Download Service Manual

Transcript

Change for Life

Service Manual

02'(/6*:+5$.'1$$

*:+5$.'1$%

*:+5$.'1$%

*:+5%.'1$%

*:+5%.'1$%

*:+5%.'1$%

5HIULJHUDQW5$

GREE ELECTRIC APPLIANCES,INC.OF ZHUHAI

7DEOHRI&RQWHQWV

7DEOHRI&RQWHQWV

6XPPDU\DQG)HDWXUHV

6DIHW\3UHFDXWLRQV

6SHFL¿FDWLRQV

2SHUDWLRQ&KDUDFWHULVWLF&XUYH &DSDFLW\9DULDWLRQ5DWLR$FFRUGLQJWR7HPSHUDWXUH 2SHUDWLRQ'DWD

1RLVH&ULWHULD&XUYH7DEOHVIRU%RWK0RGHOV

&RQVWUXFWLRQ9LHZV

,QGRRU8QLW

2XWGRRU8QLW

5HIULJHUDQW6\VWHP'LDJUDP

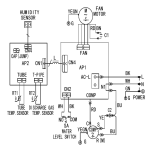

6FKHPDWLF'LDJUDP

(OHFWULFDO:LULQJ

3ULQWHG&LUFXLW%RDUG

)XQFWLRQDQG&RQWURO

5HPRWH&RQWURO2SHUDWLRQV

'HVFULSWLRQRI(DFK&RQWURO2SHUDWLRQ

,QVWDOODWLRQ0DQXDO

1RWLFHVIRU,QVWDOODWLRQ

,QVWDOODWLRQ'LPHQVLRQ'LDJUDP

,QVWDOO,QGRRU8QLW

,QVWDOO2XWGRRU8QLW

&KHFNDIWHU,QVWDOODWLRQDQG7HVW2SHUDWLRQ

,QVWDOODWLRQDQG0DLQWHQDQFHRI+HDOWK\)LOWHU

7DEOHRI&RQWHQWV

([SORGHG9LHZVDQG3DUWV/LVW

,QGRRU8QLW

2XWGRRU8QLW

7URXEOHVKRRWLQJ

0DOIXQFWLRQ$QDO\VLV

0DOIXQFWLRQ&RGH

5HPRYDO3URFHGXUH

5HPRYDO3URFHGXUHRI,QGRRU8QLW

5HPRYDO3URFHGXUHRI2XWGRRU8QLW

6XPPDU\DQG)HDWXUHV

6XPPDU\DQG)HDWXUHV

,QGRRU8QLW

*:+5$.'1$$,

*:+5$.'1$%,

*:+5%.'1$%,

*:+5%.'1$%,

*:+5$.'1$%,

*:+5%.'1$%,

2XWGRRU8QLW

*:+5$.'1$$2

*:+0$.'1$%2

*:+0%.'1$%2

5HPRWH&RQWUROOHU

<$$)%

6DIHW\3UHFDXWLRQV

6DIHW\3UHFDXWLRQV

Installing, starting up, and servicing air conditioner can be

hazardous due to system pressure, electrical components,

and equipment location, etc.

Only trained, qualified installers and service personnel are

allowed to install, start-up, and service this equipment.

Untrained personnel can perform basic maintenance functions such as cleaning coils. All other operations should

be performed by trained service personnel.

Make sure the outdoor unit is installed on a stable, level

surface with no accumulation of snow, leaves, or trash

beside.

When handling the equipment, observe precautions in the

manual and on tags, stickers, and labels attached to the

equipment. Follow all safety codes. Wear safety glasses

andwork gloves. Keep quenching cloth and fire extinguisher

nearby when brazing.

Follow all the installation instructions to minimize the risk

of damage from earthquakes, typhoons or strong winds.

Read the instructions thoroughly and follow all warnings or

cautions in literature and attached to the unit. Consult local

building codes and current editions of national as well as

local electrical codes.

Recognize the following safety information:

Warning

Incorrect handling could result in

personal injury or death.

Caution

Incorrect handling may result in

minor injury,or damage to product

or property.

Warning

All electric work must be performed by a licensed technician

according to local regulations and the instructions given in

this manual.

Before installing, modifying, or servicing system, main

electrical disconnect switch must be in the OFF position.

There may be more than 1 disconnect switch. Lock out

and tag switch with a suitable warning label.

Never supply power to the unit unless all wiring and tubing are completed, reconnected and checked.

This system adopts highly dangerous electrical voltage.

Incorrect connection or inadequate grounding can cause

personal injury or death. Stick to the wiring diagram and

all the instructions when wiring.

Have the unit adequately grounded in accordance with

local electrical codes.

Have all wiring connected tightly. Loose connection may

lead to overheating and a possible fire hazard.

All installation or repair work shall be performed by your dealer or a specialized subcontractor as there is the risk of fire,

electric shock, explosion or injury.

Make sure the ceiling/wall is strong enough to bear the

weight of the unit.

Make sure the noise of the outdoor unit does not disturb

neighbors.

Avoid contact between refrigerant and fire as it generates

poisonous gas.

Apply specified refrigerant only. Never have it mixed with

any other refrigerant. Never have air remain in the

refrigerant line as it may lead to rupture and other hazards.

Make sure no refrigerant gas is leaking out when installation is completed.

Should there be refrigerant leakage, the density of refrigerant in the air shall in no way exceed its limited value,

or it may lead to explosion.

Keep your fingers and clothing away from any moving

parts.

Clear the site after installation. Make sure no foreign objects are left in the unit.

Always ensure effective grounding for the unit.

Caution

Never install the unit in a place where a combustible gas

might leak, or it may lead to fire or explosion.

Make a proper provision against noise when the unit is

installed at a telecommunication center or hospital.

Provide an electric leak breaker when it is installed in a

watery place.

Never wash the unit with water.

Handle unit transportation with care. The unit should not

be carried by only one person if it is more than 20kg.

Never touch the heat exchanger fins with bare hands.

Never touch the compressor or refrigerant piping without

wearing glove.

Do not have the unit operate without air filter.

Should any emergency occur, stop the unit and disconnect the power immediately.

Properly insulate any tubing running inside the room to

prevent the water from damaging the wall.

6SHFL¿FDWLRQV

6SHFL¿FDWLRQV

0RGHO

3URGXFW&RGH

3RZHU

6XSSO\

*:+5$.'1$$

*:+5$.'1$%

&%

&%

5DWHG9ROWDJH

9a

5DWHG)UHTXHQF\

+]

3KDVHV

3RZHU6XSSO\0RGH

,QGRRU

,QGRRU

&RROLQJ&DSDFLW\0LQa0D[

:

a

a

+HDWLQJ&DSDFLW\0LQa0D[

:

a

a

&RROLQJ3RZHU,QSXW0LQa0D[

:

a

a

+HDWLQJ3RZHU,QSXW0LQa0D[

:

a

a

&RROLQJ&XUUHQW,QSXW

$

+HDWLQJ&XUUHQW,QSXW

$

5DWHG,QSXW

:

5DWHG&XUUHQW

$LU)ORZ9ROXPH6++0/6/

'HKXPLGLI\LQJ9ROXPH

$

PK

/K

((5

::

&23

::

6((5

+63)

$SSOLFDWLRQ$UHD

P

,QGRRU8QLW0RGHO

,QGRRU8QLW3URGXFW&RGH

)DQ7\SH

*:+5$.'1$$,

*:+5$.'1$%,

&%1

&%1

&URVVÀRZ

&URVVÀRZ

)DQ'LDPHWHU/HQJWK';/

PP

ĭ;

ĭ;

&RROLQJ6SHHG6++0/6/

UPLQ

+HDWLQJ6SHHG6++0/6/

UPLQ

)DQ0RWRU3RZHU2XWSXW

:

)DQ0RWRU5/$

$

)DQ0RWRU&DSDFLWRU

ȝ)

(YDSRUDWRU)RUP

(YDSRUDWRU3LSH'LDPHWHU

,QGRRU8QLW (YDSRUDWRU5RZ¿Q*DS

(YDSRUDWRU&RLO/HQJWK/;';:

PP

)XVH&XUUHQW

$OXPLQXP)LQFRSSHU7XEH

ĭ

ĭ

PP

PP

;;

;;

03$$

03$$

6ZLQJ0RWRU0RGHO

6ZLQJ0RWRU3RZHU2XWSXW

$OXPLQXP)LQFRSSHU7XEH

:

$

6RXQG3UHVVXUH/HYHO6++0/6/

G%$

6RXQG3RZHU/HYHO6++0/6/

G%$

'LPHQVLRQ:;+;'

PP

;;

;;

'LPHQVLRQRI&DUWRQ%R[/;:;+

PP

;;

;;

'LPHQVLRQRI3DFNDJH/;:;+

PP

;;

;;

1HW:HLJKW

NJ

*URVV:HLJKW

NJ

6SHFL¿FDWLRQV

2XWGRRU8QLW0RGHO

2XWGRRU8QLW3URGXFW&RGH

*:+5$.'1$$2

*:+0$.'1$%2

&%:

&%:

=+8+$,/$1'$&2035(6625 =+8+$,/$1'$&2035(6625

&RPSUHVVRU0DQXIDFWXUHU

&RPSUHVVRU0RGHO

&RPSUHVVRU2LO

&RPSUHVVRU7\SH

&RPSUHVVRU/5$

&RPSUHVVRU5/$

&RPSUHVVRU3RZHU,QSXW

&RPSUHVVRU2YHUORDG3URWHFWRU

7KURWWOLQJ0HWKRG

6HW7HPSHUDWXUH5DQJH

&RROLQJ2SHUDWLRQ$PELHQW7HPSHUD

WXUH5DQJH

+HDWLQJ2SHUDWLRQ$PELHQW7HPSHUD

WXUH5DQJH

&RQGHQVHU)RUP

&RQGHQVHU3LSH'LDPHWHU

&RQGHQVHU5RZV¿Q*DS

&RQGHQVHU&RLO/HQJWK/;';:

)DQ0RWRU6SHHG

2XWGRRU

)DQ0RWRU3RZHU2XWSXW

8QLW

)DQ0RWRU5/$

)DQ0RWRU&DSDFLWRU

2XWGRRU8QLW$LU)ORZ9ROXPH

)DQ7\SH

)DQ'LDPHWHU

'HIURVWLQJ0HWKRG

&OLPDWH7\SH

,VRODWLRQ

0RLVWXUH3URWHFWLRQ

3HUPLVVLEOH([FHVVLYH2SHUDWLQJ

3UHVVXUHIRUWKH'LVFKDUJH6LGH

3HUPLVVLEOH([FHVVLYH2SHUDWLQJ

3UHVVXUHIRUWKH6XFWLRQ6LGH

6RXQG3UHVVXUH/HYHO+0/

6RXQG3RZHU/HYHO+0/

'LPHQVLRQ:;+;'

'LPHQVLRQRI&DUWRQ%R[/;:;+

'LPHQVLRQRI3DFNDJH/;:;+

1HW:HLJKW

*URVV:HLJKW

5HIULJHUDQW

5HIULJHUDQW&KDUJH

&RQQHFWLRQ3LSH/HQJWK

&RQQHFWLRQ3LSH*DV$GGLWLRQDO

&RQQHFWLRQ

3LSH

&KDUJH

2XWHU'LDPHWHU/LTXLG3LSH

2XWHU'LDPHWHU*DV3LSH

0D['LVWDQFH+HLJKW

0D['LVWDQFH/HQJWK

&

&2/7'

4;$%=&*5((

(3

5RWDU\

,17/

&DSLOODU\

a

&2/7'

4;$%=&*5((

(3

5RWDU\

,17/

&DSLOODU\

a

&

a

a

&

a

a

$OXPLQXP)LQFRSSHU7XEH

ĭ

;;

$[LDOÀRZ

ĭ

$XWRPDWLF'HIURVWLQJ

7

,

,3

$OXPLQXP)LQFRSSHU7XEH

ĭ

;;

