Download SJ200 & L200 Service Manual NBS650XR

Transcript

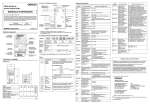

HITACHI INVERTER

SJ200/L200 Series

SERVICE MANUAL

(ADJUSTMENT AND MAINTENANCE)

Model:

European Version

SJ200/L200-002NFE(F) to SJ200/L200-022NFE(F)

SJ200/L200-004HFE(F) to SJ200/L200-075HFE(F)

US Version

SJ200/L200-002NFU to SJ200/L200-022NFU

SJ200/L200-037LFU to SJ200/L200-075LFU

SJ200/L200-004HFU to SJ200/L200-075HFU

After reading this manual, keep it at hand for future reference

NBS650X

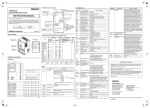

Appearance and name of each parts

SJ200-002 - 007LFR

SJ200-015 - 037LFR

SJ200-004 - 037HFR

potentiometer

digital operator

digital operator

front cover

potentiometer

front cover

top cover

top cover

housing

housing

cooling fin

cooling fin

rear cover

rear cover

ground

ground

The front cover can be removed without any instruments. When you remove the front cover, you can

set the mode switch and set wire at the control-terminal, the main-terminal and the intelligent relay

output terminal.

control-terminal A

control-terminal A

(TM1C)

(TM1C)

control-terminal B

(TM2C)

control-terminal B

(TM2C)

upper cover

intelligent relay

output terminal

intelligent relay

output terminal

main terminal

main terminal

Note: The upper cover is for maintenance.

Please do not remove.

1-2

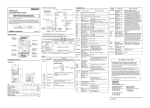

SJ200-055~075LFR

SJ200-055~075HFR

volume

digital operator

front cover

top cover

housing

rear cover

case

cooling fin

The front cover can be removed without any instruments When you remove the front cover, you can set

the mode switch and set wire at the control-terminal, the main-terminal and the intelligent relay output

terminal.

intelligent relay output terminal

control-terminal A

control-terminal B

main terminal

1-4

knob of potentiometer

Note:The knob can be taken.

digital operator

communication connector for operator

and RS-485

connector of

digital operator

POWER light

ALARM light

RUN light

control-terminal A

control-terminal B

intelligent relay output

terminal

input logic switch

main-terminal

turning switch RS-485/Operator

turning switch of frequency source and

run command source

1-3

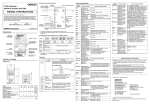

L200-002~007LFR

L200-015~037LFR

L200-004~037HFR

connector cover

volume

digital operator

digital operator

front cover

connector cover

volume

front cover

top cover

top cover

housing

housing

rear cover

cooling fin

rear cover

cooling fin

ground

ground

The front cover can be removed without any instruments. When you remove the front cover, you can set the mode

switch and set wire at the control-terminal, the main-terminal and the intelligent relay、output terminal.

control-terminal

control-terminal

intelligent relay

output terminal

upper cover

intelligent relay

output terminal

main terminal

main terminal

Note: The upper cover is for maintenance.

Please do not remove.

1-6

L200-055~075LFR

L200-055~075HFR

volume

digital operator

front cover

top cover

housing

rear cover

case

cooling fin

The front cover can be removed without any instruments. When you remove the front cover,

you can set the mode switch and set wire at the control-terminal, the main-terminal and the

intelligent relay output terminal.

intelligent relay output

terminal

control-terminal

main-terminal

1-7

(L200)

The way to open the connector cover

Removing the volume

volume

The volume can be removed

communication

connector

L200-002~007LFR type

L200-002~007LFR type

Items inside frontcover

L200-002~007LFR type

mode switch

control-terminal

intelligent relay output terminal

input logic switch

main terminal

turning switch RS-485/

Operator

turning switch frequency source/

run command source

1-8

Appearance

The appearance of SJ200 follows below.

OPE

I/O PCB (PCB3)

Power PCB (PCB2)

Core PCB (PCB1)

IGBT / DM

OPE is a control unit.

Formally OPE is attached to SJ200.

But another OPE can be used optionally.

This part is a logic circuit.

It has a microcomputer,

which does calculation of the

intelligent input, output, communication task

and so on

This part is a power circuit.

It has a translator

This part is a core circuit.

It has a microcomputer , which manages INV main

function.

IGBT / DM. is a transistor unit for outputting to the

motor. It depends on the capacity and the voltage class

whether IGBT or DM is used.

1-4

1-1

Introduction

Getting Started

Inverter Specifications Label

The Hitachi SJ200 inverters have product labels located on the right side of the housing,

as pictured below. Be sure to verify that the specifications on the labels match your

power source, motor, and application safety requirements.

Specifications label

Inverter model number

Motor capacity for this model

Power Input Rating:

frequency, voltage, phase, current

Output Rating:

Frequency, voltage, current

Manufacturing codes:

Lot number, date, etc.

Model Number Convention

The model number for a specific inverter contains useful information about its operating

characteristics. Refer to the model number legend below:

SJ200

037

H

F

E

F

EMC filter

Restricted distribution:

E=Europe, U=USA, R=Japan

Series name

Configuration type

F = with digital operator (keypad)

Input voltage:

N = single or three-phase 200V class

H = three-phase 400V class

L = three phase only, 200V class

Applicable motor capacity in kW

022 = 2.2 kW

002 = 0.2 kW

030 = 3.0 kW

004 = 0.4 kW

037 = 3.7 kW

005 = 0.55 kW

040 = 4.0 kW

007 = 0.75 kW

055 = 5.5 kW

011 = 1.1 kW

075 = 7.5 kW

015 = 1.5 kW

2–2

Orientation to Inverter Features

Orientation to Inverter Features

Unpacking and Inspection

Please take a few moments to unpack your new SJ200 inverter and perform these steps:

1. Look for any damage that may have occurred during shipping.

2. Verify the contents of the box include:

a. One SJ200 inverter

Inverter Mounting

and Installation

b. One Instruction Manual

c. One SJ200 Quick Reference Guide

3. Inspect the specifications label on the side of the inverter. Make sure it matches the

product part number you ordered.

Main Physical Features

The SJ200 Series inverters vary in size according to the current output rating and motor size

for each model number. All feature the same

basic keypad and connector interface for consistent ease of use. The inverter construction has a

heat sink at the back of the housing. The larger

models include a fan(s) to enhance heat sink

performance. The mounting holes are predrilled in the heat sink for your convenience.

Smaller models have two mounting holes, while

larger ones have four. Be sure to use all the

mounting holes provided.

Two chassis GND screws are located on the

metal tab on the heat sink at the bottom of the

inverter. Never touch the heat sink during or just

after operation; it can be very hot.

The electronics housing and front panel are built

onto the front of the heat sink.

Inverter Keypad - The inverter uses a digital

operator interface, or keypad. The four-digit

display can show a variety of performance

parameters. LEDs indicate whether the display

units are Hertz or Amperes. Other LEDs

indicate Power (external), and Run/Stop Mode

and Program/Monitor Mode status. Membrane

keys Run and Stop/Reset, and an output

frequency potentiometer (speed setting knob)

control motor operation. The FUNC., 1 , and

2 keys allow an operator to navigate to the

inverter’s functions and parameter values. The

Store key is used when changing a setting.

*Keypad doesn't display

when it is connected badly.

