Download SERVICE MANUAL - Galco Industrial Electronics

Transcript

HITACHI INVERTER

SJ300 / L300P SERIES

SERVICE MANUAL

After reading this manual , keep it hand for future reference.

HITACHI

NBS611BX

NBS611 X

Revision History Table

No.

1

2

Revision Contents

Japanese font was removed.

The Date

of Issue

Operation

Manual No.

Nov. 2000

NBS611BX

.

Table of contents

1. Investigation of the inverter

1.1 Specification label(Model name , Manufacturing number ; MFG)

1.1.1 Model name - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-1

1.1.2 MFG number - - - - - - - - - - - - - - -- - - - - - - - - - - - - - - 1-1

1.2 Inverter specification

1.2.1 SJ300 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-2

1.2.2 L300P - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-10

2. Trouble shooting

2.1 INV trip contents , remedy , advice - - - - - - - - - - - - - - - - - - - 2-1

2.2 Option error

2.2.1 Feedback card - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-3

2.2.2 Digital option card - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-3

2.3 Confirmation of the trip monitor contents - - - - - - - - - - - - - - - - - 2-3

2.4 Confirmation of the warning monitor contents - - -- - - - - - - - - - - 2-4

3. Debug mode

3.1 Monitor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-1

3.2 Parameter settings for inverter - - - - - - - - - - - - - - - - - - - - - - - - 3-2

4. Maintenance and Inspection

4.1 Maintenance and Inspection

4.1.1

Daily inspection - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-1

4.1.2

Cleaning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-1

4.1.3

Periodical inspection - - - - - - - - - - - - - - - - - - - - - - - - - 4-1

4.2 Daily and annual maintenance - - - - - - - - - - - - - - - - - - - - - - - - 4-2

4.3 Megger test - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-3

4.4 Withstand voltage test - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-3

4.5 How to check inverter & converter portion - - - - - - - - - - - - - - - 4-4

4.6 Parts replacement - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-5

4.7 Unit replacement - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-8

Appendix

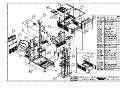

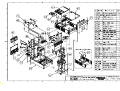

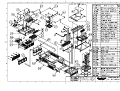

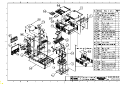

Circuit Diagram

Internal block diagram

1. Investigation of the inverter

1.1 Specification label (Model name, Manufacturing number ; MFG)

• There are 2 specification label attached to the inverter as shown in Fig 1-1.

Specification label

Fig 1-1 Specification label location

• Please confirm the model name and MFG number from the specification label as follows.

Model name

Applicable motor

Input ratings

Output ratings

MFG number

Fig 1-2 contents of specification label

1.1.1 Model name

SJ300-055 H F (R)

R : with POT meter

F : with digital operator

L : 3φ 200V class

H : 3φ 400V class

Applicable motor (055 : 5.5kW)

Model name

1.1.2 MFG number

94 A T12345 9 0001

Serial No. (0001 ~ 9999)

Year of production (9 : 1999)

Production No.

REV. No.

Production year & month (94 : 1999 / April)

1-1

1.2 Inverter specification

(Note1)

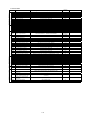

1.2.1 SJ300

Monitor Mode

Display

code

d001

d002

d003

d004

SJ300 monitor or data range

(digital operator)

Function name

Output frequency

monitor

Output current

monitor

Operation direction

monitor

PID feedback

monitor

0.00-99.99/100.0-400.0(Hz)

-

0.0-999.9(A)

-

F(forward)/o(stop)/r(reverse)

-

0.00-99.99/100.0-999.9/1000. –9999. /

1000-9999/{100-{999 (10000-99900)

-

(Example) FW, terminal 7,2,1: ON

Terminal 8,6,5,4,3:OFF

ON

FW

d005

Intelligent input

terminal monitor

-

OFF

8

d006

Initial

data

7 6

5

4

3 2

1

(Example) Terminal 12,11:ON

AL, 15,14,13:OFF

ON

Intelligent output

terminal monitor

-

OFF

AL 15 14 13 12

Frequency

0.00-99.99/100.0-999.9/1000. –9999. /

d007

conversion monitor

1000-3996

d012 torque monitor

-300.-+300.%

Output voltage

d013

0.0-600.0 V

monitor

Input electric power

d014

0.0-999.9 kW

monitor

Accumulated time

d016 monitor during

0.-9999./1000-9999/{100-{999 hr

RUN

Power ON time

d017

0.-9999./1000-9999/{100-{999 hr

monitor

Number of trip time

d080

0.-9999./1000-6553(10000-65530) (time)

monitor

d081 Trip monitor 1

d082 Trip monitor 2

d083 Trip monitor 3

Trip Code, frequency(Hz), current(A),

voltage(V),RUN time(hr) power ON time(hr)

d084 Trip monitor 4

d085 Trip monitor 5

d086 Trip monitor 6

d090 Warning monitor

Warning code

Output

frequency 0.0, starting frequency-Max. frequency

F001

0.00

setting

(2 nd max. 3 rd max. frequency)(Hz)

st

F002 1 acceleration time 0.01-99.99/100.0-999.9/1000. -3600.(s)

30.00

F202 2 nd acceleration time 0.01-99.99/100.0-999.9/1000. -3600.(s)

30.00

F302 3 rd acceleration time

0.01-99.99/100.0-999.9/1000. -3600.(s)

30.00

F003 1 st deceleration time 0.01-99.99/100.0-999.9/1000. -3600.(s)

30.00

F203 2 nd deceleration time 0.01-99.99/100.0-999.9/1000. -3600.(s)

30.00

F303 3 rd deceleration time 0.01-99.99/100.0-999.9/1000. -3600.(s)

30.00

Operation direction

F004

00(forward)/01(reverse)

00

selection

(Note1) Change mode during run by selection of b031 (software lock selection).

(Note2) Do not forget to press “STR” key when you change the display.

1 –2

Note

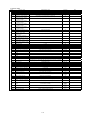

Function Mode

V/f characteristic

Multistage speed,jogging frequency setting

Analog input setting

Base setting

Code

SJ300 Setting range

Initial data

-FE/-FU/-F

A001

Frequency setting selection

01(terminal)/02(operator)/03(RS485)/04(option1)/05(option2)

01/01/02

A002

Operation setting selection

01(terminal)/02(operator)/03(RS485)/04(option1)/05(option2)

01/01/02

A003

Base frequency

30. - Maximum. frequency(Hz)

50./60./60.

A203

Base frequency, 2nd motor

A303

Base frequency, 3rd motor

A004

Maximum frequency

30. – 400. (Hz)

50./60./60.

A204

Maximum frequency, 2nd motor

30. – 400. (Hz)

50./60./60.

A304

Maximum frequency, 3rd motor

30. – 400. (Hz)

50./60./60.

A005

AT terminal selection

00( Changing of O and OI with AT terminal)/

01(Changing of O and O2 with AT terminal)

00

A006

02 selection

A011

30. – 2nd Maximum. frequency (Hz)

30. -

3rd

Maximum. frequency (Hz)

50./60./60.

50./60./60.

00(single)/01(auxiliary speed of O, OI) [no reversible] /

02(auxiliary speed of O, OI [reversible]

00

0 start

0.00-99.99/100.0-400.0 (Hz)

0.00

A012

0 end

0.00-99.99/100.0-400.0 (Hz)

0.00

A013

0 start rate

0.-100.0 (%)

0.

A014

0 end rate

0.-100.0(%)

100.

00 (external starting frequency)/01(0Hz)

01

1.-30.(times)

8.

A015

0 start selection

A016

O, OI, O2 sampling

00(binary : range is to 16 stage speed with 4 terminals)/

01(bit : range is to 8 stage speed with 7 terminals)

00

0.00, starting frequency-maximum. frequency(Hz)

0.00

0.00

A019

Multi-speed selection

A020

Multi-speed 0

A220

Multi-speed 0, 2 nd motor

0.00, starting frequency-2 nd maximum frequency(Hz)

A320

Multi-speed 0, 3 rd motor

0.00, starting frequency-3 rd maximum frequency(Hz)

0.00

A021

Multi-speed1

0.00, starting frequency-maximum frequency(Hz)

0.00

A022

Multi-speed2

0.00, starting frequency-maximum frequency(Hz)

0.00

A023

Multi-speed3

0.00, starting frequency-maximum frequency(Hz)

0.00

A024

Multi-speed4

0.00, starting frequency-maximum frequency(Hz)

0.00

A025

Multi-speed5

0.00, starting frequency-maximum frequency(Hz)

0.00

A026

Multi-speed6

0.00, starting frequency-maximum frequency(Hz)

0.00

A027

Multi-speed7

0.00, starting frequency-maximum frequency(Hz)

0.00

A028

Multi-speed8

0.00, starting frequency-maximum frequency(Hz)

0.00

A029

Multi-speed9

0.00, starting frequency-maximum frequency(Hz)