$[LDOÀRZ

ĭ

$XWRPDWLF'HIURVWLQJ

7

,

,3

03D

03D

G%$

G%$

PP

PP

PP

NJ

NJ

NJ

P

;;

;;

;;

5$

;;

;;

;;

5$

JP

PP

PP

P

P

ĭ

ĭ

ĭ

ĭ

$

$

:

PP

PP

PP

USP

:

$

ȝ)

PK

PP

7KHDERYHGDWDLVVXEMHFWWRFKDQJHZLWKRXWQRWLFH3OHDVHUHIHUWRWKHQDPHSODWHRIWKHXQLW

6SHFL¿FDWLRQV

0RGHO

*:+5$.'1$%

3URGXFW&RGH

3RZHU

6XSSO\

&%

5DWHG9ROWDJH

9a

5DWHG)UHTXHQF\

+]

3KDVHV

3RZHU6XSSO\0RGH

,QGRRU

&RROLQJ&DSDFLW\

:

+HDWLQJ&DSDFLW\

:

&RROLQJ3RZHU,QSXW

:

+HDWLQJ3RZHU,QSXW

:

&RROLQJ&XUUHQW,QSXW

$

+HDWLQJ&XUUHQW,QSXW

$

5DWHG,QSXW

:

5DWHG&XUUHQW

$

PK

$LU)ORZ9ROXPH6++0/6/

'HKXPLGLI\LQJ9ROXPH

/K

((5

::

&23

::

6((5

+63)

$SSOLFDWLRQ$UHD

P

,QGRRU8QLW0RGHO

*:+5$.'1$%,

,QGRRU8QLW3URGXFW&RGH

&%1

)DQ7\SH

&URVVÀRZ

)DQ'LDPHWHU/HQJWK';/

PP

&RROLQJ6SHHG

UPLQ

+HDWLQJ6SHHG

UPLQ

:

)DQ0RWRU5/$

$

)DQ0RWRU&DSDFLWRU

ȝ)

+HDWHU3RZHU,QSXW

:

)DQ0RWRU3RZHU2XWSXW

(YDSRUDWRU)RUP

,QGRRU8QLW

ĭ;

$OXPLQXP)LQFRSSHU7XEH

(YDSRUDWRU3LSH'LDPHWHU

PP

ĭ

(YDSRUDWRU5RZ¿Q*DS

PP

(YDSRUDWRU&RLO/HQJWK/;';:

PP

;;

6ZLQJ0RWRU0RGHO

6ZLQJ0RWRU3RZHU2XWSXW

)XVH&XUUHQW

03$$

:

$

6RXQG3UHVVXUH/HYHO6++0/6/

G%$

6RXQG3RZHU/HYHO6++0/6/

G%$

'LPHQVLRQ:;+;'

PP

;;

'LPHQVLRQRI&DUWRQ%R[/;:;+

PP

;;

'LPHQVLRQRI3DFNDJH/;:;+

PP

;;

1HW:HLJKW

NJ

*URVV:HLJKW

NJ

6SHFL¿FDWLRQV

2XWGRRU8QLW0RGHO

*:+0$.'1$%2

2XWGRRU8QLW3URGXFW&RGH

&%:

&RPSUHVVRU0DQXIDFWXUHU

=+8+$,/$1'$&2035(6625&2/7'

&RPSUHVVRU0RGHO

4;$%=&*5((

&RPSUHVVRU2LO

(3

&RPSUHVVRU7\SH

5RWDU\

&RPSUHVVRU/5$

$

&RPSUHVVRU5/$

$

&RPSUHVVRU3RZHU,QSXW

:

&RPSUHVVRU2YHUORDG3URWHFWRU

,17/

7KURWWOLQJ0HWKRG

&DSLOODU\

6HW7HPSHUDWXUH5DQJH

R

&

a

&RROLQJ2SHUDWLRQ$PELHQW7HPSHUDWXUH5DQJH

R

&

a

+HDWLQJ2SHUDWLRQ$PELHQW7HPSHUDWXUH5DQJH

R

&

a

&RQGHQVHU)RUP

PP

ĭ

&RQGHQVHU5RZV¿Q*DS

PP

&RQGHQVHU&RLO/HQJWK/;';:

PP

;;

)DQ0RWRU6SHHG

USP

:

)DQ0RWRU5/$

$

)DQ0RWRU&DSDFLWRU

ȝ)

PK

)DQ0RWRU3RZHU2XWSXW

2XWGRRU8QLW

$OXPLQXP)LQFRSSHU7XEH

&RQGHQVHU3LSH'LDPHWHU

2XWGRRU8QLW$LU)ORZ9ROXPH

)DQ7\SH

)DQ'LDPHWHU

$[LDOÀRZ

PP

'HIURVWLQJ0HWKRG

&OLPDWH7\SH

7

,VRODWLRQ

0RLVWXUH3URWHFWLRQ

3HUPLVVLEOH([FHVVLYH2SHUDWLQJ3UHVVXUHIRUWKH

'LVFKDUJH6LGH

3HUPLVVLEOH([FHVVLYH2SHUDWLQJ3UHVVXUHIRUWKH

,

,3

03D

03D

6XFWLRQ6LGH

6RXQG3UHVVXUH/HYHO+0/

G%$

6RXQG3RZHU/HYHO+0/

G%$

'LPHQVLRQ:;+;'

PP

;;

'LPHQVLRQRI&DUWRQ%R[/;:;+

PP

;;

'LPHQVLRQRI3DFNDJH/;:;+

PP

;;

1HW:HLJKW

NJ

*URVV:HLJKW

NJ

5HIULJHUDQW

NJ

&RQQHFWLRQ3LSH/HQJWK

P

JP

&RQQHFWLRQ 2XWHU'LDPHWHU/LTXLG3LSH

PP

ĭ

PP

ĭ

0D['LVWDQFH+HLJKW

P

0D['LVWDQFH/HQJWK

P

2XWHU'LDPHWHU*DV3LSH

7KHDERYHGDWDLVVXEMHFWWRFKDQJHZLWKRXWQRWLFH3OHDVHUHIHUWRWKHQDPHSODWHRIWKHXQLW

5$

5HIULJHUDQW&KDUJH

&RQQHFWLRQ3LSH*DV$GGLWLRQDO&KDUJH

3LSH

ĭ

$XWRPDWLF'HIURVWLQJ

6SHFL¿FDWLRQV

0RGHO

3URGXFW&RGH

3RZHU

6XSSO\

*:+5%.'1$%

*:+5%.'1$%

&%

&%

5DWHG9ROWDJH

9a

5DWHG)UHTXHQF\

+]

3KDVHV

3RZHU6XSSO\0RGH

,QGRRU

,QGRRU

&RROLQJ&DSDFLW\0LQa0D[

:

a

+HDWLQJ&DSDFLW\0LQa0D[

:

a

&RROLQJ3RZHU,QSXW0LQa0D[

:

a

+HDWLQJ3RZHU,QSXW0LQa0D[

:

a

&RROLQJ&XUUHQW,QSXW

$

+HDWLQJ&XUUHQW,QSXW

$

5DWHG,QSXW

:

5DWHG&XUUHQW

$

$LU)ORZ9ROXPH6++0/6/

P K

/K

((5

::

&23

::

'HKXPLGLI\LQJ9ROXPH

6((5

+63)

$SSOLFDWLRQ$UHD

P

,QGRRU8QLW0RGHO

,QGRRU8QLW3URGXFW&RGH

)DQ7\SH

*:+5%.'1$%,

*:+5%.'1$%,

&%1

&%1

&URVVÀRZ

&URVVÀRZ

)DQ'LDPHWHU/HQJWK';/

PP

ĭ;

ĭ;

&RROLQJ6SHHG6++0/6/

UPLQ

+HDWLQJ6SHHG6++0/6/

UPLQ

)DQ0RWRU3RZHU2XWSXW

:

)DQ0RWRU5/$

$

)DQ0RWRU&DSDFLWRU

ȝ)

(YDSRUDWRU)RUP

(YDSRUDWRU3LSH'LDPHWHU

,QGRRU8QLW (YDSRUDWRU5RZ¿Q*DS

(YDSRUDWRU&RLO/HQJWK/;';:

PP

$OXPLQXP)LQFRSSHU7XEH

$OXPLQXP)LQFRSSHU7XEH

ĭ

ĭ

PP

PP

;;

;;

03$$

03$$

6ZLQJ0RWRU0RGHO

6ZLQJ0RWRU3RZHU2XWSXW

:

)XVH&XUUHQW

$

6RXQG3UHVVXUH/HYHO6++0/6/ G%$

6RXQG3RZHU/HYHO6++0/6/

G%$

'LPHQVLRQ:;+;'

PP

;;

;;

'LPHQVLRQRI&DUWRQ%R[/;:;+

PP

;;

;;

'LPHQVLRQRI3DFNDJH/;:;+

PP

;;

;;

1HW:HLJKW

NJ

*URVV:HLJKW

NJ

6SHFL¿FDWLRQV

2XWGRRU8QLW0RGHO

2XWGRRU8QLW3URGXFW&RGH

*:+0%.'1$%2

*:+0%.'1$%2

&%:

&%:

=+8+$,/$1'$&2035(6625 =+8+$,/$1'$&2035(6625

&RPSUHVVRU0DQXIDFWXUHU

&RPSUHVVRU0RGHO

&RPSUHVVRU2LO

&RPSUHVVRU7\SH

&RPSUHVVRU/5$

&RPSUHVVRU5/$

&RPSUHVVRU3RZHU,QSXW

&RPSUHVVRU2YHUORDG3URWHFWRU

7KURWWOLQJ0HWKRG

6HW7HPSHUDWXUH5DQJH

&RROLQJ2SHUDWLRQ$PELHQW

7HPSHUDWXUH5DQJH

+HDWLQJ2SHUDWLRQ$PELHQW

7HPSHUDWXUH5DQJH

&RQGHQVHU)RUP

&RQGHQVHU3LSH'LDPHWHU

&RQGHQVHU5RZV¿Q*DS

&RQGHQVHU&RLO/HQJWK/;';:

)DQ0RWRU6SHHG

2XWGRRU

)DQ0RWRU3RZHU2XWSXW

8QLW

)DQ0RWRU5/$

)DQ0RWRU&DSDFLWRU

2XWGRRU8QLW$LU)ORZ9ROXPH

)DQ7\SH

)DQ'LDPHWHU

'HIURVWLQJ0HWKRG

&OLPDWH7\SH

,VRODWLRQ

0RLVWXUH3URWHFWLRQ

3HUPLVVLEOH([FHVVLYH2SHUDWLQJ

3UHVVXUHIRUWKH'LVFKDUJH6LGH

3HUPLVVLEOH([FHVVLYH2SHUDWLQJ

3UHVVXUHIRUWKH6XFWLRQ6LGH

6RXQG3UHVVXUH/HYHO+0/

6RXQG3RZHU/HYHO+0/

'LPHQVLRQ:;+;'

'LPHQVLRQRI&DUWRQ%R[/;:;+

'LPHQVLRQRI3DFNDJH/;:;+

1HW:HLJKW

*URVV:HLJKW

5HIULJHUDQW

5HIULJHUDQW&KDUJH

&RQQHFWLRQ3LSH/HQJWK

&RQQHFWLRQ3LSH*DV$GGLWLRQDO

&RQQHFWLRQ

3LSH

&KDUJH

2XWHU'LDPHWHU/LTXLG3LSH

2XWHU'LDPHWHU*DV3LSH

0D['LVWDQFH+HLJKW

0D['LVWDQFH/HQJWK

&

&2/7'

4;$%=&*5((

(3

5RWDU\

,17/

&DSLOODU\

a

&2/7'

4;$%=&*5((

(3

5RWDU\

,17/

&DSLOODU\

a

&

a

a

&

a

a

$OXPLQXP)LQFRSSHU7XEH

ĭ

;;

$[LDOÀRZ

ĭ

$XWRPDWLF'HIURVWLQJ

7

,

,3

$OXPLQXP)LQFRSSHU7XEH

ĭ

;;