SJ200 Inverter

2–3

Inverter Keypad

Internal LED Indicators / Communications Connector - Refer to the illustration

below. After removing the keypad, the internal LED viewing window will be visible.

These LEDs indicate status for your convenience when the keypad is remotely mounted

and you are nearer to the inverter location.

The RJ45 connection consists of two parts. The clear plastic RJ45 modular interconnect

makes the connection between the inverter and the keypad. It is easily removed to allow

you to plug a communications cable into the modular connector.

Internal LED indicators:

Power

POW

Alarm

ALM

RJ45 modular

interconnect /

communications

connector

Run Mode RUN

Keypad bay

Installing the Keypad - Follow these steps:

1. Remember to install the RJ45 modular interconnect. Otherwise, there will be no

connection to the keypad.

2. Set the bottom edge of the keypad into the inverter keypad bay.

3. Tilt the top edge of the keypad forward. If it stops before seating firmly, DO NOT

force the keypad. You may need to adjust the end RJ45 modular connector slightly

(upward or downward). Then seat the keypad.

4. Make sure the retention latch clicks into place on the inverter housing top edge.

Otherwise, vibration may cause the keypad to loosen in the future.

Inverter Mounting

and Installation

Keypad Removal - The SJ200 has a removable

keypad. To remove the keypad, locate the

retention latch as shown to the right. Press

downward on the latch, while gently pulling

toward you. The keypad will tilt forward, as two

retaining tabs at the bottom edge of the keypad

also hold it in place. Then remove the keypad

from the keypad bay.

*Caution - Do not remove keypad when the

power is on.

2–4

Orientation to Inverter Features

Front Housing Cover

Housing Cover Removal - The front housing cover is held in place by two pairs of tabs.

Since these are hidden from view, it is good to become familiar with their locations

before attempting to remove the cover. The figure below shows a typical housing cover

in upside-down position to reveal the tabs. The two locking tabs are the ones which you

will need to press to remove the cover. The two hinging tabs will allow the cover to tilt

open once the unlocking tabs are released.

PRESS

Inverter Mounting

and Installation

Hinging tabs

Locking tabs

PRESS

The figure below shows the procedure for removing the housing cover. While pressing

inward on the housing, it is helpful to wiggle the cover side-to-side in order to release the

locking tabs. DO NOT force the cover open; it is possible to break a tab in this way.

1. Press inward on both sides.

2. Tilt upward after both locking

tabs are free.

Removing the Cover (Slide type)

1. Press downward on the cover at the two areas indicated to release the retaining tabs.

2. Slide the cover forward and away from the keypad until the top edge of the cover reaches the notch in the

inverter chassis.

3. Lift the cover upward to remove it.

Installing the Cover (Slide type)

1. Align the tabs on the front housing cover with the notch on each edge of the inverter chassis. Then lower

the cover into position.

2. Slide the cover toward the keypad, keeping it flush against the inverter chassis. Continue until the cover

latches into place.

The notch on

front housing cover

The notch on frame case

Note: The example inverter in the diagrams is model L200-004LFU. The cover removal or installation method is the same for the other models.

WARNING: Be sure to turn off the power supply and wait 10 minutes before you remove the front housing

cover. Otherwise, there is a shock hazard.

SJ200 Inverter

2–5

Logic Connector Locations - After removing the front housing cover, take a moment to

become familiar with the connectors, as shown below.

Relay output

contacts

Logic inputs

Logic Connector Removal/Replacement - The two 8-position main logic connectors

are removable from the circuit board to make testing or service more convenient. Note

that the relay output connector is not removable, as it must carry higher currents and

provide high integrity for alarm conditions. The alarm circuit may carry hazardous live

voltages even when the main power to the inverter is OFF. So, never directly touch any

terminal or circuit component.

The logic input connector (top connector) can be removed by pulling gently upward as

shown (below left). DO NOT force the connector, as damage to the circuit board may

occur. Try gently shifting the connector side-to-side while pulling, if having difficulty.

The analog input/output and logic output connector (bottom connector) has retention

screws. DO NOT attempt to remove the connector before loosening the screws. As the

figure shows (below right), use a small Phillips screwdriver to loosen the screw at each

end. The connector can be pulled forward easily after the screws are removed.

Inverter Mounting

and Installation

Analog input/

output and logic

outputs

2–6

Orientation to Inverter Features

Inverter Mounting

and Installation

Power Wiring Access - First, ensure no

power source of any kind is connected to the

inverter. If power has been connected, wait

five minutes after powerdown and verify the

Power LED is OFF to proceed. After

removing the front housing cover, the housing

partition that covers the power wiring exit will

be able to slide upward as shown to the right.

Notice the four wire exit slots (on larger

model inverters) in the housing partition. This

helps keep the power wiring (to the left)

separate from signal-level logic or analog

wiring (to the right).

Remove the housing partition and as shown as

set it aside in a secure place while wiring.

Never operate the inverter drive with the partition removed or the front housing cover

removed.

The power input and motor 3-phase wiring

connect to the lower row of terminals. The

upper row of power terminals connect to

optional dynamic braking components.

The following sections in this chapter will

describe the system design and guide you

through a step-by-step installation process.

After the section on wiring, this chapter

will show how to use the front panel keys

to access functions and edit parameters.

Power and motor

connector terminals

B–4

Connecting the Inverter to ModBus

OPE / 485 DIP Switch The difference between OPE-S and OPE-Smini is the short-circuit inside the connector.

If you set 485-side OPE-S,SRW says "----"(communication error)

But OPE-Smini works properly.

SR

485

TM

OPE

PRG

Appendix B

SK

C–2

Introduction

Introduction

This section lists the user-programmable parameters for the SJ200 series inverters and

the default values for European and U.S. product types. The right-most column of the

tables is blank, so you can record values you have changed from the default. This

involves just a few parameters for most applications. This section presents the parameters in a format oriented toward the keypad on the inverter.

Parameter Settings for Keypad Entry

SJ200 series inverters provide many functions and parameters that can be configured by

the user. We recommend that you record all parameters that have been edited, in order to

help in troubleshooting or recovery from a loss of parameter data.

Inverter model

}

This information is printed

on the specification label

located on the right side of

the inverter.

SJ200

Appendix C

MFG. No.

Main Profile Parameters

“F” Group Parameters

Func.

Code

Name

Default Setting

–FE

(Europe)

–FU

(USA)

F001

Output frequency setting

0.0

0.0

F002

Acceleration (1) time setting

10.0

10.0

F202

Acceleration (1) time setting, 2nd

motor

10.0

10.0

F003

Deceleration (1) time setting

10.0

10.0

F203

Deceleration (1) time setting, 2nd

motor

10.0

10.0

F004

Keypad Run key routing

00

00

User

Setting

SJ200 Inverter

C–3

Standard Functions

“A” Group Parameters

Func.

Code

Name

Default Setting

-FEF

(EU)

-FU

(USA)

Frequency source setting

01

00

A002

Run command source setting

01

02

A003

Base frequency setting

50.0

60.0

A203

Base frequency setting, 2nd

motor

50.0

60.0

A004

Maximum frequency setting

50.0

60.0

A204

Maximum frequency setting, 2nd

motor

50.0

60.0

A005

[AT] selection

00

00

A011

O–L input active range start

frequency

0.0

0.0

A012

O–L input active range end

frequency

0.0

0.0

A013

O–L input active range start

voltage

0.0

0.0

A014

O–L input active range end

voltage

100.

100.

