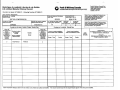

Download PT6A-66 S/N:PCE-RK0121 FINAL ACCEPTANCE TEST RECORD

Transcript

PRATT

& WHITNEY CANADA CORP. P68 PROGR

.29

================================================================

PT6A-66

S/N:PCE-RK0121 FINAL ACCEPTANCE TEST RECORD

......................................................

2004 JUL 27 TEST CELL : 0113 BUILD SPEC.: 676

ENGINE TESTED AND ACCEPTED IN ACCORDANCE WITH E&TI : 453

FINAL VANE FLOW AREAS

FIRST STAGE : 13529 IS5

SECOND STAGE : 01466 2S2

7.18

24.04

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..

PERFORMANCE DATA

TAKE-OFF

PART-POWER

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SPEC ACTUAL

SPEC ACTUAL

. . . . . . . . . . . . . . . . . . . . . .

PROP SPEED

S.L.S. STD.DAY POWER

I.T.T. (T5A TRIMMED)

DEG R

T5D (DERIVED)

DEG R

GAS GEN. SPEED

RPM

SFC @ 18400 BTU/LB LB/SHP.HR

PRESSURE RATIO @ 34500

2000.

850.

1681.

1720.

34550-35150

0.683

RPM

7.91

2000.

650.

1597.

1580.

34150.

0.754

2000.

850.

1645.

1630.

34900.

0.656

7.80

FUEL TYPE : CPW 204

BTU/LB

TEST LHV : 18502.

S.G. :0.812 @ 81. DEG F

OIL TYPE

OIL CONSUMPTION

T.O. OIL PRESSURE

OIL TEMPERATURE

:

:

:

:

I.T.T. TRIM DELTA T (UNTRIMMED-TRIMMED) :

I.T.T. TRIM DELTA T (UNTRIMMED-TRIMMED) :

I.T.T. TRIM CLASS :

TRIM RESISTANCE :

COLD HARNESS RESISTANCE :

B.O.V. SEAT CLASS AS TESTED :

B.O.V. SEAT CLASS AS SHIPPED :

PWA 521

0.0

114.5

150

TYPE I1

LB/ HR

PSI

DEG F

0.0

0.0

20

0

0

1.44

13

16

DEG F

DEG C

OHMS

OHMS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HANDLING AND CONTROL SETTINGS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RPM

TRIMMED MAX NG : N/A

RPM

UNTRIMMED MAX NG : 39000

RPM

DATA PLATE SPEED : 34900

IDLE SPEED : ;)0 2 9 =L RPM

ACCEL. TIME F.I. TO MAX @ TI : 2.23 SECS @ 70.8 DEGF

ENGINE DRY WEIGHT : 452.5

LBS .

fls-

PRODUCTION SIGNATURE

0

INSPECTION SIGNATURE

.

GOVERNMENT INSPECTOR

:

THE UNDERSIGNED CERTIFIES THAT THIS RECORD ACCURATELY SETS

FORTH THE EVENTS DURING THE TEST MADE ON TbfET-EAIGINE THEREIN IDENTIFIED.

1

.E

JUL

8

FOREMAN,ASSY .&TEST INSP

:

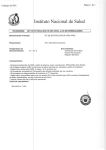

Index of Engine Documentation

Engine Number: PCE- RK0121

Quantity of

Documents

Document Name

I

I

Final Acceptance Test

~ e c o r dSheet

I

Engine Serialized

Component Summary

(Quantity of set) X (Quantity per set)

Life Limited Material

History Record

1

Life Limited Blades History

Record(when applicable)

Engine Build Record Status

I

(Quantity of set) X (Quantity per set)

Report (SB)

Note: (1) copy or set is staple in the

SB section of the Yellow Book

Engine Log Book

(Yellow Book)

I

1

Final Vibration Survey

(when applicable)

1

Authorized Released

Certificate(Form 24-0078)

Date

Note: This index reflects the quantity of Shipping

Documentation supplied with the engine

Issue Date: June 10,2000

Pratl8 Whihriay Canada Cis. 1

Prail8 Wh'tney Canada Corp.

Pratt & Whitney Canada

Une .odOMde W i d Techn&+slAUniledT~(ihnologim

Liste des composants moteur a numeros de serie

Engine Serialized Component Summary

I

Aod&le

Aodel

3008012

I

:ode de trait.

hermique

leat Code

2OUPLING SHAFT FLEX 2ND STAGE RED'N

>EAR-SUN.2STG RDCN.46 TEETH

4DAPTER-1ST STAGE CARRIER

SARRIER-SECOND STAGE REDUCTION

3EARING OPTION

DISC TURBINE

DISC-TURBINE

FLOW DIVIDER AND PURGE VALVE

PUMP-FUEL

- COMPRESSOR-TURBINE STATOR,ASSY OF

ROTOR COMPRESSOR

ROTOR - COMPRESSOR

ROTOR COMPRESSOR

VANE RING-POWER TURBINE

VANE RING-TURBINE

SHAFT-STUB.COMPRESSOR ROTOR

HOUSING-POWER TURBINE STATOR

WIRING HARNESS - ELECTRICAL

DUCT-TURBINE EXHAUST,ASYO

GEAR - RlNG FIRST STAGE REDUCTION

DISC -TURBINE

SHAFT-PROPELLER

LINER-COMB CHMBR,OUTER,ASYO

HEATER-OIL TO FUEL

CARRIER-FIRST STAGE REDUCTION

BEARING-BALL FLANGED

-

Carad. de montage

BUIM Spec NO.