$[LDOÀRZ

ĭ

$XWRPDWLF'HIURVWLQJ

7

,

,3

03D

03D

G%$

G%$

PP

PP

PP

NJ

NJ

NJ

P

;;

;;

;;

5$

;;

;;

;;

5$

JP

PP

PP

P

P

ĭ

ĭ

ĭ

ĭ

$

$

:

PP

PP

PP

USP

:

$

ȝ)

PK

PP

7KHDERYHGDWDLVVXEMHFWWRFKDQJHZLWKRXWQRWLFH3OHDVHUHIHUWRWKHQDPHSODWHRIWKHXQLW

6SHFL¿FDWLRQV

0RGHO

*:+5%.'1$%

3URGXFW&RGH

3RZHU

6XSSO\

&%

5DWHG9ROWDJH

9a

5DWHG)UHTXHQF\

+]

3KDVHV

3RZHU6XSSO\0RGH

,QGRRU

&RROLQJ&DSDFLW\

:

+HDWLQJ&DSDFLW\

:

&RROLQJ3RZHU,QSXW

:

+HDWLQJ3RZHU,QSXW

:

&RROLQJ&XUUHQW,QSXW

$

+HDWLQJ&XUUHQW,QSXW

$

5DWHG,QSXW

:

5DWHG&XUUHQW

$

$LU)ORZ9ROXPH6++0/6/

'HKXPLGLI\LQJ9ROXPH

P K

/K

((5

::

&23

::

6((5

+63)

$SSOLFDWLRQ$UHD

P

,QGRRU8QLW0RGHO

*:+5%.'1$%,

,QGRRU8QLW3URGXFW&RGH

&%1

)DQ7\SH

&URVVÀRZ

)DQ'LDPHWHU/HQJWK';/

PP

ĭ;

&RROLQJ6SHHG6++0/6/

UPLQ

+HDWLQJ6SHHG6++0/6/

UPLQ

)DQ0RWRU3RZHU2XWSXW

:

)DQ0RWRU5/$

$

)DQ0RWRU&DSDFLWRU

ȝ)

+HDWHU3RZHU,QSXW

:

(YDSRUDWRU)RUP

,QGRRU8QLW

$OXPLQXP)LQFRSSHU7XEH

(YDSRUDWRU3LSH'LDPHWHU

PP

(YDSRUDWRU5RZ¿Q*DS

PP

(YDSRUDWRU&RLO/HQJWK/;';:

PP

;;

6ZLQJ0RWRU0RGHO

ĭ

03$$

6ZLQJ0RWRU3RZHU2XWSXW

:

)XVH&XUUHQW

$

6RXQG3UHVVXUH/HYHO6++0/6/

G%$

6RXQG3RZHU/HYHO6++0/6/

G%$

'LPHQVLRQ:;+;'

PP

;;

'LPHQVLRQRI&DUWRQ%R[/;:;+

PP

;;

'LPHQVLRQRI3DFNDJH/;:;+

PP

;;

1HW:HLJKW

NJ

*URVV:HLJKW

NJ

6SHFL¿FDWLRQV

2XWGRRU8QLW0RGHO

*:+0%.'1$%2

2XWGRRU8QLW3URGXFW&RGH

&%:

&RPSUHVVRU0DQXIDFWXUHU

=+8+$,/$1'$&2035(6625&2/7'

&RPSUHVVRU0RGHO

4;$%=&*5((

&RPSUHVVRU2LO

(3

&RPSUHVVRU7\SH

5RWDU\

&RPSUHVVRU/5$

$

&RPSUHVVRU5/$

$

&RPSUHVVRU3RZHU,QSXW

:

&RPSUHVVRU2YHUORDG3URWHFWRU

7KURWWOLQJ0HWKRG

&DSLOODU\

6HW7HPSHUDWXUH5DQJH

R

&

a

&RROLQJ2SHUDWLRQ$PELHQW7HPSHUDWXUH5DQJH

R

&

a

+HDWLQJ2SHUDWLRQ$PELHQW7HPSHUDWXUH5DQJH

R

&

&RQGHQVHU)RUP

2XWGRRU8QLW

PP

ĭ

&RQGHQVHU5RZV¿Q*DS

PP

&RQGHQVHU&RLO/HQJWK/;';:

PP

;;

)DQ0RWRU6SHHG

USP

)DQ0RWRU3RZHU2XWSXW

:

)DQ0RWRU5/$

$

)DQ0RWRU&DSDFLWRU

ȝ)

PK

)DQ7\SH

)DQ'LDPHWHU

$[LDOÀRZ

PP

'HIURVWLQJ0HWKRG

7

,VRODWLRQ

0RLVWXUH3URWHFWLRQ

3HUPLVVLEOH([FHVVLYH2SHUDWLQJ3UHVVXUHIRUWKH'LVFKDUJH

6LGH

3HUPLVVLEOH([FHVVLYH2SHUDWLQJ3UHVVXUHIRUWKH6XFWLRQ

ĭ

$XWRPDWLF'HIURVWLQJ

&OLPDWH7\SH

,

,3

03D

6LGH

6RXQG3UHVVXUH/HYHO+0/

03D

G%$

6RXQG3RZHU/HYHO+0/

G%$

'LPHQVLRQ:;+;'

PP

;;

'LPHQVLRQRI&DUWRQ%R[/;:;+

PP

;;

'LPHQVLRQRI3DFNDJH/;:;+

PP

;;

1HW:HLJKW

NJ

*URVV:HLJKW

NJ

5HIULJHUDQW

5$

5HIULJHUDQW&KDUJH

NJ

&RQQHFWLRQ3LSH/HQJWK

P

JP

PP

ĭ

&RQQHFWLRQ3LSH*DV$GGLWLRQDO&KDUJH

&RQQHFWLRQ 2XWHU'LDPHWHU/LTXLG3LSH

2XWHU'LDPHWHU*DV3LSH

PP

ĭ

0D['LVWDQFH+HLJKW

P

0D['LVWDQFH/HQJWK

P

7KHDERYHGDWDLVVXEMHFWWRFKDQJHZLWKRXWQRWLFH3OHDVHUHIHUWRWKHQDPHSODWHRIWKHXQLW

a

$OXPLQXP)LQFRSSHU7XEH

&RQGHQVHU3LSH'LDPHWHU

2XWGRRU8QLW$LU)ORZ9ROXPH

3LSH

,17/

6SHFL¿FDWLRQV

2SHUDWLRQ&KDUDFWHULVWLF&XUYH

Cooling

Heating

8

10

9

7

8

6

12K

12K

7

5

Current(A)

Current(A)

6

09K

5

4

3

Condition

Indoor:DB 27 WB19

Indoor air flow: Turbo

Pipe length:5m

Voltage:230V

2

09K

4

3

Condition

Indoor:DB 20

Indoor air flow:Turbo

Pipe length:5m

Voltage:230V

2

1

1

0

0

0

20

40

60

80

100

0

120

20

Compressor Speed(rps)

40

60

80

100

120

Compressor Speed(rps)

&DSDFLW\9DULDWLRQ5DWLR$FFRUGLQJWR7HPSHUDWXUH

Heating

110

120

100

100

90

80

Capacity ratio(%)

Capacity ratio(%)

Cooling

80

70

60

Condition

Indoor:DB27℃ WB19℃

Indoor air flow: Turbo

Pipe length:5m

50

32 33 34 35 36 37 38 39 40 41 42 43 44 45 46

Outdoor temp. (°C)

60

40

Condition

Indoor:DB20℃

Indoor air flow: Turbo

Pipe length:5m

20

0

-7

-5

0

5

10

Outdoor temp. (°C)

6SHFL¿FDWLRQV

2SHUDWLRQ'DWD

&RROLQJ

7HPSHUDWXUH

FRQGLWLRQ&

,QGRRU 2XWGRRU

6WDQGDUG

+HDWH[FKDQJHUSLSH

QDPH

SUHVVXUH

303D

.

.

a

WHPS

7&

7&

LQa

LQa

0RGHO

RXWa

RXWa

,QGRRUIDQ 2XWGRRUIDQ

PRGH

&RPSUHVVRU

PRGHUSP UHYROXWLRQ+]

7XUER

7XUER

+HDWLQJ

7HPSHUDWXUH

FRQGLWLRQ&

,QGRRU 2XWGRRU

6WDQGDUG

+HDWH[FKDQJHUSLSH

QDPH

SUHVVXUH

303D

.

.

a

WHPS

7&

7&

LQa

LQa

0RGHO

RXWa

RXWa

,QGRRUIDQ 2XWGRRUIDQ

&RPSUHVVRU

PRGH

PRGHUSP

UHYROXWLRQ+]

7XUER

7XUER

7,QOHWDQGRXWOHWSLSHWHPSHUDWXUHRIHYDSRUDWRU

7,QOHWDQGRXWOHWSLSHWHPSHUDWXUHRIFRQGHQVHU

33UHVVXUHRIDLUSLSHFRQQHFWLQJLQGRRUDQGRXWGRRUXQLWV

127(6

0HDVXUHVXUIDFHWHPSHUDWXUHRIKHDWH[FKDQJHUSLSHDURXQGFHQWHURIKHDWH[FKDQJHUSDWK8

EHQW7KHUPLVWRUWKHPRPHWHU

&RQQHFWLQJSLSLQJFRQGLWLRQP

1RLVH&ULWHULD&XUYH7DEOHVIRU%RWK0RGHOV

Indoor side noise when blowing

54

45

Heating

52

12K

Noise dB(A)

Noise dB(A)

50

35

48

46

Cooling

44

09K

42

25

40

Low

Middle

Indoor fan motor rotating speed

High

20

30

40

50

60

Compressor frequency(Hz)

70

80

&RQVWUXFWLRQ9LHZV

&RQVWUXFWLRQ9LHZV

,QGRRU8QLW

*:+5$.'1$%,*:+5$.'1$%,

*:+5$.'1$$,*:+5%.'1$%,

*:+5%.'1$%,*:+5%.'1$%,

8QLWPP

&RQVWUXFWLRQ9LHZV

2XWGRRU8QLW

712

540

257

320

776

286

510

8QLWPP

5HIULJHUDQW6\VWHP'LDJUDP

5HIULJHUDQW6\VWHP'LDJUDP

INDOOR UNIT

OUTDOOR UNIT

4-Way valve

HEAT

EXCHANGER

(EVAPORATOR)

Accumlator

Compressor

HEAT

EXCHANGER

(EVAPORATOR)

Strainer

Capillary

Strainer

COOLING

HEATING

5HIULJHUDQWSLSHGLDPHWHU

/LTXLGPP

*DVPP

6FKHPDWLF'LDJUDP

6FKHPDWLF'LDJUDP

(OHFWULFDO:LULQJ

(OHFWULFDO'DWD

Symbol

Color symbol

Symbol

Parts name

BU

BLUE

COMP

COMPRESSOR

YE

YELLOW

CT12

OVERLOAD

4V

RD

RED

OG

ORANGE

BN

BROWN

BK

BLACK

YEGN

YELLOW GREEN

WH

WHITE

4-WAY VALVE

PROTECTIVE EARTH

ELECTRONIC

EXPANSION VALVE

EKV

,QGRRU8QLW

0

RT1

DISPLAY

TUBE

TEM.SENSOR

L1

AP1

CN1 CN2

0

RT2

L1

DISP-1

TUBE

DISP-2

COM-OUT

W1 BU

W2 BK

W3 BN

CAP

AP2

AC-L

W4 YEGN

EVAPORATOR

PE

SWING-UD

HEALTH-L HEALTH-N

M

M

RD

BU

COOL PLASMA

GENERATOR

YEGN

FAN MOTOR

SWING MOTOR(U.D)

PE

L

N

XT1

N(1)

2

3

L-OUT

K4

JUMP

PGF PG

POWER

13

N

ROOM

BN

YEGN

BU

OUTDOOR UNIT

ROOM

TEM.SENSOR

6FKHPDWLF'LDJUDP

2XWGRRU8QLW

*:+5$.'1$$2&%:

ROOM DISCHARGE

TUBE

TEMP. TEMP. TEMP.