A015

O–L input start frequency enable

01

01

A016

External frequency filter time

constant

2.

8.

A020

Multi-speed 0 setting

0.0

0.0

A220

Multi-speed 0 setting, 2nd motor

0.0

0.0

A021

Multi-speed 1 setting

0.0

0.0

A022

Multi-speed 2 setting

0.0

0.0

A023

Multi-speed 3 setting

0.0

0.0

A024

Multi-speed 4 setting

0.0

0.0

A025

Multi-speed 5 setting

0.0

0.0

A026

Multi-speed 6 setting

0.0

0.0

A027

Multi-speed 7 setting

0.0

0.0

A028

Multi-speed 8 setting

0.0

0.0

A029

Multi-speed 9 setting

0.0

0.0

A030

Multi-speed 10 setting

0.0

0.0

A031

Multi-speed 11 setting

0.0

0.0

Appendix C

A001

User

Setting

C–4

Parameter Settings for Keypad Entry

“A” Group Parameters

Appendix C

Func.

Code

Name

Default Setting

-FEF

(EU)

-FU

(USA)

A032

Multi-speed 12 setting

0.0

0.0

A033

Multi-speed 13 setting

0.0

0.0

A034

Multi-speed 14 setting

0.0

0.0

A035

Multi-speed 15 setting

0.0

0.0

A038

Jog frequency setting

1.00

1.00

A039

Jog stop mode

00

00

A042

Manual torque boost value

5.0

5.0

A242

Manual torque boost value, 2nd

motor

0.0

0.0

A043

Manual torque boost frequency

adjustment

3.0

3.0

A243

Manual torque boost frequency

adjustment, 2nd motor

0.0

0.0

A044

V/f characteristic curve selection

02

02

A244

V/f characteristic curve selection,

2nd motor

02

02

A045

V/f gain setting

100.

100.

A046

iSLV voltage compensation

gain

100

100

A246

iSLV voltage compensation

gain, 2nd motor

100

100

A047

iSLV slip compensation

gain

100

100

A247

iSLV slip compensation

gain, 2nd motor

100

100

A051

DC braking enable

00

00

A052

DC braking frequency setting

0.5

0.5

A053

DC braking wait time

0.0

0.0

A054

DC braking force for deceleration

0

0

A055

DC braking time for deceleration

0.0

0.0

A056

DC braking / edge or level detection for [DB] input

01

01

A061

Frequency upper limit setting

0.0

0.0

A261

Frequency upper limit setting,

2nd motor

0.0

0.0

User

Setting

SJ200 Inverter

“A” Group Parameters

Func.

Code

Name

C–5

Default Setting

-FEF

(EU)

-FU

(USA)

Frequency lower limit setting

0.0

0.0

A262

Frequency lower limit setting,

2nd motor

0.0

0.0

A063,

A065,

A067

Jump (center) frequency setting

0.0

0.0

A064,

A066,

A068

Jump (hysteresis) frequency

width setting

0.5

0.5

A071

PID Enable

00

00

A072

PID proportional gain

1.0

1.0

A073

PID integral time constant

1.0

1.0

A074

PID derivative time constant

0.0

0.0

A075

PV scale conversion

1.00

1.00

A076

PV source setting

00

00

A077

Reverse PID action

00

00

A078

PID output limit

0.0

0.0

A081

AVR function select

00

00

A082

AVR voltage select

230/400

230/460

A092

Acceleration (2) time settin

15.00

15.00

A292

Acceleration (2) time setting,

(2nd motor)

15.00

15.00

A093

Deceleration (2) time setting

15.00

15.00

A293

Deceleration (2) time setting,

(2nd motor)

15.00

15.00

A094

Select method to switch to Acc2/

Dec2 profile

00

00

A294

Select method to switch to Acc2/

Dec2 profile, 2nd motor

00

00

A095

Acc1 to Acc2 frequency transition point

0.0

0.0

A295

Acc1 to Acc2 frequency transition point, 2nd motor

0.0

0.0

A096

Dec1 to Dec2 frequency transition point

0.0

0.0

Appendix C

A062

User

Setting

C–6

Parameter Settings for Keypad Entry

“A” Group Parameters

Appendix C

Func.

Code

Name

Default Setting

-FEF

(EU)

-FU

(USA)

A296

Dec1 to Dec2 frequency transition point, 2nd motor

0.0

0.0

A097

Acceleration curve selection

00

00

A098

Deceleration curve selection

00

00

A101

[OI]–[L] input active range start

frequency

0.0

0.0

A102

[OI]–[L] input active range end

frequency

0.0

0.0

A103

[OI]–[L] input active range start

current

0.0

0.0

A104

[OI]–[L] input active range end

current

100.

100.

A105

[OI]–[L] input start frequency

enable

01

01

A141

A input select for calculate

function

02

02

A142

B input select for calculate

function

03

03

A143

Calculation symbol

00

00

A145

ADD frequency

0.0

0.0

A146

ADD direction select

00

00

User

Setting

SJ200 Inverter

C–7

Fine Tuning Functions

“B” Group Parameters

Func.

Code

Name

Default Setting

-FEF

(EU)

-FU

(USA)

Selection of automatic restart

mode

00

00

B002

Allowable under-voltage power

failure time

1.0

1.0

B003

Retry wait time before motor

restart

1.0

1.0

B004

Instantaneous power failure /

under-voltage trip alarm enable

00

00

B005

Number of restarts on power

failure / under-voltage trip events

00

00

B012

Level of electronic thermal

setting

Rated

current for

each

inverter

Rated

current for

each

inverter

B212

Level of electronic thermal

setting, 2nd motor

Rated

current for

each

inverter

Rated

current for

each

inverter

B013

Electronic thermal characteristic

01

01

B213

Electronic thermal characteristic,

2nd motor

01

01

B021

Overload restriction operation

mode

01

01

B022

Overload restriction setting

Rated

current x

1.5

Rated

current x

1.5

B023

Deceleration rate at overload

restriction

1.0

30.0

B031

Software lock mode selection

01

01

B080

[AM] analog signal gain

100.

100.

B082

Start frequency adjustment

0.5

0.5

B083

Carrier frequency setting

5.0

5.0

B084

Initialization mode (parameters

or trip history)

00

00

B085

Country code for initialization

01

02

B086

Frequency scaling conversion

factor

1.0

1.0

Appendix C

B001

User

Setting

C–8

Parameter Settings for Keypad Entry

“B” Group Parameters

Appendix C

Func.

Code

Name

Default Setting

-FEF

(EU)

-FU

(USA)

B087

STOP key enable

00

00

B088

Restart mode after FRS

00

00

B090

Dynamic braking usage ratio

0.0

0.0

B091

Stop mode selection

00

00

B092

Cooling fan control

00

00

B095

Dynamic braking control

00

00

B096

Dynamic braking activation level

360/720

360/720

B130

Over-voltage LADSTOP enable

00

00

B140

Over-current trip suppression

00

00

B150

Carrier mode

00

00

User

Setting

SJ200 Inverter

C–9

Intelligent Terminal Functions

“C” Group Parameters

Func.