0.00

A030

Multi-speed10

0.00, starting frequency-maximum frequency(Hz)

0.00

A031

Multi-speed11

0.00, starting frequency-maximum frequency(Hz)

0.00

A032

Multi-speed12

0.00, starting frequency-maximum frequency(Hz)

0.00

A033

Multi-speed13

0.00, starting frequency-maximum frequency(Hz)

0.00

A034

Multi-speed14

0.00, starting frequency-maximum frequency(Hz)

0.00

A035

Multi-speed15

0.00, starting frequency-maximum frequency(Hz)

0.00

A038

Jogging frequency

0.00, starting frequency-9.99(Hz)

1.00

A039

Jogging selection

00(free-run on JG stop / invalid on running) / 01(stop decelerating on

JG stop / invalid on running) / 02(DC braking on JG stop/invalid on

running) / 03(free-run on JG stop/valid on running[JG after stop

decelerating]) / 04 (stop decelerating on JG stop/valid on running) / 05

(DC braking on JG stop/valid on operating)

00

A041

Torque boost selection

00 (manual torque boost) / 01 (automatic torque boost)

00

A241

Torque

motor

00 (manual torque boost) / 01 (automatic torque boost)

00

A042

Manual torque boost

0.0-20.0(%)

1.0

A242

Manual torque boost, 2 nd motor

0.0-20.0(%)

1.0

A342

Manual torque boost, 3rd motor

0.0-20.0(%)

1.0

A043

Manual torque boost point

0.0-50.0(%)

5.0

A243

Manual torque boost point, 2 nd

motor

0.0-50.0(%)

5.0

A343

A044

Direct current braking

Function name

boost

selection,

2nd

Manual torque boost point, 3

motor

rd

1st control

nd

A244

2

A344

3rd control

control

A045

0.0-50.0(%)

5.0

00/(VC)/01(VP1.7power)/02(free V/f setting)/03(SLV)/

04(0Hz-SLV)/05(V2)

00

00/(VC)/01(VP1.7power)/02(free V/f setting) /03(SLV)/04(0Hz-SLV)

00

00/(VC)/01(VP1.7power)

00

Output voltage gain

20. - 100.

100.

A051

DC braking selection

00(invalid)/01(valid)

00

A052

DC braking frequency

0.00-60.00(Hz)

0.50

0.0 - 5.0(s)

0.0

A053

DC braking wait time

A054

DC braking power

0. - 100. (%)

0.

A055

DC braking time

0.0 - 60.0(s)

0.0

A056

DC braking edge/level selection

00(edge action)/01(level action)

01

A057

DC braking power (starting time)

0. - 100. (%)

0.

A058

DC braking time(starting time)

0.00-60.0(s)

0.0

A059

DC carrier frequency

0.5-15(kHz) Derating

5.0

1- 3

Note

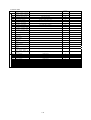

Function Mode

Operation mode/ adjustable function

PID control

AVR

Upper and lower limiter,jump

frequency

Code

1st frequency maximum limiter

2nd frequency maximum limiter

1st frequency minimum limiter

2nd frequency minimum limiter

Jump frequency1

Jump frequency Width 1

Jump frequency2

Jump frequency Width 2

Jump frequency3

Jump frequency Width 3

Acceleration stop frequency

Acceleration stop time

PID selection

PID-P gain

PID-I gain

PID-D gain

PID scale

PID feedback selection

AVR selection

A082

Motor voltage selection

A085

A097

A098

A101

A102

A103

A104

A105

A111

A112

A113

A114

A131

Operation mode selection

Energy-saving responseaccuracy adjustment

Acceleration time2

Acceleration time2(2 nd motor)

Acceleration time2(3rd motor)

Deceleration time2

Deceleration time2(2 nd motor)

Deceleration time2(3rd motor)

2nd stage adjustable selection

2nd stage adjustable

selection(2 nd motor)

2nd acceleration frequency

2nd acceleration

frequency(2 nd motor)

2nd deceleration frequency

2nd deceleration frequency

(2nd motor)

Acceleration pattern selection

Deceleration pattern selection

OI start

OI end

OI start rate

OI end rate

OI start selection

O2 start

O2 end

O2 start rate

O2 end rate

Acceleration curve constant

A132

Deceleration curve constant

b001

Retry selection

A086

A092

A292

A392

A093

A293

A393

A094

A294

A095

A295

A096

Accel,

Decel

External frequency

adjustment

A296

Instantaneous power failure

restart

Function name

A061

A261

A062

A262

A063

A064

A065

A066

A067

A068

A069

A070

A071

A072

A073

A074

A075

A076

A081

b002

b003

b004

b005

b006

b007

Allowable under-voltage power

failure time

Retry wait time

Instantaneous power failure/

under-voltage trip during stop

Instantaneous power failure/

under-voltage retry time

selection

Open-phase selection

Frequency setting to match

SJ300 Setting range

0.00, 1st frequency lower limitter - maximum frequency(Hz)

0.00, 2 nd frequency lower limiter-2 nd setting maximum frequency(Hz)

0.00, start frequency-maximum frequency(Hz)

0.00, start frequency-2 nd setting maximum frequency(Hz)

0.00-99.99/100.0-400.0(Hz)

0.00-10.00(Hz)

0.00-99.99/100.0-400.0(Hz)

0.00-10.00(Hz)

0.00-99.99/100.0-400.0(Hz)

0.00-10.00(Hz)

0.00-99.99/100.0-400.0(Hz)

0.00-60.0(s)

00(invalid)/01(valid)

0.2-5.0

0.0-3600.(s)

0.00-100.0(s)

0.01-99.99(%)

00(feedback : OI)/01(feedback : O)

00(ON always)/01(OFF always)/02(OFF on decelerating)

200/215/220/230/240,

380/400/415/440/460/480

00(normal operation)/01(energy-saving operation)/02(Fuzzy)

Initial data

-FE/-FU

0.00

0.00

0.00

0.00

0.00

0.50

0.00

0.50

0.00

0.50

0.00

0.0

00

1.0

1.0

0.00

1.00

00

02

(230/400)/

(230/460)/

(200/400)

00

0.0-100.0

50.0

0.01-99.99/100.0-999.9/1000.-3600.(s)

0.01-99.99/100.0-999.9/1000.-3600.(s)

0.01-99.99/100.0-999.9/1000.-3600.(s)

0.01-99.99/100.0-999.9/1000.-3600.(s)

0.01-99.99/100.0-999.9/1000.-3600.(s)

0.01-99.99/100.0-999.9/1000.-3600.(s)

00(change with 2CH terminal)/01(change with setting)

15.00

15.00

15.00

15.00

15.00

15.00

00

00(change with 2CH terminal)/01(change with setting)

00

0.00-99.99/100.0-400.0(Hz)

0.00

0.00-99.99/100.0-400.0(Hz)

0.00

0.00-99.99/100.0-400.0(Hz)

0.00

0.00-99.99/100.0-400.0(Hz)

0.00

00(straight line)/01(S-curve)/02(U-curve)/03(reverse U-curve)

00(straight line)/01(S-curve)/02(U-curve)/03(reverse U-curve)

0.00-99.99/100.0-400.0(Hz)

0.00-99.99/100.0-400.0(Hz)

0.-100. (%)

0.-100. (%)

00(external start frequency)/01(0Hz)

-400.--100./-99.9-0.00-99.9/100.-400.(Hz)

-400.--100./-99.9-0.00-99.9/100.-400.(Hz)

-100. - 100. (%)

-100. - 100. (%)

01(small swelling)-10(large swelling)

00

00

0.00

0.00

20.

100.

01

0.00

0.00

-100.

100.

