Download Service Manual Service Manual

Transcript

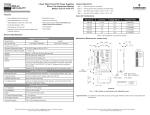

DVD PLAYER DVP3320X/78 DVD PLAYER DVP3320X/78 Service Manual Service Manual Conteúdo Especificações Técnicas Instruções de Segurança Instruções Mecânicas e Desmontagem Atualização de Software Fluxos de Solução de Problemas Diagrama de Ligações Painel Frontal Painel Switch Painel OK Painel Power Painel Principal Guias de Placas Vista Explodida Impresso no Brasil Sujeito a Alterações 08/2009 2 3 5 9 10 21 22 23 24 25 26 30 35 CLASS 1 LASER PRODUCT 4806 727 17377 CLASS 1 LASER PRODUCT Todos os Direitos Reservados PHILIPS 08/2009 Impresso no Brasil Página Sujeito a Alterações Todos os Direitos Reservados 4806 727 17377 PHILIPS DVP3320 Especificações Nota • Especificações e aparência estão sujeitas a alterações sem prévio aviso. Acessórios fornecidos • Controle remoto • Cabos de áudio/vídeo • Cabo de força Desempenho do áudio • Conversor DA: 24 bits, 192 kHz • Resposta de frequência: • DVD: 4 Hz - 22 kHz (48 kHz); 4 Hz - 44 kHz (96 kHz) • SVCD: 4 Hz - 20 kHz (44.1 kHz); 4 Hz - 22 kHz (48 kHz) • CD/VCD: 4 Hz - 20 kHz (44.1 kHz) • Sinal-Ruído(1 kHz): > 90 dB (Aweighted) • Relação Dinâmica(1 kHz): > 80 dB (Aweighted) • Crosstalk (1 kHz): > 90 dB • Distorção/ruído(1 kHz): > 65 dB • MPEG MP3: MPEG Audio L3 Mídia de reprodução • DVD-Video, Video CD/SVCD, Audio CD, Formato de áudio CD-R/CD-RW, DVD+R/+RW, DVD-R/• Digital: RW, Picture CD, MP3-CD, WMA-CD, • MPEG/AC-3/PCM: Compressão USB flash drive digital (16, 20, 24 bits fs, 44.1, 48, 96 USB kHz) • Compatível: USB • MP3 (ISO 9660): 96, 112, 128, 256 • Classe suportada: UMS (USB Mass Storage kbps & variable bit rate fs, 32, 44.1, Class) 48 kHz • Audio analógico estéreo • Downmix compatível Dolby surround TV padrão do áudio Dolby Digital multi-channel • Número de linhas: • 625 (PAL/50Hz); 525 (NTSC/60Hz) Conexões • Reprodução: Multi-standard (PAL/NTSC) • Saída YPbPr: Cinch3x • Saída de Vídeo: Cinch (amarelo) Desempenho de vídeo • Saída de Áudio: (L+R): Cinch (branco/vermelho) • Video DAC: 14 bits, 108 MHz • Saída Digital : • Y Pb Pr: 0.7 Vpp ~ 75 ohm • 1 coaxial: IEC60958 para CDDA/ • Saída de vídeo: 1 Vpp ~ 75 ohm LPCM; IEC61937 para MPEG 1/2, Dolby Digital Unidade Principal Formato de vídeo • Dimensões (L x A x P): 360 x 37 x 209 • Compressão Digital: (mm) • MPEG 2: DVD/SVCD • Peso: aproximado 1.3 kg • MPEG 1: VCD Alimentação • Resolução Horizontal: • Tensão de alimentação : 110 V - 240 V; 50/60 • DVD: 720 pixels (50 Hz); 720 pixels Hz (60 Hz) • Consumo de energia: < 10 W • VCD: 352 pixels (50 Hz); 352 pixels • Consumo de energia no modo standby: (60 Hz) <1W • Resolução Vertical: • • DVD: 576 pixels (50 Hz); 480 pixels (60 Hz) VCD: 288 lines (50 Hz); 240 lines (60 Hz) Especificação do Laser • Tipo: Semicondutor laser InGaAIP (DVD), AIGaAs (CD) • Comprimento de onda: 655 nm (DVD), 790 nm (CD) • Potência de saída: 10 mW (DVD), 5 mW (VCD/CD) • Divergência do feixe: 60 graus 3139 785 3093x Safety Information, General Notes & Lead Free Requirements 2. EN 5 DVP3320 2. Safety Information, General &Requirements Lead Free3139 Requirements 3139 3093x Safety Information, General Notes & Notes Lead Free 785785 3093x Safety Information, General Notes & Lead Free Requirements 2.1 deInformation, segurança, Notas General Gerais & Exigência Sem Chumbo 2.Informações Safety Notes & Lead Free Requirements 2.2. Safety Information, General Notes &de& Lead Free Requirements Safety General Notes Lead Free Requirements 2. 2.1 Instruções deInformation, Segurança General Safety 2.2.1 General 2.1.1 2.1.2 EN 4 2. 3139 785 31500 Safety Instructions Safety Instructions 2.12.1.1 Segurança geral 2.1 Safety Instructions Safety that during a repair: 2.1 regulations Safetyrequire Instructions 2. 2. ENEN 5 5 Safety Information, General Notes & Lead Free Requirements 2.2 Warnings 2.2 Cuidados 2.2 Warnings Warnings 2.2 • 2.2 and many other semiconductors are susceptible to Warnings All ICs 2.2.1 Geral • Connect the unit to the mains via an isolation transformer. electrostatic discharges (ESD, ). Careless handling As normas de Safety segurança requerem que durante um reparo: 2.1.1 General General 2.1.1 General Safety 2.2.12.2.1 General • 2.1.1 Replace safety components, indicated by theum symbol , repairos can reduce life drastically. Make sure that, during • Todos CIs e muitos outros semicondutores são suscetí- •Conecte a unidade principais transformador 2.2.1 General Safety aos cabos General onlyde byisolamento. components identical to the original ones. Any duringveis repair, you are at the same potential asw) thea mass as descargas eletrostáticas (ESD, manipulação Safety regulations require that during a repair: • All ICs and many other semiconductors are susceptible Safety regulations require (other that during a repair:type) • set Allby ICsa and many with otherresistance. semiconductors susceptible to to component than original of the wristband Keep are descuidada durante o reparo pode reduzir a vida drasticamente. other •Recoloque ossubstitution componentes de segurança, indicados pelo sím- Safety regulations require that during a repair: • All ICs and many other semiconductors are susceptible to • Connect the unit to the mains via an isolation transformer. electrostatic discharges (ESD, ). Careless handling Connect unit to the mainsshock via anhazard. isolation transformer. electrostatic discharges (ESD, ). Careless handling may•bolo increase riskthe ofthe re or electrical components and tools this same potential. i, somente pelos componentes idênticos originais. Certifique-se queat durante o reparo, você estáMake no mesmo Connect unit to the mains via anby isolation electrostatic discharges (ESD, ). Careless handling Replace safety components, indicated byaos thetransformer. symbol, , during repair can reduce life drastically. sure that, • • •Replace safety components, indicated the symbol during repair can reduce life drastically. Make sure that, Available ESD protection equipment: Qualquer outra substituição de componente (com exceção potencial que a terra doare aparelho por uma pulseira com resis- • onlyReplace safety components, indicated byones. the symbol during repair Make only by components identical to original the original ones. during repair, you at life the drastically. same potential assure the that, mass byrequire components identical to the Any Any , during repair, youcan arereduce attablemat, the same potential as the mass – Complete kit repair, ESD3 (small wristband, Safety thataumentar after a repair, you must return regulations do tipoonly original) pode o risco de fogo ou choque tência. Mantenha os componentes eresistance. ferramentas mesma by components identical to the original ones. Any during you are at the same potential asnathe mass other component substitution (other than original type) of set the by setaby a wristband with Keep other component substitution (other than original type) of the wristband with resistance. Keep the unit elétrico. in its original condition. Pay, in particular, attention to type) extension cablewith andresistance. earth cable) connection potência. other component (other than original ofcomponents thebox, set by aand wristband Keep may increase of or reelectrical or electrical shock hazard. tools at this same potential. increase risk risk of substitution re shock hazard. components tools at this same potential. the followingmay points: 310 10671.and 4822 Equipamentos de proteção disponíveis ESD: may increase risk of re or electrical shock hazard. components and tools at this same potential. Available ESD protection equipment: Available ESD protection equipment: – Wristband tester 4822(pequenas 344 13999. • Route wires/cables correctly, and x them with the Asthe normas de segurança requerem queadepois de um - Kit completo ESD3 TABLEMAT, WRISTBAND, ESD protection equipment: –Complete Complete kit ESD3 (small tablemat, wristband, caixa Safety regulations require repair, return – Available kit ESD3 (small tablemat, wristband, Safety regulations require that that afterafter a repair, you you mustmust return • Be careful during measurements in(small the