Download Service Manual 05/2007

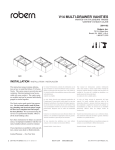

Transcript