1x 104 dunng step 158. The 152456, following table summarizes the operation of the analog ' sWitch matrix 104 during step 158 and steps 154-156 for a 7-Wire touch screen: 60 STEP 152 REGISTER EFFECT 0840604 Pull Y+ high, Shoit sY- to VSS TEST RESULT ADC conversion on Y+ High = Other type of touch screen connected STEP 65 158 REGIS. TER EFFECT TEST 0408601 Pii11x+ high, Short ADC sX+ to VSS conversion on RESULT High= Other type of touch US 7,327,354 B2 STEP 154 154 REGISTER 9 10 -continued -continued EFFECT 0401601 Pull X+ high, Short X- to VSS 0402601 Pull X+ high, Short Y+ to VSS RESULT X+ screen Wire touch COHH?Ct?d LoW = 7-Wire SCIBOH connected check that X+ is lOW check that X+ is lOW 154 0404601 Pull X+ high, Short check that X+ touch screen connected (5 Wire With feedback) Operational 10 160 160 EFFECT 154 Operational 154 0410601 Pull X+ high, Short check that X+ 0402601 Pull X+ high, Short ADC Y+ to VSS conversion on X+: voltage A 0600601 Pull X+ high, Short ADC Y- to VSS conversion on X+: voltage B 0401601 Pull X+ high, Short ADC Operational 15 X+ LoW = Touch screen pressed conversion on X+: voltage C value (A > C ADC conversion on Y+: voltage D or B > C or D > F or E > F) = 4 0800E04 Pull Y+ high, Short X+ to VSS 160 0801604 Pull Y+ high, Short ADC X- to VSS conversion on 20 160 0804604 Pull Y+ high, Short or shorted Y- to VSS RESULT Conversion value (A < C and B < C and D < P and E < F) = 5 Wire touch screen Conversion 160 is lOW 0420601 Pull X+ high, Short ADC sY+ to VSS conversion on TEST X- to VSS Operational is lOW check that X+ is lOW 156 160 Operational Y- to VSS 0408601 Pull X+ high, Short sX+ to VSS sX- to VSS STEP REGIS TER TEST Wire touch screen Y+: voltage E ADC conversion on High = No Y+: voltage F touch screen press 25 If a 7_Wh.e touch Screen is Connected then the X+ The ?rst step is to determine if a 4-Wire touch screen can be directly detected. This is done by determining Whether terminal 120 is pulled low because the only touch Screen the X-axis and Y-taxls layers of the screen are connected. In typeS that have sX+ and SX_ COhhected are the 7_Wire and the case of a 5-W1re touch screen, the same layer is used for 8_Wire touch Screens, and the 8_Wire touch Screen has both the X-axis and the Y-axis, and therefore the X+ terminal already been eliminated. As a result, When the sWitch matrix 30 18 and the Y'terminal 32 are resistively Connected In the 104 is con?gured as shown in FIG, 5C, the voltage at the X+ case of a 4-W1re touch screen, the X-axls and Y-axls layers terminal 120 can be measured using the A/D converter 102 to determine Whether an 7-Wire touch screen is connected. If a 7-Wire touch screen is connected, then the process proceeds to step 154, Where it is determined Whether the 35 are different, and therefore connecting the Y-axis layer to ground Will only pull the x-axis layer loW if the touch screen is being pressed. Although this is also true for 8-Wire touch screens, 8-Wire touch screens have already been eliminated touch screen is operating properly. The various con?gura- in step 152_ tions for the analog sWitch matrix 104 are set forth in the AS a result if the X+ terminal 120 is high then a 4_Wh.e table above. Ifall the conditions in the table are met, then the teueh Sereen as eenneeted If the X+ termin’at 120 is low touch screen is operating properly; otherwise, the touch ' ’ Screen is not 0 eratin r0 ert 40 then a 4-W1re screen may be connected and pressed, or a Next at Ste? 156 gitp ispdesehnined Whether the touch screen is pressed. To ,perform this test the X+ terminal 120 5-Wire screen may be connected. In this event, the remaining .Con?gurations of the table above are ui?ized' By using the is pulled high and the Wiper terminal 132 is connected to the Internal pun-up reslstors’ the analog SWltCh array 104 can be ground terminal’ and it is determined Whether the X+ con?gured to perform relat1ve lmpedance measurements. If terminal 120 is high or loW (i.e., Whether the X-axis layer is 45 a 5'W1re toheh Screen 15 Connected’ the reslsthhee between touching the Wiper layer). If the X+ terminal 120 is loW, then any tWe adJaeeht comers Ofthe touch Screen Wlh be less than the touch Screen is pressed (although an alternative reason the resistance d1agonally across the touch screen. Because of may be that the touch screen is shorted). If the X+ terminal the Why X+/X_ and Y'h/Yf are connected’ thls 1S exactly 120 is high, then the touch Screen is hot pressed‘ opposlte of a pressed 4-W1re touch screen. In a' pressed If it is determined at step 158 that an 7-Wire touch screen 50 4_'W1re tohch Screen’ depehdmg on Where the press 15 Occur' is not connected to the interface circuit 100, then the process proceeds to step 160. At step 160, it is determined Whether a 4-Wire touch screen is connected