SENSOR SENSOR SENSOR

W8 YEGN

RT1

0

PE

W9

YEGN

XT

INDOOR UNIT

BU

N(1)

BK

2

BN

3

YEGN

RT3

0

RT2

0

L3

CN2

CN1

L1

L4

N

W2 BK

W3 BN

L4

COM-OUT

L1

L4

AC-L

4V

CN3

N1

W6 BU

AC-N

W5 BN

AC-N2

AC-L

OVC-COMP

V W

W13 W14 W15

BU YE RD

PE

W12

BU

OFAN

U

CLAPBOARD

SUB-ASSY

ELECTRICAL BOX

AC-L3

AC-N1

AP2

AC-L1

PE

L3

W11 BN

W10 BU

LX1-1 LX1-2

W21

AC-L2

BN

E

W7

PE

AP1

W1 BU

L REACTOR

4YV

HEAT-L

HEAT-N1

W22

RD

HEAT-N2

EH1

EH2

PE

W20

L2 L2 L2

W16 W17 W18

BU YE RD

YEGN

W19 YEGN

V

U

BOTTOM BAND

HEATER

M

SAT

W

COMP.BAND

HEATER

FAN MOTOR

YEGN

PE

OVERLOARD

PROTECTOR

OUTDOOR UNIT

COMP.

PE

COMP.

*:+0$.'1$%2&%:

*:+0%.'1$%2&%:

ROOM DISCHARGE

TUBE

TEMP. TEMP. TEMP.

SENSOR

SENSOR

SENSOR

RT1

0

PE

RT3

0

RT2

0

L3

W9

YEGN

INDOOR UNIT

BU

BK

BN

YEGN

XT

W1 BU

N(1)

L1

2

3

AP1

PE

W23 BN

AC-L1

AC-L

L1

N1

W5 BN

W6 BU

W2 BK

PE

W24 BU

CLAPBOARD

SUB-ASSY

ELECTRICAL BOX

PE

L3

W10 BU W11 BN

LX1-1 LX1-2

N

W3 BN

REACTOR

L

4YV

CN2

AC-L5

AC-L4

AC-L

4V

AC-L2

AC-L3

AC-N1

AP2

AC-N

COMU

AC-N3 OVC-COMP

U V W

W13 W14 W15 W22

BU YE RD

RD

W21

BN

AC-N2

W12

BU

OFAN

HEAT-L

HEAT-N1

EH2

HEAT-N2

EH1

PE

YEGN

W19 YEGN

W20

BOTTOM BAND COMP.BAND

L2 L2 L2

M

HEATER

HEATER

SAT

W16 W17 W18

FAN MOTOR

BU YE RD

YEGN

OVERLOARD

V W

PE

PROTECTOR

U

COMP

OUTDOOR UNIT

PE

COMP.

6FKHPDWLF'LDJUDP

*:+0$.'1$%2&%:

*:+0%.'1$%2&%:

TUBE ROOM DISCHARGE

TEMP. TEMP. TEMP.

SENSOR SENSOR SENSOR

RT1

0

XT

INDOOR UNIT

BU

W1 BU

N(1)

BK

2

3

BN

YEGN

W9

YEGN

PE

AP1

L1

L4

W3 BN

L4

L1

L4

W23 BN

AC-L1

PE

L4

ELECTRICAL BOX

PE

L3

L3

W5 BN

CN2

AC-L5

AC-L4

AC-L

W6 BU AC-N

W2 BK COMU

W24 BU AC-N3

U V W

CLAPBOARD

W13 W14 W15

BU YE RD

SUB-ASSY

4V

AC-L2

AP2

AC-L3

AC-N1

N1

AC-N2

OVC-COMP

W21

BN

W12

BU

OFAN

W22

RD

PE

YEGN

W19 YEGN

W20

L2 L2 L2

W16 W17 W18

BU YE RD

WARNING

Please don't touch any terminal when

the voltage of terminal DC+ and DC- at

AP2 is higher than 30V to prevent the

risk of electrical shock!

4YV

RT3

0

W10 BU W11 BN

LX1-1 LX1-2

N

AC-L

RT2

0

REACTOR

L

V

U

PE

W

SAT

M

FAN MOTOR

OVERLOARD

PROTECTOR

YEGN

PE

COMP

COMP.

7KHVHFLUFXLWGLDJUDPVDUHVXEMHFWWRFKDQJHZLWKRXWQRWLFHSOHDVHUHIHUWRWKHRQHVXSSOLHGZLWKWKHXQLW

6FKHPDWLF'LDJUDP

3ULQWHG&LUFXLW%RDUG

,QGRRUXQLW

TOP VIEW

Solid-state relay

Port of neutral wire

Auto button Feedback of indoor fan

Live wire of health function

Port of indoor fan

Port of motor for vertical swing

Port of motor for

horizontal swing

Protective

tube

Buzzer

Port of indoor ambient

temp sensor

Port of indoor pipe

temp sensor

Power of

switch

Port of display

High-frequency transformer

Communication port

Main chip

BOTTOM VIEW

6FKHPDWLF'LDJUDP

2XWQGRRUXQLW

*:+5$.'1$$2&%:

Ɣ7239,(:

inductance pin1

inductance pin2

fan neilsbed four-way valve

compressor

electric heater

chassis e ectric heater

10-core communication cable

compressor

Ɣ%277209,(:

temp. sensor overload protection

electric expansion valve

6FKHPDWLF'LDJUDP

*:+0$.'1$%2&%:*:+0%.'1$%2&%:

*:+0$.'1$%2&%:*:+0%.'1$%2&%:

Ɣ7239,(:

inductance pin1

inductance pin2

fan

four-way valve

compressor

electric heater chassis e ectric heater

communication cable

compressor

temp. sensor

low pressure valve

overload

protection

electric expansion valve

Ɣ%277209,(:

)XQFWLRQDQG&RQWURO

)XQFWLRQDQG&RQWURO

5HPRWH&RQWURO2SHUDWLRQV

1

ON/OFF

Press it to start or stop operation.

2

Press it to decrease temperaturesetting.

3

+

Press it to increase temperaturesetting.

4

• •

MODE

Press it to select operation mode(AUTO/COOL/DRY/FAN/HEAT).

1

5

FAN

Press it to set fan speed.

3

2

6

SWING

Press it to set swing angle.

7

I FEEL

8

4

Press it to set HEALTH or AIR function.

5

6

9

10

7

8

9

10

11

11

SLEEP

TEMP

TIMER ON

Press it to set auto-on timer.

12

CLOCK

Press it to set clock function.

12

13

13

14

16

14

TIMER OFF

Press it to set auto-off timer.

15

15

TURBO

LIGHT

Press it to turn on/off the light.

16

X-FAN

25

17

24

23

22

18 19 20 21

17

MODE icon:

If MODE button is pressed,current operation mode icon

pumpmodels) will show.

18

SLEEP icon :

19

LIGHT icon:

20

TEMP icon:

(AUTO),

( COOL),

(DRY),

(FAN) or

(HEAT only for heat

is displayed by pressing the SLEEP button. Press this button again to clear the display.

is displayed by pressing the LIGHT button. Press LIGHT button again to clear the display.

Pressing TEMP button,

circularly.

21

(set temperature),

(indoor ambient temperature),

(outdoor ambient temperature) and blank is displayed

Up & down swing icon:

is displayed when pressing the up & down swing down button. Press this button again to clear the display.

)XQFWLRQDQG&RQWURO

22

LOCK icon:

is displayed by pressing "+" and “-” buttons simultaneously. Press them again to clear the display.

23

SET TIME display:

After pressing TIMER button,ON or OFF will blink.This area will show the set time.

24

DIGITAL display:

This area will show the set temperature. In SAVE mode,"SE" will be displayed.

25

AIR icon:

is displayed when pressing the AIR button.Press this button again to clear the display.

30

29

28

31

26

27

26

HEALTH icon:

is displayed when pressing the HEALTH button.Press this button again to clear the display.

27

X-FAN icon:

28

TURBO icon:

29

FAN SPEED display:

is displayed when pressing the X-FAN button. Press this button again to clear the display.

is displayed when pressing the TURBO button.Press this button again to clear the display.

Press FAN button to select the desired fan speed setting(AUTOLow-Med-High).Your selection will be displayed in the LCD windows,

except the AUTO fan speed.

30

I FEEL icon:

is displayed when pressing the I FEEL button.Press this button again to clear the display.

31

8℃ Heating icon:

is displayed when Pressing “TEMP” and “CLOCK” simultaneously in Heat mode.

1

Remote Controller Description

ON/OFF :

Press this button to turn on the unit. Press this button again to turn off the unit.

2

-:

Press this button to decrease set temperature. Hold it down for above 2 seconds to rapidly decrease set temperature. In AUTO mode,

set temperature is not adjustable.

3

+:

Press this button to increase set temperature. Hold it down for above 2 seconds to rapidly increase set temperature. In AUTO mode,

set temperature is not adjustable.

4

MODE :

Each time you press this button, a mode is selected in a sequence that goes from AUTO, COOL,DRY, FAN,and HEAT *, as the following:

AUTO

COOL

DRY

FAN

HEAT*

*Note:Only for models with heating function.

After energization, AUTO mode is defaulted. In AUTO mode, the set temperature will not be displayed on the LCD, and the unit will

automatically select the suitable operation mode in accordance with the room temperature to make indoor room comfortable.

5

FAN :

This button is used for setting Fan Speed in the sequence that goes from AUTO,

to

then back to Auto.

Auto

Low speed

Medium speed

High speed

)XQFWLRQDQG&RQWURO

6

SWING:

Press this button to set up & down swing angle, which circularly changes as below:

OFF

This remote controller is universal. If any command

,

or

is sent out,the unit will carry out the command as

indicates the guide louver swings as:

7

I FEEL:

Press this button to turn on I FEEL function. The unit automatically adjust temperature according to the sensed temperature. Press this

button again to cancel I FEEL function.

8

/

Press this button to achieve the on and off of healthy and scavenging functions in operation status. Press this button for the first time to

start scavenging function; LCD displays“

”. Press the button for the second time to start healthy and scavenging functions simultaneously; LCD displays“

” and “

” . Press this button for the third time to quit healthy and scavenging functions simultaneously. Press

the button for the fourth time to start healthy function; LCD display “

”. Press this button again to repeat the operation above.

9

SLEEP:

Press this button to go into the SLEEP operation mode. Press it again to cancel this function. This function is available in COOL , HEAT

(Only for models with heating function) or DRY mode to maintain the most comfortable temperature for you.

10

TEMP:

Press this button, could select displaying the indoor setting temperature or indoor ambient temperature.When the indoor unit firstly power

on it will display the setting temperature, if the temperature's displaying status is changed from other status to"

",displays the

ambient temperature, 5s later or within 5s, it receives other remote control signal that will return to display the setting temperature. if the

users haven't set up the temperature displaying status,that will display the setting temperature.

11

TIMERON :

Press this button to initiate the auto-ON timer. To cancel the auto-timer program, simply press this button again.

After press of this button,

disappear sand " ON " blinks .00:00 is displayed for ON time setting. Within 5 seconds, press + or - button

to adjust the time value. Every press of either button changes the time setting by 1 minute. Hold down either button to rapidly change the

time setting by 1 minute and then 10 minutes. Within 5 seconds after setting, press TIMER ON button to confirm.

12

CLOCK :

Press CLOCK button,

blinking. Within 5 seconds, pressing + or - button adjusts the present time. Hold down either button for above

2 seconds to increase or decrease the time by 1 minute every 0.5 second and then by 10 minutes every 0.5 second. During blinking after

setting, press CLOCK button again to confirm the setting, and then

will be constantly displayed.

13

TIMER OFF :

Press this button to initiate the auto-off timer. To cancel the auto-timer program, simply press the button again. TIMER OFF setting is the

same as TIMER ON.

14

TURBO:

Press this button to activate / deactivate the Turbo function which enables the unit to reach the preset temperature in the shortest time. In

COOL mode, the unit will blow strong cooling air at super high fan speed. In HEAT mode, the unit will blow strong heating air at super high

fan speed.

