Download Service Manual

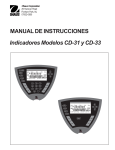

Transcript