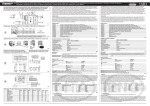

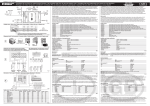

Download User manual

Transcript