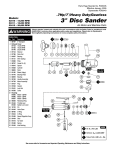

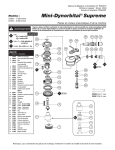

Download Dynabrade.com

Transcript