Code

Name

Default Setting

-FEF

(EU)

-FU

(USA)

Terminal [1] function

00

00

C002

Terminal [2] function

01

01

C003

Terminal [3] function

02

16

C004

Terminal [4] function

03

13

C005

Terminal [5] function

18

09

C006

Terminal [6] function

09

18

C011

Terminal [1] active state

00

00

C012

Terminal [2] active state

00

00

C013

Terminal [3] active state

00

00

C014

Terminal [4] active state

00

01

C015

Terminal [5] active state

00

00

C016

Terminal [6] active state

00

00

C021

Terminal [11] function

01

01

C022

Terminal [12] function

00

00

C026

Alarm relay terminal function

05

05

C028

[AM] signal selection

00

00

C031

Terminal [11] active state

00

00

C032

Terminal [12] active state

00

00

C036

Alarm relay active state

01

01

C041

Overload level setting

Inverter

rated

current

Inverter

rated

current

C042

Frequency arrival setting for

acceleration

0.0

0.0

C043

Arrival frequency setting for

deceleration

0.0

0.0

C044

PID deviation level setting

3.0

3.0

C052

PID FBV function high limit

100.0

100.0

C053

PID FBV function low limit

0.0

0.0

C071

Communication speed selection

06

04

C072

Node allocation

1.

1.

C074

Communication parity selection

00

00

Appendix C

C001

User

Setting

C–10

Parameter Settings for Keypad Entry

Appendix C

“C” Group Parameters

Func.

Code

Default Setting

Name

-FEF

(EU)

-FU

(USA)

C075

Communication stop bit selection

1

1

C076

Communication error select

02

02

C077

Communication erorr time-out

0.00

0.00

C078

Communication wait time

0.

0.

C081

O input span calibration

100.0

100.0

C082

OI input span calibration

100.0

100.0

C085

Thermistor input tuning

100.0

100.0

C086

[AM] terminal offset tuning

0.0

0.0

C091

Debug mode enable

00

00

C101

Up/Down memory mode

selection

00

00

C102

Reset selection

00

00

C141

Input A select for logic output

00

00

C142

Input B select for logic output

01

01

C143

Logic function select

00

00

C144

Terminal [11] ON delay

0.0

0.0

C145

Terminal [11] OFF delay

0.0

0.0

C146

Terminal [12] ON delay

0.0

0.0

C147

Terminal [12] OFF delay

0.0

0.0

C148

Output relay ON delay

0.0

0.0

C149

Output relay OFF delay

0.0

0.0

User

Setting

SJ200 Inverter

C–11

Motor Constants Functions

“H” Group Parameters

Func.

Code

Name

Default Setting

-FEF

(EU)

-FU

(USA)

Motor capacity

Specified

by the

inverter

capacity

Specified

by the

inverter

capacity

H203

Motor capacity, 2nd setting

Specified

by the

inverter

capacity

Specified

by the

inverter

capacity

H004

Motor poles setting

4

4

H204

Motor poles setting, 2nd motor

4

4

H006

Motor stabilization constant

100

100

H206

Motor stabilization constant, 2nd

motor

100

100

H007

Motor voltage select

Specified

by the

inverter

voltage

Specified

by the

inverter

voltage

H207

Motor voltage select, 2nd motor

Specified

by the

inverter

voltage

Specified

by the

inverter

voltage

Appendix C

H003

User

Setting

Troubleshooting

and Maintenance

6–2

Troubleshooting

Troubleshooting

Safety Messages

Please read the following safety messages before troubleshooting or performing maintenance on the inverter and motor system.

WARNING: Wait at least five (5) minutes after turning OFF the input power supply

before performing maintenance or an inspection. Otherwise, there is the danger of

electric shock.

WARNING: Make sure that only qualified personnel will perform maintenance, inspection, and part replacement. Before starting to work, remove any metallic objects from

your person (wristwatch, bracelet, etc.). Be sure to use tools with insulated handles.

Otherwise, there is a danger of electric shock and/or injury to personnel.

WARNING: Never remove connectors by pulling on its wire leads (wires for cooling

fan and logic P.C.board). Otherwise, there is a danger of fire due to wire breakage and/or

injury to personnel.

General Precautions and Notes

• Always keep the unit clean so that dust or other foreign matter does not enter the

inverter.

• Take special care in regard to breaking wires or making connection mistakes.

• Firmly connect terminals and connectors.

• Keep electronic equipment away from moisture and oil. Dust, steel filings and other

foreign matter can damage insulation, causing unexpected accidents, so take special

care.

Inspection Items

This chapter provides instructions or checklists for these inspection items:

• Daily inspection

• Periodic inspection (approximately once a year)

• Insulation resistance test

SJ200 Inverter

6–3

Troubleshooting Tips

Symptom/condition

Probable Cause

• Is the frequency command source

Solution

• Make sure the parameter

A001 parameter setting correct?

setting A001 is correct.

• Is the Run command source A002

• Make sure the parameter

parameter setting correct?

• Is power being supplied to terminals [L1], [L2], and [L3/N]? If so,

the POWER lamp should be ON.

• Is there an error code E X X

displayed?

The inverter

outputs [U], [V],

[W] are not

• Are the signals to the intelligent

supplying

input terminals correct?

voltage.

• Is the Run Command active?

The motor

• Is the [FW] terminal (or [RV])

will not run.

connected to [P24] (via switch,

etc.)

• Has the frequency setting for F001

been set greater than zero?

• Are the control circuit terminals

[H], [O], and [L] connected to the

potentiometer?

• Is the RS (reset) function or FRS

setting A002 is correct.

• Check terminals [L1], [L2],

and [L3/N], then [U/T1],

[V/T2], and [W/T3].

• Turn ON the power supply

or check fuses.

• Press the Func. key and

determine the error type.

Eliminate the error cause,

then clear the error (Reset).

• Verify the terminal functions

for C001 – C006 are correct.

• Turn ON Run Command

enable.

• Supply 24V to {FW] or

[RV] terminal, if configured.

• Set the parameter for F001

to a safe, non-zero value.

• If the potentiometer is the

frequency setting source,

verify voltage at [O] > 0V.

• Turn OFF the command(s).

(free-run stop) function ON?

Inverter outputs

[U], [V], [W]

are supplying

voltage.

• Is the motor load too heavy?

The optional

remote operator

is used (SRW).

• Are the operational settings

motor independently.

between the remote operator and

the inverter unit correct?

• Are the connections of output

The direction of the motor is

reversed.

• Reduce load, and test the

terminals [U/T1], [V/T2], and

[W/T3] correct?

• Is the phase sequence of the motor

forward or reverse with respect to

[U/T1], [V/T2], and [W/T3]?

• Check the operator type

setting.

• Make connections according

to the phase sequence of the

motor. In general:

FWD = U-V-W, and

REV=U-W-V.

• Are the control terminals [FW] and • Use terminal [FW] for

[RV] wired correctly?

• Is parameter F004 properly set?

forward, and [RV] for

reverse.

• Set motor direction in F004.

Troubleshooting

and Maintenance

The table below lists typical symptoms and the corresponding solution(s).

6–4

Troubleshooting

Troubleshooting

and Maintenance

Symptom/condition

Probable Cause

• If using the analog input, is the

current or voltage at [O] or [OI]?

Solution

• Check the wiring.

• Check the potentiometer or

signal generating device.

• Is the load too heavy?

The motor speed will not reach

the target frequency (desired

speed).

overload restriction feature

(reduces output as needed).

• Is the inverter internally limiting

the output frequency?

• Is the load fluctuation too great?

The rotation is unstable.

• Was power turned OFF after a

Inverter data

is not

correct.

A parameter

will not

change after

an edit

(reverts to

old setting).

