Download RGD551 / RGD1101 - Jacks Small Engines

Transcript

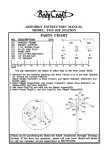

CONTENTS Title Section Page 1. SPECIFICATIONS 2. EXTERNAL 3. ................................................ VliWS .............................................. 3 .............................................. 3 2-l. Model RGD551 2-2. Model RGD1101 PERFORMANCE 3-1. 3-2. Model Model 5. OPERATION 6. WIRING .. Phase 3 phase Generator Generator For Single Phase, 2 Wires Generator For Single Phase, 4 Wires Generator CHECKING SHOOTING FUNCTIONAL PARTS 13 13 ............................... ............................... . . . . . . . . . . . . .. . . . . . . . . ... ... . .... ... .. .. .... . ... ... ... ... .. ... .. . .. ... .. ... . Stator 8-2. 8-3. Rotor/&y Voltmeter ................................................... 9. 10. 8.9. SR Assy .................................................... Injection of Residual DISASSEMBLING SAFETY AND PRECAUTlONS Magnetism . .. 15 15 16 16 16 16 16 ................................. REASSEMBLING 15 15 15 B-4. Neon Lamp .................................................. 8.5. Slip Rings ................................................... 8-6. Brush Assy .................................................. 8-7. AVR Assy (Single phase) ....................................... ........................................... 8-8. CT Assy (3 phase) 8-l 0. 14 15 Assy .................................................. .................................................. 8-l. 13 13 .................................. 6-2. 6-3. 8. 12 12 ......................................... ............................................ .. ... . ..... ... ... .. .... ... ... .. .. ... ... .. .... . DIAGRAM 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 For 3 Phase, 4 Wires Generator TROUBLE 8 .. ... ... .. ... .. .... .. .. ... .... ... .. ... .. .... .. 6-l. 7. 5 ............................................. .. ... Single 5 ......................................... .............................................. RGD551 RGDllOl CONSTRUCTION 4 ............................................. CURVES 4. 5-l. 5-2. 1 .. ... .... .. ... ... ... .. .... . . .... .. ... ... .. .. ... .. .. .. .. .. .. ... . 18 23 1. SPECIFICATIONS RGD551 Model Self exciting, 2 pole I / Type Single phase, Single phase, 2 wires 3 phase, 4 wires 4 wires I 50Hz L : a : Max. E I output E ! u’ Rated 50Hz i 60Hz (VI 5000VA Current (A) 2201380 .230/400 7.6 Revolution (rpm) 7.0 60Hz 4ooow I .I271220 ! 2401415 I120/208 7.2 : 50Hz I 4500w 5500VA 110 I : 120 36.4 ’ 33.3 : I : Voltage / Rated 60Hz I , 13.9 13.1 I I 220 110 : 36.4 18.2 240 17.4 1 16.7 3000 3600 3000 i 230 ! 3600 i i llOl220 36.4118.2 / 3000 ; 3600 I i Power 0.8 Factor 1 .o ! Air-cooled, Type 4cycle. Singlecylinder I Diesel Engine DY40-A Model I I Piston Displacement 402cc (24.53) fcu.in) E .e :. Maximum w Fuel a PS Horsepower Diesel Oil Fuel Tank Capacity 15i (3.96) (U.S. gal.) Starting Starting System Motor I output Output Terminal Output 4 Terminal 2 Terminal Terminal Output Socket Output 2 CT type Voltage Protection Breaker fluctuation Breaker I Dry Weight flbs) Dimensions LxWxHfinchl fluctuation I Breaker1 : !lP 37A. 140kg Breaker (309) al lx598x773mm(31.9x23.5x30.4~ -l- 3P 15A : Output / Socket 2 type Voltage +5% 3P 7.3A Socket AVR I Regulator Voltage Circuit 4 ! 1P 18A Breaker ~5% Breaker; /lP37A’lP35Aj Breaker 2P 1BA 2 I - ,Model I RGDllOl I- Self exciting, 2 pole Type 1 Single phase, 3 phase, 4 wires Single phase, 2 wires 4 wires ’ Frequency 50Hz 50Hz 60Hz 1 Max. 60Hz 11 OOOVA 50Hz 1 60Hz I 9ooow output 1 OOOOVA Voltage (VI 2301400 2201380. Current (A) Rated Revolution 15.2 (rpm) ! 