15

LIGHT:

Press LIGHT button to turn on the display's light and press this button again to turn off the display 's light. If the light is turned on ,

displayed. If the light is turned off,

disappears.

16

is

X-FAN:

Pressing X-FAN button in COOL or DRY mode, the icon

is displayed and the indoor fan will continue operation for 10 minutes in order

to dry the indoor unit even though you have turned off the unit.

After energization, X-FAN OFF is defaulted. X-FAN is not available in AUTO, FAN or HEAT mode.

17

Combination of "+" and "-" buttons: About lock

Press "+ " and "-" buttons simultaneously to lock or unlock the keypad. If the remote controller is locked,

is displayed. In this case,

pressing any button,

blinks three times.

18 Combination of "MODE " and "-" buttons : About switch between Fahrenheit and centigrade At unit OFF, press "MODE" and "- "

buttons simultaneously to switch between ℃ an d ℉ .

19

Combination of " TEMP " and "CLOCK" buttons : About Energy-saving Function

Press “TEMP” and “CLOCK” simultaneously in COOL mode to start energy-saving function. Nixie tube on the remote controller displays

“SE”. Repeat the operation to quit the function.

20

Combination of " TEMP " and "CLOCK" buttons : About 8℃ Heating Function

)XQFWLRQDQG&RQWURO

Press “TEMP” and “CLOCK” simultaneously in HEAT mode to start 8℃ Heating Function Nixie tube on the remote controller displays “

and a selected temperature of “ 8℃”. (46 if Fahrenheit is adopted). Repeat the operation to quit the function.

21

”

About Back-lighting Function

The unit lights for 4s when energizing for the first time, and 3s for later press.

Replacement of Batteries

1.Remove the battery cover plate from the rear of the remote controller.

(As shown in the figure)

2.Take out the old batteries.

3.Insert two new AAA1.5V dry batteries, and pay attention to the polarity.

4. Reinstall the battery cover plate.

★Notes:

●When replacing the batteries, do not use old or different types of batteries,

otherwise, it may cause malfunction.

●If the remote controller will not be used for a long time, please

remove batteries to prevent batteries from leaking.

●The operation should be performed in its receiving range.

●It should be kept 1m away from the TV set or stereo sound sets.

●If the remote controller does not operate normally, please take the

batteries out and reinsert them after 30 seconds.If it still can't operate properly,

replace the batteries.

Sketch map for

replacing batteries

)XQFWLRQDQG&RQWURO

'HVFULSWLRQRI(DFK&RQWURO2SHUDWLRQ

1. Temperature Parameters

Indoor preset temperature (Tpreset)

Indoor ambient temperature (T amb.)

2. Basic Functions

Once energized, in no case should the compressor be restarted within less than 3 minutes. In the situation that memory

function is available, for the first energization, if the compressor is at stop before de-energization, the compressor will be

started without a 3-minute lag; if the compressor is in operation before de-energization, the compressor will be started with

a 3-minute lag; and once started, the compressor will not be stopped within 6 minutes regardless of changes in room

temperature;

(1)COOL mode

The condition and process of cooling

If Tamb. ≥Tpreset COOL mode will act, the compressor and outdoor fan will run, and the indoor fan will run at the set speed.

If Tamb. ≤Tpreset-2 , the compressor will stop, the outdoor fan will delay 30 seconds to stop, and the indoor fan will run at the set speed.

If Tpreset-2

≤Tamb ≤Tpreset , the unit will keep running in the previous mode.

In this mode, the reversal valve will not be powered on and the temperature setting range is 16

~30 .

Start cooling

Tamb.

Tpreset +1 ˚C

Original operating status

Tpreset –1 ˚C

≥ 6 min.

≥ 3 min.

≥ 6 min.

Stop cooling

Compressor

Outdoor fan

Setting fan speed

Indoor fan

Run

Protection function

Overcurrent protection

Stop

If total current is high, the compressor will run in limited frequency. If total current is too high, the compressor will stop, the

outdoor fan will delay 30 seconds to stop, indoor unit will display E5 and outdoor yellow light will blink 5 times.

Antifreezing protection

When the antifreezing protection is detected, the compressor will stop, the outdoor fan will stop after 30 seconds, and the

indoor fan and swing motor will keep running in the original mode. When antifreezing protection is eliminated and the

compressor has stopped for 3 minutes, the compressor will resume running in the original mode.

During antifreeze protection

min

Compressor

Outdoor fan

Preset speed

Indoor fan

Run

Stop

(2) Dehumidifying Mode

Working conditions and process of dehumidifying

If T amb. T preset, the unit will enter cooling and dehumidifying mode, in which case the compressor and the outdoor fan will

operate and the indoor fan will run at low speed.

If T preset -2

T amb. T preset, the compressor remains at its original operation state.

If T amb.< T preset -2 , the compressor will stop, the outdoor fan will stop with a time lag of 30s, and the indoor fan will

operate at low speed.

Protection

Protection is the same as that under the cooling mode.

)XQFWLRQDQG&RQWURO

(3) HEAT mode

The condition and process of heating

If Tamb≤Tpreset+2

, HEAT mode will act, the compressor, outdoor fan and reversal valve will run, the indoor fan will delay

3min to stop at the latest

If Tpreset +2

Tamb Tpreset +5

If Tamb≥Tpreset +5

,the unit will keep running in the original mode.

, the compressor will stop, the outdoor fan will delay 30sec to stop and indoor fan will blow 60S at low

speed, the fan speed cannot be shifted within blow residual heat.

In this mode, the temperature setting range is 16

~30

.

The air conditioner will adjust the running frequency of the compressor automatically according to the change of ambient

temperature.

When the unit is turned off in HEAT mode, or switched to other mode from HEAT mode, the four-way valve will be powered

off after the compressor stops.

Stop heating

Tpreset+4

Original operating status

Tpreset+2

Tamb.

min.

min.

min.

Start heating

Compressor

Outdoor fan

Indoor fan

preset wind

min.

min.

preset wind

Reversing valve

Run

Stop

The condition and process of defrosting

When frost is detected in the condenser, the system will enter into defrosting state. When defrosting starts, the compressor and

indoor fan will stop, and the outdoor fan and four-way valve will delay 30 seconds to stop. The compressor will start after 15 seconds

and then defrosting will be started. When the compressor has run for 7 minutes or defrosting is finished, the compressor will stop.

After 30 seconds the four-way valve opens and after another 60 seconds, the compressor and outdoor fan resume running. The

indoor fan will delay 3 minutes to run at the latest and temperature on the display panel shows H1.

The period of defrosting

30s

30s

Four-way valve

Compressor

15s

7min

60s

30s

Outdoor Unit

Indoor Unit

3min Set fan speed

Run

Stop

Protection function

Anti-cold-wind protection

In HEAT mode, in order to prevent the indoor unit from blowing out cold wind, each time the compressor starts, the indoor fan

will delay 3 minutes after the compressor to run at the latest and it can adjust fan speed automatically when temperature is low.

Overcurrent protection

Overcurrent protection is the same with that in COOL mode.

3.Protection

Cold air prevention

The unit is started under heating mode (the compressor is ON):

In the case of Tindoor amb. <24 : if T tube 40 and the indoor fan is at stop state, the indoor fan will begin to run at low

speed with a time lag of 2 minutes. Within 2 minutes, if T tube 40 , the indoor fan also will run at low speed; and after

1-minute operation at low speed, the indoor fan will be converted to operation at preset speed.Within 1-minute low speed

operation or 2-minute non-operation, if T tube 42 , the fan will run at present speed.

In the case of T indoor amb. 24 : if T tube 42 , the indoor fan will run at low speed, and after one minute, the indoor fan

will be converted to preset speed. Within one-minute low speed operation, if T tube 42 , the indoor fan will be converted

to preset speed.

)XQFWLRQDQG&RQWURO

Note: Tindoor amb. indicated in 1 and 2 refers to, under initially heating mode, the indoor ambient temperature before the

command to start the compressor is performed according to the program, or after the unit is withdrawn from defrost, the

indoor ambient temperature before the defrost symbol is cleared.

Total current up and frequency down protection

If the total current Itotal W, frequency rise will be allowed; if I total X, frequency rise will not be allowed; if I total Y, the compressor

will run at reduced frequency; and if I total Z, the compressor will stop and the outdoor fan will stop with a time lag of 30s.

(4) Fan Mode

Under the mode, the indoor fan will run at preset speed and the compressor, the outdoor fan, the four-way valve and the

electric heater will stop.

Under the mode, temperature can be set within a range of 16 - 30 .

(5) AUTO Mode

a. When Tamb.26ć, the unit will operate under cooling mode, while the implied setting temperature is 25ć.

b. When Tamb.22ć, the heat pump unit will operate under heating mode, while the implied setting temperature is 20ć; the cooling only unit will operate under

fan mode, while the displaying setting temperature is 25ć.

c. When 23ćTamb.25ć, the unit will operate as previous mode. If it is the first time energized, the unit will operate under fan mode.

d. When the unit is operating under auto mode, the compressor frequency is the same as cooling/heating mode when the unit is under cooling/heating operation.

2.Protection

a. In cooling operation, protection is the sam e as that under the cooling mode;

b. In heating operation, protection is the same as that under the heating mode;

c. When ambient temperature changes, operation mode will be converted preferentially. Once started, the compressor will

remain unchanged for at least 6 minutes.

(6) Common Protection Functions and Fault Display under COOL, HEAT, DRY and AUTO Modes

Overload protection

T tube: measured temperature of outdoor heat exchanger under cooling mode; and measured temperature of indoor heat

exchanger under heating mode.

1) Cooling overload

a. If T tube 52 , the unit will return to its original operation state.

b. If T tube 55 , frequency rise is not allowed.

c. If T tube 58 , the compressor will run at reduced frequency.

d. If T tube 62 , the compressor will stop and the indoor fan will run at preset speed.

2) Heating overload

a. If T tube 52 , the unit will return to its original operation state.

b. If T tube 55 , frequency rise is not allowed.

c. If T tube 58 , the compressor will run at reduced frequency.

d. If T tube 62 , the compressor will stop and the indoor fan will blow residue heat and then stop.

Exhaust temperature protection of compressor

If exhaust temperature 98 , frequency is not allowed to rise.

If exhaust temperature 103 , the compressor will run at reduced frequency.

If exhaust temperature 110 , the compressor will stop.

If exhaust temperature 90 and the compressor has stayed at stop for at least 3 minutes, the compressor will resume its

operation.

Communication fault

If the unit fails to receive correct signals for durative 3 minutes, communication fault can be justified and the whole system

will stop.

Module protection

Under module protection mode, the compressor will stop. When the compressor remains at stop for at least 3 minutes, the

compressor will resume its operation. If module protection occurs six times in succession, the compressor will not be started

again.

Overload protection

If temperature sensed by the overload sensor is over 115 , the compressor will stop and the outdoor fan will stop with a

time lag of 30 seconds. If temperature is below 95 , the overload protection will be relieved.

If voltage on the DC bus is below 150V or over 420V, the compressor will stop and the outdoor fan will stop with a time

lag of 30 seconds. When voltage on the DC bus returns to its normal value and the compressor has stayed at stop for at least

3 minutes, the compressor will resume its operation.

Faults of temperature sensors

)XQFWLRQDQG&RQWURO

Designation of sensors

Indoor ambient temperature

Indoor tube temperature

Outdoor ambient temperature

Outdoor tube temperature

Exhaust

Overload

Faults

The sensor is detected to be open-circuited or short-circuited for successive 30

seconds

The sensor is detected to be open-circuited or short-circuited for successive 30

seconds

The sensor is detected to be open-circuited or short-circuited for successive 30

seconds

The sensor is detected to be open-circuited or short-circuited for successive 30

seconds, and no detection is performed within 10 minutes after defrost begins.

After the compressor has operated for 3 minutes, the sensor is detected to be

open-circuited or short-circuited for successive 30 seconds.

After the compressor has operated for 3 minutes, the sensor is detected to be

open-circuited or short-circuited for successive 30 seconds.

