Download 1 nm 1111015111115! 11111011 |||||||||||||| 11

Transcript

||||1|m||||| 1 nm 1111015111115!11111011 |||||||||||||| 11

United States Patent [19]

Hoffman et al.

[54]

[11]

Patent Number:

[451

Date of Patent:

COMPUTERIZED DIAGNOSTIC AND

WO89/12279 12/1989

WtPO .

MONITORING SYSTEM

WO92/04693

WIPO .

[75] Inventors: John P. Holfman, Peoria; Ricky D.

Vance, Washington; Dennis A- Bam‘eyi

Morton; J?seph G- Kozlevcar, P9999,

an of I11_

_

3/1992

5,453,939

Sep. 26, 1995

OTHER PUBLICATIONS

Caterpillar Service Manual — “Computerized Monitoring

System With LCD Bargraph Gauges”, published in 1991.

Journal Article — “Microelectronics takes to the road in a

big way: a special report”, pp. 113-122 in the Nov. 20, 1980

_

[73] Assignee: Caterpillar Inc., Peona, Ill.

edition of Electronics

Journal Article — “Expert-systems applied to earth-moving

[21] Appl. No.: 945,451

_

vehicle transmission troubleshooting”, pp. 3840, published

_

[22] med‘

in the Dec., 1990 edition of Automotive Engineer.

Sep' 16,1992

Publication entitled “Introducing the Vital Signs Monitor

[51]

Int. Cl.“ ............................. .. G06F 11/00; B60Q 1/00

p111S Load Weighing System”, by Marathon LeTrouneau,

[52]

US. Cl. .............................. .. 364/551.01; 364/424.03;

Pubhshed 9“ or ab0ut1988-

[58]

73/1172; 340/433; 340/439; 340/461

Field of Search ....................... .. 364/55101, 424.01,

Journal Article — “all on board with O & K” behved to have

been Published on 0‘ abm“ Jan-t 199°, and Sales literature

364/424.03, 424.04; 73/116, 117.2, 117.3;

attaFhed there“)-

340/438, 439, 461, 945, 959

[56]

.. .... .

_

' _

_

Al’tlCl6 from Ropec II‘ldUS'tl'l?S, 1116., re “MlCtOlOgllC, trn

Model SW100, which is a Vehicle Management System”.

References Clted

U‘S_ PATENT DOCUMENTS

Utter

_

Primary Examiner—Emanuel T. Voeltz

Assistant Examiner—M. Kemper

Attorney, Agent, or Finn-Thomas J. Bluth; Steven R. Janda

3,509,529

4/1970

3,516,063

6/1970 Arkin et a1. ....... ..

. . . . ..

340/52

3,866,166

2/1975 Kerscher, HI et a1. ..

340/52

3,393,103 7/1975 McBride, In et a1 __

3,906,437 9/1975 Brandwein et a1. .

4,053,868 10/1977 COX 9t 31- ---------- “

4,072,925 2/1978 Yashlma 6‘ a1‘

340/420

340/27

340/52

340/52

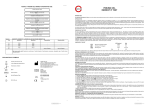

Systems for monitoring sensed parameters and diagnosing

fault conditions are useful in many applications. Advanta

geously, such systems are capable of operating in a plurality

of operating modes and in connection with each of a

340/163

[57]

ABSTRACT

'

4’128’005 12/1978 Amston et a1- '

73/111743

plurality of machines. In the subject invention, a plurality of

4’197’650

4,223,302

4 271 402

4/1980 Bade?’ et a1‘

9/1980 Hocking ........ ..

6,1981 Kasmm et al

33/ 3

340/525

340/52

gauges are included for indicating the levels of the sensed

.

.

.

.

parameters. A plurality of symbols are included for identi

4,376,298

4,442,424

Simon et

3/1933 Sokol et al

4/1984 Shimsaki et a1,

364/551

,,,, __ 340/52

sensed parameters. A Control reC€iV€S an identi?cation

code and selectively illuminates one or more of a plurality

of gauges and symbols in response to the identi?cation code.

4,497,057

1/1985 Kato et a1. .... ..