02

01(small swelling-10(large swelling)

02

00(trip)/01(0Hz start)/02(start after equal frequency)/

03(trip after equaling frequency and deceleration stop)

00

0.3-1.0(s)

1.0

0.3-100.(s)

00(invalid/01(valid)/02(invalid during stop and deceleration by stop

command)

1.0

00(16 times)/01(free)

00

00(invalid)/01(valid)

0.00-99.99/100.0-400.0(Hz)

00

0.00

1- 4

00

Note

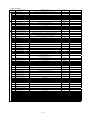

Function mode

Code

Function name

b012

Electronic thermal level

0.2*constant current-1.20*constant current(A)

b212

Electronic thermal level

(2nd motor)

0.2*constant current-1.20*constant current(A)

b312

Electronic thermal level

(3rd motor)

0.2*constant current-1.20*constant current(A)

st

Electronic thermal

b013

b213

b313

b015

b016

b017

b018

b019

Free V/f setting

Overload limit

b020

Intelligent input terminal setting

SJ300 Setting range

1 electronic thermal

characteristic selection

2nd electronic thermal

characteristic selection

3rd electronic thermal

characteristic selection

Free electronic thermal

frequency 1

Free electronic thermal

current 1

Free electronic thermal

frequency 2

Free electronic thermal

current 2

Free electronic thermal

frequency 3

Free electronic thermal

current 3

b021

Overload restriction selection

b022

Overload restriction level

b023

Overload restriction limit

constant

b024

Overload restriction 2

selection

b025

Overload restriction level 2

b026

Overload restriction constant

2

b031

Software lock mode selection

b100

b101

b102

b103

b104

b105

b106

b107

b108

b109

b110

b111

b112

b113

Free

Free

Free

Free

Free

Free

Free

Free

Free

Free

Free

Free

Free

Free

C001

Intelligent input 1 setting

C002

Intelligent input 2 setting

C003

Intelligent input 3 setting

C004

Intelligent input 4 setting

C005

Intelligent input 5 setting

C006

Intelligent input 6 setting

C007

Intelligent input 7 setting

C008

Intelligent input 8 setting

V/f

V/f

V/f

V/f

V/f

V/f

V/f

V/f

V/f

V/f

V/f

V/f

V/f

V/f

frequency

voltage 1

frequency

voltage 2

frequency

voltage 3

frequency

voltage 4

frequency

voltage 5

frequency

voltage 6

frequency

voltage 7

1

2

3

4

5

6

7

00(reduced characteristic)/ 01(constant torque characteristic)/

02(free setting)

00(reduced characteristic)/ 01(constant torque characteristic)/

02(free setting)

00/(reduced characteristic)01(constant torque characteristic)/

02(free setting)

Initial data

-FE/-FU/-F

Rated

Current of

inverter

Rated

Current of

Inverter

Rated

current of

inverter

01/01/00

01/01/00

01/01/00

0.-400.(Hz)

0.

0.0-1000.(A)

0.0

0.-400.(Hz)

0.

0.0-1000. (A)

0.0

0.-400.(Hz)

0.

0.0-1000.(A)

0.0

00(invalid)/01(enabled on acceleration / constant speed)/

02(enabled on constant speed)/03(enabled on acceleration / constant

speed (speed increasing at regenerating mode))

01

0.50* rated current-2.00* rated current(A)

Rated current

of Inverter

x 1.50

0.10-30.00(s)

1.00

00(invalid)/01(enabled on acceleration / constant speed)/

02(enabled on constant speed)/03(enabled on acceleration / constant

speed (speed increasing at regenerating mode))

01

0.50*rated current-2.00*rated current(A)

Rated current

of inverter

x1.50

0.10-30.00(s)

1.00

00(impossible to change the data except this item when SFT terminal is

ON)/01(impossible to change the data except setting frequency item

when SFT terminal is ON)/02(impossible to change the data except this

item)/

03(impossible to change the data except setting frequency item)/

10(possible to change data on operating)

0.- Free V/f frequency2(Hz)

0.-800.0(V)

0.- Free V/f frequency3(Hz)

0.-800.0(V)

0.- Free V/f frequency4(Hz)

0.-800.0(V)

0.- Free V/f frequency5(Hz)

0.-800.0(V)

0.- Free V/f frequency6(Hz)

0.-800.0(V)

0.- Free V/f frequency7(Hz)

0.-800.0(V)

0.-400.(Hz)

0.-800.0(V)

01/(RV:Reverse is valid)/02(CF1:Multi-speed1)/ 03(CF2:Multi-speed2)/

04(CF3:Multi-speed3)/ 05(CF4:Multi-speed4)/ 06(JG:Jogging)/

07(DB:External DC braking)/ 08(SET:2 nd control)/

09(2CH:two-stage adjustable speed)/ 11(FRS:Free-run)/ 12(EXT:External

trip)/

13(USP:Unattended start protection)/ 14(CS:commercial change)/

15(SFT:software lock)/ 16(AT:Analog input voltage/current select)/

17(SET3:3 rd control)/ 18(RS:Reset inverter)/ 20(STA:3wire run)/

21(STP:3wire keep)/ 22(F/R:3wire forward/reverse)/

23(PID:PID selection valid/invalid)/ 24(PIDC:PID integrating reset)/

26(CAS:Control gain switch function)/ 27(UP:Remote control UP function)/

28(DWN:Remote control DOWN function)/29(UDC:Remote control data clear)/

31(OPE:Operating by operator select)/ 32(SF1:Multi-speed bit1)/

33(SF2:Multi-speed bit2)/ 34(SF3:Multi-speed bit3)/ 35(SF4:Multi-speed bit4)/

36(SF5:Multi speed bit5)/ 37(SF6:Multi-speed bit6)/ 38(SF7:Multi-speed bit7)/

39(OLR:Overload restriction change) / 40(TL:Torque limit select)/

41(TRQ1:Torque limit switch 1)/ 42(TRQ2:Torque limit switch 2)/

43((PPI:P/PI switch)/ 44(BOK:Braking comformation)/ 45(ORT:Orientation)/

46(LAC:LAD cancel)/ 47(PCLR:Position error clear)/

48(STAT:Permission of pulse train)/ no(NO:No assign)

1- 5

01

0.

0.0

0.

0.0

0.

0.0

0.

0.0

0.

0.0

0.

0.0

0.

0.0

18

16

06

11

09

03/13/03

02

01

Note

Function mode

Code

C011

Input terminal setting

intelligent

C012

C013

C014

C015

C016

C017

C018

Intelligent output terminal setting

C019

Intelligent output 11 setting

C022

Intelligent output 12 setting

C023

Intelligent output 13 setting

C024

Intelligent output 14 setting

C025

Intelligent output 15 setting

C026

Alarm relay output

C027

FM selection

C028

AM selection

state

terminal

setting,Output level setting

Output

SJ300 Setting range

Initial data

-FE/-FU/-F

00(NO)/01(NC)

00

00(NO)/01(NC)

00

00(NO)/01(NC)

00

00(NO)/01(NC)

00

00(NO)/01(NC)

00

00(NO)/01(NC)

00/01/00

00(NO)/01(NC)

00

00(NO)/01(NC)

00

00(NO)/01(NC)

00

00(RUN:running)/01(FA1:Frequency arrival type1 signal)/

02(FA2:over setting frequency)/03(OL:Overload advance notice signal)/

04(OD:Output deviation for PID control)/05(AL:Alarm signal)/

06(FA3:Only setting frequency)/07(OTQ:Over-torque signal)/

08(IP:On instantaneous stop)/09(UV:Under voltage)/

10(TRQ:Torque limit)/11(RNT:RUN time over/12(ONT:ON time over)/

13(THM:thermal caution)/19(BRK:Brake release signal)/

20(BER:Brake error signal)/21(ZS:Zero speed detect signal)/

22(DSE:Speed error over signal)/23(POK:Positioning completion signal)

24(FA4:Over frequency 2 signal)/25(FA5:Only setting frequency)/

26(OL2: Overload advance notice signal 2)

(Intelligent output terminal 11-13 or 11-14 becomes AC0-AC2 or AC0-AC3

(Can:Alarm cord output) forcibly when alarm cord output is selected in

C062)

00(Output frequency)/01(Output current) /02(Output torque)/

03(Digital output frequency)/04(Output voltage)/

05(Input electric power)/06(thermal load rate)/07(LAD frequency)

00(Output frequency)/01(Output current)/02(Output torque)/

04(Output voltage)/05(Input electric power)/06(thermal load rate)/

07(LAD frequency)

00(Output frequency)/01(Output current)/02(Output torque)/

04(Output voltage)/05(Input electric power)/

06(Thermal load rate)/07(LAD frequency)

00(NO)/01(NC)

00(NO)/01(NC)

00(NO)/01(NC)

00(NO)/01(NC)

00(NO)/01(NC)

00(NO)/01(NC)

01

00

03

07

08

05

00

00

C029

AMI selection

C031

C032

C033

C034

C035

C036

C072

C073

C074

C075

C078

Intelligent output 11 a/b

Intelligent output 12 a/b

Intelligent output 13 a/b

Intelligent output 14 a/b

Intelligent output 15 a/b

Alarm relay output a/b

Overload advance notice

signal output mode

Overload advance notice

level

Frequency arrival setting for

acceleration.

Arrival frequency setting for

deceleration.

PID deviation setting level

Frequency arrival setting for

acceleration 2.

Arrival frequency setting for

deceleration 2.

Over torque level setting

(Forward-driving)

Over torque level setting

(Reverse-regenerating)

Over torque level setting

(Reverse-driving)

Over torque level setting

(Forward-regenerating)

Thermal warning level

setting

Alarm code selection

Zero speed detection level

setting

Data command

Communicating transmission

speed

Communication code

Communication bit

Communication parity

Communication stop bit

Communication waiting time

C081

O adjustment

0.-9999./1000-6553(10000-65530)

C082

OI adjustment

0.-9999./1000-6553(10000-65530)

C083

O2 adjustment

0.-9999./1000-6553(10000-65530)

Setting on

forwarding

Setting on

forwarding

Setting on

forwarding

C085

C086

C087

Thermistor adjustment

AM offset adjustment

AMI adjustment

0.0 - 1000.

0.0 - 10.0(V)

0. - 255.