14.4 aooow 2401415 I 1201208 13.9 3000 I ’ 1271220 I: 26.2 27.8 3600 I I ’ 110 1 72.7 220 1I 230 240 110 120 1101220 36.4 I 34.8 33.3 72.7 66.7 72.7136.4 3000 / 3600 3000 : 3600 I Power Factor 0.8 1 .o , Aircooled, Type 4cycle. Model Piston 2cylinder I Diesel Engine DYBO-2A Displacement a04cc (49.06) (cu.in) Maximum Horsepower 16PSl3000rpm Fuel Diesel Oil Fuel Tank Capacity 24C (6.34) (U.S. gal.) Starting Starting System Output Terminal Motor 4 Output Terminal output 2 Terminal 4 output Output Socket Output 2 Socket 2 / Socket I CT type Voltage Voltage Breaker Circuit AVR type Regulator Protection Dry Weight (Ibs) Dimensions LxWxHfinch) 3P 16A I 1 1 Breaker ! fluctuation =5X Voltage -Breaker/Breaker 3P 15A Breaker 3P 30A lP 75A’lP 220kg 96lx650xB72mm -2- .Breaker 37Aj (485) (37.8x25.4x34.3) fluctuation 1P 35A +5% Breaker -lP 75A’lP Breaker Breaker 70A’ 2P 37A 2 ’ 2. EXTERNAL 0 2-1. Model -EXTERNAL VIEWS RGD551 VIEW (1) / ! Air cleaner Pipe frame Fuel tank \ \ i ! i Decompression lever ( I Fuel tank cap! Fuel gauge, Control i \ \ let \ \ Control box i ‘!, :.: i:. ,I I, CA Oil filler Gel filter 0 Earth cord / \Oil filter I Caster / EXTERNAL VIEW (2) - CONTROL PANEL (VIEW “A”) vibration isolator .. AC voltmeter ,No-fuse Neon lamp Rubber : / breaker ;Terminal cover For 3 phase, 4 wires Generator Output For single phase, 2 wires Generator socket For single phase, 4 wires Generator 2-2 Model EXTERNAL RGDllOl VIEW (1) Air cleaner ,Engine : ‘? Control iPipe frame :-Decompression ; .!; : lever I! , . Fuel tank I Fue! tank cap ,. ‘. : . lever Muffler / :Fuel gauge Control 9 / t i Oil filler Rubber Caster .’ EXTERNAL VIEW (2) - CONTROL PANEL (VIEW “A”) isolator! AC voltmeter ,No-fuse Neon lamp 1 vibration :’ / breaker ;Terminal cover output Ij ,n ! QJb Output terminal ‘j D ’0 0 0 0 For 3 phase, 4 wires Generator Neon lamp. For single phase, 4 wires Generator For single phase, 2 wires Generator -4- box 3. PERFORMANCE 0 3-1 Model CURVES RGD551 l Self exciting, 80% ........................................ Engine Output Max ............................... Rated ............................ Voltage ........................................ 53 I j : power Factor Engine Output Rated Frequency Voltage Engine Output ............................ Frequency 22OV/38OV Voltage l Self exciting, power E.ngine Output : o3 / Max Voltage (A) 6 8 100% DY40-A .............................. 45OOW ............................ ................................... 4OOOW 50Hz 1 1ov/22ov ....................................... 5000 4500 I 5 E 50 Tu.Ez 49 10 2 pole, single phase, 4 wires 53 j I 230/400\/ _^I -Li I- 32 51 I 5500 ’ : 5OHz ........................................ Frequency I & 5000VA ............................... Rated 240\1/4 15V -L Factor 550()VA I woe ............................ .................................. 2 Current Dy40-A ! 5500VA 1 : 50Hz 53 Dy4f-JA ............................... ........................................ 5000VA ................................... Y 435 ---vi 425 - Max Rated 80% ............................... 8056 ........................................ 5OHz 2 pole, 3 phase, 4 wires ............................... Wuency 2 pole, 3 phase, 4 wires ............................... 10 ....................................... 52r-F 51m Factor (A) La ........................................ Max bY40-A 5500VA I ; ! 2 Curren: l Self exciting, power 5000VA .................................. Frequency l Self exciting, 2 pole, 3 phase, 4 wires power Factor ............................... 1 /I .--^ 4,“” 4ooo3 3500 ; 4000 1 3000 230 220 210 12345678910 Current (A)- 2500° 5 5 (10) Current -5- ~10~ (20) (A)& 15 (30) 20 (40) ~~~, - l Self exciting, Power Factor Engine.. 2 pole, single phase, 2 wires ................................ Frequency DY4@A Engine Output Rated 4O()()w ............................. .................................... I 10 l Self exciting, Power Factor Engine 20 30 Current (A)- Voltage Voltage ............................... .................................... 5 l Self exciting, joey;, Power Factor DY40-A Engine 45OOW Output ........................................ 10 15 Current (A)- 20 1 25 1(-jay< DY40-A ......................................... Rated 50Hz 22OV 2 pole, single phase, 2 wires ............................... Max 45()(&V 4o()()\Jv ........................................ 50 4(-J(-JOW .................................... ............................. ! ! 2 pole, single phase, 2 wires ............................... Output Max .................................. Rated Frequency 1lOV 40 DY4()-A Max ................................ Rated . 1()0X .......................................... 50Hz (60Hz) T. 2 pole, single phase, 2 wires ............................... I .......................................... Frequency Power Factor 45()OW ........................................ Voltage loo?6 Max ................................ ......................................... Output l Self exciting, ............................... 45OOW ............................. 4O()()W 50Hz Frequency 23OV Voltage ......................................... ................................... 50Hz 240~ 53 52 -4500 -4000 -3500 -3000 -2500 -2000 -1500 I 5 10 Current (AIF I I 15 20 25 5 -6- 10 Currenr 15 IAl- 20 25 _ l Self exciting, Output Max 0 Self exciting, 2 pole, 3 phase, 4 wires Power Factor ............................... Engine .......................................... ............................... Rated .............................. Frequency ..................................... ........................................ Voltage DY40-A Engine 5500VA Output 2 pole, 3 phase, 4 wires 80% ............................... Power Factor 80% .......................................... Max DY4@A ............................... 55OOVA Rate-J ............................. 5OOOV A 5000VA (j(-jHz ................................... 60Hz Frequency J~OV!~O@J Voltage ......................................... 63 I 127V,i22OV I -3500 I / Current l Self exciting, Power Factor Engine Output -3000 I 2500 -2500 Current (A)- 2 pole, single phase, 4 wires ............................... .......................................... l Self exciting, 100% Power Factor DY4@A Engine Max ................................ 45OOW Output Rated .............................. 4OOOW Frequency .................................... Voltage. ........................................ 60Hz Voltage 2 pole, single phase, 2 wires ............................... .......................................... 100% DY40-A ............................... 45OOW Rated .............................. 4OOOW Max Frequency 1 1OV/22OV iA)- .................................... ........................................ 60Hz 12ov 63 62 61 61 4500 60 4000 59 -4500 60. -4000 59 -3500 3500 3000 230 220 210 I 2500 5 (10) Current IO (20) 15 /30! 20 (40) 25 (50) 10 (A)- -7- 20 30 Current IAl- 40 50 3-2 Model RGDllOl l Self exciting, 2 pole, 3 phase, 4 wires l Self exciting, 2 pole, 3 phase, 4 wires Power Factor ..__._...._....___.______________ 80’$& Power Factor ................................. ._.____.____.._.............................. Dy80-2A Engine Output Max . .. .. ... .. .. . .. . ... .. .. ... . .. .. .. Rated Frequency ._........_................... Engine 1 1000VA Output Frequency . ...____.......____.................... 50Hz N 521 i , - : DY80-2A ................................. Max Rated 1 OOOOVA . . .... . .. .. . . ... ... . .. .. . .... .. . .. .. . .... . 22OVl38OV Voltage ............................................. .............................. ....................................... 1 1 (-J-J-Jv,~, 1 OOOOVA 5()Hz 230/400\1 .......................................... Voltage 80% I -.- I50000 / I f 2 4 6 Current 8 I 10 12 14 16 18 20 (A)- o Self exciting, 2 pole, 3 phase, 4 wires Power Factor ................................. l Self exciting, 80% Power Factor 2 pole, single phase, 4 wires ................................. l(-J(-J% ............................................. Dy80-2A Engine ............................................. Dy80-2A Engine Output Max 1 lOOOVA Output Max .................................... .................................... Rated Frequency Voltage ................................. ....................................... .......................................... xI 53 I 2z$ IL 50 52 51 49 Rated ................................. 1 O(-jO()VA 50Hz Frequency 24OV,‘41 5V Voltage ....................................... iI 8OOOW 5()Hz 1 1 OV!22OV ............................................. 