live voltage cable clamps. mounted reparo, você deve retornar a unidade na sua condição original. de conexão, cabo de extensão e fio terra) 4822 310 10671. Safety regulations require that after a repair, you must return – Complete kit ESD3 tablemat, wristband, connection box, extension cable and earth cable) the unit in its original condition. Pay, in particular, attention to box, extension cable and earth cable) thethe unitinsulation in its original condition. Pay,forinexternal particular, attention to • Check of the mains lead section. Theconnection primary side of theextension power supply, Preste atenção, particularmente, pontos: - Verificador Wristband 4822 344 13999 connection box, cableincluding and earth cable) the in points: its original Pay,seguintes in particular, attention to theunit following points: condition.nos 4822 310 10671. the following 4822 310 10671. heatsink, carries live mains voltage na when you damage. •Distribua os fios ewires/cables cabos corretamente, eand separe-os com os the • Tenha–cuidado durante a medida seção 4822 310 10671. following •Route Route thepoints: correctly, x them Wristband tester 4822 344 13999.viva da tensão. O –the Wristband tester 4822 344when 13999. • the the wires/cables correctly, andthe x them withwith the the connect player to mains (even the • Check electrical DC resistance between mains suportes de montagem de cabos. lado primário dathe fonte de energia (pos. 105), incluindo o dissi- •the Route the wires/cables correctly, and x them with the – Wristband tester 4822 344 13999. • Be careful during measurements in the live voltage mounted cable clamps. • isBe careful measurements in the live voltage mounted cable clamps. player ‘off’!). Itcalor, isduring possible to copper tracks and/ and the secondary side: plug •Verifique se não há danos na dos fiosfor daexternal rede elétrica. pador decareful carrega atouch tensão dos fios devoltage rede quando mounted cable clamps. • section. Be during measurements in the live section. The primary side ofviva the power supply, including •Check Check the insulation ofisolação the mains lead The primary side of the power supply, including • the insulation of the mains lead for external Unplug thea mains cord,elétrica andof connect a wire or components in this unshielded primary area, when 1. •Verifique resistência DCmains entre os between fios plugue de vocêsection. conecta o aparelho na rede elétrica (mesmo quando o The primary side of the power supply, including • damage. Check the insulation the lead fordo external damage. the heatsink, carries live mains voltage when the heatsink, carries livepersonnel mains voltage when you you two pins ofsecundário: the mains plug. you service theheatsink, player. Service must take the rede e o lado aparelho está desligado!). É possível tocar nas trilhas the carries live mains voltage when you e nos damage. •Check Check the electrical DC resistance between the mains connect the player to mains the mains (even the connect the player to the (even when the • the electrical DC resistance between the mains precautions to prevent touching this areapreliminar or(even components mainsthe switch to de theDC ‘on’resistance position (keep 2. 1.Set • the Desplugue othe cabo rede, e conecte um the fio entre os componentes de cobre desprotegida, connect topossible the área mains when the Check electrical between the mains player isthe ‘off’!). isnesta to touch copper tracks plug and secondary side: player is ‘off’!). Itplayer is Itpossible touch copper tracks and/and/ plug andunplugged!). the secondary side: cord in thisquando area. A você ‘lightning stroke’ and ato stripe-marked mains dois pinos do cabo de rede. prestar serviços de manutenção no aparelho. plug and the secondary side: player is ‘off’!). It is possible to touch copper tracks and/ or components in this unshielded primary area, when 1. Unplug the mains cord, and connect a wire between or components in thisboard, unshielded primary area, when 1. Unplug the mainsvalue cord,between and connect a wire between printing thecomponents printed wiring indicate the primary the thenamains 3. 2.Measure Ajuste osresistance fios do interruptor de rede posição O on pessoal de serviço deve tomar precauções para evitar this unshielded primary area, 1.the Unplug the and connect a wire“ON” between the two pins of mains thecord, mains plug. you service theinplayer. Service personnel must taketocar two pins ofmains the plug. youor service the player. Service personnel must takewhen side of the power supply. plug and the front panel, controls, and chassis (mantenha o cabo de rede desplugado!) esta you área ou em the componentes destapersonnel área. Ummust “lightning stroke” service player. Service take the two pins of the mains plug. 2. Set the mains switch to the ‘on’ position (keep the precautions to prevent touching this area or components precautions to prevent touching this area or components 2. Set the mains switch to the ‘on’ position (keep the bottom. Never éreplace modules, components, the unit 3. Meça omains valor da resistência os pinos do (keep cabo de uma marcada impressa no while painel destripe-marked fiação, indica o lado precautions toAorprevent touching this area or iscomponents 2.mains Set the cord mains switch toentre the ‘on’ position theforça • unplugged!). inlistra this area. ‘lightning stroke’ and a cord unplugged!). in this area. A ‘lightning stroke’ and a stripe-marked 4. Repair correct unit when thede resistance ‘on’. preliminar e oorpainel frontal, botões controle e chassis. da fonte de alimentação. inprinting thison area. A ‘lightning stroke’ and a indicate stripe-marked mains cord unplugged!). Measure the resistance value between the mains on printed the printed wiring board, the primary 3. 3. Measure the resistance value between the mains printing the wiring board, indicate the primary measurement isreparado less than 1 Mȍ. 4. O3.produto está normal quando a resistência • Nunca substitua módulos ou componentes enquanto o produto printing on the printed wiring board, indicate the primary Measure the resistance value between the mains plug and the front panel, controls, and chassis side of the power supply. plug and the front panel, controls, and chassis side of the power supply. 5. Verifymedida this, plug before you the unitcontrols, to the customer/ é de mais de 1 MΩ. estiver ligado. side of replace the power supply. and thereturn front panel, and chassis 2.2.2 Laser bottom. •Never Never modules, or components, while the unit bottom. • replace modules, or components, while the unit is is user Verifique (ref. UL-standard no.de 1492). 5. isto, or antes retornar o produto ao cliente / usuá- • ‘on’.Never bottom. ‘on’. replace modules, or components, while the unit is 4. Repair correct when the resistance 4. the Repair or correct unit unit when the resistance 6. Switch unit ‘off’, and remove the wire between the • The use of optical instruments with this product, will rio4.(ref. UL- padrão no. 1492). 2.2.2 Laser ‘on’. Repair or correct resistance measurement is unit less than 1the Mȍ. measurement is less thanwhen 1 Mȍ. increase eye hazard. two pins ofmeasurement mains para plug. 6. Mude othe produto “OFF”, e remova ounit fio to entre os dois 2.2.2 is less than 1 MΩ. Laser 5. Verify this, before you return the the customer/ 2.2.2OnlyLaser 5. Verify this, before you return the unit to the customer/ personnel may com remove cover irá or aumentar o pinos do plugue de força. •quali OLaser usoeddeservice instrumentos ópticos estethe produto 5. Verify this, before you the unit to the customer/ • 2.2.2 user UL-standard no. 1492). (ref.(ref. UL-standard no.return 1492). attempt to service this device, due to possible eye injury. Laser Safety user perigo de danos aos olhod. user (ref. UL-standard no. 1492). •The The of optical instruments this product, Switch the unit remove the wire between • handling use use of optical instruments withwith this product, will will 6. 