105.0

0.0

80

C088

AMI offset adjustment

0. - 20.0(mA)

Setting on

forwarding

C041

C042

C043

C044

C045

C046

C055

C056

C057

C058

C061

C062

C063

Communication

function adjustment

Intelligent input 1 a/b

(NO/NC) selection

Intelligent input 2 a/b

(NO/NC) selection

Intelligent input 3 a/b

(NO/NC) selection

Intelligent input 4 a/b

(NO/NC) selection

Intelligent input 5 a/b

(NO/NC) selection

Intelligent input 6 a/b

(NO/NC) selection

Intelligent input 7a/b

(NO/NC) selection

Intelligent input 8 a/b

(NO/NC) selection

Input FW a/b (NO/NC)

Selection

C021

C040

Analog meter setting

Function name

C070

C071

00

00

00

00

00

00

01

00(On accel. And decel, constant speed)/01(Only constant speed)

01

0.0-2.0*rated current(A)

Inverter

rated current

0.00-99.99/100.0-400.0(Hz)

0.00

0.00-99.99/100.0-400.0(Hz)

0.00

0.0-100.0(%)

3.0

0.00-99.99/100.0-400.0(Hz)

0.00

0.00-99.99/100.0-400.0(Hz)

0.00

0.-200.(%)

100.

0.-200.(%)

100.

0.-200.(%)

100.

0.-200.(%)

100.

0.-100.(%)

80.

00(Invalid)/01(3bit)/02(4bit)

00

0.00-99.99/100.(Hz)

0.00

02(operator)/03(RS485)/04(option1)/05(option2)

02(loop-back test)

03(2400bps)/04(4800bps)/05(9600bps)/06(19200bps)

1. -32.

7(7bit)/8(8bit)

00(no parity name)/01(even parity)/02(odd parity)

1(bit)/2(bit)

0.-1000.(ms)

02

1- 6

04

1.

7

00

1

0.

Note

Function mode

Code

RUN time/Power ON time level

0.-9999./1000-6553(10000-65530)hr

00(Reverse is valid)/01(Only forward)/02(Only reverse)

00(Start reduced voltage time small)-06(Start reduced voltage time large)

00(all display)/01(each function display)/02(User setting / main setting)

00(4 quadrant mode)/01(Terminal operation)/

02(Analog input)/03(Option1)/04(Option2)

0.

00

06

00

0.-200.(%)/no(Invalid)

150.

0.-200.(%)/no(Invalid)

150.

0.-200.(%)/no(Invalid)

150.

0.-200.(%)/no(Invalid)

150.

00(Invalid)/01(Valid)

00

00(Invalid)/01(Valid)

00

00(Invalid)/01(Valid)

00

0.0-1000.(V)

0.0

0.0-1000.(V)

0.0

0.01-99.99/100.0-999.9/1000.-3600.(s)

1.00

0.00-10.00(Hz)

0.00

0. - 255.

0. - 255.

0.10-9.99(Hz)

0.5-15.0(kHz) Derating enable,

00(Trip history clear)/01(Data initialization)/

02(Trip history clear + data initialization)

00(Interior)/01(EC)/02(USA)

180

60

0.50

5.0

01/02/00

0.1-99.9

1.0

00(valid)/01(invalid)

00

Operation direction restrict

Start reduced voltage

Display selection

b040

Torque limit mode selection

b080

b081

b082

b083

Torque limit level 1 setting

(Forward-driving at

4 quadrant mode)

Torque limit level 2 setting

(Reverse-regenerating at

4 quadrant mode)

Torque limit level 3 setting

(Reverse-driving at

4 quadrant mode)

Torque limit level 4 setting

(Forward-regenerating at

4 quadrant mode)

Torque LAD-STOP selection

Reverse run prevention

selection

Selection of non-stop

function at instantaneous

power failure

Start voltage of non-stop

function setting

OV LAD-STOP level of nonstop function setting

Deceleration time of nonstop function setting

Deceleration frequency width

of non-stop function setting

AM adjustment

FM adjustment

Start frequency adjustment

Carrier frequency setting

b084

Initialize mode

b085

b090

b091

Country code for initialization

Frequency scalar conversion

factor

STOP key enable

Resume on FRS cancellation

mode

BRD usage ratio

Stop mode selection

b092

Cooling fan control

b095

b096

b098

b099

b120

BRD selection

BRD ON level

Thermistor selection

Thermistor error level

Braking control selection

Waiting time for releasing

braking conformation

Waiting time for acceleration

Waiting time for stop

Waiting time for signal

conformation

Releasing frequency

b042

b043

b044

b045

b046

b050

b051

b052

The others

SJ300 Setting range

b034

b035

b036

b037

b041

b053

b054

b086

b087

b088

b121

b122

b123

b124

b125

Initial data

-FE/-FU/-F

Function name

00

0.0-100.0(%)

00(deceleration stop)/01(Free-run stop)

00(Always ON)/

01(ON during run, After power ON, then for 5 minutes on stop is implied.)

00(invalid)/01(valid<invalid during stop>)/02(valid<valid during stop>)

330-380/660-760(V)

00(invalid)/01(Positive temperature coefficient enable)/02 (NTC enable)

0. - 9999. (ohm)

00(Invalid)/01(valid)

0.0

00

00

360/720

00

3000.

00

0.00-5.00(s)

0.00

0.00-5.00(s)

0.00-5.00(s)

0.00

0.00

00

0.00-5.00(s)

0.00

0.00-99.99/100.0-400.0(Hz)

0.00

Rated

current of

inverter

00

00

b126

Releasing current

Debug mode selection

UP/DWN selection

0.00*rated current-2.00*rated current(A)

C102

Reset selection

C103

Reset f frequency matching

selection

C111

Overload

level

C121

O zero adjustment

C122

OI zero adjustment

0.-9999./1000-6553(10000-65530)

C123

O2 zero adjustment

0.-9999./1000-6553(10000-65530)

00(No display)/01(Display)

00(No frequency data)/01(Keep frequency data)

00(Trip cancel during ON)/01(Trip cancel during OFF)/

02(Valid only during trip<Cancel during ON>)

notice

00

00(0Hz start)/01(Start f-equaling)

C091

C101

advance

00

00

00(0Hz start)/01(Start f-equaling)

00

0.0-2.0*rated current(A)

Inverter

rated

current

0.-9999./1000-6553(10000-65530)

1- 7

Set on

forwarding

Set on

forwarding

Set on

forwarding

Note

Function mode

The others

Code

Function name

H001

Autotuning selection

H002

1st motor constant selection

H202

2nd motor constant selection

Initial data

-FE/-FU/-F

SJ300 Setting range

00(Invalid)/01(Valid(the motor does not rotate))/

02(Valid(the motor rotates))

00(Hitachi general purpose motor data)/01(Autotuning data)/

02(Autotuning data with online autotuning)

00(Hitachi general purpose motor data)/01(Autotuning data)/

02(Autotuning data with online autotuning)

00

00

00

H003

1 allowable motor selection

0.20-75.0(kW)

H203

2nd allowable motor selection

0.20-75.0(kW)

Set on

forwarding

Set on

forwarding

H004

H204

H005

H205

H006

H206

H306

1st motor pole selection

2nd motor pole selection

1st speed response setting

2nd speed response setting

1st stabilized factor

2nd stabilized factor

3rd stabilized factor

2/4/6/8(pole)

2/4/6/8(pole)

0.001-9.999/10.00-65.53

0.001-9.999/10.00-65.53

0. - 255.

0. - 255.

0. - 255.

4

4

1.590

1.590

100.

100.

100.

H020

1st motor constant R1

st

nd

0.000-9.999/10.00-65.53(ohm)

Set on

forwarding

Set on

forwarding

Set on

forwarding

Set on

forwarding

Set on

forwarding

Set on

forwarding

Set on

forwarding

Set on

forwarding

Set on

forwarding

Set on

forwarding

Set on

forwarding

0.000-9.999/10.00-65.53(ohm)

Set on

forwarding

0.000-9.999/10.00-65.53(ohm)

Set on

forwarding

0.000-9.999/10.00-65.53(ohm)

Set on

forwarding

0.00-99.99/100.0-655.3(mH)

Set on

forwarding

0.00-99.99/100.0-655.3(mH)

Set on

forwarding

0.00-99.99/100.0-655.3(A)

Set on

forwarding

0.000-9.999/10.00-65.53(ohm)

H220

2

motor constant R1

0.000-9.999/10.00-65.53(ohm)

H021

1st motor constant R2

0.000-9.999/10.00-65.53(ohm)

H221

2nd motor constant R2

0.000-9.999/10.00-65.53(ohm)

H022

1st motor constant L

0.00-99.99/100.0-655.3(mH)

H222

2nd motor constant L

0.00-99.99/100.0-655.3(mH)

H023

1st motor constant I 0

0.00-99.99/100.0-655.3(A)

H223

2nd motor constant I 0

0.00-99.99/100.0-655.3(A)