53 9OOOW I 10000~ 11000 9000 6> L 80001 7000 2 = 435 425 415 405 230-Voltage / 220 210 / y_ 7 50006 6000 5 7 z 1,201 “‘g1100; I1 10;. , Voltage / Y 3 > 2 4 Current 6 8 5 10 15 20 25 30 35 40 45 50 i301 (SOi ‘7Oi igoi ilO! i2oj i40, iE.0: 18Oi ilOO! 10 12 14 16 18 20 (A)- Current -8- (A) - I 0 l Self exciting, 2 pole, single phase, 2 wires l Self exciting, 2 pole, single phase, 2 wires Power Factor _._....__........................ Power Factor ................................. Engine .. ... .. .. .. . ..._..._......................... Output Max Voltage zzI Output Max .................................... Rated ___._.._..._..................... 8000W .. .. ..._............................... .. .. . .. .. . . .._...__.................... ............................................. Engine DY80-2A ___.._______._._.___................ 9OOOW Rated Frequency 100% Frequency 50Hz (60Hz) 1 1 ov ................................. ....................................... .......................................... Voltage 100% D’,‘8@2/, g()()OW 8OOOW 5()Hz 22ov (62152 g (61151 : (60150 =I $ (59!49 LL 120 -110 > -100 8 J ! 2 I I 20 40 Current l Self exciting, 60 80 Y I 100 10 (A) - 40 50 Curren?(A)- 2 pole, single phase, 2 wires ................................. 100% 0 Self exciting, 2 pole, single phase, 2 wires Power . .. .. ... .. .. .. .. .. .. ... . . .. . ... .. 100% Power Factor Engine ............................................. Dy80-2A Engine ... .. . . ... .. .. . .. . . .... .. . .. .. . .. .. .. . ... . .. . DY80-2A Output Max .................................... 9OOOW Output Max Rated ................................. 80(3)W Frequency ............... -....................... Voltage ............................................ Factor .. . .. .. . .. ... .. .. ... . .. .. .. .. .. .. .. . 9OOOW Rated 50Hz Frequency 23OV Voltage . . .. .._...__._._._............... 8000~ . ... . . . .. .. .._.._...................... 50Hz ___.........._.._._.......................... 240V ,800O .6000 2 -5000 ‘;: 2 t -4000 2 .3000$ I 230 I z5 220 /: g,210 s > , 30 40 1 50 kkren?(A)- Current -9- (A) - l Self exciting, Power Factor Engine Output 2 pole, 3 phase, 4 wire ......................................... Max Rated Frequency l Self exciting, 80% ............................... ............................... ............................. Power Factor DY8@2A Engine 1 1 OO()VA Output Voltage ......................................... 8()9& .......................................... Dy8()-2A Max ................................ Rated .............................. 1 OOOOVA .................................... 2 pole, 3 phase, 4 wires ............................... 60Hz Frequency 12OV,l208V Voltage .................................... ........................................ 1 lOOOVA 1OOOOVA 60Hz 127Vi22oV 62 61 -11000 11000 60 59 8000 z $ 2 Z t > 210 220 6000 7000 5000 2 L -8000 8000 -6000 6000 120 130 l Self exciting, 20 (A)- -7000 7000 220 2 5 - t 0 140 10 Current -9000 9000 230 130 I/ -10000 10000 59 9000 5000 I 30 40 Current l Self exciting, 2 pole, single phase, 4 wires 10(-J?& IAl- 2 pole, single phase, 2 wires ............................... 100% .............................. Power Factor ......................................... Engine Dy80-2A Engine Output Max ................................ 9OOOW Output Rated ............................. 8OOOW 800(34/ 6()Hz Frequency Voltage ......................................... 12(-J/ Frequency Voltage .................................... ......................................... DY80-2A Max ................................ Rated gOO()W ............................ ................................... 6()Hz 1 1ov/22ov ........................................ 63 Power Factor I 631 I ; 62 / 61 / ---loo ac .n,-. 