6. Switch the unit ‘off’,‘off’, and and remove the wire between the the should take place as much asthis possible 2.1.2 Segurança de of laser • Apenas ouse pessoal de serviço qualificado pode remover • increase The ofeye optical instruments with product, willa tampa 6.twoSwitch andplug. remove the wire between the • Repair increase hazard. two pins the‘off’, mains eye hazard. pins ofthe theunit mains plug. with a disc loaded inside the player. This unit employs a laser. Only quali ed service personnel ou tentar prestar serviço depersonnel manutenção a remove esse dispositivo, two pins of the mains plug. increase eye hazard. •Only Only quali ed service may the cover • quali ed service personnel may remove the cover or or Text below is a placed inside the aos unit, on the laser cover the cover may remove the cover, or attempt to service this device (due 2.1.2 EssaLaser unidade emprega um laser. Somente pessoal de serviço • devido possível danos olhos. • Only quali ed service personnel may remove or attempt to service this device, due to possible eye injury. Safety attempt to service this device, due to possible eye injury. 2.1.2 Laser to possible eyeSafety injury). qualificado pode remover a tampa, ou tentar prestar serviços de shield: • A manipulação do reparo deve ocorrer tanto quanto possível 2.1.2 Laser Safety attempt to service this device, due toaspossible injury. Repair handling should take place much aseye possible • •Repair handling should take place as much as possible manutenção nesse dispositivo (devido a possível danos aos com um disco carregado dentro aparelho • Repair should take place as much as possible with a handling disc loaded inside thedo player. This unit employs a laser. Only quali ed service personnel with a disc loaded inside the player. This unit employs a laser. Only quali ed service personnel Laser Device Unit CAUTION VISIBLE AND RADIATION WHENé OPEN AVOID inside EXPOSURE TO BEAM olhos). INVISIBLE • O•LASER texto abaixo dentro da unit, unidade, nolaser protetor de This unit employs a laser. quali service personnel abelow disc loaded the player. may remove the cover, orOnly attempt to ed service device (due SYNLIG OG Text iscolocado placed inside the on laser the cover • LASERSTRÅLING Textwith below placed the on the cover remove the cover, attempt to service this this device (dueADVARSEL USYNLIG VEDis ÅBNING UNDGÅ inside UDSÆTTELSE FORunit, STRÅLING Type may :orSemiconductor laser ADVARSEL SYNLIG OG USYNLIG NÅR DEKSEL ÅPNES UNNGÅ EKSPONERING STRÅLEN tampa dobelow laser: may remove the injury). cover, or attempt to service this device (due •LASERSTRÅLING Text is placed inside the FOR unit, on the laser cover to possible shield: shield: to possible eye eye injury). VARNING SYNLIG OCH OSYNLIG LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD BETRAKTA EJ STRÅLEN GaAlAs VARO! AVATTAESSA OLET ALTTIINA NÄKYVÄLLE JA NÄKYMÄTTÖMÄLLE LASER SÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN Unidade do dispositivo de Laser shield: to possible eye injury). VORSICHT SICHTBARE UND UNSICHTBARE LASERSTRAHLUNG WENN ABDECKUNG GEÖFFNET NICHT DEM STRAHL AUSSETSEN Wavelength : GaAlAs 650 nm (DVD) DANGER VISIBLE AND INVISIBLE LASER RADIATION WHEN OPEN AVOID DIRECT EXPOSURE TO BEAM Tipo: Laser laser semi-condutor Device Unit Laser Device Unit ATTENTION RAYONNEMENT LASER VISIBLE INVISIBLE EN CAS D’OUVERTURE EXPOSITION DANGEREUSE AU FAISCEAU CAUTION VISIBLE AND ET INVISIBLE LASER RADIATION WHEN OPEN AVOID EXPOSURE TO BEAM : 780 (VCD/CD) CAUTION VISIBLE AND INVISIBLE LASER RADIATION WHEN OPEN AVOID EXPOSURE TO BEAM Comprimento de onda: nmnm (DVD) ADVARSEL SYNLIG OG USYNLIG LASERSTRÅLING VED ÅBNING UNDGÅ UDSÆTTELSE FOR STRÅLING Laser Unit 650 Type Device : Semiconductor ADVARSEL SYNLIG OG USYNLIG LASERSTRÅLING VED ÅBNING UNDGÅ UDSÆTTELSE FORTO STRÅLING CAUTION VISIBLE AND RADIATION WHEN OPENÅPNES AVOID EXPOSURE BEAM FOR STRÅLEN Type : Semiconductor laserlaser ADVARSEL SYNLIG OGINVISIBLE USYNLIG LASER LASERSTRÅLING NÅR DEKSEL UNNGÅ EKSPONERING Output Power : 20 mW ADVARSEL SYNLIG OG USYNLIG LASERSTRÅLING NÅR DEKSEL ÅPNES UNNGÅ EKSPONERING FOR STRÅLEN ADVARSEL SYNLIG OG USYNLIG LASERSTRÅLING VED ÅBNING UNDGÅ UDSÆTTELSE FOR STRÅLING 780nm (VCD/CD) VARNING SYNLIG OCH OSYNLIG LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD BETRAKTA EJ STRÅLEN Type : Semiconductor laser GaAlAs VARNING SYNLIGSYNLIG OCH OSYNLIG LASERSTRÅLNING NÄRNÅR DENNA DEL ÄR ÖPPNAD BETRAKTA EJ STRÅLEN ADVARSEL OGOLET USYNLIG LASERSTRÅLING DEKSEL ÅPNES UNNGÅ FOR STRÅLEN GaAlAs VARO! AVATTAESSA ALTTIINA NÄKYVÄLLE JA NÄKYMÄTTÖMÄLLE LASER EKSPONERING SÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN Figure 2-2 (DVD+RW writing) VARO!VARNING AVATTAESSA OLET ALTTIINA NÄKYVÄLLE JA NÄKYMÄTTÖMÄLLE LASER SÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN SYNLIG OCH OSYNLIG LASERSTRÅLNING NÄR DENNAWENN DEL ÄR ÖPPNAD BETRAKTA EJNICHT STRÅLEN Potência de saída: 20 mW (DVD+RW writing) VORSICHT SICHTBARE UND UNSICHTBARE LASERSTRAHLUNG ABDECKUNG GEÖFFNET DEM STRAHL AUSSETSEN GaAlAs Wavelength : 650 nm (DVD) VORSICHT SICHTBARE UND UNSICHTBARE LASERSTRAHLUNG WENN ABDECKUNG GEÖFFNET NICHT DEM STRAHL AUSSETSEN VARO! AVATTAESSA OLET ALTTIINALASER NÄKYVÄLLE JA NÄKYMÄTTÖMÄLLE LASER SÄTEILYLLE. ÄLÄ Wavelength : 650 nm (DVD) DANGER VISIBLE AND INVISIBLE RADIATION WHEN OPEN AVOID DIRECT EXPOSURE TOKATSO BEAM SÄTEESEEN : 0.8 mW DANGER VISIBLESICHTBARE AND INVISIBLE LASER RADIATION WHEN OPEN AVOID DIRECT EXPOSURE TO BEAM VORSICHT UND UNSICHTBARE LASERSTRAHLUNG WENN ABDECKUNG GEÖFFNET NICHT DEM STRAHL AUSSETSEN : 0.8 mW (leitura de DVD) ATTENTION RAYONNEMENT LASER VISIBLE ET INVISIBLE EN CAS D’OUVERTURE EXPOSITION DANGEREUSE AU FAISCEAU Wavelength : : 650 780 nm(DVD) (VCD/CD) ATTENTION RAYONNEMENT LASER VISIBLE ETRADIATION INVISIBLE WHEN EN CAS D’OUVERTURE EXPOSITION DANGEREUSE DANGER VISIBLE AND INVISIBLE LASER OPEN AVOID DIRECT EXPOSURE TO BEAM AU FAISCEAU : reading) 780 nmnm (VCD/CD) (DVD 2.2.3 Notes ATTENTION RAYONNEMENT LASERFigura VISIBLE ET INVISIBLE : 0.3 mW (leitura de VDC/CD) 2-2 EN CAS D’OUVERTURE EXPOSITION DANGEREUSE AU FAISCEAU : 780 nm (VCD/CD) Output Power : 20 mW Output Power : 20 mW 0.3 mW : 20 mW Divergência do feixe: 60: graus Output Power Figure (DVD+RW writing) Figure 2-2 2-2 (DVD+RW (VCD/CD reading) writing) Dolby 2.2.3 Notas Figure 2-2 : (DVD+RW 0.8 mW writing) : 0.8 mW Beam divergence : 60 degree Manufactured under licence from Dolby Laboratories. “Dolby”, : 0.8 mWreading) (DVD 2.2.3Notes Notes (DVD reading) 2.2.3 “Pro Logic” and the double-D symbol are trademarks of Dolby Dolby reading) 2.2.3 Notes : (DVD 0.3 mW : 0.3 mW Laboratories. Condential Works. Manufaturado sob Unpublished licença do Dolby Laboratories. "Dolby", "Pro : 0.3 mW (VCD/CD reading) Dolby (VCD/CD reading) ©1992-1997 Dolby Laboratories, Inc. Allmarcas rights reserved. Dolby Logic" e o símbolo duplo-D são resgistradas do Laborató (VCD/CD reading) Dolby Beam divergence 60 degree Manufactured under licence Dolby Laboratories. “Dolby”, Beam divergence : 60: degree under licence fromfrom Dolby Laboratories. “Dolby”, Manufactured rio Manufactured Dolby. CLASS 1 Beam divergence : 60 degree under licence from Dolby Laboratories. “Dolby”, “Pro Logic” and the double-D symbol are trademarks of Dolby “Pro Logic” and the double-D symbol are trademarks of Dolby © 1992-1997 Laboratório Dolby, Inc. Todos os direitos reservados. LASER PRODUCT “Pro Logic”Con andCon the double-D symbolWorks. areWorks. trademarks of Dolby Laboratories. dential Unpublished Laboratories. dential Unpublished Laboratories. Con dential Unpublished Works. ©1992-1997 Dolby Laboratories, Inc. All rights reserved. ©1992-1997 Dolby Laboratories, Inc. All rights reserved. Figura 2-1 CLASS 1 ©1992-1997 Dolby Laboratories, Inc. All rights reserved. CLASS 1 Figure 2-3 Figure 2-1PRODUCT CLASS 1 LASER LASER PRODUCT Nota: o uso dos controles ou do ajuste ou o desempenho do pro- LASER PRODUCT cedimento à exceção daqueles especificado neste manual, podem Trusurround TRUSURROUND, SRS and symbol (g 2-4) are trademarks Figura 2-3 resultar na exposição perigosa à radiação. Evite a exposição direta Note: Use of controls or adjustments or performance of Figure 2-3 Figure 2-3 Figure 2-1 of SRS Labs, Inc. TRUSURROUND technology is Figure 2-1may ao feixe. Figure 2-3 