3. Other Controls

(1) ON/OFF

Press the remote button ON/OFF: the on-off state will be changed once each time you press the button.

(2) Mode Selection:

Press the remote button MODE, then select and show in the following ways: AUTO, COOL, DRY, FAN, HEAT, AUTO.

(3) Temperature Setting Option Button

Each time you press the remote button TEMP+ or TEMP-, the setting temperature will be up or down by 1 . Regulating

Range: 16~30 , the button is useless under the AUTO mode.

(4) Time Switch

You should start and stop the machine according to the setting time by remote control.

(5) SLEEP State Control

a. When the air conditioner is under the mode of COOL, DRY, and the SLEEP mode has been set well, after the SLEEP

state keeps about 1 hour, the pre-setting T will raise 1 , and it will raise 1

again after 2 hours, so it raise 2 in 2 hours,

then it will run on at the setting temperature and wind speed.

b. When the air conditioner is under the mode of HEAT, and the Timer has been set well, after the SLEEP state keeps about

1 hour, the pre-setting T will reduce 1 , and it will reduce 1

again after 2 hours, so it reduce 2 in 2 hours, then it will

run on at the setting temperature and wind speed.

c. The setting temperature keeps the same under the FAN mode and AUTO mode.

(6) Indoor Fan Control

Indoor fan could be set at ultra-high, high, medium, low speed by wireless remote controller and operated as that speed.

Auto fan speed could be set as well, indoor fan will operate under auto fan speed as following:

1. Under heating mode: auto speed under heating or auto heating mode:

a. When Tamb.Tpreset+1ć, indoor fan will operate at high speed;

b. When Tpreset+1ć˘Tamb.˘Tpreset+3ć, indoor fan will operate at medium speed;

c. When Tamb.Tpreset+3ć, indoor fan will operate at low speed;

There should be at least 180s operation time during switchover of each speed.

2. Under cooling mode: auto speed under cooling or auto cooling mode:

a. When Tamb.Tpreset+2ć, indoor fan will operate at high speed;

b. When Tpreset˘Tamb.˘Tpreset+2ć, indoor fan will operate at medium speed;

c. When Tamb.Tpreset, indoor fan will operate at low speed

There should be at least 180s operation time during switchover of each speed.

(7) Buzzer Control

The buzzer will send a “Di” sound when the air conditioner is powered up or received the information sent by the remote

control or there is a button input, the single tube cooler doesn’t receive the remote control ON signal under the mode of

heating mode.

(8) Auto button

If the controller is on, it will stop by pressing the button, and if the controller is off, it will be automatic running state by

pressing the button, swing on and light on, and the main unit will run based on the remote control if there is remote control

order.

(9) Up-and-Down Swinging Control

When power on, the up-and-down motor will firstly move the air deflector to o counter-clockwise, close the air outlet.

After starting the machine, if you don’t set the swinging functi on, heating mode and auto-heating mode, the up-and-down

air deflector will move to D clockwise; under other modes, the up-and-down air deflector will move to L1. If you set the

swinging function when you start the machine, then the wind blade will swing between L and D. The air deflector has 7

)XQFWLRQDQG&RQWURO

swinging states: Location L, Location A, Location B, Location C, Location D, Location L to Location D, stop at any

location between L-D (the included angle between L~D is the same). The air deflector will be closed at 0 Location, and the

swinging is effectual only on condition that setting the swinging order and the inner fan is running. The indoor fan and

compressor may get the power when air deflector is on the default location.

Heating angle

O(0°)

Cooling angle

O(0°)

L

A

B

C

D

L1

A1

B1

C1

D1

(10) Display

Operation pattern and mode pattern display

All the display patterns will display for a time when the poweron, the operation indication pattern will display in red under

standby status. When the machine is start by remote control, the indication pattern will light and display the current

operation mode (the mode light includes: Cooling, heating and dehumidify). If you close the light key, all the display

patterns will close.

Double-8 display

According to the different setting of remote control, the nixie light may display the current temperature (the temperature

scope is from 16 to 30 ) and indoor ambient temperature. The heating and air supply temperature will display 25 under

auto-mode, the temperature will display 20 under the auto-heating mode, and the temperature will display H1 under the

defrosting mode.(If you set the fahrenheit temperature display, the nixie light will display according to fahrenheit

temperature)

(11) Protection function and failure display

E2: Freeze-proofing protection E4: Exhausting protecti on E5: Overcurrent protection

E6: Communication failure

F1: Indoor ambient sensor start and short circuit (continuously measured failure in 30S)

F2: Indoor evaporator sensor start and short circuit (continuously measured failure in 30S)

F3: Outdoor ambient sensor start and short circuit (continuously measured failure in 30S)

F4: Outdoor condenser sensor start and short circuit (continuously measured failure in 30S, and don’t measure within 10

minutes after defrosted)

F5: Outdoor exhausting sensor start and short circuit (continuously measured failure in 30S after the compressor operated 3

minutes)

H3: Overload protection of compressor

H5: Module protection

PH: High-voltage protection

PL: Low-voltage protection

P1: Nominal cooling and heating test

P2: Maximum cooling and heating test

P3: Medium cooling and heating test

P0: Minimum cooling and heating test

(12) Drying Function

You may start or stop the drying function under the modes of cooling and dehumidify at the starting status (The modes of

automatism, heating and air supply do not have drying function). When you start the drying function, after stop the

machine by pressing the switch button, you should keep running the inner fans for 10 minutes under low air damper (The

swing will operate as the former status within 10 minutes, and other load is stopped), then stop the entire machine; When

you stop the drying function, press the switch button will stop the machine directly.

When you start the drying function, operating the drying button will stop the inner fans and close the guide louver.

(13) Memory Function

When interrupting the power supply memory content: mode, swing function, light, set temperature and wind speed.

After interrupted the power supply, the machine will start when recovering the power according to the memory content

automatically.

,QVWDOODWLRQ0DQXDO

,QVWDOODWLRQ0DQXDO

1RWLFHVIRU,QVWDOODWLRQ

7KHXQLWLQVWDOODWLRQZRUNPXVWEHGRQHE\TXDOL¿HGSHUVRQQHODFFRUGLQJWRWKHORFDOUXOHVDQGWKLVPDQXDO

%HIRUH LQVWDOODWLQJ SOHDVH FRQWDFW ZLWK ORFDO DXWKRUL]HG PDLQWHQDQFH FHQWHU LI XQLW LV QRW LQVWDOOHG E\ WKH DXWKRUL]HG

PDLQWHQDQFHFHQWHUWKHPDOIXQFWLRQPD\QRWVROYHG

GXHWRGLVFRPPRGLRXVFRQWDFWV

:KHQUHPRYLQJWKHXQLWWRWKHRWKHUSODFHSOHDVH¿UVWO\FRQWDFWZLWKWKHDXWKRUL]HG0DLQWHQDQFH&HQWHULQWKHORFDODUHD

WKHDSSOLDQFHPXVWEHSRVLWLRQHGVRWKDWWKHSOXJLVDFFHVVLEOH

$IWHUSXOORXWWKHSRZHUSOXJWKHQPDNHWKHDSSOLDQFH RSHUDWLRQ DJDLQWR DYRLG WKH LFLQJ RI RXWGRRU XQLW GDPDJH D[LDOÀRZ

IDQVKRXOGHOHFWULI\WKHDSSOLDQFHEXWQRWRSHUDWLRQIRUKRXUVIRUZDUPXSSXUSRVH

,QVWDOODWLRQ6LWH,QVWUXFWLRQV

,QVWDOOLQWKHIROORZLQJSODFHPD\FDXVHPDOIXQFWLRQ,ILWLVXQDYRLGDEOHFRQWDFWZLWKVHUYLFHFHQWHUSOHDVH

ƔVWURQJKHDWVRXUFHVYDSRXUVÀDPPDEOHJDVRUYRODWLOHOLTXLGVDUHHPLWWHG

ƔKLJKIUHTXHQF\HOHFWURPDJQHWLFZDYHVDUHJHQHUDWHGE\UDGLRHTXLSPHQWZHOGHUVDQGPHGLFDOHTXLSPHQW

ƔVDOWODGHQDLUSUHYDLOVVXFKDVFORVHWRFRDVWDODUHDV

ƔWKHDLULVFRQWDPLQDWHGZLWKLQGXVWULDOYDSRXUVDQGRLOV

ƔWKHDLUFRQWDLQVVXOSKXUHVJDVVXFKDVLQKRWVSULQJ]RQHV

ƔFRUURVLRQRUSRRUDLUTXDOLW\H[LVWV

,QVWDOODWLRQ6LWHRI,QGRRU8QLW

7KHDLULQOHWDQGRXWOHWVKRXOGEHDZD\IURPWKHREVWUXFWLRQV(QVXUHWKHDLUFDQEHEORZQWKURXJKWKHZKROHURRP

6HOHFWDVLWHZKHUHWKHFRQGHQVDWHFDQEHHDVLO\GUDLQHGRXWDQGZKHUHLWLVHDVLO\FRQQHFWHGWRRXWGRRUXQLW

6HOHFWDSODFHZKHUHLWLVRXWRIUHDFKRIFKLOGUHQ

6HOHFWDSODFHZKHUHWKHZDOOLVVWURQJHQRXJKWRZLWKVWDQGWKHIXOOZHLJKWDQGYLEUDWLRQRIWKHXQLW

%HVXUHWROHDYHHQRXJKVSDFHWRDOORZDFFHVVIRUURXWLQHPDLQWHQDQFH7KHLQVWDOODWLRQVLWHVKRXOGEHFPRUPRUHDERYH

WKHÀRRU

6HOHFWDSODFHDERXWPRUPRUHDZD\IURP79VHWRUDQ\RWKHUHOHFWULFDSSOLDQFH

6HOHFWDSODFHZKHUHWKH¿OWHUFDQEHHDVLO\WDNHQRXW

0DNHVXUHWKDWWKHLQGRRUXQLWLVLQVWDOOHGLQDFFRUGDQFHZLWKLQVWDOODWLRQGLPHQVLRQLQVWUXFWLRQV

'RQRWXVHWKHXQLWLQWKHODXQGU\RUE\VZLPPLQJSRROHWF

,QVWDOODWLRQ6LWHRI2XWGRRU8QLW

6HOHFWDVLWHZKHUHQRLVHDQGRXWÀRZDLUHPLWWHGE\WKHXQLWZLOOQRWDQQR\QHLJKERUV

6HOHFWDVLWHZKHUHWKHUHLVVXI¿FLHQWYHQWLODWLRQ

6HOHFWDVLWHZKHUHWKHUHLVQRREVWUXFWLRQEORFNLQJWKHLQOHWDQGRXWOHW

7KHVLWHVKRXOGEHDEOHWRZLWKVWDQGWKHIXOOZHLJKWDQGYLEUDWLRQ

6HOHFWDGU\SODFHEXWGRQRWH[SRVHWKHXQLWWRGLUHFWVXQOLJKWRUVWURQJZLQG

0DNHVXUHWKDWWKHRXWGRRUXQLWLVLQVWDOOHGLQDFFRUGDQFHZLWKWKHLQVWDOODWLRQLQVWUXFWLRQVDQGLVFRQYHQLHQWIRUPDLQWHQDQFH

DQGUHSDLU

7KHKHLJKWGLIIHUHQFHEHWZHHQLQGRRUDQGRXWGRRUXQLWVLVZLWKLQPDQGWKHOHQJWKRIWKHFRQQHFWLQJWXELQJGRHVQRWH[FHHG

P.RUP.