8Guu 60 .8000 59 -7000 7000 6000 5000 ! I 20 30 40 (80) 60 20 50 (100) Cur% w -lO- (A)- 80 100 4. CONSTRUCTION (2) The Generator control box frame. (RGD551 and a fuel The stator cover which stator, engine. frame available ard for is directly rubber Control bolts to the engine. with coupling The for RGD551 The (The fuel voltmeter, a neon lamp, terminals, control box regulator assembly inside A 2-pole and and is a no-fuse a terminal equipped (AVR), breaker,output cover. with or a current an automatic transformer (3) AC voltmeter, \ voltage output (CT) and diode is is coil for excitation coupled with CONTROL secured on the rotor with bolts a coup1 ing and coupling is cooled of and is wound by the engine’s to the plate. cooling fan. load Variations in the load voltage to the 2 output sockets of the output are automatically regulator (AVR) and the 2 voltage controlled due to by the or the current trans- breaker Terminal coves ,Stator ’ is attached, which terminals. changes former (CT). no-fuse breaker When overloads (N.F.B.) ; thus protecting The engine is started with circuits occur, and cut-off the generator. the starting motor and stopped lever. cover PANEL Brush assy Brush holder Slip ring SECTIONAL VIEW Rubber i vibration isolator Note CT (Current transformer) ..... CTcontrols output voltage to maintain it at rated voltage. SR (diode stack) ...... SR converts alternate current generated at secondary coil to direct current, and transfers it to rotor coil. N. F. B. (No-fuse breaker)--. When overloads or short circuits occur, the N.F.B. will operate to cut-off the output voltage. A VR (Automatic voltage regulator) ......’ A VR automatically controls output voltage when change in the load makes output voltage vary. -ll- the the out- Engine cover cover ! Front or short will operate put voltage, Stator terminal assembly which with the engine control Output Inside the the brush and lead wires) is supported The load is connected automatic ,No-fuse ‘\ and by the collar is directly Connecting of the stack (SR). Neon lamp the electricity. to which plate, (output the rear cover and by the flywheel rotor The generator an AC sockets The inside brush coils is sunk to receive the ball bearing. engine flywheel box are mounted generate stator on the engine side. and as a stand- tank bands.) panel of the control the is a holder springs, rotor situated is with which there and the collar in the pipe in the pipe frame. coils), (brushes, the which is wound rear cover, to the battery, stator auxiliary to a pipe Inside are installed isolators. is also installed The a a rear cover and a front connected equipment of a stator, box On the front and cover, with and the engine as an optional RGDllOl, consists attached bolts vibration tank is secured with (1) with The generator using tank has a stator is fixed a rotor & RGDllOl) Generator 5. OPERATION 5-1 Single phase Generator When the engine is started, as a result poles, of the a minute induced rotor the rotor residual voltage voltage assembly magnetism increases passes through the the excitation rated voltage. indicate the (N.F.B.) is thrown until At rated of the is induced this in the the AVR coil; this increases the induced rotates magnetic stator. which voltage point the voltmeter no-fuse When the OFF while the further the induced voltage. This and excites voltage ON from and, reaches will breaker generating, the neon lamp will light. Should the speed change due to variations terminal voltage action of will the always AVR in the load, the be kept constant which increases through the or decreases the excitation. 5-2 Three phase Generator When the engine as a result poles, of the a minute induced the is started, rotor further coil; residual voltage voltage this increases thrown in the the induced until magnetic stator. When ON from OFF while the change due will always voltage the induced At this point voltage. and This the CT and SR to excite the excitation rated rotates of the is induced reaches the rated voltage. the assembly magnetism passes through increases indicate the rotor which voltage the voltmeter the no-fuse generating, will breaker is the neon lamp in the load, will light. Should the terminal the action speed voltage of the CT which tovariations be kept constant increases through or decreases the excitation. Since the induced the rotor, voltage the voltage is proportional can be adjusted to the speed of by controlling the speed. -12- 6. WIRING 0 DIAGRAM Blue 6-1 For 3 phase, 4 wires Generator Brown 6-2 For single phase, 2 wires Generator 63 For single‘phase, 4 wires Generator -I- Blue Blue L A u V U’ V’ a B Black I I Name of-Parts- II Symbols 1 Stator coil (output) II c 1 AC outout Stator coil (auxiliary) II p I Plug-in Rotor coil.