procedure other than those specied herein, result in Figure 2-1 manufactured under licence frm SRS labs, Inc. Trusurround hazardous radiation exposure. Avoid direct exposure to beam. Trusurround Trusurround TRUSURROUND, SRS e o símbolo (fig. 2-4) são marcas registra Trusurround TRUSURROUND, SRS and symbol (g 2-4) are trademarks TRUSURROUND, and symbol (g 2-4) are trademarks Note: Use of controls or adjustments or performance of das do LaboratórioSRS SRS, Inc. A tecnologia é Note: Use of controls or adjustments or performance of TRUSURROUND, SRS and symbol (technology gTRUSURROUND 2-4) are trademarks of SRS Labs, Inc. TRUSURROUND is of SRS Labs, Inc. TRUSURROUND technology is Note: Use of controls or adjustments or performance of procedure other those speci ed herein, result manufaturada sob licença do laboratório SRS, Inc. procedure other thanthan those speci ed herein, maymay result in in ofmanufactured SRS Labs, Inc. TRUSURROUND technology under licence frm SRS labs, manufactured under licence frm SRS labs, Inc. Inc. is procedure other than those speci ed herein, may result hazardous radiation exposure. Avoid direct exposure toinbeam. hazardous radiation exposure. Avoid direct exposure to beam. manufactured under Figure 2-4licence frm SRS labs, Inc. hazardous radiation exposure. Avoid direct exposure to beam. Figura 2-4 Figure Figure 2-4 2-4 Figure 2-4 93x Safety Information, General Notes & Lead Free Requirements 3139 785 3093x EN 6 2. Safety Information, General Notes & Lead Free Requirements 6 EN DVP3320 3139 785 3093x Safety Information, General Notes &some Lead Free Requirements Due to lead-free technology rules have to be respected by the Video 2. Plus workshopby during “Video Plus+” Due and to “PlusCode” are registered trademarks of to be respected lead-free technology some rules have the a repair: the Gemstar Development Corporation. workshop during a repair: The “Video Plus+” stered trademarks of Due to lead-free technology some rules have to beSAC305 respected byorder the Video Plus x Use only lead-free solder alloy Philips with system is manufactured under licence from the Gemstar n. The “Video Plus+” Vídeo Plus companhias externas. workshop during a repair: “Video Plus+” and “PlusCode” are registered trademarks of code 0622 149 00106. If lead-free solder-pate is required, Development Corporation. x Use only lead-free solder alloy Philips SAC305 with order from the Gemstar "Video e "Plus Code" são marcas registradas do Plus+” Gemstar • Informações para ICs BGA sem chumbo: estes ICs thePlus+" Gemstar Development Corporation. The “Video pleaseespeciais contact the manufacturer of your solder-equipment. code 0622 149 00106. If lead-free solder-pate is required, Development Corporation. O sistema "Video Plus+" é fabricado serão entregues no chamado “pacote a seco” para proteger o IC system is manufactured under licence from the Gemstar x Use only lead-free solder alloy Philips SAC305 with order In general use of solder-paste within workshops should be please contact the manufacturer of your solder-equipment. sob Development a licença da Gemstar Development Corporation. contracode umidade. Este pacote só pode ser aberto pouco antes de 0622 149 00106. If lead-free solder-pate is required, Corporation. avoided In general use of solder-paste within workshops should be because paste is not easy to store and to handle. ser usado Oumanufacturer então o corpo doyour IC fica “molhado” dentro please contact the solder-equipment. Use(soldado). only adequate solder tools of applicable for lead-free avoided because paste is not easy to store and to x handle. e durante o tempo de aquecimento a estrutura do IC será destruInsolder general use of solder-paste within workshops should be alloy. The solder tool must be able x Use only adequate solder tools applicable for lead-free ída por causa da altaattemperatura corpo. pacote for avoided pasteaissolder-temperature notdentro easy todostore and toohandle. o To because reach least ofSe 400°C, solder alloy. The solder tool must be able aberto antes uso, o the ICsolder deve ser por algumas horas x Use onlydoadequate toolsesquentado applicable for lead-free adjusted temperature at the solder-tip o To reach at least a solder-temperature of 400°C, o To stabilize o (em torno de 90 ) Para secar (pense na proteção ESD!). NÃO solder alloy. The solder tool must be able Figure 2-5 o To exchange solder-tips for different applications. REo To stabilize the adjusted temperature at the solder-tip Figura 2-5 modo algum! o To de reach at least a solder-temperature of 400°C, USExBGAs Adjust your solder tool so that a temperature around 360°C o To exchange solder-tips for different applications. • Para produtos produzidos ante de 1.1.2005, contendo ferramenta o To stabilize the adjusted temperature at the solder-tip 380°C is reached and stabilized at the solder joint. x Adjust your solder tool so that a temperature around –360°C Figure 2-5 Microvision de solda chumbo solder-tips e componentes, toda a applications. lista de peças será o com To exchange for different Macrovision – 380°C is reached and stabilized at the solder joint. Heating-time of the solder-joint should not exceed ~ 4 sec. Este produto incorpora tecnológia de proteção de cópia que é that avaliada atéyour o fimsolder do período serviço. Para reparo destes x Adjust tool sodethat a temperature around 360°C This product incorporates copyright protection technology Heating-time of the solder-joint should not exceed ~ Avoid 4 sec. temperatures above 400°C otherwise wear-out of tips o metódo dethat proteção exigidoclaims da certificado U.S depatents patentes e aparelhos, nada muda. – will 380°C is reached and stabilized at the solder joint. is protected by method of certain U.S. and otection technology rise drastically and ux- uid will be destroyed. To avoid Avoid temperatures above 400°C otherwise wear-out of tips Macrovision • No website outros proprietários intelectuais da própria Macrovision Corporawww. atyourservice.ce.Philips.com encontra mais Heating-time of the solder-joint should notvocê exceed ~ 4 sec. other property rights owned by Macrovision in U.S. patents and intellectual will rise drastically and ux-uid will be destroyed. Towear-out avoid of tips switch off un-used equipment, or reduce This product incorporates copyright protection technology that tion. Corporation and other rights owners. informações sobe: Avoid temperatures above 400°C otherwise wear-out of tips d by Macrovision heat. wear-out of tipsU.S. switch off un-used or reduce isUse protected method claims ofde certain patents and equipment, O uso desta de protection proteção cópia deve ser be autorizada • (De) xSolda BGA (+ instruções de operação). will rise drastically and ux- uid will be destroyed. To avoid of tecnologia thisby copyright technology must Mix of lead-free solder alloy / parts with leaded solder alloy heat. other intellectual property rights owned by Macrovision pela Macrovision Corporation e é permitido para casas e outros • Perfis de aquecimento dos BGAs e outros ICs usados em aparewear-out ofpossible tips switch off un-used equipment, or reduce Corporation, and is intended for logy must be authorized by Macrovision / parts is but PHILIPS recommends strongly to x Mixowners. of lead-free solder alloy / parts with leaded solder alloy Corporation and other rights somente da Macrovision Corporation. A lhos Philips. heat. mixed solder alloy types (leaded and lead-free). home otherautorização limited viewing only unless otherwise n, and is limites intended forand com / partstechnology isuses possible but PHILIPS recommends stronglyavoid to Use of this écopyright protection must beengineering desmontagem proíbida. x Mix of lead-free solderoralloy parts withwhether leaded solder alloy authorized by Macrovision Corporation. Reverse nly unless otherwise If one cannot avoid does/ not know product is avoid mixed solder alloy types (leaded and lead-free). authorized by Macrovision Corporation, and is intended for Você /encontra estas e mais informações técnicas em “magazine”, parts is possible but PHILIPS recommends strongly to or disassembly is prohibited. n. Reverse engineering lead-free, clean carefully the solder-joint from old solder If one uses cannot avoid or does not know whether product is home and other limited viewing only unless otherwise capítulo “workshop news”. 