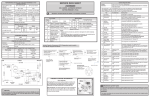

Download OPERA TION AND MAINTENANCE

Transcript