. 371/29

A plurality of warning lights are each associated with a

4,521,885 6/1985 Melocik 6'1 a1---- -- 371/29

4,551,801 11/1985 Sokol ................ ..

364/424

4,583,176 4/1986 YEIHBIO et a1. .................. .. 364/431.“

switch-type input. A display selectively indicates a pin code

for each switch_type input having a fault condition The

indicator lights having an associated switch_type input in the

(List Continued on next page_)

fault condition are ?ashed. A device selectively indicates a

pin code in response to each diagnosable input having a

present or a previous fault condition.

FOREIGN PATENT DOCUMENTS

3837592A1

5/1990

60-107109 of 1985

Germany .

Japan .

2 Claims, 17 Drawing Sheets

/ so

‘7

MACHINE

42 \. IDENTIFICATION

/ 52

SERVICE

CLEAR

BFtlGHTNESS

[?sh/é‘!

mpur

INPUT

SWITCH

SELECT

Ill-"l “I

34 “°

38

I

31: art

jl/

\

/V

(é‘étt tn}

34th.. @m?

El [El

ms 4F

/\

43 ->

46->

E?bmg?c

I

'3'"

— — —

SENSORS

’ 11

new

mm

mm

~11

5,453,939

Page 2

US. PATENT DOCUMENTS

4,667,176

5/1987

4,694,408

9,1987 Zaleski ____ u

4,975,848

12/1990 Abe 61:11. ........................ .. 364/42403

4’977’389

12/1990

364,551

5,019,799

5/1991

Matsuda .................................. .. 340/52

shufnshl

'''‘‘

' ' ' " 340/461

Osh1age (it al. ....................... .. 340/438

4,748,843

6/1938 schafer et a1_

____ __ 73/1173

5,034,889

7/1991 Abe .................................. .. 364/424.04

4,809,177

4,811,240

2/1989 Windle 6t a1. ................... .. 364/424.01

3/1989 B31101! 6131. ................ .. 364/424.01 X

5,041,980

5,050,080

8/1991 Maddock er a1. ................ .. 364/43103

9/1991 Abe .................................. .. 364/424.04

4,812,744

3/1989

4,815,824

3/1989 Shawl“

Havel

. . . . . .. .

. . . . . ..

324/115

5,091,858

2/1992

350/336

5,150,609

9/1992 Ebner BI a1. ......................... .. 73/1173

4’843’557

6/1989 Ina etal

4,862,395

8/1989 Fey e161.

4,896,276

1/1990

..... .. 364/550

4,926,331

5/1990 Windle B131.

Paielli

364'431'77

5,157,610

10/1992 Asano et a1. ..................... .. 364/424.03

..... .. 364/561

5214 582

5,1993 Gm

364,431.12

364,424 03

-

4,939,652

4,967,143

Saglimbeni 61 a1.

3

Y ------ -

5,257,190 19/1993 Crane ~

364424-03

364/42404

5,313,388

5/1994 Cortis -------- -

364/424-04

10/1990 Raviglione et a1. ................. .. 324/731

5,327,344

7/1994 Hoffman et a1- ................. -- 364/424.03

7/1990

Steiner ............ ..

.. 364/42404

3

US. Patent

Sep. 26, 1995

Sheet 1 0f 17

5,453,939

[I

I]

QB I]

U

@U

U I]

EEIU

FI

/

3634 /

§“%8

g/E'miCI)

<1: 38

3 ‘I2

9CRBB3E0D3c/anVI GEE

B

8

35%!

6§

r/

k\ 2

/

30 /

a 33

US. Patent

Sep. 26, 1995

Sheet 2 0f 17

/////z’

5,453,939

U.S. Patent

Sep. 26, 1995

Sheet 4 of 17

5,453,939

US. Patent

Sep. 26, 1995

r_H_

(Em.

Sheet 5 of 17

m.E

Emu

5,453,939

PCmmv

s

a

8\“_r

B

_H_

5%(/8Q

K

x

mm

US. Patent

Sep. 26, 1995

Sheet 6 of 17

[I]

‘5

E

[II-CHE]

aw Um @w

mm

mm

5,453,939

US. Patent

Sep. 26, 1995

5,453,939

Sheet 7 of 17

m5

m

{X

(w

gmm.