2.3 Solda sem chumbo avoid mixed solder alloy (leaded and(SAC305). lead-free). alloy and re-solder withtypes new solder alloy clean carefully the solder-joint from old solder authorized by Macrovisionlead-free, Corporation. Reverse engineering If Use one only cannot avoidspare-parts or does notlisted knowinwhether product is 2.3 orLead Free Requirement x original the Service-Manuals. alloy and re-solder with new solder alloy (SAC305). disassembly is prohibited. Para lead-free, questões por favor, contate o from helphas desk local. A Philips CE está produzindo aparelhos sem chumbo (PBF) de clean carefully the solder-joint old solder Not listedadicionais, standard-material (commodities) to be x Use only original spare-parts listed in the Service-Manuals. 1.1.2005 para frente. alloy and re-solder with new solder alloy (SAC305). purchased at external companies. Not listed standard-material (commodities) has to be Information about Lead-free produced sets 2.3 Lead Free Requirement xxUse only original spare-parts listed in the Service-Manuals. Special information for BGA-ICs: purchased at external companies. ed sets 3. Instrução destandard-material Usothe 12nc-recognizable Identificação: A etiqueta de modelo tem um número de série de 14 Not listed (commodities) has to be - always use soldering temperature x Special information BGA-ICs: Philips CE is starting production of lead-freefor sets from dígitos. Os dígitosabout 5 e 6 Lead-free referem-seproduced ao ano desets produção, os dígitos purchased at external companies. Information pro le of the speci c BGA (for de-soldering always use the - always use the 12nc-recognizable soldering temperature 1.1.2005 onwards. d-free sets Manualinformation no GIP. for BGA-ICs: 7 efrom 8 referem-se à semana de produção (no exemplo abaixo, é Veja x oSpecial lead-free prole of the specic BGA (for de-soldering always use the temperature prole, in case of doubt) 1991Philips na semana - always useBGA-ICs the 12nc-recognizable soldering temperature CE is 18). starting production of lead-free setspro from - lead free will be delivered in so-called ‘drylead-free temperature le, in case of doubt) INDENTIFICATION: pro le of the speci c BGA (for de-soldering always use 1.1.2005 onwards. packaging’ (sealed pack including a silica gel pack) to the - lead free BGA-ICs will be delivered in so-called ‘drylead-free temperature le, in case doubt) dependent protect the IC againstpro moisture. Afterofopening, packaging’ (sealed pack including a silica gel pack) to Regardless of special logo (not always indicated) - lead free BGA-ICs willindicator-label be delivered ininso-called INDENTIFICATION: of MSL-level seen on the bag, ‘drythe protect the IC against moisture. After opening, dependent s indicated) packaging’ (sealed pack including a silica gel pack) to of MSL-level seen on indicator-label in the bag, the BGA-IC possibly still has to be baked dry. (MSL=Moisture One must treat all sets from 1 Jan 2005 onwards, according protect the IC against moisture. After opening, dependent Sensitivity Level). This will be communicated via AYSpossibly still has to be baked dry. (MSL=Moisture Regardless of special logoBGA-IC (not always indicated) next 05 onwards, according Apesar do rules. logo especial sem chumbo (que nem sempre é ofwebsite. MSL-level seen on indicator-label in the bag, the Sensitivity Level). This will be communicated via AYSindicado),todos os aparelhos desta data pra frente de acordo com BGA-IC still has to be baked dry. (MSL=Moisture Do not possibly re-use BGAs at all. website. One treat all sets from 1 Jan 2005 onwards, according Example S/N:must as regras descritas abaixo. Sensitivity Level). This will be communicated via AYSDo not re-use BGAs at all. next rules. xwebsite. For sets produced before 1.1.2005 (except products of Do not re-use BGAsleaded at all. solder-alloy and components, containing Example S/N: x For sets produced before 1.1.2005 (except products 2004), of all needed spare-parts will be available till the end of the 2004), containing leaded solder-alloy and components, x For sets produced before products of For repair1.1.2005 of such (except sets nothing changes. all needed spare-parts will be available till the end ofservice-period. the 2004), containing leaded solder-alloy and components, service-period. For repair of such sets nothing changes. needed spare-parts will be available till the end of theyou xallOn our website www.atyourservice.ce.Philips.com service-period. For repair nd more information to:of such sets nothing changes. x On our website www.atyourservice.ce.Philips.comyou nd more information to: x On our website www.atyourservice.ce.Philips.com you BGA-de-/soldering (+ baking instructions) nd more information to: and other ICs used in Philips-sets Heating-pro les of BGAs BGA-de-/soldering (+ baking instructions) Heating-proles of BGAs and other ICs used in Philips-sets Com a tecnologia sem chumbo, algumas regras devem ser respei BGA-de-/soldering (+ baking instructions) You will nd this and more technical information within the Bottom line of typeplate gives a 14-digit S/N. Digit 5&6 is the year, digit 7&8 is tadas pelo posto autorizado durante o reparo: Heating-pro les of BGAs and other ICs used in Philips-sets “magazine”, chapter “workshop news”. You the the week number, so in this case 1991 wkwill 18 nd this and more technical information within 6 is the year, digit 7&8 is • Use apenas ferramentas de solda sem chumbo Philips SAC305 “magazine”, chapter “workshop news”. o0501 código de pedido 149 Seisathe pasta solda sem You will nd this and more technical information within the Socom from onwards = from 10622 Jan 2005 onwards Bottom line of typeplate gives a 14-digit S/N.00106. Digit 5&6 year,de digit 7&8 is chumbo for necessária, favor contate o fabricante do equi“magazine”, chapter “workshop news”. the week number, so in this casepor 1991 wk 18 For additional questions please contact your local repair-helpdesk. pamento de solda. No geral, o uso de pasta de solda em postos For additional questions please contact your local repair-helpdesk. SoImportant from 0501 onwards = from 1 Jan 2005 onwards In fact alsopois products of yearnão 2004émust be treated manuseada in this way as long as you deve note: ser evitada a pasta facilmente nem avoid mixing solder-alloys (leaded/ lead-free). So best to always use SAC305 and the higher armazenada. For additional questions please contact your local repair-helpdesk. ated in this way as long as you temperatures belong to this. ys use•SAC305 the higher Useand apenas ferramentas de solda aplicáveis para ferramenta de Important note: In fact also products of year 2004 must be treated in this way as long as you solda sem chumbo. A ferramenta de solda deve: avoid mixing solder-alloys (leaded/ lead-free). So best to always use SAC305 and the higher temperatures - Alcançar nathis. ponta da ferramenta a temperatura de pelo menos belong to 400o - Estabilizar o ajuste de temperatura na ponta da solda. - Troque a ponta de solda para diferentes aplicações. • Ajuste sua ferramenta de solda para que a temperatura de 360o - 380o seja alcançada e estabilizada na junção da solda. O tempo de aquecimento da junção da solda não deve exceder ~ 4s. Evite temperaturas acima de 400o , ou então "wear-out" das pontas irá aumentar drasticamente e o fluxo- fluido será destruído. Para evitar "wear-out" de pontas, desligue o equipamento quando não usado ou reduza a temperatura. • Misturar parte/ ferramenta de solda sem chumbo com partes/ ferramentas de solda com chumbo é possível mas a PHILIPS recomenda que se evite isso. Se não puder ser evitado, cuidadosamente limpe a solda da antiga ferramenta e re-solde com uma nova ferramenta. • Use apenas peças originais listadas no Manual de Serviço. Materiais padrão não listados (comodities) devem ser comprados em DVP3320 Instruções Mecânicas e Desmontagem Instruções