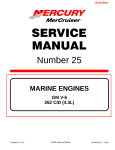

Download ENGINE

Transcript