6HOHFWDSODFHZKHUHLWLVRXWRIUHDFKRIFKLOGUHQ

6HOHFWDSODFHZKHUHWKHXQLWGRHVQRWKDYHQHJDWLYHLPSDFWRQSHGHVWULDQVRURQWKHFLW\

,QVWDOODWLRQ0DQXDO

6DIHW\3UHFDXWLRQVIRU(OHFWULF$SSOLDQFHV

$GHGLFDWHGSRZHUVXSSO\FLUFXLWVKRXOGEHXVHGLQDFFRUGDQFHZLWKORFDOHOHFWULFDOVDIHW\UHJXODWLRQV

'RQ

WGUDJWKHSRZHUFRUGZLWKH[FHVVLYHIRUFH

7KHXQLWVKRXOGEHUHOLDEO\HDUWKHGDQGFRQQHFWHGWRDQH[FOXVLYHHDUWKGHYLFHE\WKHSURIHVVLRQDOV

7KHDLUVZLWFKPXVWKDYHWKHIXQFWLRQVRIPDJQHWLFWULSSLQJDQGKHDWWULSSLQJWRSUHYHQWVKRUWFLUFXLWDQGRYHUORDG

7KHPLQLPXPGLVWDQFHEHWZHHQWKHXQLWDQGFRPEXVWLYHVXUIDFHLVP

7KHDSSOLDQFHVKDOOEHLQVWDOOHGLQDFFRUGDQFHZLWKQDWLRQDOZLULQJUHJXODWLRQV

$QDOOSROHGLVFRQQHFWLRQVZLWFKZLWKDFRQWDFWVHSDUDWLRQRIDWOHDVWPPLQDOOSROHVVKRXOGEHFRQQHFWHGLQ¿[HGZLULQJ

1RWH

Ɣ0DNHVXUHWKHOLYHZLUHQHXWUDOZLUHDQGHDUWKZLUHLQWKHIDPLO\SRZHUVRFNHWDUHSURSHUO\FRQQHFWHG

Ɣ7KHUHVKRXOGEHUHOLDEOHFLUFXLWLQWKHGLDJUDP,QDGHTXDWHRULQFRUUHFWHOHFWULFDOFRQQHFWLRQVPD\FDXVHHOHFWULFVKRFNRU¿UH

(DUWKLQJ5HTXLUHPHQWV

$LUFRQGLWLRQHULVW\SH,HOHFWULFDSSOLDQFH3OHDVHHQVXUHWKDWWKHXQLWLVUHOLDEO\HDUWKHG

7KH\HOORZJUHHQZLUHLQDLUFRQGLWLRQHULVWKHHDUWKLQJZLUHZKLFKFDQQRWEHXVHGIRURWKHUSXUSRVHV,PSURSHUHDUWKLQJPD\

FDXVHHOHFWULFVKRFN

7KHHDUWKUHVLVWDQFHVKRXOGDFFRUGWRWKHQDWLRQDOFULWHULRQ

7KHSRZHUPXVWKDYHUHOLDEOHHDUWKLQJWHUPLQDO3OHDVHGRQRWFRQQHFWWKHHDUWKLQJZLUHZLWKWKHIROORZLQJ

ķ :DWHUSLSHĸ *DVSLSHĹ &RQWDPLQDWLRQSLSHĺ 2WKHUSODFHWKDWSURIHVVLRQDOSHUVRQQHOFRQVLGHULVXQUHOLDEOH

7KHPRGHODQGUDWHGYDOXHVRIIXVHVVKRXOGDFFRUGZLWKWKHVLONSULQWRQIXVHFRYHURUUHODWHG3&%

,QVWDOODWLRQ0DQXDO

,QVWDOODWLRQ'LPHQVLRQ'LDJUDP

Space to the ceiling

15 cm

Above

Space to the wall

15 cm Above

15 cm Above

Space to the wall

300 cm

Above

250

cm

Above

Air outlet side

Space to the floor

The dimensions of the space necessary for proper

installation of the appliance include the minimum

permissible distances to adjacent structures.

Space to the obstruction

50 cm Above

●

Air inlet side

e

ov

30 cm Above

30

cm

Ab

Space to the wall

Space to the wall

50 cm Above

ve

o

m

0c

Ab

20

Air outlet side

,QVWDOODWLRQ0DQXDO

,QVWDOO,QGRRU8QLW

,QVWDOODWLRQRI0RXQWLQJ3ODWH

0RXQWLQJ SODWH VKRXOG EH LQVWDOOHG KRUL]RQWDOO\$V WKH ZDWHU WUD\

V RXWOHW IRU WKH LQGRRU XQLW LV WZRZD\ W\SH GXULQJ

LQVWDOODWLRQWKHLQGRRUXQLWVKRXOGVOLJKWO\VODQWWRZDWHUWUD\

VRXWOHWIRUVPRRWKGUDLQDJHRIFRQGHQVDWH

)L[WKHPRXQWLQJSODWHRQWKHZDOOZLWKVFUHZV

%HVXUHWKDWWKHPRXQWLQJSODWHKDVEHHQ¿[HG¿UPO\HQRXJKWRZLWKVWDQGDERXWNJ0HDQZKLOHWKHZHLJKWVKRXOG

EHHYHQO\VKDUHGE\HDFKVFUHZ

Wall

Wall

Mark on the middle of it

Space

to the

wall

150

above

Gradienter

Φ55

Space

to the

wall

150

above

Φ55

Right

Left

(Rear piping hole)

8QLWPP

(Rear piping hole)

'ULOO3LSLQJ+ROH

Outdoor

Indoor

Wall pipe

6ODQWWKHSLSLQJKROHRQWKHZDOOVOLJKWO\GRZQZDUGWRWKHRXWGRRUVLGH

ĭ

Seal pad

,QVHUWWKHSLSLQJKROHVOHHYHLQWRWKHKROHWRSUHYHQWWKHFRQQHFWLRQSLSLQJDQG

Φ55

ZLULQJIURPEHLQJGDPDJHGZKHQSDVVLQJWKURXJKWKHKROH

,QVWDOODWLRQRI'UDLQ+RVH

&RQQHFWWKHGUDLQKRVHWRWKHRXWOHWSLSHRIWKHLQGRRUXQLW%LQGWKHMRLQWZLWK

UXEEHUEHOW

3XWWKHGUDLQKRVHLQWRLQVXODWLQJWXEH

outlet pipe of

indoor unit

drain hose

outlet pipe of

indoor unit

rubber belt

:UDS WKH LQVXODWLQJ WXEH ZLWK ZLGH UXEEHU EHOW WR SUHYHQW WKH VKLIW RI LQVXODWLQJ

outlet pipe of

indoor unit

WXEH

6ODQWWKHGUDLQKRVHGRZQZDUGVOLJKWO\IRUVPRRWKGUDLQDJHRIFRQGHQVDWH

drain hose

rubber belt insulating tube

rubber belt

outlet pipe of

indoor unit

1RWH7KHLQVXODWLQJWXEHVKRXOGEHFRQQHFWHGUHOLDEO\ZLWKWKHVOHHYHRXWVLGHWKHRXWOHW

SLSH7KHGUDLQKRVHVKRXOGEHVODQWHGGRZQZDUGVOLJKWO\ZLWKRXWGLVWRUWLRQEXOJHRU

ÀXFWXDWLRQ'RQRWSXWWKHRXWOHWLQWKHZDWHU

connected

bulge

insulating tube

distortion

Flooded

&RQQHFWLQJ,QGRRUDQG2XWGRRU(OHFWULF:LUHV

2SHQWKHIURQWSDQHO

Wiring Cover

5HPRYHWKHZLULQJFRYHUFRQQHFWDQG¿[SRZHUFRQQHFWLRQFRUG

WRWKHWHUPLQDOERDUGDVVKRZQLQ)LJ

0DNHWKHSRZHUFRQQHFWLRQFRUGSDVVWKURXJKWKHKROHDWWKH

EDFNRILQGRRUXQLW

N(1)

5HLQVWDOOWKHFRUGDQFKRUDJHDQGZLULQJFRYHU

5HLQVWDOOWKHIURQWSDQHO

yellow-green

outdoor unit connection

Fig 2

3

brown

,QVWDOODWLRQ0DQXDO

127(

$OOZLUHVEHWZHHQLQGRRUDQGRXWGRRUXQLWVPXVWEHFRQQHFWHGE\WKHTXDOL¿HGHOHFWULFFRQWUDFWRU

Ɣ(OHFWULFZLUHVPXVWEHFRQQHFWHGFRUUHFWO\,PSURSHUFRQQHFWLRQPD\FDXVHPDOIXQFWLRQ

Ɣ7LJKWHQWKHWHUPLQDOVFUHZVVHFXUHO\

Ɣ$IWHUWLJKWHQLQJWKHVFUHZVSXOOWKHZLUHVOLJKWO\WRFRQ¿UPZKHWKHULWLV¿UPRUQRW

Ɣ0DNHVXUHWKDWWKHHOHFWULFFRQQHFWLRQVDUHHDUWKHGSURSHUO\WRSUHYHQWHOHFWULFVKRFN

Ɣ0DNHVXUHWKDWDOOZLULQJFRQQHFWLRQVDUHVHFXUHDQGWKHFRYHUSODWHVDUHUHLQVWDOOHGSURSHUO\3RRULQVWDOODWLRQPD\

FDXVH¿UHRUHOHFWULFVKRFN

,QVWDOODWLRQRI,QGRRU8QLW

Ɣ7KHSLSLQJFDQEHRXWSXWIURPULJKWULJKWUHDUOHIWRUOHIWUHDU

Gas side pipe

:KHQURXWLQJWKHSLSLQJDQGZLULQJIURPWKHOHIWRUULJKWVLGHRILQGRRUXQLW

FXWRIIWKHWDLOLQJVIURPWKHFKDVVLVZKHQQHFHVVDU\$VVKRZQLQ)LJ

External connection

electric wire

Liquid side piping

Tailing 2

side piping

Tailing 1 Gas

insulation

&XWRIIWDLOLQJZKHQURXWLQJWKHZLULQJRQO\

Fig.3

Liquid side

Piping insulation

Finally wrap it

Water drainage pipe

with tape

&XWRIIWDLOLQJDQGWDLOLQJZKHQURXWLQJERWKWKHZLULQJDQGSLSLQJ

7DNHRXWWKHSLSLQJIURPERG\FDVHZUDSWKHSLSLQJSRZHUFRUGVGUDLQKRVH

ZLWKWKHWDSHDQGWKHQPDNHWKHPSDVVWKURXJKWKHSLSLQJKROH$VVKRZQLQ

Left

)LJ

Left rear

Right

Fig.4

Right rear

+DQJ WKH PRXQWLQJ VORWV RI WKH LQGRRU XQLW RQ WKH XSSHU KRRNV RI WKH

Fixing hook

PRXQWLQJSODWHDQGFKHFNLILWLV¿UPHQRXJK$VVKRZQLQ)LJ

Mounting

plate

7KHLQVWDOODWLRQVLWHVKRXOGEHFPRUPRUHDERYHWKHÀRRU

Mounting

plate

Fig.5

,QVWDOODWLRQRI&RQQHFWLRQ3LSH

$OLJQWKHFHQWHURIWKHSLSHÀDUHZLWKWKHUHODWHGYDOYH

6FUHZ LQ WKH IODUH QXW E\ KDQG DQG WKHQ WLJKWHQ WKH QXW ZLWK VSDQQHU DQG

WRUTXHZUHQFKE\UHIHUULQJWRWKHIROORZLQJ

Hex nut diameter

Tightening torque

Ф6.35

Ф9.52

Ф12.7

Ф15.88

Ф19.05

15

31

50

60

70

(N·m)