de Desmontagem O guia a seguir mostra como desmontar o aparelho. Passo 1: Remova os 5 parafusos da Tampa Superior e retire-a. (Figura 1). Figura 1 Passo 2: Se for necessário desmonte o Painel Frontal ou o Carregador, a porta Frontal deve ser removida primeiro. (Figura 2) Nota: Certifique-se de operar gentilmente ou o guia pode ser danificado. Certifique-se de desmontar a porta frontal cuidadosamente para não danificar a bandeja e a porta frontal. Figura 2 DVP3320 3-2 Mechanical and Dismantling Instructions Instruções de Desmontagem Dismantling Instruction Detailed information please refer to the model set. Passo Se can’t a bandeja não pode way, ser aberta normalmente, podemos abri-la seguindo instruções Step3: If the3:tray open in normal you can make it through the instruction as belowas(Figure 3). abaixo (Figura 3). de operar gentilmente nãowould danificar o guia. Note:Nota: MakeCertifique-se sure to operate gently otherwise thepara guider be damaged. Figura 3 Figure 3 Passo 4: Desmontagem do disconnect Painel Frontal, solte os conectores (XP1), solte 4assnaps 4 travas do Painel Step4: Dismantling Front Panel, the connectors (XP1), need release of Front PanelFrontal as 2 travas do gabinete então retire Painel aparelho. and 2e snaps of bottom cabinet ,inferior, then gently pull the oPanel outdofrom the set.(Figura (Figure44- -Figura Figure6)6) XP7 XP5 XP6 XP8 XP9 FigureFigura 4 4 XP10 XP2 XP1 DVP3320 Figura 5 Passo 5 : Desmontagem do Carregador, solte os 3 conectores (XP7, XP8, XP9 ) conforme a figura abaixo e remova o parafuso que conecta o carregador e o gabinete frontal. (Figura 5 & 6) Figura 6 DVP3320 Passo 6: Desmontagem do Painel Principal, primeiro desconecte (XP2), e remova os 4 parafusos. (Figura 7) Passo 7: Remova os 4 parafusos do Painel Power para desmontá-lo. (Figura 7) Figura 7 DVP3320 Atualização do Software B. Lendo a versão do Firmware para confirmar a Como atualizar o software 1) A. atualização Grave os dados em um disco CD-R ou RW virgem. 1) Ligue o aparelho e Abra a porta da bandeja. 2) Pressione as teclas <9><6><6> para checar as Procedimentos para atualização do software: 1) Ligue o aparelho e insira o CDR de atualização A versão do software e as outras informações aparecem na tela do TV como segue: preparado. 2) O aparelho ligará lendo o disco e aparecerá Versão BE: DVP33XX_XX.XX Versão FE: XXXX.XXXXXX a seguinte tela no TV: Versão DSP: DSP.XX Loading Firmware Upgrade Erase and program. OK informações do software. Código da Região: X Cancel Selecione OK para iniciar a atualização. 3) Pressione a tecla <OK> para confirmar, a tela mostrará : Firmware Upgrade Programming, Please Wait... Do not Switch the Player Off ! 4) O disco de atualização dairá automaticamente quando estiver completada a cópia dos arquivos, retire o disco. 5) Após 1 minuto, a bandeja fechará automaticamente quando a atualização estiver completa. Troca do Código da Região 1) Ligue o aparelho e abra a porta da bandeja; 2) Pressione "9" "8" "7" "9" e o número código da região (0-6) no controle remoto. Notas: reinicie após os passos acima. Atenção: O aparelho não deve ser desligado durante a atualização, pois o Painel Principal será danificado inteiramente. 10 DVP3320 FLUXOS SOLUÇÃO DE PROBLEMAS Motor Spindle não funciona Motor não funciona Acesse Cheque o conector FFC Não Faça a conexão correta de 24P no carregador Sim Cheque se “RFA5V” Não Cheque a alimentação RFA5V Não Cheque/Troque Q4,Q5 tensão (+5V) esta normal Sim Cheque se tensão de laser (2,3V para DVD & 1,9V para CD) no Coletor de Q4 e Q5 Sim 1.Se tensão no pino 97 do U2 varia entre 0 e 3.3V (3.3V para CD e 0V para DVD), 2. Se componentes periféricos estão corroídos ou mal soldados Não Cheque/troque U2. Sim Não tem foco Não 1. Cheque U2 pino 89, sinais FOCUS_PWM 2.Se existe sinais F+, F-, T+ e Tnas saídas de U4. Sim Cheque/troque o carregador forma de onda FOCUS_PWN DVP3320 Não é possível ligar ou desligar Não é possível ligar ou desligar Acesse Cheque se a alimentação Não no painel power esta normal Repare o painel power Sim Cheque se o CON2 no painel Yes frontal do XP6 no painel decodificador Não Cheque/Faça a conexão correta esta com bom contato. Sim Cheque se XP1 no painel decodificador para XS301 no painel frontal esta com bom contato. Sim Não Faça a conexão correta 11 12 DVP3320 Todas as saídas de tensões do painel power estão 0V ou erradas. Todas as saídas de tensões do painel power estão 0V ou erradas Sim Cheque se Sim Troque F1 F1 está queimado Não Cheque se existe Não Troque C1 e C2 se D1, D2, D3, D4 estiverem normal. 300V no C1 ou C2. Sim Cheque se sinal do oscilador Não Cheque/troque U1. de 100KHz no Pino 6 do U1 U1(PINO 3 - RC forma de onda) U1(PINO 8 - Desenho da forma de onda) Sim Cheque se +5V e +12V estão em curto Sim Cheque se os componente na tensão do curto-circuito estão defeituosos ou corroídos. Não Cheque se U2 está corroído DVP3320 Disco não pode ser lido Disco não pode ser lido Sim Cheque a conexão FFC de Não Cheque o circuito carregador 24P até o carregador Sim Cheque se existe tensão laser (2,3V para DVD e 1,9V para CD) no coletor de Q4 e Q5 1.Cheque se a tensão no pino 97 de U2 varia entre 0 e 3.3V: 3.3V para CD 0V para DVD 2. Cheque se componentes periféricos estão corroídos ou defeituosos. Não Sim Cheque U2, U4,e componentes periféricos estão corroídos ou mal soldados Não Re-solde ou troque as partes defeituosas Sim Cheque se existe sinal RFO no pino 10 do XP7. (O sinal normal RFO é uma onda reticulada limpa) Não Cheque U1 e componentes periféricos Sim Cheque a conexão de U2 Sim Troque U2 ou o carregador Não Faça a conexão correta 13 14 DVP3320 Somente disco DVD ou somente disco exceto DVD é reproduzido Somente disco DVD ou somente disco exceto DVD é reproduzido Acesse Cheque a conexão FFC de 24 pinos até o carregador Não Cheque o circuito carregador Sim Cheque a tensão de saída do laser (2,3V) no coletor de Q4 e se o pino 87 de U2 está em nível baixo Não Cheque a solda em U2 e componentes periféricos Sim Cheque se existe tensão variavel no pino 88 do U2. Não Cheque se solda esta ruim em U2 e componentes periféricos Sim Cheque se os pinos de U2 e componentes periféricos estão mau soldados ou defeituosos Não Troque as partes defeituosas Sim Cheque s e Q4 está em boas condições Sim Troque U2 ou o carregador Não Faça a conexão correta DVP3320 Sem display e teclas não funcionam Sem display e teclas não funcionam Sim Cheque se existe contato correto entre XS301 e XP1 Não Faça a conexão correta Sim Cheque a tensão VCC (+5v) no painel power e no painel frontal Não Troque o painel power Sim Cheque se existem os sinais CS,DATA e CLK no XS301 no painel frontal Não Cheque os pinos 48, 95, 96 do U2 cheque as condições do conector XP1. XP1 (PINO 1 CLK) XP1 (PINO3 DOUT) Sim 1.Cheque se solda esta ruim em U600 e pinos do LED, 2.Cheque se os circuitos conectados em K301, K302 estão quebrados, 3.Cheque se R303, R301 e R302 estão com circuito aberto. Sim Troque U301 ou LED Não Faça a conexão correta 15 16 DVP3320 Distorção do áudio e ruído alto Distorção no áudio e ruído alto Sim Cheque as tensões de alimentação +12V Não Cheque se a saída do painel Power esta normal. Se anormal, troque painel Power. Sim Cheque se os transistores mute R73, R77 estão normais Não Troque R77, R73 Sim Cheque se os transistores mute Q8, Q10,Q12 estão normais Não Troque Q8, Q10,Q12 Sim Cheque os fios U5 não estão quebrados ou abertos Não Faça a conexão correta Sim Cheque se a alimentação de U7 ou U8 estão normais Sim Troque U7 ou U8 Não Cheque U7, U8 DVP3320 Cor anormal da imagem Cor anormal da imagem Sim Cheque se o sinal de saída Não de 27MHz está normal Cheque Y2, R28, C31 e C33 Sim Cheque se as tensões 3.3V e 1.8V da alimentação no painel decodificador estão normais Não Cheque outros circuitos elétricos da alimentação Sim Cheque se o circuito da rede do filtro de vídeo esta normal Não Faça a conexão correta Sim Cheque se o sinal de vídeo nos pinos 58,60,61,63 de U1 estão normais Não Troque U2 17 18 DVP3320 Recepção remoto está insensível ou falhando. Recepção do remoto está insensível ou falhando Acesse Cheque se o controle remoto funciona apropriadamente Não Cheque as pilhas Sim Cheque se a tensão da alimentação para o sensor do remoto está normal Não Cheque L2 Sim Use um osciloscópio para checar se existe saída da forma de onda do primeiro pino IR do sensor do remoto após pressionar um botão Não IR600 (pino1-forma de onda do controle remoto) Sim Cheque se existe sinal IR no pino 49 do U2 Sim Troque U2 IR forma de onda Não Faça a conexão correta DVP3320 19 Sem vídeo e sem áudio Sem vídeo e sem áudio Cheque se todas as tensões do painel power para o painel decodificador estão normais Não Cheque o circuito carregador CVBS(ponto R1) forma de onda Sim Cheque se o circuito de reset (CE3, D2 e R21) está normal (no nível alto para milisegundos, está constante no 3,3V). Não Troque CE3, D6 e R21 Sim 27Mhz forma de onda Cheque se existe sinal de saída 27MHz Oscilador Cristal Y2 e componentes periféricos estão defeituosos ou corroídos Não Sim Cheque se existe sinal de Cheque se existe curto-circuito ou solda ruim em U1,U3 Não saída 135MHz em R31 SDRAM(R31 PCLK) forma de onda Não Sim Cheque se existe curtocircuito e solda ruim no pino 60 Sim Reconecte o componente Não Cheque U2. 