H024

1st motor constant J

0.001-9.999/10.00-99.99/100.0-9999.(kgm2 )

H224

2nd motor constant J

0.001-9.999/10.00-99.99/100.0-9999.(kgm2 )

H030

H230

H031

H231

H032

H232

H033

1st motor constant R1

(Autotuning data)

2nd motor constant R1

(Autotuning data)

1st motor constant R2

(Autotuning data)

2nd motor constant R2

(Autotuning data)

1st motor constant L

(Autotuning data)

2nd motor constant L

(Autotuning data)

1st motor constant I 0

(Autotuning data)

2nd motor constant I 0

(Autotuning data)

H034

1 motor constant J

0.001-9.999/10.00-99.99/100.0-9999.(kgm )

H234

2nd motor constant J

0.001-9.999/10.00-99.99/100.0-9999.(kgm2 )

Set on

forwarding

Set on

forwarding

Set on

forwarding

0.00-99.99/100.0-999.9/1000.(%)

100.0

0.00-99.99/100.0-999.9/1000.(%)

100.0

H233

st

0.00-99.99/100.0-655.3(A)

2

st

H050

H250

H051

H251

H052

H252

H060

H260

H070

H071

H072

1 PI-control proportion gain

setting

2nd PI-control proportion gain

setting

1st PI-control integration gain

setting

2nd PI-control integration gain

setting

1st P-control proportion gain

setting

2nd P-control proportion gain

setting

1st 0Hz-SLV limiter setting

2nd 0Hz-SLV limiter setting

PI-control proportion gain for

switching

PI-control integration gain for

switching

P-control proportion gain for

switching

0.00-99.99/100.0-999.9/1000.(%)

100.0

0.00-99.99/100.0-999.9/1000.(%)

100.0

0.01-10.00

1.00

0.01-10.00

1.00

0.-100.(%)

0.-100.(%)

100.

100.

0.00-99.99/100.0-999.9/1000.(%)

100.0

0.00-99.99/100.0-999.9/1000.(%)

100.0

0.00-10.00

1.00

1- 8

Note

Function mode

Code

U001

U002

U003

U004

U005

U006

U007

U008

U009

U010

U011

U012

User2 selection

User3 selection

User4 selection

User5 selection

User6 selection

User7 selection

User8 selection

User9 selection

User10 selection

User11 selection

User12 selection

P001

P002

P010

P011

P012

P013

P014

P015

P016

Option

P017

P018

P019

P020

P021

P022

P023

P025

P026

P027

P031

P032

User selection

Function name

Option1 operation selection

on error

Option2 operation selection

on error

Feed-back option selection

Encoder pulse number

setting

Control mode selection

Pulse train input mode

selection

Orientation stop position

setting

Orientation speed setting

Orientation direction

selection

Orientation completion range

setting

Orientation completion delay

time setting

Electronic gear position

selection

Electronic gear numerator of

ratio setting

Electronic gear denominator

of ratio setting

Position control feed-forward

gain setting

Position control loop gain

setting

Compensation of secondary

resistor selection

Over-speed detect level

setting

Speed-error over detect level

setting

Digital input option input

mode selection (Acc/Dec)

Stop position setting for

orientation

input

mode

selection

User1 selection

SJ300 Setting range

Initial data

-FE/-FU/-F

00(TRP)/01(RUN)

00

00(TRP)/01(RUN)

00

00(Invalid)/01(Valid)

00

128.-9999./1000-6500(10000-65000) (pulse)

1024

00(ASR mode)/01(APR mode)

00

00(Mode 0)/01(Mode 1)/02(Mode 2)/03(Mode 3)

00

0.-4095.

0.

0.00-99.99/100.0-120.0(Hz)

5.00

00(Forward)/01(Reverse)

00

0.-9999./1000(10000) (pulse)

5

0.00-9.99(s)

0.00

00(Feedback)/01(Reference)

00

0.-9999.

1.

0.-9999.

1.

0.00-99.99/100.0-655.3

0.00

0.00-99.99/100.0

0.50

00(Invalid)/01(Valid)

00

0.00-99.99/100.0-150.0(%)

135.0

0.00-99.99/100.0-120.0(Hz)

7.50

00(operator)/01(option1)/02(option2)

00

00(operator)/01(option1)/02(option2)

00

no/d001-P032

no

no/d001-P032

no/d001-P032

no/d001-P032

no/d001-P032

no/d001-P032

no/d001-P032

no/d001-P032

no/d001-P032

no/d001-P032

no/d001-P032

no/d001-P032

no

no

no

no

no

no

no

no

no

no

no

1- 9

Note

1.2.2 L300P

Monitor code

Display

code

d001

d002

d003

d004

L300P monitor or data range

(digital operator)

Function name

Output frequency

monitor

Output current

monitor

Operation direction

monitor

PID feedback

monitor

0.00-99.99/100.0-400.0(Hz)

-

0.0-999.9(A)

-

F(forward)/o(stop)/r(reverse)

-

0.00-99.99/100.0-999.9/1000. -9999. /

1000-9999/{100-{999 (10000-99900)

-

(Example) FW, terminal2, and 1: ON

Terminal 5, 4, 3 :OFF

ON

FW

d005

Initial

data

Intelligent input

terminal monitor

-

OFF

5 4

d006

(Example) Terminal2, 1:ON

AL :OFF

Intelligent output

terminal monitor

d013

d014

d016

d017

d080

Frequency

conversion monitor

Output voltage

monitor

Electric power

monitor

Accumulated time

monitor during RUN

Power ON time

monitor

Number of trip time

monitor

d081

Trip monitor 1

d082

Trip monitor 2

d083

Trip monitor 3

d084

Trip monitor 4

d085

Trip monitor 5

d086

Trip monitor 6

d090

1

ON

AL

d007

3 2

12

OFF

11

0.00-99.99/100.0-999.9/1000. –9999. /

1000-3996

-

0.0-600.0

-

V

0.0-999.9 kW

-

0.-9999./1000-9999/{100-{999 hr

-

0.-9999./1000-9999/{100-{999 hr

-

0.-9999./1000-6553(10000-65530) (time)

-

Trip Code, frequency(Hz), current(A),

voltage(V),RUN time(hr) power ON time(hr)

Trip Code, frequency(Hz), current(A),

voltage(V),RUN time(hr) power ON time(hr)

Trip Code, frequency(Hz), current(A),

voltage(V),RUN time(hr) power ON time(hr)

Trip Code, frequency(Hz), current(A),

voltage(V),RUN time(hr) power ON time(hr)

Trip Code, frequency(Hz), current(A),

voltage(V),RUN time(hr) power ON time(hr)

Trip Code, frequency(Hz), current(A),

voltage(V),RUN time(hr) power ON time(hr)

Warning code

0.0, starting frequency-Max. frequency

(2 nd max. frequency)(Hz)

0.01-99.99/100.0-999.9/1000.-3600.(s)

0.01-99.99/100.0-999.9/1000. -3600. (s)

0.01-99.99/100.0-999.9/1000. -3600. (s)

0.01-99.99/100.0-999.9/1000. -3600. (s)

-

Warning monitor

Output

frequency

0.00

F001

setting

st

F002 1 acceleration time

30.00

F202 2 nd acceleration time

30.00

F003 1 st deceleration time

30.00

F203 2 nd deceleration time

30.00

Operation direction

F004

00(forward)/01(reverse)

00

selection

(Note1) Change mode during run by selection of b031 (software lock selection).

(Note2) Do not forget to press “STR” key when you change the display.

1 -10

Note

Function Mode

L300P Setting range

Initial data

-FE/-FU/-FR

Frequency setting selection

00(VR)/01(terminal)/02(operator)/03(RS485)/

04(option1)/05(option2)

01/01/00

A002

Operation setting selection

01(terminal)/02(operator)/03(RS485)/04(option1)/05(option2)

01/01/02

A003

Base frequency

30. - Maximum. frequency(Hz)

50./60./60.

A203

Base frequency, 2nd motor

30. - 2 nd Maximum. frequency (Hz)

50./60./60.

A004

Maximum frequency

30. - 400. (Hz)

50./60./60.

A204

Maximum frequency, 2nd

motor

30. - 400. (Hz)

50./60./60.

A005

AT terminal selection

00( Changing of O and OI with AT terminal)/01(Changing of O and O2

with AT terminal)

00

00(single)/01(auxiliary speed of O, OI) [no reversible]

/02(auxiliary speed of O, OI [reversible]

00

Code

Direct current braking

V/f characteristic

Multistage speed,jogging frequency setting

Analog input setting

Base setting

A001

A006

Function name

02 selection

A011

0 start

0.00-99.99/100.0-400.0 (Hz)

0.00

A012

0 end

0.00-99.99/100.0-400.0 (Hz)

0.00

A013

0 start rate

0.-100.0 (%)

0.

A014

0 end rate

0.-100.0(%)

100.