5/

mglwsCum

?aw

(AVQ

QEé/t/\muma‘

\

/

US. Patent

Sep. 26, 1995

Sheet 8 of 17

5,453,939

FLEJEIE

READ THE

IDENTIFICATION

CODE

ARE TURN

SIGNALS USED ON

THIS VEHICLE?

READ THE TURN

SIGNAL INPUTS

V

IS THE RIGHT

RN

TURN SIGNAL ON?

N THE RIGHT

Tl?l'uRNolNDlcATOR

4

I

IS THE LEFT

TURN SIGNAL ON‘?

L

‘

.

I

US. Patent

Sep. 26, 1995

Sheet 9 of 17

5,453,939

PLE_EI:I_

IS

THE HIGH

BEAM INDICATOR

USED ON THIS

MACHINE?

READ THE HIGH ‘

BEAM INPUT

IS THE HIGH

BEAM ON?

TURN ON THE HIGH

BEAM INDICATOR

I

IS THE

' ETARDER INDICATOR

USED ON THIS

ACHINE

READ THE

RETARDER INPUT

IS THE

RETARDER ON‘?

TURN ON THE

RETARDER INDICATOR

‘

I

US. Patent

Sep. 26, 1995

Sheet 10 0f 17

5,453,939

$112.15 |:_

IS BRIGHTNESS

CONTROL PHOTOCELL

ONLY?

CONTROL BRIGHTNESS

IN RESPONSE TO

PHOTOCELL OUTPUT

IS BRIGHTNESS

'

CONTROL

SPST?

Y

EXECUTE LOGIC

FOR SPST

BRIGHTNESS

CONTROL SWITCH

EXECUTE LOGIC

FOR SPDT

BRIGHTNESS

CONTROL SWITCH

US. Patent

Sep. 26, 1995

Sheet 11 0f 17

5,453,939

FLEJEIEI.

IS THIS A

LOW WARNING

STYLE GAUGE ?

TURN ON LOWER

GAUGE OUTLINE

I

TURN ON UPPER

GAUGE OUTLINE

I

ENABLE UPPER

WARNING SEGMENTS

I

I

READ GAUGE

DATA

I

MAP GAUGE DATA

TO SEGMENT DATA

I

READ SINGLE/FILL

INPUT

I

BUILD AND TRANSMIT

SENSOR DATA

MESSAGE

ENABLE LOWER

WARNING SEGMENTS

US. Patent

Sep. 26, 1995

@

Sheet 12 of 17

5,453,939

:::.I__:-_EIE_

#I

550

TURN ON THE

APPROPRIATE

SYMBOL

IS THE GAUGE

IN SINGLE SEGMENT

MODE’?

IS THIS A

LOW WARNING

STYLE GAUGE?

IS THE GAUGE

IN A LOW WARNING

CONDITION?

FLASH THE

LOW WARNING

SEGMENTS

I

IS THIS A

HIGH WARNING)

STYLE GAUGE-

ILLUMINATE

INDICATING

SEGMENTS

4

N

IN IISIIQEI

(IIv'ZUFICi?NG

CONDITION?

Y

1

FLASH THE HIGH

ILLUMINATE

WARNING SEGMENTS

AND ALL THE

INDICATING SEGMENTS

INDICATING

SEGMENTS

I

1

US. Patent

Sep. 26, 1995

Sheet 13 of 17

5,453,939

..:"_T.. E

IS THIS A

LOW WARNING

IS THE GAUGE

IN A LOW WARNING

STYLE GAUGE?

CONDITION?

FLASH A

LDW WARNING

SEGMENT

ILLUMINATE A

SINGLE INDICATING

SEGMENT

I

IS THIS A

HIGH WARNING

STYLE GAUGE?

IS THE GAUGE

IN A HIGH WARNING

CONDITION?