20 ANOTAÇÕES: DVP3320DVD703 /XX DVP3320 6-1 DIAGRAMA DE LIGAÇÕES 6-1 A B C D E DVP3320(2CH+USB) WIRING DIAGRAM 4 4 XP5 Y Pb CVBS AUDIO AMP&LPF 24 VIDEO LPF&DRIVE XP7 24PIN*0.5 1 LOAD+ LOADTROUT GND TRIN 2 XP9 5PIN*2.0 5 64M/16M SDRAM AM5888S 6 1 MOTER DRIVER 1 1 SPSP+ LIMIT GND SLSL+ 6PIN*2.0 XP8 ZR36966XE2/XF2 8M/16M FLASH XP1 6PIN*2.0 1 6 +5V G ND 5 2 4 4PIN*2.0 1 6 XS301 (3-8PIN) 6PIN*2.0 1 USB LED- POWER+ POWER-K XS302 XP601 (4-7PIN) 1 LED+ 4PIN*2.0 4 4 SWITCH XP1 BOARD 4PIN*2.0 CON2 5PIN*2.5 +5V GND +12V 5 3 IR 5V GND DATA CS CLK MAIN BOARD MP-1 1 XP11 4PIN*2.0 1 POWER SUPPLY 1 ASA + SANYO DV38 P2 XP2 5PIN*2.5 DVD LOADER R L P1 DOWN-LOAD 3 COAX Pr 4 1 1 A B C D E 21 22 DVP3320 PAINEL FRONTAL - ESQUEMA ELÉTRICO 7-1 7-1 5 4 3 2 1 Front Board Electric Diagram for DVP3320: VCC D U5V D R315 )5200$,1%2$5' 5 REM301 5 4 4 VCC GND IR 3 2 1 for dvp331x IR VCC GND DATA CS CLK 1 2 3 4 5 6 7 8 9 10 11 C306 0.1u C315 47p WAKE_SW U5V R320 V CC 0R 100R/NC + REM XS301 1 2 3 4 100 ohm R318 IR LED+ LEDPOWER_K1 POWER_K XS302 CON4(2.0) CE301 47uF C316 100p IR DATA CS CLK U5V STB_LED C307 100p C308 100p VCC POWER_K STB_LED R303 R304 R305 5VL CON11(2.0) LEDC309 C310 0.1uF 0.1uF R306 4K7 4K7 4K7 R317 33R 51K U301 ET6202 C DATA CLK CS R300 R301 R302 100 100 100 R307 R308 10K 10K R309 R310 100P C303 0.1u 1K 1K SEG1 SEG2 SEG3 SEG4 SEG5 SEG6 C300 C301 C302 100P 100P 1 2 3 4 5 6 7 8 9 10 11 12 13 14 CE300 + GRID[1:7] OSC DI/O CLK STB KEY1 KEY2 VDD SEG1/KS1 SEG2/KS2 SEG3/KS3 SEG4/KS4 SEG5/KS5 SEG6/KS6 SEG7/KS7 GND GRID1 GRID2 GND GRID3 GRID4 GND VDD SEG14/GRID5 SEG13/GRID6 SEG12/GRID7 SEG10/KS10 SEG9/KS9 SEG8/KS8 28 27 26 25 24 23 22 21 20 19 18 17 16 15 GRID1 GRID2 GRID3 GRID4 5VL GRID7 GRID6 GRID5 LED+ R316 33R LED1 GRID1 GRID2 GRID3 GRID4 GRID5 GRID6 GRID7 SEG1 SEG2 SEG3 SEG4 SEG5 SEG6 1 2 3 4 5 6 7 8 9 10 11 12 13 C GRID1 GRID2 GRID3 GRID4 GRID5 GRID6 GRID7 SEG1 SEG2 SEG3 SEG4 SEG5 SEG6 JDD350501AG 47uF SEG[1:6] KEY1 KEY2 K301 B 1N4148 D301 R312 1N4148 D302R311 1K 1K R313 KS2 1K K302 open/close WAKE_SW POWER_K B R314 R319 0R play/pause 0R/nc POWER_K1 C304 100p C305 100p A A 5 4 3 2 1 DVP3320 PAINEL SWITCH - ESQUEMA ELÉTRICO 7-2 A 7-2 B C D E Switch Board Electric Diagram for DVP3320: 1 1 K303 1 2 3 4 2 XP1 CON4(2.0) POWER 2 LED3 C319 47p SWITCH C317 47p C318 47p BOARD 3 3 4 4 A B C D E 23 24 DVP3320 7-3 PAINEL OK - ESQUEMA ELÉTRICO 7-3 1 2 3 4 5 OK Board Electric Diagram for DVP3320: A A R210 12VA 150 CE201 22uF REF 22K 0.1u CE200 22uF R203 22K C205 47p R205 180K B C210 20K 2.2uF R200 10K 2 3 C203 U5A 100K 1 2.2uF/NC NJM4558 OPA CE202 1000p REF C211 12VA 8 R201 C208 100p 10uF C204 100p C 5 + 6 - NJM4558 OPA MIC_OUT 7 4 1 2 3 4 R211 8 KARAOKE ĭ3.5mm 47-EAR024-XX0 P601 KARAOKE INPUT C201 + B R202 12VA - 12V U5B C R206 R207 100K 20K C206 47p C209 2.2uF R208 MIC_OUT MIC 12V 1K D R209 1 2 3 D 3PIN/2.0mm XP601 750R E E 1 2 3 4 5 DVP3320 7-4 PAINEL POWER - ESQUEMA ELÉTRICO 7-4 A B C D E Power Board Electric Diagram for DVP3320: 1 1 F1 T2AL/250ac TR1 NTC 10&20 D1 1N4007 2 1 P3 D2 1N4007 + 1 RV1 10K471 AC INPUT D3 1N4007 1 1 + + 2 + L1 CON1 AC INPUT + C1 D4 1N4007 680uH + C2 10uF/400V(250V/450V) P2 15uF/400V(250V/450V) L6 ⺕⦴ T1 5 C5 152/1KV 2 R2 R3 1/4W120K 1/4W120K EEL19 4 D5 FR102 6 D8 IN4007 EN/UV S CON2 6 5 4 3 2 1 R4 C6 47uF/25V 1/6W10k D10 R1 NU 2 SR360/SR340 C14 NU L2 6.8uH + C7 1000uF/16V + C8 470uF/16V R5 1/6W12K 1% R10 1/6W100 R13 -22V GND +12V GND +5V +5V 6X2.5 HEADER 10 1/6W22 4 1 1/6W100k 8 S S 7 S 11 1 2 BP/M 3 4 Drain NC 6 10uF/50V 8 1 12 5 + D7 FR102 9 R11 U1 TNY176/177 C3 7 3 C9 104/50V + AC INPUT C N1 R8 1/6W1k C11 0.1uF/63V R9 1/6W10k 3 2 3 U2 PC123X92 1 R7 1/6W11.3k 1% 2 U3 TL431 3 3 CY1 102/400Vac * CAUTION : THE PARTS MARKED WITH ARE IMPORTANT PARTS ON THE SAFETY. PLEASE USE THE PARTS HAVING THE DESIGNATED PARTS NUMBER WITHOUT FAIL. 4 4 A B C D E 25 26 DVP3320 7-5 7-5 PAINEL PRINCIPAL - ESQUEMA ELÉTRICO - POWER A B C D E R1 CE1 CVBS_C CVBS_C L1 C1 150pF R2 4.7K 1 CLK CS DAT GND LED_5V IR 0R RCA_CVBS_OUT + DSPVCC33 Main Board Electric Diagram for DVP3320: Power 0R 220uF/16V C2 100pF 1 XP1 6PIN/2.0mm R90 R91 R86 1 2 3 4 5 6 100R 100R 100R FPC_CLK FPC_STB FPC_DOUT L2 R3 500 33R FPC_CLK FPC_STB FPC_DOUT M5V IRRCV Imax 60mA Y_R_V Y_R_V L3 0R V_OUT C3 150pF C4 150pF C10 100p C5 C6 C8 C7 0.1uF 100pF 100pF 100pF CVBS_G_Y CVBS_G_Y L4 0R Y_OUT C11 150pF 2 C12 150pF 2 M5V RFA5V RFA5V Imax=17mA C13 10nF TO POWER BOARD XP2 1 2 3 4 5 5PIN/2.5mm Imax 800mA +P12V U_OUT C16 0.1uF 0R U_OUT C15 150pF U11 V_OUT M5V 20mA L6 C14 150pF 6 2 5 3 4 [NM] P1 RCA/AUDIO OUT 1 2 3 4 5 6 +12V LED/PCON 4.7K Q2 BT3904 1 C18 47pF LED/PCON: L: STBY. H: Working. 4 A 3 2 1 2 1 D12 PESD5V0S(L)1BA R7 PCON D11 PESD5V0S(L)1BA 4.7K 2 C88 0.1uF D10 PESD5V0S(L)1BA R13 4.7K 2 R6 PESD5V0S(L)1BA D9 1 8550D DSPVCC33 Y_OUT RCA_CVBS_OUT Y_OUT U_OUT V_OUT Q3 R12 22K RCA_CVBS_OUT PESD3V3L5UY R9 C17 0.1uF 1 RCA 47-RCA151-XX1 3 C_B_U C_B_U 4 B C D E DVP3320 PAINEL PRINCIPAL - ESQUEMA ELÉTRICO 7-6- VADDIS_SDRAM_FLASH 7-6 B C RESET Circuit CE19 10uF/16v CEL5-5 Close to Vaddis! FOCUS_PWM TRACK_PWM 8 7 6 5 R19 C82 NC 0.1U U2A R22 4.7K F1 MBRX120 2USB5V [FUSE(500MA)] S FCS MUTE_CTL SFCS_0 SFDO SF DI SFDO_0 SFDI_0 SFCLK R85 XP11 USB_DP USB_DN 4 3 2 1 USB5V 4PIN/2.0mm R106 C90 C91 15K/NC 0.1U PCON 27R/NC R105 27R/NC C92 15K/NC 0.1U C27 0.1U VDDPLL R18 9MA 4.7 DSPVCC18 C29 0.1U 33R SFCLK_0 RAMADD4 RAMADD3 RAMADD5 RAMADD2 RAMADD6 RAMADD1 RAMADD7 103 104 105 106 107 108 109 110 111 112 113 114 115 116 117 118 119 120 121 122 123 124 125 126 127 128 Gen_4/VID7 SFCS GND SFDO/RS_SF SFDI/RS128_Bootsel2 VDDC VDDP SFCLK/RS128_Bootsel1 GPIO[5] SD_D/IGPIO[7] PWM5 SD_CMD/GPIO[6] SD_CLK/IGPIO[7] VDDP DP DN RAMADD[4] RAMADD[3] RAMADD[5] VDDIP RAMADD[2] RAMADD[6] RAMADD[1] RAMADD[7] VDDC GND RSET DAC1 VDDDAC DAC2 DAC3 VDDDAC DAC4 GNDC XIN XO VDDPLL GNDPLL RESET# VDDC VDDP IGPIO[44] GPIO[43]/DUPRD0/TDO/SSCTXD GND GPIO[32]/SPDIFO VDDP GPIO[29]/AMCLK/APWM0GPIO[28]/APWM1GPIO[26]/APWM2GPIO[25]/AOUT2/APWM3GPIO[24]/DUPRD1/ALRCLK/APWM4IGPIO[23]/DUPTD1/ABCLK/APWM5- Vaddis-966XE/XF 64 63 62 61 60 59 58 57 56 55 54 53 52 51 50 49 48 47 46 45 44 43 42 41 40 39 R23 392 Ohm 1% Close to Vaddis VDD DAC 2 C_B_U C_B_U Y_R_V CVBS_C VDD DAC OSCIN OSCOUT VDDPLL Y_R_V CVBS_C CVBS_G_Y CVBS_G_Y RESET# OSCOUT IR RCV DU PRD0/FPC_DOUT S/PDIF_OUT S/PDIF_OUT GP-0 GP-1 R30 100 C31 33pF IR RCV FPC_DOUT APWM_LAPWM_R- VDDAPWM C32 0.1uF Crystal Y2 27.000MHz R28 220K GP-4 GP-5 OSCIN C33 33pF 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 0.1U R104 R107 C26 10nF RAMADD[0] RAMADD[8] RAMADD[10] VDDP RAMADD[9] RAMADD[11]/GPO[64] RAMCS0# RAMBA RAMCS1#/GPO[65] RAMRAS# RAMCAS# VDDP RAMWE# RAMDQM GNDPCLK PCLK VDDPCLK RAMDAT[8] RAMDAT[7] RAMDAT[9] RAMDAT[6] RAMDAT[10] RAMDAT[5] RAMDAT[11] RAMDAT[4] RAMDAT[12] RAMDAT[3] VDDIP RAMDAT[13] RAMDAT[2] VDDC RAMDAT[14] RAMDAT[1] RAMDAT[15] RAMDAT[0] VDDP GNDAPWM VDDAPWM MUTE_CTL M5V DSPVCC33 500 C9 DSPVCC33 D1 1 165MA L8 VDD DAC DSPVCC18 DSPVCC33I 4.7K SFCLK SFDO SPI FLASH-SOP8 Atmel: AT26DF081A 2 RF 1% 1% 1% 1% 4.7K /CS VDD SO /HOLD /WP SCK GND SI RF C24 33pF 75R 75R 