(excitation) II B I Brush CT- I SR 1 Symbols Y!? No-fuse breaker Automatic voltage II regulator 11 AC voltmeter PL i__ UY Neon T lamp AC output ~ terminal -13- Name of Parts pin terminal ~GrrentLansfoYmer Diode Output I socket I (red) ~ I 1 I stack terminal Pl Plug-in pin terminal (blue) P2 Plug-in.pin (red) terminal -7. TROUBLE SHOOTING Phenomenon 1. Generator Remedy Cause will not generate. 1. Disconnection plug-in or poor contact 3. Break in the rotor load cannot is normal, but rated Generated higher 5. Repair or replace. coil circuit. :o Replace. .z Replace. AVR, 1. Faulty CT or SR. of slip ring. o Repair or replace. magnetism. c Induce or poor contact 2. Faulty insulation 3. Faulty AVR, CT or SR. 4. Poor contact of brushes. of output anew. ,o Repair or replace. is greatly than rated voltage. 1. Erroneous 2. Faulty =: Repair or replace. of coil windings. output .o Repair or replace. of engine. : c Repair or replace. i 2 Adjust 3 Correct. o Replace. o Adjust. wiring. AVR i or CT. 3. Over-speeding 4. o terminals. be applied. voltage of brushes. 5. Faulty 5. Low power 3. Repair or replace. :z Replace. 7. No residual voltage o 4. Break in the stator coil circuit. 6. Distortion No-load ; pin terminals. 2. Wear or poor contact 2. of of engine. or repair. Voltmeter needle will not move, or 1. Faulty voltmeter. -2 Repair or replace. indication is faulty. 2. Faulty lead wire. c Replace. Generator is generating, 1. Faulty neon lamp. lamp will not light. but neon 2. Faulty 3. No-fuse lead wire. breaker -14- in wrong position. .: Replace. I ! o Replace. l o Turn to ON. 0 8-l Stator Assy (3 phase) a. With the lead, all lead wires blue lead wire are tested for as the common continuity tester. If all lead wires show continuity: (Single phase, 2 wires) With the white b. common for continuity (Single a lead wire as the lead, the blue and red lead wires are tested with continuity: c. with OK. a tester. If these lead wires show OK. phase, 4 wires) blue and yellow In addition lead wires to the above, are tested If all lead wires show continuity: the i Stator for continuity. assy OK. 8-2 Rotor Assy If there is continuity slip rings: when a tester is applied to the two OK. (The resistance is 6 to 10 ohms for single phase, and 10 to 50 ohms for 3 phase.) 8-3 Voltmeter Give an alternating meter 84 current If volt- voltage to a terminal. shows the given voltage: OK Neon Lamp If the lamp applied lights when a voltage to the lamp terminals: of about AC 1OOV is OK. 8-5 Slip Rings If the surface of the slip rings is uniformly Slip rings showing wear should The while slip the rotor spots, excessive OK. About AC wear, or uneven be repaired. ring turning Care should black bright: should the rotor, be polished until w/th the rough be taken to prevent fine sandpaper, spots disappear. the sandpaper Voltmeter touching coils. Neon lamp i AC1 OOV ..:‘/sout “Sandpaper -l5- 8-6 Brush Assy If the surface this in contact surface surface with is rough, the slip ring is clean: repair of the slip ring will using OK. If fine sandpaper. also be rough, (The so polish this Brush assy with fine sandpaper Brushes should 12mm from 8-7 AVR also.) be replaced the contact when worn to a height of (Standard surface. Service Assy (single phase) If the epoxy AVR cover protecting is clean: discoloured OK. (The the functional AVR parts of the is faulty if the cover is or burnt.) 8-8 CT Assy (3 phase) When continuity 3 and 4, with is shown a tester: (The CT is faulty between terminals 1 and 2, and OK. if continuity is shown between terminals 2 and 3.) 8-9 SR Assy If no continuity lead wires continuity wires: is shown of the is shown OK. with a tester 3 yellow lead for one only (If both applied wires: to any 2 OK. Also, if of the green or red lead show continuity, the SR assembly is faulty.) 