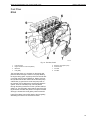

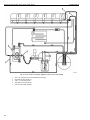

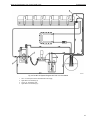

Download Fuel System - D12,D12A,D12B,D12C

Transcript