FLASH A

HIGH WARNING

SEGMENT

I

ILLUMINATE A

SINGLE INDICATING

SEGMENT

US. Patent

Sep. 26, 1995

5,453,939

Sheet 14 0f 17

4-1.5 -EE

READ THE HARNESS

IDENTIFICATION

CODE

I

READ ALL

INPUTS

I

PERFORM SYSTEM

DIAGNOSTICS

IS THE SYSTEM

IN SERVICE MODE ‘.7

DISPLAY FAULT

CODES AND STATUS

IS SERVICE

INPUT GROUNDED ?

DISPLAY NEXT

FAULT CODE AND

STATUS

SOUND THE

ALARM FOR

0.5 SECONDS

I

DISPLAY INPUT

PIN NUMBER

US. Patent

Sep. 26, 1995

HAVE ANY

Sheet 15 0f 17

Y

DISPLAY THE INPUT

olHAilij?Tlgpéil?seAg

PIN # FOR ALL CHANGED

TATUS?

>

FAULT CONDITIONS

1

IS THE SYSTEM

IN STATUS MODE ?

FLASH ALL INDICATOR

LIGHTS CORRESPONDING

TO INPUTS THAT ARE

NOT GROUNDED

I

DISPLAY PIN # FOR ALL

SWITCH INPUTS THAT

ARE NOT GROUNDED

I

STEADILY ILLUMINATE

INDICATOR LIGHT

CORRESPONDING TO

DISPLAYED PIN #

SOUND HORN FOR

0.5 SECOND

I

DISPLAY INPUT # FOR

SWITCH INPUTS THAT

CHANGED STATUS

5,453,939

‘

US. Patent

Sep. 26, 1995

Sheet 16 of 17

5,453,939

FLE__I_[:IE_

IN NUMEFIlC

Baggy

N

RESET

TIMER

SET PARAMETER

NUMBER TO ZERO

SCROLL

ACTIVE?

TIMER

EXPIRED?

INCREM ENT

PARAMETER #

N

V

RESET

TIMER

'N

DISPLAY CURRENT

PARAMETER #

I

DISPLAY CURRENT

PARAMETER DATA

US. Patent

Sep. 26, 1995

Sheet 17 of 17

5,453,939

Flaulljh;

IS THIS A

GAUGE

PAHAM ETER?

IS THE

PARAMETER

ENGINE SPD?

IS THE

PARAMETER

VEHICLE SPD?

NK THE

GAUGE OUTLINE

__>_._

TURN ON THE

RPM ISO SYMBOL

F

+

Y

IS THE SPD

INUAIGIFJSQC

TURN ON THE

l'KMH" ISO SYMBOL

‘ @D

T

TURN ON THE

"MPH" ISO SYMBOL

_>__

5,453,939

1

2

COIVIPUTERIZED DIAGNOSTIC AND

MONITORING SYSTEM

particularly large off-highway work vehicles, are becoming

increasingly complex in their design thus making it more

TECHNICAL FIELD

and more di?icult for service personnel to locate defects in

machine sensors and systems. This is particularly true of

intermittent defects not resulting in a breakdown of a system

or the vehicle but which interfere with its operation.

The invention relates generally to a computerized moni

toring and diagnostic system, and more particularly, to a

A major frustration when troubleshooting electrical prob

monitoring and diagnostic system having a plurality of

operating modes.

lems on a large work vehicle is caused by intermittent

10

BACKGROUND ART

problems. Typically, the operator reports some symptom to

a technician and before the technician can get to the machine

the problem is no longer present.

If the condition is not present it is helpful for the techni

In a variety of engine-powered vehicles, monitoring and

diagnostic devices are employed to detect the presence of

various undesirable operating conditions, such as overheat

ing of the engine, low oil pressure, low fuel, and the like, and

cian to re-create the fault condition. In many cases the fault

condition is caused by a short to ground potential or an open

circuit. To recreate these fault conditions, the technician

manipulates the wire harnesses or wire connectors to deter

indicators are provided to warn the operator of such condi

tions. These instruments are typically connected to various

tions on the vehicle via a wire harness and/or a communi

mine the point at which the fault has occurred.