8-10 4 Injection The of Residual source minute of electric electricity after completely disappear, Also, when residual Methods (a) power generated Sometimes, CT Magnetism of the generator by the residual long disuse the residual the and will rotor magnetism has magnetism. magnetism have to be newly been is the replaced, may injected. injection of box and will be necessary. for inducing residual magnetism. 3 phase Generator (1) When a battery Remove is available. the disconnect cover the two of the pin terminals body and the SR. Then through or 2 from connecting the generator residual magnetism from coil lead wires the generator seconds, connected green and brown, by passing a current the rotor coming control lead wires, from be induced the so that the the battery (the lead wires body), green to (+) and the brown Diode stack CSFI)~’ can for about lead 1 wire is lead wire to (-I of the battery. After induction its former state. is finished, restore Use a battery the wiring to of 72 to 48 V . -16- limit 18mm) 12mm 0 (2) When an AC power While line is available. operating the generator, power line to the generator series resistance of disconnect the voltmeter deflects. Use an AC power terminals from AC apply 10 to power the through 50 ohms, line as soon line near the rated 3 phase Generator AC a and as the voltage of the generator. (b) Single Phase Generator (1) When a battery Remove is available. the cover disconnect the two connecting the of the lead wires, generator the pin terminals. control black body Then box, by connecting the battery wires from the generator body seconds, so that connected the green can to the lead for to (+) and the black from magnetism be induced 2 and green, and AVR residual and about lead 1 to wire is lead wire to (-) of the battery. After 0 induction its former is finished, to -AC power line of 12 to 48V. When an AC power line is available. While operating power line to the output through the wiring state. Use a battery (2) restore the generator, the voltmeter deflects. AC Use an AC power the AC Single phase Generator socket of the generator a series resistance disconnect apply of 10 to 50 ohms, and power line as soon line near the rated as the voltage of the generatoc CAUTION: REFER RELATION NOT OF EXCEED I TO THE FOLLOWING TABLE VOLTAGE AND RESISTANCE A SECOND FOR EXCITING. VOLTAGE I : RESISTANCE loo-12ov 10R 200-240V 20,0, 36O-45OV 409 0 lac FOR R. DO I R I R(lO- -17- 50.0.! a.111 . +AC . power line 9. DISASSEMBLING AND REASSEMBLING COMPONENT 1. Battery DISASSEMBLING 1) Disconnect 2) Remove 3) Remove nuts from battery 4) Demount 2. Fuel tank battery PROCEDURE cords from(+) battery fitting battery DISASSEMBLED from terminals. fitting bracket. Nut M6 - 2 ea. I Spring washer M6 - 2 ea. ’ Washer M6 - 2 ea. bracket. frame. 1) Drain fuel. (Fuel tank capacity 2) Disconnect fuel pipe from Battery fitting bracket ’ Battery fitting bolt - 2 ea. : Battery - - 1 ea. 1 ea. I = 24 E) upper part of fuel tank by hand, and fuel pipe from PART Banjo bolt - 1 ea. Gasket - 2 ea. lower part by loosen- ing banjo bolt. 3) Remove nuts and screws from fuel tank bands that secure fuel tank. 3. Control box 4) Remove fuet tank bands. 5) Demount fuel tank from 1) Remove bolts from frame. control ; Nut M6 - 8 ea. / Band clip - 4 ea. / ScrewM6x3-4ea. ! Fuel tank band assy - 2 ea. I box cover. I Fuel tank - 1 ea. Bolt M4 x 10 - 6 ea. Spring washer M4 - 6 ea. 2) Remove control 3) Disconnect * lead wires extending The number between box cover. and color out of yoke. of wires are different 3 phase units and single phase units. Wires are also connected to different connec- I i Control : For 3 phase units only ’ box cover - 1 ea. Screw M4 x 10 - 3 ea. Washer M4 - 3 ea. Nut M4 - 3 ea. tors. 4) Remove bolts and nuts that fasten control box to Bolt M5 x 30 - 4 ea. Nut M5 - 4 ea. frame. Spring washer M5 - 4 ea. 5) Demount control box from frame. -18- Control box - 1 ea. DISASSEMBLING COMPONENT 4. Brush assy 1) Remove bolts that fasten 2) Remove brush cover. l When separating separate 3) Loosen l 5. Rubber vibration isolator (Battery DISASSEMBLED PROCEDURE / Bolt M5x brush cover. brush cover, not