or Whether a 5-Wire touch screen is connected. The folloWing table summarizes the nnggg’ thiglmpegancelflrim X+ to Y; W1; be grgatesrtthan 55+ to, 11 g’ + tto th WIY e ggeater télht 3:0 b + to t+ If; 8? gtreaYer Oan t'l'thO 15;: (1+ 0 d; W1 ,1? Ere? er an + O _' ne 0 ese e Con 1 Ions W1, e me operation of the analog sWitch matrix 104 during step 160: 55 (and they ,may all be true because the eomaet resletahce 1S usually fairly h1gh compared to the 1nd1um t1n ox1de layer resistance). As a result, a determination can be made Whether a 4-Wire touch screen or a 5-Wire touch screen is REGIs. STEP 160 TER connected based on the relative impedance comparisons set EFFECT TEST 0404601 Pun X+ high, Shott ADC Y- to VSS conversion on X+ RESULT High : 4_Whe touch screen 001mm“ I 21311132256 (pressed or shorted) or 5 60 forth above, Regardless Whether a 4-Wire or 5-Wire touch screen is connected, the process proceeds to step 154 Where it is determined Whether the touch screen is operating properly. After that, at step 156, it is determined Whether the touch 65 screen is pressed. The folloWing table summarizes the operation of the analog sWitch matrix 104 during steps 154-156 for a 4-Wire touch screen: US 7,327,354 B2 11 12 The operation is similar to the operation at step 150 as described above, except that the X+ terminal 120 is mea sured at the output of the inverting logic gate 106. STEP 154 REGIS TER EFFECT TEST 0401601 Pull X+ high, Short Check that X+ X- to VSS Assuming a touch screen is connected, it is next deter RESULT Operational mined at step 174 Whether a 4-Wire or 8-Wire touch screen is connected, or Whether a 5-Wire or 7-Wire touch screen is Operational connected. In this step, the Y+ and X+ terminals are ?rst manually shorted together at the touch screen connector. The is lOW 154 0804604 Pull Y+ high, Short check that Y+ 154 Y- to VSS 0402601 Pull X+ high, Short Y+ to VSS is lOW ADC conversion on X+ LoW = touch screen pressed or shorted 10 folloWing table summarizes the operation of the analog sWitch matrix 104 during step 174: High = No touch screen press STEP The following table summarizes the operation of the analog switch matrix 104 during steps 154-156 for a 5-Wire 15 174 REGIS TER EFFECT 0840605 Pull Y+ high, Short sY- to VSS TEST RESULT Check TouchiDetect LoW = 5-Wire or 7-Wire touch bit: touch screen: screen connected High = 8-Wire or 4-Wire touch 20 154 0401601 Pull X+ high, Short check that X+ 154 0402601 Pull X+ high, Short check that X+ X- to VSS Y+ to VSS 154 156 is lOW Operational is lOW 0404601 Pull X+ high, Short check that X+ Y- to VSS 0420601 Pull X+ high, Short sY+ to VSS screen connected Operational is lOW ADC conversion on X+ Operational 25 LoW = touch screen pressed screen), then the process proceeds to step 176, Where it is determined Whether a 4-Wire touch screen is connected or Whether an 8-Wire touch screen is connected. The folloWing or shorted High = No touch screen press If step 174 determines that a 4-Wire or an 8-Wire touch screen is connected (instead of a 5-Wire or a 7-Wire touch table summarizes the operation of the analog sWitch matrix 104 during step 176: 30 Referring noW to FIG. 4B, a second method for determining a touch screen type is illustrated. The second method is STEP digital detection method that avoids using the A/D converter 176 35 102. False A/D converter readings can occur due to back ground noise, and other problems. For example, some delta sigma converters produce invalid samples during resynchro nization. An analog algorithm may require sampling and averaging to reject noise and false readings. In addition, REGIS TER EFFECT 0820605 Pull Y+ high, Short sY+ to VSS, Short Y+ and X+ together TEST RESULT Check TouchiDetect bit: LoW = 4-Wire touch screen connected High = 8-Wire touch screen connected 40 When detecting differences between a 5-Wire touch screen Regardless Whether a 4-Wire touch screen or an 8-Wire and a pressed 4-Wire touch screen for example, timing of the touch screen is connected, the process proceeds to steps 178 and 180 Where it is determined Whether the touch screen is algorithm can be critical in the presence of intermittent or bouncing contact. Although some re-sampling may be required, a digital method can help to avoid potential timing 45 operating properly and Whether the touch screen is pressed. The folloWing table summarizes the operation of the analog and sampling issues during the algorithm. sWitch matrix 104 during step 178-180 for a 4-Wire touch At step 172, it is ?rst determined Whether a touch screen is connected to the interface circuit 100. The ?rst tWo parts of this step ensure that the Touch Detect circuit is Working. screen: The folloWing table summarizes the operation of the analog sWitch matrix 104 during step 172: 50 STEP 178 REGIS