• Check max frequency

setting (A004)

• Check frequency upper limit

setting (A061)

• Increase the motor capacity

(both inverter and motor).

• Is the supply voltage unstable?

• Fix power supply problem.

• Is the problem occurring at a partic- • Change the output

ular frequency?

frequency slightly, or use the

jump frequency setting to

skip the problem frequency.

The RPM of the motor does not • Is the maximum frequency setting

match the inverter output

A004 correct?

frequency setting.

• Does the monitor function D001

display the expected output

frequency?

No downloads

have occurred.

• Reduce the load.

• Heavy loads activate the

parameter edit but before pressing

the Store key?

• Edits to data are permanently

stored at power down. Was the time

from power OFF to power ON less

than six seconds?

• Verify the V/f settings match

motor specifications.

• Make sure all scaling (such

as A011 to A014) is

properly set.

• Edit the data and press the

Store key once.

• Wait six seconds or more

before turning power OFF

after editing data.

A download to

the inverter was

attempted.

• Was the power turned OFF within

True for certain

parameters

• Is the inverter in Run Mode? Some • Put inverter in Stop Mode

True for all

parameters

• If you’re using the [SFT] intelligent • Change the state of the SFT

six seconds after the display

changed from REMT to INV?

parameters cannot be edited during

Run Mode.

input (software lock function)—is

the [SFT] input ON?

• Copy the data to the inverter

again, and keep power ON

for six seconds or more after

copying.

(press the Stop/reset key).

Then edit the parameter.

input, and check the B031

parameter (SFT mode).

SJ200 Inverter

6–5

Fault Detection and Clearing

The microprocessor in the inverter detects a variety

STOP

RESET

of fault conditions and captures the event, recordRun

Stop

ing it in a history table. The inverter output turns

RUN

OFF, or “trips” similar to the way a circuit breaker

STOP

trips due to an over-current condition. Most faults

RESET

Fault

occur when the motor is running (refer to the

Trip

Fault

diagram to the right). However, the inverter could

have an internal fault and trip in Stop Mode. In

either case, you can clear the fault by pressing the Stop/Reset key. Additionally, you can

clear the inverter’s cumulative trip history by performing the procedure “Restoring

Factory Default Settings” on page 6–8 (setting B084=00 will clear the trip history but

leave inverter settings intact).

Error Codes

An error code will appear on the display automatically when a fault causes the inverter to

trip. The following table lists the cause associated with the error.

Error

Code

E 01

E 02

E 03

E 04

Name

Over current event while

at constant speed

Over current event during

deceleration

Over current event during

acceleration

Cause(s)

The inverter output was short-circuited, or the motor

shaft is locked or has a heavy load. These conditions

cause excessive current for the inverter, so the

inverter output is turned OFF.

The dual-voltage motor is wired incorrectly.

If b083 is too high, please reduce the value.

Over current event during

other conditions

E 05

Overload protection

When a motor overload is detected by the electronic

thermal function, the inverter trips and turns OFF its

output.

E 06

Braking resistor overload

When the regenerative braking resistor exceeds the

usage time allowance or usage ratio, the inverter trips

and turns OFF its output to the motor.

E 07

Over voltage protection

When the DC bus voltage exceeds a threshold, due to

regenerative energy from the motor.

E 08

EEPROM error

When the built-in EEPROM memory has problems

due to noise or excessive temperature, the inverter

trips and turns OFF its output to the motor.

E 09

Under-voltage error

A decrease of internal DC bus voltage below a threshold results in a control circuit fault. This condition can

also generate excessive motor heat or cause low

torque. The inverter trips and turns OFF its output.

Troubleshooting

and Maintenance

Monitoring Trip Events, History, & Conditions

Troubleshooting

and Maintenance

6–6

Monitoring Trip Events, History, & Conditions

Error

Code

E1 1

E22

E1 2

Name

Cause(s)

CPU error

A malfunction in the built-in CPU has occurred, so

the inverter trips and turns OFF its output to the

motor.

External trip

A signal on an intelligent input terminal configured as

EXT has occurred. The inverter trips and turns OFF

the output to the motor.

E1 3

USP

When the Unattended Start Protection (USP) is

enabled, an error occurred when power is applied

while a Run signal is present. The inverter trips and

does not go into Run Mode until the error is cleared.

E1 4

Ground fault

The inverter is protected by the detection of ground

faults between the inverter output and the motor upon

during powerup tests. This feature protects the

inverter, and does not protect humans.

Input over-voltage

(*)

When the input voltage is higher than the specified

value, it is detected 100 seconds after powerup and

the inverter trips and turns OFF its output.

E21

Inverter thermal trip

When the inverter internal temperature is above the

threshold, the thermal sensor in the inverter module

detects the excessive temperature of the power

devices and trips, turning the inverter output OFF.

E23

Gate array error

An internal inverter error has occurred in communications between the CPU and gate array IC.

E35

Thermistor

When a thermistor is connected to terminals [6] and

[L] and the inverter has sensed the temperature is too

high, the inverter trips and turns OFF the output.

E 60

Communications error

The inverter’s watchdog timer for the communications network has timed out.

Under-voltage (brownout) with output shutoff

Due to low input voltage, the inverter turns its output

OFF and tries to restart. If it fails to restart, then the

alarm trips to record the under-voltage error event.

E1 5

---

NOTE: If an EEPROM error (E08) occurs, be sure to confirm the parameter data values

are still correct. If the power is turned OFF while the [RS] (Reset) intelligent input

terminal is ON, an EEPROM error will occur when power is restored.

Caution: EXT,PTC trip has a possibility of breaking I/O circuit and breaking EEPROM data

*:OVSRC(E15) trip level is relatively changed for 200/400V class in 3440(Core) and

3524(I/O) software.

SJ200 Inverter

6–7

Trip History and Inverter Status

The following Monitor Menu map shows how to access the error codes. When fault(s)

exist, you can review their details by first selecting the proper function: D081 is the most

recent, and D083 is the oldest.

Monitor Menu

2

2

d 083

2

1

d 081

1

d 082

FUNC.

No error

Error

exists?

____

No

FUNC.

Yes

2

E 09

1

DC bus voltage

at trip point

2

15

1

Motor current

at trip point

2

1 8 9.8

1

Output frequency

at trip point

2

0.25

1

Error Code

2

1 0.0

1

Trip

Conditions

2

18

Cumulative inverter

operation time at

trip point

Cumulative powerON time at trip point

1

FUNC.

2

Troubleshooting

and Maintenance

We recommend that you first find the cause of the fault before clearing it. When a fault

occurs, the inverter stores important performance data at the moment of the fault. To

access the data, use the monitor functions (Dxxx) and select D081 for details about the

present fault (En). The previous two faults are stored in D082 and D083, with D(En-1 and

En-2). Each error shifts D081–D082 to D082–D083, and writes the new error to D081.

Troubleshooting

and Maintenance

6–8

Restoring Factory Default Settings

Restoring Factory Default Settings

You can restore all inverter parameters to the original factory (default) settings for the

intended country of use. After initializing the inverter, use the powerup test in Chapter 2

to get the motor running again. To initialize the inverter, follow the steps below.

No.

Action

Display

Func./Parameter

b–––

“B” Group selected

b 001

First “B” parameter selected

b 085

Country code for initialization

selected

1

Use the FUNC. , 1 , and 2 keys to

navigate to the “B” Group.