A015

0 start selection

00 (external starting frequency)/01(OHz)

01

A016

O, OI, O2 sampling

A019

Multi-speed selection

A020

Multi-speed 0

A220

Multi-speed 0, 2 nd motor

A021

1.-30.(times)

8.

00(binary : range is to 16 stage speed with 4 terminals)/01(bit : range

is to 6 stage speed with 5 terminals)

00

0.00, starting frequency-maximum. frequency(Hz)

0.00

0.00, starting frequency-2 nd maximum frequency(Hz)

0.00

Multi-speed1

0.00, starting frequency-maximum frequency(Hz)

0.00

A022

Multi-speed2

0.00, starting frequency-maximum frequency(Hz)

0.00

A023

Multi-speed3

0.00, starting frequency-maximum frequency(Hz)

0.00

A024

Multi-speed4

0.00, starting frequency-maximum frequency(Hz)

0.00

A025

Multi-speed5

0.00, starting frequency-maximum frequency(Hz)

0.00

A026

Multi-speed6

0.00, starting frequency-maximum frequency(Hz)

0.00

A027

Multi-speed7

0.00, starting frequency-maximum frequency(Hz)

0.00

A028

Multi-speed8

0.00, starting frequency-maximum frequency(Hz)

0.00

A029

Multi-speed9

0.00, starting frequency-maximum frequency(Hz)

0.00

A030

Multi-speed10

0.00, starting frequency-maximum frequency(Hz)

0.00

A031

Multi-speed11

0.00, starting frequency-maximum frequency(Hz)

0.00

A032

Multi-speed12

0.00, starting frequency-maximum frequency(Hz)

0.00

A033

Multi-speed13

0.00, starting frequency-maximum frequency(Hz)

0.00

A034

Multi-speed14

0.00, starting frequency-maximum frequency(Hz)

0.00

A035

Multi-speed15

0.00, starting frequency-maximum frequency(Hz)

0.00

A038

Jogging frequency

0.00, starting frequency-9.99(Hz)

1.00

A039

Jogging selection

00(free-run on JG stop / invalid on running) / 01(stop decelerating on

JG stop / invalid on running) / 02(DC braking on JG stop/invalid on

running) / 03(free-run on JG stop/valid on running[JG after stop

decelerating]) / 04 (stop decelerating on JG stop/valid on running) /

05 (DC braking on JG stop/valid on operating)

00

A041

Torque boost selection

00 (manual torque boost) / 01 (automatic torque boost)

00

A241

Torque

motor

00 (manual torque boost) / 01 (automatic torque boost)

00

1.0

boost

selection,

2 nd

A042

Manual torque boost

0.0-20.0(%)

A242

Manual torque boost, 2 nd motor

0.0-20.0(%)

1.0

A043

Manual torque boost point

0.0-50.0(%)

5.0

A243

Manual torque boost point, 2 nd

motor

0.0-50.0(%)

5.0

00

st

A044

1 control

00/(VC)/01(VP1.7power)/02(free V/f setting)

A244

2 nd control

00/(VC)/01(VP1.7power)/02(free V/f setting)

00

A045

Output voltage gain

20. - 100. (%)

100.

A051

DC braking selection

00(invalid)/01(valid)

00

A052

DC braking frequency

0.00-60.00(Hz)

0.50

A053

DC braking wait time

0.0 - 5.0(s)

0.0

A054

DC braking power

0. - 70. (%)

0.

A055

DC braking time

0.0 - 60.0(s)

0.0

A056

DC braking edge/level

selection

00(edge action)/01(level action)

01

A057

DC braking power

(starting time)

0. - 70. (%)

0.

A058

DC braking time

(starting time)

0.00-60.0(s)

0.0

A059

DC carrier frequency

0.5-12(kHz) Derating

3.0

1- 11

No t e

Function Mode

Instantaneous power failure

restart

Accel External frequency

Decel adjustment

Operation mode/ adjustable function

AVR PID control

Upper and lower limiter / jump

frequency

Code

L300P Setting range

1 s t frequency upper limiter

2 nd frequency upper limiter

A062

A262

A063

A064

A065

A066

A067

A068

A069

A070

A071

A072

A073

A074

A075

A076

A081

1 s t frequency lower limiter

2 nd frequency lower limiter

Jump frequency1

Jump frequency Width 1

Jump frequency2

Jump frequency Width 2

Jump frequency3

Jump frequency Width 3

Acceleration stop frequency

Acceleration stop time

PID selection

PID-P gain

PID-I gain

PID-D gain

PID scale

PID feedback selection

AVR selection

A082

Motor voltage selection

200/215/220/230/240, 380/400/415/440/460/480

A085

Operation mode selection

Energy-saving responseaccuracy adjustment

Acceleration time2

2 nd acceleration time2

Deceleration time2

2 nd deceleration time2

2 nd stage adjustable selection

2 nd stage adjustable

selection(2 nd motor)

2 nd acceleration frequency

2 nd acceleration

frequency(2 nd motor)

2 nd deceleration frequency

2 nd deceleration frequency

(2 nd motor)

Acceleration pattern selection

Deceleration pattern selection

OI start

OI end

OI start rate

OI end rate

OI start selection

O2 start

O2 end

O2 start rate

O2 end rate

Acceleration curve constant

00(normal operation)/01(energy-saving operation)

A086

A092

A292

A093

A293

A094

A294

A095

A295

A096

A296

A097

A098

A101

A102

A103

A104

A105

A111

A112

A113

A114

A131

A132

Deceleration curve constant

b001

Retry selection

0.00, 1 s t frequency lower limiter-maximum frequency(Hz)

0.00, 2 nd frequency lower limiter-2 nd setting maximum

frequency(Hz)

0.00, start frequency-maximum frequency(Hz)

0.00, start frequency-2 nd setting maximum frequency(Hz)

0.00-99.99/100.0-400.0(Hz)

0.00-10.00(Hz)

0.00-99.99/100.0-400.0(Hz)

0.00-10.00(Hz)

0.00-99.99/100.0-400.0(Hz)

0.00-10.00(Hz)

0.00-99.99/100.0-400.0(Hz)

0.00-60.0(s)

00(invalid)/01(valid)

0.2-5.0

0.0-3600.(s)

0.00-100.0(s)

0.01-99.99

00(feedback : OI)/01(feedback : O)

00(ON always)/01(OFF always)/02(OFF on decelerating)

50.0

15.00

15.00

15.00

15.00

00

00(change with 2CH terminal)/01(change with setting)

00

0.00-99.99/100.0-400.0(Hz)

0.00

0.00-99.99/100.0-400.0(Hz)

0.00

0.00-99.99/100.0-400.0(Hz)

0.00

0.00-99.99/100.0-400.0(Hz)

0.00

00(straight line)/01(S-curve)/02(U-curve)/03(reverse U-curve)

00(straight line)/01(S-curve)/02(U-curve)/03(reverse U-curve)

0.00-99.99/100.0-400.0(Hz)

0.00-99.99/100.0-400.0(Hz)

0.-100. (%)

0.-100. (%)

00(external start frequency)/01(0Hz)

-400.--100./-99.9-0.00-99.9/100.-400.(Hz)

-400.--100./-99.9-0.00-99.9/100.-400.(Hz)

-100. - 100. (%)

-100. - 100. (%)

01(small swelling)-10(large swelling)

00

00

0.00

0.00

20.

100.

01

0.00

0.00

-100.

100.

02

01(small swelling-10(large swelling)

00(trip)/01(0Hz start)/02(start after equal frequency)/

03(trip after equaling frequency and deceleration stop)

02

0.3-1.0(s)

1.0

0.3-100.(s)

1.0

00(invalid/01(valid)/

02(invalid during stop and deceleration by stop command)

00

b012

Electronic thermal level

0.2*constant current-1.20*constant current(A)

b212

Electronic thermal level

(2 nd motor)

0.2*constant current-1.20*constant current(A)

b004

b005

b213

b015

b016

b017

b018

b019

b020

Electronic thermal

characteristic selection

Electronic thermal

characteristic selection

(2 nd motor)

Free electronic thermal

frequency 1

Free electronic thermal

current 1

Free electronic thermal

frequency 2

Free electronic thermal

current 2

Free electronic thermal

frequency 3

Free electronic thermal

current 3

0.00

0.00

0.00

0.00

0.50

0.00

0.50

0.00

0.50

0.00

0.0

00

1.0

1.0

0.00

1.00

00

02

(230/400)

(230/460)

(200/400)

00

0.0-100.0

b006

b007

b003

Initial data

-FE/-FU/-FR

0.00

0.01-99.99/100.0-999.9/1000.-3600.(s)

0.01-99.99/100.0-999.9/1000.-3600.(s)

0.01-99.99/100.0-999.9/1000.-3600.(s)

0.01-99.99/100.0-999.9/1000.-3600.(s)

00(change with 2CH terminal)/01(change with setting)

Allowable under-voltage

power failure time

Retry wait time

Instantaneous powerfailure/under-voltage trip

during stop

Instantaneous powerfailure/under-voltage

retry time selection

Open-phase selection

Frequency setting to match

b002

b013

Electronic thermal

Function name

A061

A261

00(16 times)/01(free)

00(invalid)/01(valid)

0.00-99.99/100.0-400.0(Hz)

00

00

00

0.00

Rated

Current of

inverter

Rated

Current of

inverter

00/(reduced characteristic)01(constant torque characteristic)/

02(free setting)

01/01/00

00/(reduced characteristic)01(constant torque characteristic)/

02(free setting)

01/01/00

0.-400.(Hz)

0.