Indoor unit piping

20

35

55

65

75

Taper nut Piping

Spanner

Torque

wrench

127(&RQQHFWWKHFRQQHFWLRQSLSHWRLQGRRUXQLWDW¿UVWDQGWKHQWRRXWGRRUXQLW

+DQGOHSLSLQJEHQGLQJZLWKFDUH'RQRWGDPDJHWKHFRQQHFWLRQSLSH(QVXUHWKDW

WKHMRLQWQXWLVWLJKWHQHG¿UPO\RWKHUZLVHLWPD\FDXVHOHDNDJH

,QVWDOO2XWGRRU8QLW

(OHFWULF:LULQJ

5HPRYHWKHKDQGOHRQWKHULJKWVLGHSODWHRIRXWGRRUXQLW

7DNHRIIZLUHFRUGDQFKRUDJH&RQQHFWDQG¿[SRZHUFRQQHFWLRQFRUG

WRWKHWHUPLQDOERDUG:LULQJVKRXOG¿WWKDWRILQGRRUXQLW

)L[ WKH SRZHU FRQQHFWLRQ FRUG FODPSV DQG WKHQ FRQQHFW WKH

FRUUHVSRQGLQJFRQQHFWRU

&RQ¿UPLIWKHZLUHKDVEHHQ¿[HGSURSHUO\

5HLQVWDOOWKHKDQGOH

Handle

N(1) 2

3

blue black brown

yellowgreen

Indoor unit

connection

127(

Ɣ,QFRUUHFWZLULQJPD\FDXVHPDOIXQFWLRQRIVSDUHSDUW

Ɣ$IWHUWKHZLUHKDVEHHQ¿[HGHQVXUHWKHUHLVIUHHVSDFHEHWZHHQWKHFRQQHFWLRQDQG¿[LQJSODFHVRQWKHOHDGZLUH

6FKHPDWLFGLDJUDPEHLQJUHIHUHQFHRQO\SOHDVHUHIHUWRUHDOSURGXFWIRUDXWKHQWLFLQIRUPDWLRQ

,QVWDOODWLRQ0DQXDO

$LU3XUJLQJDQG/HDNDJH7HVW

&RQQHFWFKDUJLQJKRVHRIPDQLIROGYDOYHWRFKDUJHHQGRIORZSUHVVXUH

YDOYHERWKKLJKORZSUHVVXUHYDOYHVPXVWEHWLJKWO\VKXW

Liquid pipe

Vacuum

gauge

Gas pipe

&RQQHFWMRLQWRIFKDUJLQJKRVHWRYDFXXPSXPS

Valve

cap

)XOO\RSHQWKHKDQGOHRI/RPDQLIROGYDOYH

2SHQ WKH YDFXXP SXPS IRU YDFXXPL]DWLRQ$W WKH EHJLQQLQJ VOLJKWO\

ORRVHQMRLQWQXWRIORZSUHVVXUHYDOYHWRFKHFNLIWKHUHLVDLUFRPLQJLQVLGH,I

QRLVHRIYDFXXPSXPSKDVEHHQFKDQJHGWKHUHDGLQJRIPXOWLPHWHULV

7KHQWLJKWHQWKHQXW

Vacuum pump

.HHS YDFXXPLQJ IRU PRUH WKDQ PLQV DQG PDNH VXUH WKH UHDGLQJ RI

PXOWLPHWHULV;SDFP+J

)LJ

)XOO\RSHQKLJKORZSUHVVXUHYDOYHV

5HPRYHFKDUJLQJKRVHIURPFKDUJLQJHQGRIORZSUHVVXUHYDOYH

7LJKWHQOLGRIORZSUHVVXUHYDOYH$VVKRZQLQ)LJ

2XWGRRU&RQGHQVDWH'UDLQDJHRQO\IRUKHDWSXPSXQLW

'XULQJ KHDWLQJ RSHUDWLRQ WKH FRQGHQVDWH DQG GHIURVWLQJ ZDWHU VKRXOG EH

Drain-water hole

Bottom frame

GUDLQHGRXWUHOLDEO\WKURXJKWKHGUDLQKRVH,QVWDOOWKHRXWGRRUGUDLQFRQQHFWRU

LQDĭKROHRQWKHEDVHSODWHDQGDWWDFKWKHGUDLQKRVHWRWKHFRQQHFWRUVR

WKDWWKHZDVWHZDWHUIRUPHGLQWKHRXWGRRUXQLWFDQEHGUDLQHGRXW7KHKROH

Drain connecter

Hose (available commercially,

inner dia. 16mm)

GLDPHWHUPXVWEHSOXJJHG

&KHFNDIWHU,QVWDOODWLRQDQG7HVW2SHUDWLRQ

&KHFNDIWHU,QVWDOODWLRQ

Items to be checked

Possible malfunction

Has it been fixed firmly?

The unit may drop, shake or emit noise.

Have you done the refrigerant leakage test?

It may cause insufficient cooling(heating)

capacity

Is heat insulation sufficient?

It may cause condensation and dripping.

Is water drainage satisfactory?

It may cause condensation and dripping.

Is the voltage in accordance with the rated

voltage marked on the nameplate?

Is the electric wiring and piping

connection installed correctly and securely?

Has the unit been connected to a secure

earth connection?

It may cause electric malfunction

or damage the product.

It may cause electric malfunction

or damage the part.

It may cause electrical leakage.

Is the power cord specified?

It may cause electric malfunction

or damage the part.

Are the inlet and outlet openings blocked?

It may cause insufficient cooling(heating)

capacity.

Is the length of connection pipes

and refrigerant capacity been recorded?

The refrigerant capacity is not accurate.

,QVWDOODWLRQ0DQXDO

&KHFNDIWHU,QVWDOODWLRQ

%HIRUH2SHUDWLRQ7HVW

'RQRWVZLWFKRQSRZHUEHIRUHLQVWDOODWLRQLV¿QLVKHGFRPSOHWHO\

(OHFWULFZLULQJPXVWEHFRQQHFWHGFRUUHFWO\DQGVHFXUHO\

&XWRIIYDOYHVRIWKHFRQQHFWLRQSLSHVVKRXOGEHRSHQHG

$OOWKHLPSXULWLHVVXFKDVVFUDSVDQGWKUXPVPXVWEHFOHDUHGIURPWKHXQLW

2SHUDWLRQ7HVW0HWKRG

6ZLWFKRQSRZHUDQGSUHVV212))EXWWRQRQWKHUHPRWHFRQWUROOHUWRVWDUWRSHUDWLRQ

3UHVV 02'( EXWWRQ WR VHOHFW WKH &22/ +($7 1RW DYDLODEOH IRU FRROLQJ RQO\ XQLW )$1 WR FKHFN ZKHWKHU WKH

RSHUDWLRQLVQRUPDORUQRW

,QVWDOODWLRQDQG0DLQWHQDQFHRI+HDOWK\)LOWHU

,QVWDOODWLRQRI+HDOWK\)LOWHU

/LIWXSWKHIURQWSDQHOIURPLWVWZRHQGVDVVKRZQE\WKHDUURZGLUHFWLRQDQG

WKHQUHPRYHWKHDLU¿OWHUDVVKRZQLQ)LJD

$WWDFKWKHKHDOWK\¿OWHURQWRWKHDLU¿OWHUDVVKRZQLQ)LJE

,QVWDOOWKHDLU¿OWHUSURSHUO\DORQJWKHDUURZGLUHFWLRQLQ)LJFDQGWKHQFORVH

WKHSDQHO

Fig. a

Fig. b

Air filter

Healthy filter

&OHDQLQJDQG0DLQWHQDQFH

Fig. c

5HPRYHWKHKHDOWK\¿OWHUDQGUHLQVWDOOLWDIWHUFOHDQLQJDFFRUGLQJWRWKHLQVWDOODWLRQLQVWUXFWLRQ'RQRWXVHEUXVKRUKDUG

REMHFWVWRFOHDQWKH¿OWHU$IWHUFOHDQLQJEHVXUHWRGU\LWLQWKHVKDGH

6HUYLFH/LIH

7KHJHQHUDOVHUYLFHOLIHIRUWKHKHDOWK\¿OWHULVDERXWRQH\HDUXQGHUQRUPDOFRQGLWLRQ$VIRUVLOYHULRQ¿OWHULWLV

LQHIIHFWLYHZKHQLWVVXUIDFHEHFRPHVEODFNJUHHQ

7KLVVXSSOHPHQWDU\LQVWUXFWLRQLVSURYLGHGIRUUHIHUHQFHWRWKHXQLWZLWKKHDOWK\¿OWHU,IWKHJUDSKLFVSURYLGHGKHUHLQ

DUHGLIIHUHQWIURPWKHDFWXDOSURGXFWSOHDVHUHIHUWRWKHDFWXDOSURGXFW7KHTXDQWLW\RIKHDOWK\¿OWHUVLVEDVHGRQWKH

DFWXDOGHOLYHU\

([SORGHG9LHZVDQG3DUWV/LVW

([SORGHG9LHZVDQG3DUWV/LVW

,QGRRU8QLW

*:+5$.'1$$,*:+5$.'1$%,

*:+5%.'1$%,*:+5%.'1$%,

14

35

37

36

13

39

38

15

12

11

10

9

16

8

17

7

18

6

5

19

4

20

3

2

21

1

22

23

24

25

27

28

26

34

29

30

33

31

32

([SORGHG9LHZVDQG3DUWV/LVW

12

'HVFULSWLRQ

3URGXFWFRGH

)URQW3DQHO$VV\

)LOWHU6XE$VV\

6FUHZ&RYHU

)URQW&DVH6XEDVV\

$LU/RXYHU

$LU/RXYHU

3DUW&RGH

*:+5$.'1$$,

*:+5$.'1$%,

&%1

&%1

4W\

+HOLFRLG7RQJXH

/HIW$[LOH%XVK

5HDU&DVHDVV\

5XEEHU3OXJ:DWHU7UD\

5LQJRI%HDULQJ

2*DVNHWVXEDVV\RI%HDULQJ

&URVV)ORZ)DQ

(YDSRUDWRU6XSSRUW

(YDSRUDWRU$VV\

:DOO0RXQWLQJ)UDPH

0RWRU3UHVV3ODWH

)DQ0RWRU

3LSH&ODPS

'UDLQDJHKRVH

6WHS0RWRU

&UDQN

*XLGH/RXYHU

$[LOH%XVK

(OHFWULF%R[

7HUPLQDO%RDUG

(OHFWULF%R[&RYHU

'LVSOD\%RDUG

&DSDFLWRU&%%

-XPSHU

0DLQ%RDUG

6KLHOGFRYHURI(OHFWULF%R[VXEDVV\

(OHFWULF%R[&RYHU

(OHFWULF%R[$VV\

3RZHU&RUG

&RQQHFWLQJ&DEOH

$PELHQW7HPSHUDWXUH6HQVRU

5HPRWH&RQWUROOHU

7XEH6HQVRU

7KHGDWDDERYHDUHVXEMHFWWRFKDQJHZLWKRXWQRWLFH

([SORGHG9LHZVDQG3DUWV/LVW

12

'HVFULSWLRQ

3URGXFWFRGH

)URQW3DQHO$VV\

)LOWHU6XE$VV\

6FUHZ&RYHU

)URQW&DVH6XEDVV\

$LU/RXYHU

$LU/RXYHU

*:+5%.'1$%,

*:+5%.'1$%,

&%1

&%1

4W\

+HOLFRLG7RQJXH

/HIW$[LOH%XVK

5HDU&DVHDVV\

5XEEHU3OXJ:DWHU7UD\

5LQJRI%HDULQJ

2*DVNHWVXEDVV\RI%HDULQJ

&URVV)ORZ)DQ

(YDSRUDWRU6XSSRUW

(YDSRUDWRU$VV\

:DOO0RXQWLQJ)UDPH

0RWRU3UHVV3ODWH

)DQ0RWRU

3LSH&ODPS

'UDLQDJHKRVH

6WHS0RWRU

&UDQN

*XLGH/RXYHU

$[LOH%XVK

(OHFWULF%R[

7HUPLQDO%RDUG

(OHFWULF%R[&RYHU

'LVSOD\%RDUG

&DSDFLWRU&%%

-XPSHU

0DLQ%RDUG

6KLHOGFRYHURI(OHFWULF%R[VXEDVV\

(OHFWULF%R[&RYHU

(OHFWULF%R[$VV\

3RZHU&RUG

&RQQHFWLQJ&DEOH

$PELHQW7HPSHUDWXUH6HQVRU

5HPRWH&RQWUROOHU

7XEH6HQVRU

7KHGDWDDERYHDUHVXEMHFWWRFKDQJHZLWKRXWQRWLFH

3DUW&RGH

([SORGHG9LHZVDQG3DUWV/LVW

*:+5$.'1$%,*:+5%.'1$%,

17

16

34

36