2

Press the

3

Press and hold the

4

Press the

5

Confirm the country code is correct. Do not change it unless you are absolutely sure the

power input voltage range and frequency match the country code setting.

FUNC.

FUNC.

key.

1

key until ->

02

key.

To change the country code, press

1

or

2

to set,

00 = Japan, 01 = Europe,

02 = U.S.

STR

to store.

6

Press the

FUNC.

key.

b 085

Country code for initialization

selected

7

Press the

2

key.

b 084

Initialization function selected

8

Press the

FUNC.

key.

00

00 = initialization disabled,

clear trip history only

9

Press the

1

key.

01

01 = initialization enabled

10

Press the

STR

key.

11

Press and hold the

2

12

,

1

, and

Initialization now enabled to

restore all defaults

b 084

First part of special key

sequence

b 084

Final part of special key

sequence

d 001

Initialization begins when

display starts blinking

keys. Do not release yet.

Holding the keys above, press and

hold the

13

FUNC.

b 084

STOP

RESET

(STOP) key for 3 sec.

STOP

Release only the RESET

(STOP) key,

and wait for the display d001 to

appear and begin blinking.

14

, and 2

keys only after the d001 display

function begins blinking.

15

Initialization is complete.

Now release the

FUNC.

,

1

EU

USA

d 001

Default parameter country code

shown during initialization

process (left-most char displays

alternating pattern)

Function code for output

frequency monitor shown

NOTE: Initialization cannot be performed with a remote operator panel. Disconnect the

device and use the inverter’s front panel keypad.

EEPROM Compulsory Initialization

All of EEPROM data are stored default setting

-method1. After setting C091=01, store ‘**FF’ at EEPROM address 11d4(C092 setting).

2. Then press and hold the FUNC, UP, and DOWN key.

HITACHI

POWER

ALARM

Hz

A

RUN

FUNC

RUN

PRG

STOP

RESET

1

2

STR

3. After that press RESET key and release.

4. Then INV starts compulsory initialization as it displays like below.

Now

initialization

At the left side the bars blink and roll

5. EEPROM compulsory initialization completes.

6. Set Voltage-class (C197),and set C195,b085(both must be the same.)

7. Set INV kW Code (C196) the wrong value once intentionally

and store, then set the right value. After that start initialization with b084

-C081,C082O-L adjustment at factory(not C81, not C82)

JPN version is 1 byte definition

Core:up to 3388(or before)

IO:up to 3433(or before)

EU/USA version is 2 byte definition from the beginning.

Core: 3440 or after

IO: 3441 or after

When initialization of b084 or copying C081 and C082 are set different value, so need to set

again.

2-1

ERROR Check

error

No display

E08/E11

E22

8888 display

OC trip/E23/

E30/E14

---(Power Off

display)

E09 with

motor

E12(EXT)

E35(PTC)

E05(Over

Load),OC

trip(L200)is prematured

Cooling FAN doesn't

work

INV doesn't work

MOV failure, or you got

returned INV

bar-bar-bar-bar

display(OPE-S,OPE-SRE,

not OPE-Smini)

or

R-ERROR

COMM.<1>(SRW)

No display

description

DC bus charged

IO board connection & cable connection

OPE connection

short bar P1- PD

Cooling FAN failure

Connection between IO board & OPE(L200)

EEPROM recovery(initilalization C92 display 11d4=ff)

IO board connection & cable connection(communication error

between ISPM & IO board)

INV type code is wrong SJ200 & L200

EEPROM

recovery(initilalization

C92

11d4=ff)(because MCU can't read EEPROM)

EEPROM data changed. check C194

Disconnect motor wire and check output voltage

display

Core(ISPM) failure(not repairable)

maybe thyristor off, please check waveform of DC bus voltage.

check C01-C06 (EXT=12)

check C06(SJ200)-C05(L200)(PTC=19) ,check C85 value

check b32 value

check b92

check DIP switch on ISPM(Power Module pcb)

check d109 display after C91 set 01

Set dip Switch from 485 to PRG

check the bar of P-line.

2-2

Debug Mode

If you set debug mode enable (C091 =01), the function below will be available.

When debugging, you can use only standard OPE (cannot use SRW)

Make sure of returning C091=00 after debugging.

There are some monitor or function-code for testing and maintenance which is not released for

users.

The content of each function follows below.

Monitor mode

No

1

2

3

4

5

6

7

Function name

Control-frequenc

y monitor

DC voltage

monitor

BRD ON time

monitor

Electric thermal

monitor

Core MCU NO.

IO MCU NO.

Peak voltage

monitor

Code

Run

Mode

Edit

Range

d101

-

0.0~400.0

d102

-

d103

Res.

defa

ult

unit

Monitors control frequency

0.1[Hz]

-

Hz

0.0~999.9

Monitors the P-N voltage

0.1[V]

-

V

-

0.0~100.0

Monitors the time during BRD ON

0.1[sec]

-

%

d104

-

0.0~100.0

0.1%

-

-

d106

-

0000~9999

1

-

-

d107

-

0000~9999

1

-

-

d109

-

0.0~999.9

0.1[V]

-

V

Description

Monitors integration of the current

when exceeding the thermal level.

Monitors the version of

the core program

Monitors the version of

the IO program

Monitors the peak P-N voltage

Function mode

No

Function name

Code

Run

Mode

Edit

Range

Description

Res.

defa

ult

unit

8

Debug mode

enable

C091

OK

00(disable)/

01(enable)

Debug mode select

-

00

-

9

Debug mode

data set

C092

OK

0000~FFFF

Hexadecimal display

(Do not set)

-

1200

-

10

Debug mode

data monitor

C093

OK

0000~FFFF

Hexadecimal display

(Do not set)

-

1200

-

11

Debug mode

bit control

C094

OK

Address set range

0000 - FFFF->

0-7 bit select

Hexadecimal display

(Do not set)

-

1200

-

12

Debug mode select

C095

OK

00(Core)/01(IO)

-

00

-

C121

-

0000~FFFF

Hexadecimal display

(Do not set)

-

3E8

-

C122

-

0000~FFFF

Hexadecimal display

(Do not set)

-

3E8

-

C123

-

0~65535

-

200

-

Area code select

-

-

-

Capacity select

Voltage-class

select

-

-

-

-

-

-

13

14

15

O input span

calibration

for function test

OI input span

calibration

for function test

OI Zero

calibration

for function test

(Do not set)

16

Area code select

C195

-

17

kW code

Voltage-class

select

C196

-

00(JPN)/01(EU)

/02(USA)

0.2~7.5

C197

-

00(200V)/01(400V)

18

Doesn’t store to

EEPROM

3-1

SJ200 Inverter

6–9

Monthly and Yearly Inspection Chart

Inspection Cycle

Item Inspected

Check for...

Month

Control

circuit

Criteria

Ambient

environment

Extreme

temperatures

& humidity

✔

Thermometer,

hygrometer

Ambient temperature

between -10 to 40°C,

non-condensing

Major devices

Abnormal

noise & vib.