0.0-1000.(A)

0.0

0.-400.(Hz)

0.

0.0-1000. (A)

0.0

0.-400.(Hz)

0.

0.0-1000.(A)

0.0

1- 12

N ot e

Function Mode

Intelligent input terminal setting

Free V/f setting

Lock

Overload limit

Code

Input terminal setting

intelligent

Intelligent output terminal setting

Initial data

-FE/-FU/-FR

01

b022

Overload restriction level

0.50* rated current-1.50* rated current(A)

Rated

current of

inverter

x 1.20

Overload restriction limit

constant

Overload restriction 2

selection

0.10-30.00(s)

1.00

00(invalid)/01(valid on acceleration / constant speed)/02(valid on

constant speed)

01

0.50*rated current-1.50*rated current(A)

Rated

current of

inverter

x1.20

0.10-30.00(s)

1.00

b023

b024

b025

Overload restriction level 2

b026

Overload restriction

constant 2

b031

Software lock mode

selection

b100

b101

b102

b103

b104

b105

b106

b107

b108

b109

b110

b111

b112

b113

Free

Free

Free

Free

Free

Free

Free

Free

Free

Free

Free

Free

Free

Free

C001

Intelligent input 1 setting

C002

Intelligent input 2 setting

C003

Intelligent input 3 setting

C004

Intelligent input 4 setting

C005

C012

C013

C014

C015

C019

Output level setting

L300P Setting range

00(invalid)/01(enabled on acceleration / constant speed)/02(enabled

on constant speed)

b021

C011

Output terminal state setting,

Function name

Overload restriction

selection

V/f

V/f

V/f

V/f

V/f

V/f

V/f

V/f

V/f

V/f

V/f

V/f

V/f

V/f

frequency

voltage 1

frequency

voltage 2

frequency

voltage 3

frequency

voltage 4

frequency

voltage 5

frequency

voltage 6

frequency

voltage 7

1

2

3

4

5

6

7

Intelligent input 5 setting

Intelligent input1 a/b

(NO/NC) selection

Intelligent input2 a/b

(NO/NC) selection

Intelligent input3 a/b

(NO/NC) selection

Intelligent input4 a/b

(NO/NC) selection

Intelligent input5 a/b

(NO/NC) selection

Input FW a/b (NO/NC)

Selection

C021

Intelligent output 11 setting

C022

Intelligent output 12 setting

C026

Alarm relay output

C027

FM selection

C028

AM selection

C029

AMI selection

C031

C032

C036

Intelligent output 11 a/b

Intelligent output 12 a/b

Alarm relay output a/b

Overload advance notice

signal output mode

Overload advance notice

level

Frequency arrival setting

for acceleration.

Arrival frequency setting for

deceleration.

PID deviation setting level

C040

C041

C042

C043

C044

00(impossible to change the data except this item when SFT terminal

is ON)/01(impossible to change the data except setting frequency

item when SFT terminal is ON)/02(impossible to change the data

except this item)/03(impossible to change the data except setting

frequency item)/10(possible to change data on operating)

0.- Free V/f frequency2(Hz)

0.-800.0(V)

0.- Free V/f frequency3(Hz)

0.-800.0(V)

0.- Free V/f frequency4(Hz)

0.-800.0(V)

0.- Free V/f frequency5(Hz)

0.-800.0(V)

0.- Free V/f frequency6(Hz)

0.-800.0(V)

0.- Free V/f frequency7(Hz)

0.-800.0(V)

0.-400.(Hz)

0.-800.0(V)

01/(RV:Reverse is valid)/02(CF1:Multi-speed1)/ 03(CF2:Multi-speed2)/

04(CF3:Multi-speed3)/ 05(CF4:Multi-speed4)/ 06(JG:Jogging)/

07(DB:External DC braking)/08(SET:2 nd control)/

09(2CH:two-stage adjustable speed)/11(FRS:Free-run)/

12(EXT:External trip)/13(USP:Unattended start protection)/

14(CS:commercial change)/15(SFT:software lock)/

16(AT:Analog input voltage/current select)/18(RS:Reset inverter)/

20(STA:3wire run)/ 21(STP:3wire keep)/22(F/R:3wire forward/reverse)/

23(PID:PID selection valid/invalid)/24(PIDC:PID integrating reset)/

27(UP:Remote control UP function)/

28(DWN:Remote control DOWN function)/

29(UDC:Remote control data clear)/31(OPE:Force operate ope)/

32(SF1:Multi-speed bit1)/

33(SF2:Multi-speed bit2)/34(SF3:Multi-speed bit3)/

35(SF4:Multi-speed bit4)/36(SF5:Multi speed bit5)/

37(SF6:Multi-speed bit6)/38(SF7:Multi-speed bit7)/

39(OLR:Overload restriction change)/no(NO:No assign)

00(NO)/01(NC)

01

0.

0.0

0.

0.0

0.

0.0

0.

0.0

0.

0.0

0.

0.0

0.

0.0

18

16

03/13/03

02

01

00

00(NO)/01(NC)

00

00(NO)/01(NC)

00/01/00

00(NO)/01(NC)

00

00(NO)/01(NC)

00

00(NO)/01(NC)

00

00(RUN:running)/01(FA1:Frequency arrivaltype1 signal)/

02(FA2:frequency arrival type2 signal)/03(OL:Overload advance

notice signal)/04(OD:Output deviation for PID control)/05(AL:Alarm

signal)/06(FA3:Only setting frequency)/08(IP:On instantaneous stop/

09(UV:Under voltage)/11(RNT:RUN time over)/12(ONT:ON time

over)/

00(Output frequency)/01(Output current) /

03(Digital output frequency)/04(Output voltage)/

05(Input electric power)/06(thermal load rate)/07(LAD frequency)

00(Output frequency)/01(Output current)/04(Output voltage)/

05(Input electric power)/06(thermal load rate)/07(LAD frequency)

00(Output frequency)/01(Output current)/04(Output voltage)/

05(Input electric power)/06(Thermal load rate)/07(LAD frequency)

00(NO)/01(NC)

00(NO)/01(NC)

00(NO)/01(NC)

01

00

05

00

00

00

00

00

01

00(On accel. And decel, constant speed)/01(Only constant speed)

01

0.0-2.0*rated current(A)

Inverter

rated current

0.00-99.99/100.0-400.0(Hz)

0.00

0.00-99.99/100.0-400.0(Hz)

0.00

0.0-100.0(%)

3.0

1- 13

N ot e

Function Mode

Code

C070

Communication

Analog meter setting function

C071

C072

C073

C074

C075

C078

L300P Setting range

02(operator)/03(RS485)/04(option1)/05(option2)

02(loop-back test)/03(2400bps)/04(4800bps)/

05(9600bps)/06(19200bps)

1. -32.

7(7bit)/8(8bit)

00(no parity name)/01(even parity)/02(odd parity)

1(bit)/2(bit)

Initial data

-FE/-FU/-FR

02

04

1.

7

00

1

0.-1000.(ms)

0.

0.-9999./1000-6553(10000-65530)

0.-9999./1000-6553(10000-65530)

Setting on

forwarding

Setting on

forwarding

Setting on

forwarding

Thermistor adjustment

AM offset adjustment

AMI adjustment

0.0 - 1000.

0.0 - 10.0(V)

0. - 255.

105.0

0.0

80

C088

AMI offset adjustment

0. - 20.0(mA)

Setting on

forwarding

b034

RUN time/Power ON time

level

b035

Operation direction restrict

b036

Start reduced voltage

b037

Display selection

b080

b081

b082

b083

AM adjustment

FM adjustment

Start frequency adjustment

Carrier frequency setting

b084

Initialize mode

C081

O adjustment

C082

OI adjustment

0.-9999./1000-6553(10000-65530)

C083

O2 adjustment

C085

C086

C087

b085

b086

b087

b088

b090

b091

The others

Function name

Data command

Communicating

transmission speed

Communication code

Communication bit

Communication parity

Communication stop bit

Communication waiting

time

Country code for

initialization

Frequency scalar

conversion factor

STOP key enable

Resume on FRS

cancellation mode

BRD usage ratio

Stop mode selection

0.-9999./1000-6553(10000-65530)hr

0.

00(Reverse is valid)/01(Only forward)/02(Only reverse)

00(Start reduced voltage time small)

-06(Start reduced voltage time large)

00(all display)/01(each function display)/

02(User setting / main setting)

0. - 255.

