Download Schaerer Coffee Vito - Whaley Food Service

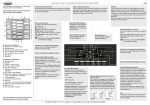

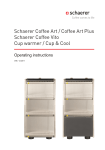

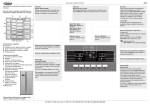

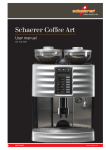

Transcript