✔

Visual and aural

Stable environment for

electronic controls

Power supply

voltage

Voltage

tolerance

✔

Digital volt meter,

measure between

inverter terminals

[L1], [L2], [L3]

200V class:

200 to 240V 50/60 Hz

400V class:

380 to 460V 50/60 Hz

Ground

Insulation

Adequate

resistance

✔

Digital volt meter,

GND to terminals

5 Meg. Ohms or greater

Mounting

No loose

screws

✔

Torque wrench

M3: 0.5 – 0.6 Nm

M4: 0.98 – 1.3 Nm

M5: 1.5 – 2.0 Nm

Components

Overheating

✔

Thermal trip

events

No trip events

Housing

Dirt, dust

✔

Visual

Vacuum dust and dirt

✔

Visual

No abnormalities

Visual

No abnormalities

Overall

Main

circuit

Year

Inspection

Method

Terminal block Secure

connections

✔

Smoothing

capacitor

Leaking,

swelling

Relay(s)

Chattering

✔

Aural

Single click when

switching ON or OFF

Resistors

Cracks or

discoloring

✔

Visual

Use Ohm meter to

check braking resistors

Cooling fan

Noise

✔

Power down,

manually rotate

Rotation must be

smooth

Dust

✔

Visual

Vacuum to clean

Visual

No abnormalities

✔

Overall

No odor,

discoloring,

corrosion

Capacitor

No leaks or

deformation

✔

Visual

Undistorted appearance

Legibility

✔

Visual

All LED segments work

Display LEDs

Note 1:

Note 2:

The life of a capacitor is affected by the ambient temperature. See “Capacitor

Life Curve” on page 6–11.

The inverter must be cleaned periodically. If dust accumulates on the fan and

heat sink, it can cause overheating of the inverter.

Troubleshooting

and Maintenance

Maintenance and Inspection

6–10

Maintenance and Inspection

Troubleshooting

and Maintenance

Megger Test

The megger is a piece of test equipment that uses a high voltage to determine if an

insulation degradation has occurred. For inverters, it is important that the power terminals be isolated from the Earth GND terminal via the proper amount of insulation.

The circuit diagram below shows the inverter wiring for performing the megger test. Just

follow the steps to perform the test:

1. Remove power from the inverter and wait at least 5 minutes before proceeding.

2. Open the front housing panel to access the power wiring.

3. Remove all wires to terminals [R, S, T, RB, PD/+1, PD/+, N/–, U, V, and W]. Most

importantly, the input power and motor wires will be disconnected from the inverter.

4. Use a bare wire and short terminals [R, S, T, RB, PD/+1, PD/+, N/–, U, V, and W]

together as shown in the diagram.

5. Connect the megger to the inverter Earth GND and to the shorted power terminals as

shown. Then perform the megger test at 500 VDC and verify 5MΩ or greater resistance.

Add test jumper wire

Disconnect

power source

Disconnect

motor wires

SJ200

R

U

S

V

T

W

RB

Motor

Megger, 500VDC

PD/+1

PD/+

N/–

Earth GND

6. After completing the test, disconnect the megger from the inverter.

7. Reconnect the original wires to terminals [R, S, T, RB, PD/+1, PD/+, N/–,

U, V, and W].

CAUTION: Do not connect the megger to any control circuit terminals such as intelligent I/O, analog terminals, etc. Doing so could cause damage to the inverter.

CAUTION: Never test the withstand voltage (HIPOT) on the inverter. The inverter has a

surge protector between the main circuit terminals above and the chassis ground.

SJ200 Inverter

6–11

Spare parts

Quantity

Part description

Symbol

Notes

Used

Spare

Cooling fan

FAN

1

1

015NF, 022NF, 030LF,

015HF to 075HF

Case

CV

1

1

•

•

•

•

Front case

Key cover

Case

Bottom cover

Capacitor Life Curve

The DC bus inside the inverter uses a large capacitor as shown in the diagram below. The

capacitor handles high voltage and current as it smooths the power for use by the

inverter. So, any degradation of the capacitor will affect the performance of the inverter.

Power

Input

Variable-frequency Drive

Converter

L1

L2

Internal

DC Bus

Inverter

Motor

+

+

Rectifier

U/T1

V/T2

L3

W/T3

–

Capacitor

Capacitor life is reduced in higher ambient temperatures, as the graph below demonstrates. Be sure to keep the ambient temperature at acceptable levels, and perform

maintenance inspections on the fan, heat sink, and other components. If the inverter is

installed on a cabinet, the ambient temperature is the temperature inside the cabinet.

Capacitor Life Curve

50

Ambient

temperature, °C

Operation for 12 hours/day

40

30

Operation for

24 hours/day

20

10

0

-10

1

2

3

4

5

6

7

8

9

10

Years

Troubleshooting

and Maintenance

We recommend that you stock spare parts to reduce down time, including these parts:

6–12

Maintenance and Inspection

Troubleshooting

and Maintenance

General Inverter Electrical Measurements

The following table specifies how to measure key system electrical parameters. The

diagrams on the next page show inverter-motor systems and the location of measurement

points for these parameters.

Parameter

Circuit location

of measurement

Measuring

instrument

Notes

Reference Value

Supply voltage

E1

ER – across L1 and L2

ES – across L2 and L3

ET – across L3 and L1

Moving-coil

Fundamental

type voltmeter or wave effective

rectifier type

value

voltmeter

Supply current

I1

Ir – L1, Is – L2, It – L3

Total effective

value

—

Supply power

W1

W11 – across L1 and L2

W12 – across L2 and L3

Total effective

value

—

Supply power

factor Pf1

Commercial

supply voltage

(200V class) 200–

240V, 50/60 Hz

400V class 380–

460V, 50/60 Hz

—

W1

Pf 1 = ------------------------------ × 100%

3 × E1 × I1

Output voltage

E0

EU – across U and V

EV – across V and W

EW – across W and U

Rectifier type

voltmeter

Total effective

value

—

Output current

Io

IU – U

IV – V

IW – W

Moving-coil

ammeter

Total effective

value

—

Output power

Wo

W01 – across U and V

W02 – across V and W

Electronic type

wattmeter

Total effective

value

—

Output power

factor Pfo

Calculate the output power factor from the output voltage E,

output current I, and output power W.

—

W0

Pf 0 = ------------------------------ × 100%

3 × E0 × I0

Note 1:

Note 2:

Note 3:

Use a meter indicating a fundamental wave effective value for voltage, and

meters indicating total effective values for current and power.

The inverter output has a distorted waveform, and low frequencies may cause

erroneous readings. However, the measuring instruments and methods listed

above provide comparably accurate results.

A general-purpose digital volt meter (DVM) is not usually suitable to measure

a distorted waveform (not pure sinusoid).

SJ200 Inverter

6–13

Single-phase Measurement Diagram

Inverter

L1

L1

I1

U

T1

I1

EU-V

E1

W1

V

T2

I1

EU-V

N

N

W

W01

Motor

W02

T3

I1

EU-V

Three-phase Measurement Diagram

Inverter

L1

R

I1

E1

L2

L3

EU-V

S

E1

V

T2

EU-V

W

W01

I1

W02

T

I3

T1

I1

W01

I2

E1

U

W02

T3

I1

EU-V

Motor

Troubleshooting

and Maintenance

The figures below show measurement locations for voltage, current, and power measurements listed in the table on the previous page. The voltage to be measured is the fundamental wave effective voltage. The power to be measured is the total effective power.

6–14

Maintenance and Inspection

Troubleshooting

and Maintenance

Inverter Output Voltage Measurement Techniques

Taking voltage measurements around drives equipment requires the right equipment and

a safe approach. You are working with high voltages and high-frequency switching

waveforms that are not pure sinusoids. Digital voltmeters will not usually produce

reliable readings for these waveforms. And, it is usually risky to connect high voltage

signals to oscilloscopes. The inverter output semiconductors have some leakage, and

no-load measurements produce misleading results. So, we highly recommend using the

following circuits to measure voltage for performing the equipment inspections.

