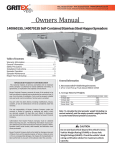

Download Parts & Maintenance Manual

Transcript