Download Digital-Analog Converter Module User`s Manual

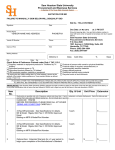

Transcript