Voltage measurement with load

L1/R

L2/S

U/T1

Inverter

L3/T

Voltage measurement without load

L1/R

V/T2

L2/S

W/T3

L3/T

U/T1

Inverter

V/T2

W/T3

Additional resistor

220 kΩ

2W

220 kΩ

2W

+

V Class

Diode Bridge

5 kΩ

30W

–

Voltmeter

+

V Class

Diode Bridge

–

Voltmeter

200V Class

600V 0.01A min. 300V range

200V Class

600V 0.01A min. 300V range

400V Class

100V 0.1A min.

400V Class

100V 0.1A min.

600V range

600V range

HIGH VOLTAGE: Be careful not to touch wiring or connector terminals when working

with the inverters and taking measurements. Be sure to place the measurement circuitry

components above in an insulated housing before using them.

6–15

SJ200 Inverter

IGBT Test Method

1. Disconnect input power to terminals [R, S, and T] and motor terminals [U, V, and W].

2. Disconnect any wires from terminals [+] and [RB] for regenerative braking.

3. Use a Digital Volt Meter (DVM) and set it for 1Ω resistance range. You can check the

status of the charging state of terminals [R, S, T, U, V, W, RB, +, and –] of the inverter

and the probe of the DVM by measuring the charging state.

D1

D2

[+1] [+] [RB]

D3

[R]

TR1

TR2

TR3

[U]

+

[S]

[V]

[T]

[W]

D4

D5

TR7

D6

TR4

TR5

TR6

[–]

Table Legend – Almost infinite resistance: ≅ ∞ Ω Almost zero resistance: ≅ 0 Ω

DVM

Part

D1

D2

D3

D4

DVM

Measured

Value

Part

D5

+

–

[R]

+1

≅∞Ω

+1

[R]

≅0Ω

[S]

+1

≅∞Ω

+1

[S]

≅0Ω

[T]

+1

≅∞Ω

+1

[T]

≅0Ω

[R]

[N]

≅0Ω

[N]

[R]

≅∞Ω

D6

TR1

TR2

TR3

DVM

Measured

Value

Part

TR4

+

–

[S]

[N]

≅0Ω

[N]

[S]

≅∞Ω

[T]

[N]

≅0Ω

[N]

[T]

≅∞Ω

[U]

[+]

≅∞Ω

[+]

[U]

≅0Ω

[V]

[+]

≅∞Ω

[+]

[V]

[W]

[+]

Measured

Value

+

–

[U]

[–]

≅0Ω

[–]

[U]

≅∞Ω

[V]

[–]

≅0Ω

[–]

[V]

≅∞Ω

[W]

[–]

≅0Ω

[–]

[W]

≅∞Ω

[RB]

[+]

≅0Ω

≅0Ω

[+]

[RB]

≅∞Ω

[+]

≅∞Ω

[RB]

[–]

≅0Ω

[W]

≅0Ω

[–]

[RB]

≅0Ω

TR5

TR6

TR7

NOTE: The resistance values for the diodes or the transistors will not be exactly the

same, but they will be close. If you find a significance difference, a problem may exist.

NOTE: Before measuring the voltage between [+] and [–] with the DC current range,

confirm that the smoothing capacitor is discharged fully, then execute the tests.

Troubleshooting

and Maintenance

The following procedure will check the inverter transistors (IGBTs) and diodes:

Replacing the fan

The following series inverter is equipped a cooling fan.

(200V class): 1,5kW, 2.2kW, 3.7kW

(400V class): 1,5kW, 2.2kW, 3.7kW

A way to replace the fan follows below.

By the way, primary released product is different from not primary (secondly -) one about the

way to remove the fan. In the case of replacing the fan, please remove the housing cover first, and

then replace the new fan. Please refer to section 4.6 about the way to remove the housing cover.

Please make sure of the specification label to discriminate whether it’s primary released product

or not.

RE V. NO. : A

- primary relea sed prod ucts

REV.NO.: not A

- not pr imary ( second ly -) released product s

1.Insert the minus screw driver etc to the insert point, and remove the upper cover.

2.Remove the connector (CN4) of the fan.

3.Remove the fan cover and replace new one.

i ns e r t poi nt

up pe r c ove r

fa n c o ve r

Removing the housing cover

There are several ways which depend on the scale of the housing cover.

scale (small) : (200V class ) 0.2kW, 0.4kW, 0.75kW

scale (middle): (200V class ) 1.5kW, 2.2kW, 3.7kW

(400V class ) 0.4kW – 3.7kW

Scale (small)

1.Remo ve the mon itor cover, front cover and rear cover.

When remov in g the mon itor cover, p lease remove the co mmun ication cab le

from t he front cover s ide.

mo ni tor c ove r

ho us i ng

fr o nt c ove r

r e a r c ove r

2.Insert the minus screw driver between the cooling fin and the housing, and unlock the tabs

(4 points at the left and right side) .

ta b1

ta b2

3. Remove the housing.

ta b3

ta b4

Scale (middle)

1.Remo ve the mon itor cover, front cover and rear cover.

When remov in g the mon itor cover, p lease remove the co mmun ication cab le

from t he front cover s ide.

mo ni tor c ov er

fr o nt c ove r

r e a r c ove r

ho us i ng

2.Remove the RB-bar.

RB- ba r

3.Insert the minus screw driver between the cooling fin and the housing, and unlock the tabs

(4 points at the left and right side.

ta b1

ta b2

4. Remove the housing.

ta b3

ta b4

Scale (large)

① Remove the monitor cover, front cover and rear cover.

When removing the monitor cover, please remove the communication cable from the front cover side.

front cover

monitor cover

rear cover

② Remove the two bolts and P-PD short bar.

P-PD short bar

bolts

4-14

③ Remove the housing

housing

4-15

5-1

PCB3

OPE

ISPM regurration

without gel.

(gel:for insulation

and cooling)

PCB2 is soldered upon

PCB1(core circuit).

PCB1 + PCB2

5-2

PCB3

OPE

ISPM regurration

without gel.

(gel:for insulation

and cooling)

PCB2 is soldered upon

PCB1(core circuit).

PCB1 + PCB2

5-3

PCB3

OPE

ISPM regurration

without gel.

(gel:for insulation

and cooling)

PCB2 is soldered upon

PCB1(core circuit).

PCB1 + PCB2

5-4

PCB3

OPE

ISPM regurration

without gel.

(gel:for insulation

and cooling)

PCB2 is soldered upon

PCB1(core circuit).

PCB1 + PCB2

5.1.構造図(5/11)

5-5

5.1.構造図(6/11)

5-6

5.1.構造図(7/11)

5-7

5.1.構造図(8/11)

5-8

5.1.構造図(9/11)

5-9

5.1.構造図(10/11)

5-10

5.1.構造図(11/11)

5-11

SJ200-002/004/005NFEF(Slide type)

SJ200-007/011NFEF/004/007HFEF (Slide type)

SJ200-015/022NFEF-015~040HFEF (Slide type)

SJ200-055/075HFEF (Slide type)

L200-002/004/005NFEF (Slide type)

L200-004/007HFEF-007NFEF (Slide type)