75R 75R 1 2 3 4 1nF 1 C21 0.1U R24 R25 R26 R27 R20 DSPVCC33 U1 S FCS SF DI C28 1nF 1nF C23 DSPVCC33 500 102 101 100 99 98 97 96 95 94 93 92 91 90 89 88 87 86 85 84 83 82 81 80 79 78 77 76 75 74 73 72 71 70 69 68 67 66 65 DSPVCC33 CD_DVD CLOSE HOMESW CD_DVD VDDAFE FPC_CLK LD_DVD LD_CD MD_DVD MD_CD 1K FOCUS_PWM LD_DVD LD _CD MD_DVD MD_CD R17 SLED_PWM SPDL_PWM TRACK_PWM FPC_STB VDDPWM 1K C22 VDDAFE C20 10nF Gen_5/GPIO[0] Gen_6 VDDP Gen_7 Gen_8 Gen_9 Gen_11 Gen_12/VID0 VDDC GPIO[52]/PWMCO[3]/HSYNC GPIO[51]/PWMCO[2]/FIELD GPIO[50]/PWMCO[1]/VCLKx2 VDDPWM GPIO[49]/PWMCO[0] DVD_LD CD_LD DVD_MD CD_MD VDDSAFE GNDREF RESOUT VREF VC GND1AFE VFE_YIN F K E J D C VDDAFE B A VDD1AFE RFN RFP GNDDACBS2 IN_OUT_SW R16 OPEN DRVSB CD_DVD_1 FPC_STB FPC_STB DUPTD0/FPC_CLK FPC_CLK SPDL_PWM SLED_PWM INSW DSPVCC33 120MA L7 C89 1uF RFN R FP + 4.7 + CE2 100U/16V RF_B RF_A 2N3904 R F_B R F_A 2N3904 R14 RESET# Q14 R102 4.7k 1 R100 1k 1MA VDDPWM VDDAFE Q13 Important power supply! C19 10nF VDDAFE R101 3.3k E D8 1N4148 R99 22k VFE_YIN R F_F SPDL_SENS+ RF_E SPDL_SENSR F_D R F_C R98 3.3k VFE_YIN R F_F SPDL_SENS+ R F_E SPDL_SENSR F_D R F_C R97 15k 15.4K 1% 0.1uF INSW DRVSB IN_OUT_SW CLOSE OPEN HOMESW VC INSW DRVSB IN_OUT_SW CLOSE OPEN HOMESW D Main Board Electric Diagram: Vaddis_SDRAM_Flash URST# R15 C25 DSPVCC33I RESOUT V REF VC A C39 0.1U C40 0.1U C43 0.1U DSPVCC33 RAMDAT14 RAMDAT1 RAMDAT15 RAMDAT0 RAMDAT13 RAMDAT2 RAMDAT8 RAMDAT7 RAMDAT9 RAMDAT6 RAMDAT10 RAMDAT5 RAMDAT11 RAMDAT4 RAMDAT12 RAMDAT3 RAMADD11 SCHEMATIC1, 3.Vaddis_SDRAM_Flash RAMADD9 RAMADD8 RAMADD7 RAMADD6 RAMADD5 RAMADD4 RAMDQM PCLK RAMCKE RAMDAT8 RAMDAT10 RAMDAT9 RAMDAT12 RAMDAT11 RAMDAT14 RAMDAT13 IPCLK RAMRASRAMCAS- RAMWERAMDQM 10R XXmA DUPTD0/FPC_CLK DU PRD0/FPC_DOUT CE4 470uF/6.3V (165.10, 185.42) GP-4 GP-5 DU PRD0/FPC_DOUT DUPTD0/FPC_CLK XP5 4PIN/2.0mm 1 2 3 4 DUPTD0 DUPRD0 Download & debug APWM_LAPWM_R- Down load Close to pin 38 DSPVCC33 GP-5 GP-4 ݐᆍ64Msdram ᴧ VSYNC_VGA HSYNC_VGA XP6 4PIN/2.0mm 1 2 3 4 Hyper Terminal VSS DQ15 VSSQ DQ14 DQ13 VDDQ DQ12 DQ11 VSSQ DQ10 DQ9 VDDQ DQ8 VSS NC DQMH CLK CKE NC A11 A9 A8 A7 A6 A5 A4 VSS DUPTD1 DUPRD1 2ch internal Audio output VGA support internal KOK support GP-0 GP-1 AMCLK AOUT0 GP-4 GP-5 ALRCLK ABCLK External 2ch Audio DAC amd ADC 4 RAMCKE A B R33 10K RAMDQM RAMWERAMCASRAMRASRAMCS1RAMBA RAMCS0RAMADD10 RAMADD0 RAMADD1 RAMADD2 RAMADD3 RAMDAT7 RAMDAT5 RAMDAT6 RAMDAT3 RAMDAT4 C49 0.1U RAMDAT1 RAMDAT2 C48 0.1U RAMDAT0 C47 0.1U RAMDAT1 RAMDAT0 C46 0.1U RAMDAT3 RAMDAT2 C45 0.1U RAMDAT5 RAMDAT4 C84 0.1U RAMDAT7 RAMDAT6 C83 0.1U RAMADD3 RAMADD2 RAMADD1 RAMADD0 RAMADD10 RAMBA RAMCS0RAMRASRAMCASRAMWERAMDQM DSPVCC33 DSPVCC33I 3 DUPRD1 DUPTD1 DUPRD0 DUPTD0 [64Mbit:K4S641632H-UC70] 25 24 23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 4 + NM U10 16Mbit: K4S161622C-TC/L70 C44 0.1U R32 DSPVCC33 VDD DQ0 VDDQ DQ1 DQ2 VSSQ DQ3 DQ4 VDDQ DQ5 DQ6 VSSQ DQ7 VDD DQML WE# CAS# RAS# CS# BA0 BA1 A10 A0 A1 A2 A3 VDD C42 0.1U DSPVCC33 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 C41 0.1U VDD A3 A2 A1 A0 A10/AP BA CS RAS CAS WE LDQM VDDQ DQ7 DQ6 VSSQ DQ5 DQ4 VDDQ DQ3 DQ2 VSSQ DQ1 DQ0 VDD SDRAM3V3 U3 VSS A4 A5 A6 A7 A8 A9 NC CKE CLK UDQM NC VDDQ DQ8 DQ9 VSSQ DQ10 DQ11 VDDQ DQ12 DQ13 VSSQ DQ14 DQ15 VSS L10 500 C35 0.1uF Net has fewer than two connections N21830557: RAMDAT15 RAMDAT12 RAMDAT13 RAMDAT10 RAMDAT11 SDRAM3V3 VDDAPWM 3.30V 54 53 52 51 50 49 48 47 46 45 44 43 42 41 40 39 38 37 36 35 34 33 32 31 30 29 28 C38 0.1U WARNING [DRC0006] 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 C37 0.1U DSPVCC18 RAMDAT8 RAMDAT9 DSPVCC18 RAMCKE PCLK RAMDQM Down load RAMADD4 RAMADD5 RAMADD6 RAMADD7 RAMADD8 RAMADD9 Close to Vaddis RAMCS1- down load C34 5P SFCLK C36 0.1U RAMADD11 PCLK RAMCS0RAMBA HYPER 1 . TP1 RAMADD9 R31 56R SF DI RAMDAT14 RAMDAT15 R29 1K [NM] RAMADD0 RAMADD8 RAMADD10 IPCLK DSPVCC33 3 SDRAM3V3 C D E 27 28 DVP3320 PAINEL PRINCIPAL - ESQUEMA ELÉTRICO -7-7 FE_REGULADOR A 7-7 B C D E Main Board Electric Diagram for DVP3320: FE_Regulator EMC Close to CN201 C50 NM [470pF] R34 4.7R C51 NM [470pF] 1 + CE5 220uF/16V Q4 9012 R36 220R LD_DVD DSPVCC33 CN201 is used for Sanyo/Samsung/Sony OPUs R38 4.7R 25 26 XP7 SMD0.5 TOP TOP C52 1nF C53 1nF R42 220R R43 OPU_HFM LD_CD OPU HOP1200W Arima681 Others R202=300R, for HOP1200W only 0R [300R] C54 1nF L11 R44 Others 4.7R 4.7R 10uH 33R + R270 100R 100R NM 2.1V RFA5V U4 VC R45 3.3K PDIC Control: DVD=LOW CD=HIGH CD_DVD R F_D R F_C TACTTACT+ FACT+ FACT- R39 100R [NM] R283 100R 100R NM VR _CD MD_CD BAT54C 2K SPDL_SENS+ SPDL_SENS+ MUTE 2 TR_B1 BIAS 27 REGO2 3 REGO2 VINTK 26 4 VINSL TR_B2 25 5 REGO1 NC 24 6 FWD VINLD 23 7 REV GND 22 30 SLED_S + CE8 47uF/16V AM5888S(HSOP-28) 28 29 GND GND 8 VCC1 VCTL 21 M5V R46 1K SPDL_S 2 M5V 9 LOAD+ VOTR- NC 20 10 VOTR+ VCC2 19 SL_MOT- 11 VOSL+ VOLD- 18 SP_M- SL_MOT+ SL_MOTHOMESW SL_MOT+12 VOSL- VOLD+ 17 SP_MOT+ FACT- 13 VOFC- VOTK- 16 TACT- SP_MOT+ SP_MOT- FACT+ 14 VOTK+ 15 TACT+ VOFC+ C55 100pF TR_B2 LOAD- C58 0.1uF DRVSB VC2 TRACK_S FOCUS_S TRACK_S Close to Vaddis! SPDL_S SLED_S R47 R48 51K [27K] 51K [27K] R49 R50 22K [22K] 51K [33K] C59 C60 C61 C62 1nF 1nF 27nF 27nF FOCUS_PWM TRACK_PWM SPDL_PWM SLED_PWM DSPVCC33 2.2 OHM 2W R52 4.7K HOMESW IN_OUT_SW INSW 3 Imax=600mA Õǂ?540mA R51 LOADLOAD+ C63 NM [1nF] C64 NM [1nF] Imax=300mA Õǂ?I=290mA HOMESW IN_OUT_SW INSW 5.6 OHM 1W R53 Imax=300mA Õǂ?250mA C65 NM [1nF] DSPVCC18 DSPVCC33 TR_B1 TR_B2 Q6 SS8550D C66 0.1uF REGO1 SS8550D + 20k/1% CE10 220uF/16v REGO2 R59 DSPVCC33 b Q7 R56 3 Close to motor driver. e 1 2 3 4 5 R41 SP_MOT- R40 100R [NM] R54 1K 1% c LOADLOAD+ OUTSW GND INSW 3 1 M5V XP9 5PIN/2.0mm DSPVCC33 VR_DVD TR_B1 OPEN 6 5 4 3 2 1 SPDL_SENS- 1 2 MD_DVD VINFC CD_DVD CE9 100uF/16V SLEDSLED+ HOMESW GND SP+ SP- SPDL_SENS- R37 1R 0603-R 1 CLOSE XP8 6PIN/2.0mm 2K D5 FOCUS_S REGO1 C57 0.1uF R35 SP_M- CE7 100uF/16V RF_E R F_F RF_B RF_A RF C56 0.1uF BEMF Current Type(Default) R40 100R 0 100R 10R 0 91R 0 NM 0 91R NM RFA5V C DLD VR_DVD VR _CD OPU5V VC1 HD65PS 3.3R 3.3R + CE6 220uF/16V Q5 9012 DV DLD OPU R34: R38: R39 100R 0 100R 10R 0 91R 0 NM 0 91R NM 27 28 2 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 OPU Sony310 DL3 IAT510 TOP1100S SEMCO-SP1 MITSM820W HD8(DV23) HOP1200W HD65/HD62 502W Arima681 C DLD DV DLD DSPVCC33 R57 4.7K/1% R60 CE11 + R55 33K VC2 R58 1K 1% 220uF/16v C67 0.1uF GND 10k/1% GND 12k/1% GND GND 4 4 A B C D E DVP3320 7-8- ÁUDIO ENTRADA/SAÍDA PAINEL PRINCIPAL - ESQUEMA ELÉTRICO A 7-8 B C D E Main Board Electric Diagram for DVP3320: Audio Input Output M5V Q8 R63 4.7K C68 75pF 4 C69 1.2nF +6VA OP- 6 OP+ 5 C70 0.1uF Q10 CE14 R71 APWM_R- 39K R70 82K R72 4.7K C71 +6VA OP- 2 OP+ 3 8 MUTE_CTL R77 4.7K R65 470 LMAIN_OUT 1 R66 10K MUTE R67 470 Q9 3904 75pF 4 C72 1.2nF R73 4.7K MUTE_CTL 10uF/16V 9012 + 220U/16V 2 CE13 MUTE + R69 3.3K 4.7K - R68 U5B LM4558 7 U5A LM4558 CE16 1 +12VA R74 R75 10K C73 0.1uF Q12 2N3904 10uF/16V 470 RMAIN_OUT + 1 82K + APWM_LR64 4.7K R61 8 39K + R62 - 9012 MUTE R76 470 Q11 3904 2 R78 22K DSPVCC33 +6VA R96 VFE_YIN 1k + VFE_YIN R103 4.7K/NC C74 CE20 1uF/NC 10uF/16V 0R MIC 1 2 3 C75 C77 C76 3300p 100p 0.1uF XP10 +6VA + CE17 100U/16V +12V R82 R79 100K +12VA R80 + 33K 100R +12V CE18 47uF/16V pitch=2.0mm*3 3 THE OK USE C74 or CE20 R81 +12VA R108 4.7K/NC 2 BAT54S/NC 1 3 D7 3 DSPVCC33 P2 RCA/AUDIO OUT C78 COAX_SPDIF 100 R84 1 2 3 4 5 6 LMAIN_OUT RMAIN_OUT COAX_SPDIF 0.1uF 100 C80 100pF C81 100pF RCA 47-RCA151-XX1 R83 S/PDIF_OUT C79 100pF 4 4 A B C D E 29 30 DVP3320 7-9 PAINEL FRONTAL & SWITCH - LAYOUT INFERIOR Front Board & Switch Board Print-layout (Bottom side): 7-9 DVP3320 PAINEL OK - LAYOUT SUPERIOR E INFERIOR OK Board Print-layout (Top side): OK Board Print-layout (Bottom side): 31 32 DVP3320 PAINEL POWER - LAYOUT INFERIOR Power Board Print-layout (Bottom side): 7-12 7-12 PAINEL PRINCIPAL - LAYOUT SUPERIOR Main Board Print-layout (Top side): DVP3320 33 7-13 34 7-13 DVP3320 PAINEL PRINCIPAL - LAYOUT INFERIOR Main Board Print-layout (Bottom side): 8-1 DVP3320 VISTA EXPLODIDA Exploded View for DVP3320/55: 12 13 11 10 8 9 7 6 5 4 3 14 15 16 17 2 18 1 21 20 19 It's a general mechanical view for DVP3320/55, pls refer to the model set for detailed information. Assy 1 component includes:1.3.4.5.21 35