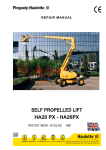

Download H14-16 GB.book

Transcript