Prior art systems have indicated when fault conditions are

present. In connection with such systems, the technician

cation link. In many applications, these instruments are also

connected to electronic control systems, for example elec

tion is present. In troubleshooting intermittent problems

sensors and switches for monitoring or controlling condi

must view a visual display to determine whether the condi

tronic engine controls, electronic transmission controls, and

when the fault condition is not currently present, the tech

the like.

nician must manipulate wire harnesses and connectors to

Most prior art systems have included dedicated instru 25 recreate the fault and thus cause the fault indication to be

displayed. When the fault condition is present, the techni

ments in which the functions and conditions of the vehicle

cian must manipulate wire harnesses and connectors and

to be monitored or diagnosed, as well as the particular

observe whether the manipulations eliminate the fault and

sensors provided on the vehicle, are identi?ed in advance.

thus cause the fault indication to disappear.

Therefore, the instruments are speci?cally designed for and

hence “dedicated” to the monitoring or diagnosing of those 30

In many cases, however, the machine is of su?icient size

particular vehicle functions and conditions in response to

that the technician must leave the area of the diagnostic tool

signals from pre-identi?ed sensors. Accordingly, such “dedi~

to recreate the fault condition. Therefore, any visual indi

cated” instruments generally cannot be readily modi?ed to

cator provided by the diagnostic tool is not visible to the

technician. To effectively troubleshoot the electrical system

accommodate different machines, different sensors and/or

different conditions and functions. Rather, such instruments

on such a large machine, typically two or more technicians

are generally limited to use with a particular vehicle type or

are required and repair expenses are thus greatly increased.

Similarly, the vehicle may not be repairable immediately if

only a single technician is available.

In addition, these machines typically include switch-type

inputs that are either in an open voltage or grounded

model for which the instrument has been designed.

However, it is advantageous for these instruments to be

usable in connection with many different machines. Lower

costs are achieved and less warehousing space is required if

a single instrument can be manufactured which can be used

condition. One of the voltage conditions is de?ned as a fault

condition. In most cases, the fault condition is de?ned as the

in many different applications. Similarly, service time is

reduced if software changes are avoided when an instrument

is moved from one machine to another.

Some prior art systems have provided for standardized

open voltage condition thus whenever the wire between the

45

sensor and the display is severed or disconnected, a fault

condition is indicated. Similarly, if the switch-type input is

monitoring systems that are usable in connection with a

connected to a switch-type sensor, the switch-type sensor

variety of machines, for example the system shown in US.

disconnects the sensor output from ground potential when

Pat. No. 4,551,801 issued to Sokol on Nov. 5, 1985. While

the sensed parameter exceeds a warning level.

being an improvement over dedicated systems, this moni

toring system is still relatively in?exible and requires the

for each switch-type sensor that is in a fault condition. Each

Some prior art systems have illuminated a warning light

addition or subtraction of monitoring modules and the use of

warning light is associated with one of the switch-type

sensors and is illuminated when the display input associated

with that switch-type sensor is indicating a fault condition.

decals to indicate the parameters being shown by each

display module.

One area of desired ?exibility is for each gauge in the

instrument to be capable of indicating parameters having a

55

advantageous to also indicate the pin number of the input

associated with the switch-type sensor. Optimally, the tech

nician should be able to determine the pin number of each

of the warning lights indicating a fault condition even

though there are more than one of such warning lights. This

would allow technicians to more readily identify the fault

condition and associate the sensor having the fault condition

high warning level, for example engine temperature, and

also parameters having a low warning level, for example

brake ?uid pressure. Prior art systems required the use of

decals to indicate that the gauge was indicating the level of

a parameter having either a high or low warning level and/or

the use of a separate warning light to show that the param

eter was outside the normal operating range.

To maximize system ?exibility, it is advantageous for the

instrument to be capable of performing a number of diag

nostic functions in addition to displaying parameter values

and indicating warning conditions. Today’s machines, and

While adequate for many purposes, in other cases it is

to the relevant connector pin.

While troubleshooting some diagnosable sensor prob

65

lems, it is sometimes di?icult to determine whether a sensor

is producing a signal that is truly representative of the actual

level of the sensed parameter. This often results in techni