Download Service Manual - Frank`s Hospital Workshop

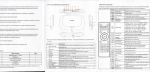

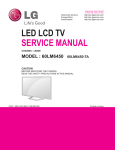

Transcript