Download EPM/MEEMM PAYLOAD AND GSE OPERATION MANUAL

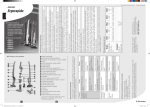

Transcript