TER EFFECT TEST 0401000 Pull X+ high, Short Check High = TouchiDetect bit: Operational X- to VSS STEP 172 REGISTER EFFECT 0000800 Short X+ to VSS TEST Check RESULT 55 178 High = bit: 172 0040000 047F000 Pull X+ high High = TouchiDetect Operational Y+ and X+ bit: Check High = Y- to VSS, Short TouchiDetect Operational TouchiDetect Operational Y+ and X+ bit: bit: together Check 178 LoW = Pull X+ high, Short Check LoW = No X—, Y+, Y—, sX+, sX—, sY+, sY- to TouchiDetect bit: touch screen connected VSS Chcck Y- to VSS, Short together TouchiDetect Operational 172 0804005 Pull Y+ high, Short RESULT 180 0404005 Pull X+ high, Short 0402000 Pull X+ high, Short Y+ to VSS Check TouchiDetect High = touch screen pressed bit: or shorted High = touch LoW = No screen touch screen connected press US 7,327,354 B2 14 13 The following table summarizes the operation of the analog switch matrix 104 during step 178-180 for an 8-Wire touch -continued screen: STEP 178 STEP 178 REGIS TER EFFECT TEST RESULT 0401000 Pull X+ high, Short Check High = TouchiDetect bit: Operational X- to VSS 178 0408000 Pull X+ high, Short sX+ to VSS 178 0410000 Pull X+ high, Short High = Operational Check High = TouchiDetect bit: Operational Check High = Y- to VSS, Short TouchiDetect Operational Y+ and X+ bit: sX- to VSS 178 Check TouchiDetect bit: 0804005 Pull Y+ high, Short 178 180 REGISTER EFFECT 0402000 0404000 0420000 TEST RESULT Pull X+ high, Short Check High = Y+ to VSS TouchiDetect bit: Operational Pull X+ high, Short Check High = Y- to VSS TouchiDetect bit: Operational Pull X+ high, Short Check High = touch sY+ to VSS TouchiDetect screen bit: pressed or shorted LoW = No touch screen press together 178 0820005 Pull Y+ high, Short Check High = sY+ to VSS, Short TouchiDetect Operational Y+ and X+ bit: 20 The folloWing table summarizes the operation of the analog together 178 0840005 Pull Y+ high, Short sWitch matrix 104 during step 178-180 for a 7-Wire touch Check High = sY- to VSS, Short TouchiDetect Operational Y+ and X+ bit: together 180 0402000 Pull X+ high, Short Y+ to VSS screen: 25 Check TouchiDetect High = touch screen pressed bit: or shorted STEP 178 LoW = No REGISTER EFFECT 0401000 touch screen press If it is determined at step 174 that a 5-Wire or 7-Wire touch screen is connected (instead of a 4-Wire or an 8-Wire touch screen), then the process proceeds to step 182, Where it is 178 35 178 0402000 0404000 0408000 determined Whether a 5-Wire touch screen is connected or Pull X+ high, Short Check High = TouchiDetect bit: Operational Pull X+ high, Short Check High = Y+ to VSS TouchiDetect bit: Operational Pull X+ high, Short Check High = Y- to VSS TouchiDetect bit: Operational Pull X+ high, Short Check High = sX+ to VSS TouchiDetect bit: Operational Whether an 7-Wire touch screen is connected. The following 178 table summarizes the operation of the analog sWitch matrix 104 during step 182: 40 STEP REGIS TER EFFECT TEST 180 0410000 0420000 RESULT X- to VSS 30 178 TEST Pull X+ high, Short Check High = sX- to VSS TouchiDetect bit: Operational Pull X+ high, Short Check High = touch sY+ to VSS TouchiDetect screen bit: pressed or shorted LoW = No RESULT touch screen 182 0408000 Pull X+ high, Short sX+ to VSS Check TouchiDetect bit: LoW = 5-Wire touch screen 45 connected High = 7-Wire touch screen In the above examples, in?nite impedance (open circuit) Wire With and relative impedance sensing techniques are used to test touch screen resistances. Similar techniques could also be feedback) applied to perform other types of impedance sensing, for connected (5 Regardless Whether a 5-Wire touch screen or an 7-Wire touch screen is connected, the process proceeds to steps 178 and 180 Where it is determined Whether the touch screen is 55 operating properly and Whether the touch screen is pressed. The folloWing table summarizes the operation of the analog sWitch matrix 104 during step 178-180 for a 5-Wire touch 60 178 REGISTER EFFECT 0401000 TEST RESULT Pull X+ high, Short Check High = X- to VSS TouchiDetect bit: Operational example, in connection With capacitive touch screens. Vari ous capacitance sensing techniques could be used to distin guish betWeen various types of capacitive touch screens and/or to distinguish capacitive touch screens from resistive touch screens. screen: STEP press 3. Touch Screen Data Processing Once a determination has been made regarding the touch screen type to Which the interface circuit 100 is connected, the interface circuit is con?gured for the touch screen type that has been determined. This is done, at least in part, by Writing various values in the registers 112-118 in accordance With the touch screen type that has been detected. The folloWing table shoWs the values stored in the reg isters 112-118 for each of the four types of touch screens.