0. - 255.

0.10-9.99(Hz)

0.5-12.0(kHz) Derating enable,

00(Trip history clear)/01(Data initialization)/

02(Trip history clear + data initialization)

00

0.1-99.9

1.0

00(valid)/01(invalid)

00

00(0Hz start)/01(Start f-equaling)

00

0.0-100.0(%)

00(deceleration stop)/01(Free-run stop)

00(Always ON)/01(ON during run, After power ON, then for 5 minutes

on stop is implied.)

00(invalid)/01(valid<invalid during stop>)/

02(valid<valid during stop>)

330-380/660-760(V)

00(invalid)/01(Positive temperature coefficient enable)/

02 (NTC enable)

0. – 9999. (ohm)

0. – 100. (%)

00(No display)/01(Display)

00(No frequency data)/01(Keep frequency data)

00(Trip cancel during ON)/01(Trip cancel during OFF)/

02(Valid only during trip<Cancel during ON>)

0.0

00

Cooling fan control

BRD selection

b096

BRD ON level

b098

Thermistor selection

b099

C061

C091

C101

Thermistor error level

Thermal warning level

Debug mode selection

UP/DWN selection

C102

Reset selection

C103

Reset f frequency matching

selection

00(0Hz start)/01(Start f-equaling)

C121

O zero adjustment

0.-9999./1000-6553(10000-65530)

C122

OI zero adjustment

0.-9999./1000-6553(10000-65530)

C123

O2 zero adjustment

0.-9999./1000-6553(10000-65530)

H203

H004

H204

H006

H206

P001

P002

P031

U001

U002

U003

U004

U005

U006

U007

U008

U009

U010

U011

U012

00

01/02/00

b095

H003

00

180

60

0.50

3.0

00(Interior)/01(EC)/02(USA)

b092

1 s t allowable motor

selection

2 nd allowable motor

selection

1 s t motor pole selection

2 nd motor pole selection

1 s t stabilized factor

2 nd stabilized factor

Option1 operation selection

on error

Option2 operation selection

on error

Digital input option input

mode selection(Acc/Dec)

User1 selection

User2 selection

User3 selection

User4 selection

User5 selection

User6 selection

User7 selection

User8 selection

User9 selection

User10 selection

User11 selection

User12 selection

06

00

00

360/720

00

3000.

80

00

00

00

00

0.20-75.0(kW)

Set on

forwarding

Set on

forwarding

Set on

forwarding

Set on

forwarding

0.20-75.0(kW)

Set on

forwarding

2/4/6/8(pole)

2/4/6/8(pole)

0. - 255.

0. - 255.

4

4

100.

100.

00(TRP)/01(RUN)

00

00(TRP)/01(RUN)

00

00(operation)/01(option1)/02(option2)

00

no/d001-P031

no/d001-P031

no/d001-P031

no/d001-P031

no/d001-P031

no/d001-P031

no/d001-P031

no/d001-P031

no/d001-P031

no/d001-P031

no/d001-P031

no/d001-P031

no

no

no

no

no

no

no

no

no

no

no

no

1- 14

N ot e

2. TROUBLE SHOOTING

2.1 Inverter trip contents, remedy, advice

Trip

contents

It’s one of INV failure by locked

motor, fast ACC/DEC because big

current will be flown.

By over current detection, INV will

shut the output by the hardware.

This detection will be done by AC

CT.

Over current detection at

output stage

Digital

operator

display

While

constant

speed

While

Over voltage detection

after BRD %ED was run

out

Over voltage detection (DC

bus voltage)

EEPROM (contradiction)

Under voltage(DC

voltage)

bus

CT offset

CPU(micro processor misoperation)

External(customer’s

selection)

USP(US version default or

customer’s selection)

Ground default at power on

at output stage

Incoming

detection

over

voltage

Instant

power

detection

failure

Load changed rapidly.

Short circuit or earth contact (ground

fault) in the motor or the motor cable.

If fast deceleration is happening

preset Decel time longer

deceleration

Over current will be detected about

200% of rated level on SJ300.

Over current will be detected about

150% of rated level on L300-p.

While

acceleration

others

Over load detection at

output stage(with motor)

Remedy, advice

INV is monitoring the output current, if the connected

motor was overload conditions, INV will detect the

overload, if the level was exceeded preset level, INV

will shut the output.

(E-thermal characteristic has deleting characteristic by

the output freq. If the freq. Is less than 5Hz, it has more

chance to have the trip.

Over current will be detected about 200% of rated level

on SJ300.

If the load has big inertia moment, while ACC, there is a

possibility to disturb the ACC by the detection.

In this case, adjust torque boost if v/f control is

selected.

This detection is over voltage detection, but the

condition is different from the normal over voltage trip.

The difference is below. If the preset BRD %ED

level(d090) was run out, BRD circuit can not work and if

DC bus voltage will detect the over voltage level, INV

will shut the output.

If DC bus voltage is exceeded specific level by

generating energy from the connected motor, high

incoming AC voltage, INV will shut the output.

The DC bus voltage level is

About 400VDC (200V class)

About 800VDC (400V class)

INV uses EEPROM to preset parameters, if the

EEPROM was affected by external noise, abnormal

heat, micro processor will detect the contradiction such

as sum check , INV will shut the output.

If DC bus voltage is low, INV can’t work properly

especially control circuit, in this case, INV will shut the

output.

The DC bus voltage level is

About 200VDC or less(200V class)

About 400VDC or less(400V class)

INV uses CT to detect motor current, if the CT outputs

unusual offset level while INV stop, INV will shut the

output.

The voltage level is about 0.6V or more.

If built in Micro processor works improper, if it detects

failure, INV will shut the output.

If the intelligent terminal detects the input signal from

external devices, INV will shut the output. This

function/trip is customer’s selection. If EXT function is

not selected, there is no chance to have the trip.

If INV is ready to start at power on, INV will shut the

output. This function/trip is customer’s selection. If USP

function is not selected, there is no chance to have the

trip.

Only at power on, INV will detect ground fault between

INV and the connected motor, INV will shut the output.

If the motor remaining voltage exists, this detection

doesn’t work.

If DC bus voltage is continuously exceeding specific

level more than 30 sec, INV will shut the output.

The DC bus voltage level is

About 380VDC or above (200V class)

About 760VDC or above (400V class)

If Instant power failure 15ms or more happened, INV

will shut the output. If the instant power failure is longer

than preset allowable time or affordable control supply

voltage time, INV will work as normal power off. This

2- 1

If fast acceleration is happening

preset Accel time longer

Any motor locked, check the wires

High preset torque boost, reduce the

value

Is the preset DC injection brake level

high

Any CT malfunction, any noise

Too heavy load

Thermal level proper ?

Perform above adjustment referring

to d104, to reduce the electronic

thermal level.

Any fast decel

Busy running cycle

Preset BRD%ED proper ? low ?

Perform above adjustment referring

to d103, to reduce the BRD usage

ratio.

Any fast decel

Earth contact (ground fault) in the

motor or the motor cable.

Any back energy from the load

Perform above adjustment referring

to d102, so that the DC bus voltage

does not exceed the trip level.

Any big noise near the INV

Ambient temp. is too high.

Any incoming AC V drop

Sufficient power capacity

Any thyristor failure

Perform above adjustment referring

to d102, so that the DC bus voltage

does not exceed the trip level.

Any high offset signal of the CT

Any big noise near the INV

Micro processor failure

Check the configuration,

wiring, conditions

signal,

Check the configuration,

wiring, conditions

signal,

Earth contact (ground fault) in the

motor or the motor cable.,

IGBT

failure

Any high incoming voltage except

deceleration

implement input ACL

Any incoming AC V drop

No contact failure in MCB,Mg?

Over heat detection

Gate array(INV domestic

problem)

Input

phase

detection

failure

IGBT

over

current

detection (equivalent as

power module)

Thermister(customer’s

selection)

means INV will re-start with the run command after the

long instant power failure.

If main circuit temp. was exceeded specific level such

as high ambient temp., fan failure, INV will shut the

output.

The temp. is detected at heat sink over 100 Celsius.

If there was any communication error between micro

processor and gate array, or if gate array can’t detect

IGBT’s turn on/off such as IGBT failure.

If one of incoming 3 phase voltage was missed, INV will

shut the output if the detect function was preset.

The detection delay is about 1 sec.

If instant over current happened between INV and the

connected motor, INV will shut the output.

Under this INV trip, the detected phase is possible to

refer at d105 display.

Even retry function is preset, INV can not retry after this

detection.

If motor over temp. happened by integrated thermistor’s

resistor value in the motor, INV will shut the output.

Option board 1 error 0–9

After INV output brake release signal, INV couldn’t

detect brake on/off within b124(waiting time for brake

operation. (if b120(brake control switch) was preset

“01”)

Detection of connected option card 1. For more details,

refer to the instruction manual of the card.

Option boad 2 error 0-9

Detection of connected option card 2. For more details,