to remove brush assy. 1) Remove nuts from vibration isolator 1 ea. I Nut M4 - 2 ea. nuts that fasten brush assy. 4) Remove 2ea. / Brush cover lead wires from them one by one in order of thickness. Use caution lo- PART nuts. Brush assy - 2 ea. top and bottom underneath of rubber Nut M8 - 4 ea. Spring washer M8 - 4 ea. yoke. Washer M8 - 2 ea. cord (-) ) Nut M8 - 4 ea. Spring washer M8 - 4 ea. Washer M8 - 4 ea. 3) Disconnect 4) Lifting (-) up yoke, battery remove cord. rubber vibration -19- isolator. Rubber vibration isolator - 2 ea. COMPONENT 6. Yoke, Stator Front cover, I DISASSEMBLING 1) Remove PROCEDURE bolts that fasten front I cover to engine. Bolt Ml0 PART x 25, P = 1.25 - 8 ea. Rear cover, Stator DISASSEMBLED cover, 2) Separate yoke from 1 Spring washer Ml0 ! - 8 ea. ; Pentagonal bolt M8 -4 engine. Brush holder l Use caution 3) Remove front not to damage slip ring of rotor. pentagonal through bolts that fasten cover and rear cover to stator, 4) Remove stator cover fastening through Spring washer M8 - 4 ea. / Screw M4 x 25 - 2 ea. screws. Spring washer M4 - 2 ea. i Washer M4 - 2 ea. i Nut M4 - 2 ea. I 5) Remove stator 6) Remove front cover. cover and rear cover from stator. Stator cover - Stator - Front cover - 1 ea. 1 ea. 1 ea. i Rear cover - 1 ea. 7) Remove brush holder screws from rear ScrewM5x20-2ea 1 Spring washer M5 - 2’ea. cover. 1 8) Remove fastening brush holder. ! Brush holder assy - 1 ea. ea. DISASSEMBLING COMPONENT 7. Rotor 1) Remove assy, Coupling DISASSEMBLED PROCEDURE bolts that fasten coupling ! Bolt M8 x 20 - 6 ea. plate to Spring washer flywheel. plate PART M8 - 6 ea. Washer M8 - 6 ea. 2) Remove * rotor When placing caution 3) Remove Rotor assy. rotor assy after removing, assy - 1 ea. use not to damage slip ring and coil. bolts that fasten coupling plate to ; BoltM8x20-6ea. j Spring washer M8 -6 coup1 ing. ea. 1 Washer M8 - 6 ea. 4) Separate coupling plate from coupling. Coupling Rotor Coupling 7. Rotor assy Ball bearing . :: \ ‘S!ip ring ‘Coil plate, plate - - 1 ea. 1 set (3 pcs.) ea. - COMPONENT DISASSEMBLING 1) Demount 8. Engine l engine from When demounting PROCEDURE ’ Engine - frame. engine, DISASSEMBLED I use firm tools like PART 1 ea. i (F rame) - 1 ea. a chain block. 9. Rubber isolator, vibration I) Remove Caster, vibration bolts and nuts that fasten rubber isolator For casters Bolt M8 x 25 - 14 ea. and casters to frame. Screw Earth cord M8 x 25 - Nut M8 - 2ea. 16 ea. Spring washer M8 Washer M8 For rubber 16 ea. 16 ea. vibration isolator Nut M8 - 4 ea. Spring washer M8 - 4 ea. 2) Remove rubber vibration isolator, casters and A unit has 2 front rotary vibration isolator - 2 ea. earth cord. l Rubber fixed casters and 2 rear Caster - 4 ea. Earth cord - 1 ea. casters. 9 Earth cord, ‘\\ 9 Rotary 3 To reassemble generator, C When disassembling make the disassembling and reassembling, procedures in the reverse sequence. please refer to Parts Catalog. -22- caste: . . / 10. SAFETY (1) PRECAUTIONS Never place inflammable objects 0 oil, Avoid placing light inflammable (2) Attention should hazards, and very avoided near the generator. When be paid dusty working in closed should power in by cables. be brought operation avoided, lation from in should 0 tunnels, fire be places monoxide be provided manholes, outside and the cannot and other and be dangerous, be poisonous adequate to prevent exhaust be stopped when ventigases accumulating.) of fuel oil engine should always ishing the fuel oil. Never operate the generator 0 and places should be operated confined since carbon Replenishing The ventilation rooms, etc. the generator gases may gather s to and damp in closed rooms (When (5) rags and other as far as possible. Never operate 3 (4) oily Place of operation 0 (3) objects near the generator matches, Never operate the there is the danger (Also, avoid touching with generator of replen- wet hands with wet hands, receiving an electric the generator when since shock. wet from rain or sea water.) (6) Storage o Store prevent in a dry room, the accumulation and cover the generator to of dust. -23- B 0 i FUJI -HEAVY INDUSTRIES LTD. :j ,:-.;r