I

Node serie

Serial No.

;EAR-PLANET,SECOND STAGE REDUCTiON

3EARING-ROLLER FIANGED

SEAR - SUN, 1ST STAGE REDUCTION, 26 TEET

SEAR RlNG 2ND STAGE RED'N

IXCITER-IGNITION

MPELLER-CENTRIFUGAL

?OTOR-COMPRESSOR

SEAR-PLANET.1ST STAGE REDUCTION

:",",",.u~~:"d~~~~~Canada

J4G 1Al

Node s e i e

Serial No.

Desi nation du materiel

gaterial Name

Nodu materiel

Mater~alNumber

Company

PZBLH

EPDEC

LARYB

LASW

EPDEC

EPDDH

EPCZU

EPDBK

EPDEM

PFOPZ

lode s6rie du

lat6nel forge

orging Ser~alNo.

de lot pour trait.

bermique

eat Treat Batch No.

de materiel du fournisseur

endor Material No.

Pratt & Whitney Canada

Une r

Liste des composants moteur a numeros de serie

Engine Serialized Component Summary

PT6A-66

Nodu materiel

Mater~alNumber

450-677-941I

310752501

310923401

3109240-01

3109251-01

3112272-01

311236801

I

COUPLING-POWER,TURBINE

BUS BAR-NEGATIVE TERMINAL,T5

BUS BAR-POSITIVE TERMINAL,T5

SHAFT-POWER.TURBINE

HOUSING ASSY-PROP REDN G.B.FR.

BEARING-ROLLER FLANGED..94X1.65X.47

COUPLING-COMPRESSOR,REAR HUB

BEARING BALL,1.181X2.8345X.743,FLG

BEARING-BALL,1.450X3.600X1.000

COUPLING-POWER TURBINE SHAFT

LINER-COMB CHMBR INNER,ASYO

GOVERNOR-PROPELLER

SHAFT-STURCOMPRESSOR-ROTOR

FUEL CONTROL-TURBOPROP

CASE ASYO-GAS GENERATOR

VPLVE-CYPRESSOR BLEED, ASSY

Approve ar \

~pprove8~y

BAA

0

I

,

-

I

PCE-RKO121

Nodeserie

Serial No.

D6si nation du materiel

gaterial Name

I

: ~ ~ ; , " ~ ~ ~ ~ ~ ~ ~ ~ C a n a

J4G IAI

P I W C JR36830-E (05-1998)

Modhle

Model

W de United Technolo~nIAUnitedTsohnoloplss Mrnpany

Pran & Whisiey Canada Cie. 1

Pratt & Whitney Canada Corp.

Node serie

Serial No.

PKAAOOOR637

NR06047

NR06030

RWAOlA610

A001HEMD

FA0413771

FA0413777

FA0413780

FA0413783

FA0413785

FA0413792

:ode de trait.

iermtque

leat Code

EPBTO

avuu

EPDCB

-

Page

2

I

Carad. de montage

Build Spec NO.

I' de .&rie du

iat6nel forge

orging Serial No.

lode!ot pour trait.

hermlque

leat Treat Batch No.

de materiel du fournisseur

endor Material No.

Historique du materiel a duree'de vie limitee

Life Limited Material History Record

Pratt & Whitney Canada

Urn sad616 da Un tsd Teohmlodw/A UnnedTechnoloped Company

Nurnero d u dessin ST3582-01 - Drawing Number ST3582-01

P8WC JR3-6834-E [6834] (199846)

Dbignation du materiel

Material Name

I

:ode de traitement thermique

{eat Code

IMPELLER-CENTRIFUGAL

-

Nurnero de sene du materiel

Material Serial Number

de serie du mall. forge

aging Mat'l. Senal No.

052

nn&s sur le moteur Imodule - Engine IModule Data

Temps de

fonctionnernent

Engine IModule

Serial Number

Model

2004.07.28

Iaooroorie. selon le cas.

I

Temps de

Cydes de

fonction.

fonction.

Time Since New Cycles S~nceNew

0

0

D o n n h sur le mt&riel- Material Data

b

Temps de

mctionnement

Numero de sene

du moteur I

module

rnis le (A-M-J

$sue Date (Y-h-D)

1

PZBLH

-

Numero du materiel

Material Number

1

Pratt 8 Whitney Canada Cie. I

Pratt 8 Whitney Canada Corp.

1000. Marie-Victorin

L~ngUeUllQuebec

Canada J ~ G

1Al

depuis

I'enlevement

du maOriel

En IModule

men

Material

Removed

TEN

Cumul. de cetle installation

4ccumulated This Installahon

Cumul. jus u'8 present

Total ~ccum8atedTo Date

Date

c

remps -Time

Cycles

Temps -Time

Cycles

Observations

(Installation d'entretien de revision, bon de

trava~let timbre du venficateur)

@

:I:;

)

Remarks

(MaintenanceIOverhauI, Facility, Work

Order 8 inspection stamp)

Historique du materiel a duree de vie limitee

Life Limited Material History Record

Pratt & Whitney Canada

Urn s

d M de UnnedT.EhmlogieslAUn(tadTeohndwieaMrnpny

Nurnero du dessin ST3582-01 - Drawing Number ST3582-01

Pratt & Whitney Canada Cie. /

Pratt & Whitney Canada Corp.

1000, Marie-Victorin

L o ~ ~ u Quebec

~uI~

1Al

Canada J ~ G

&WC JR3-6634-E [6834] (199866)

Xsignation du materiel

daterial Name

Code de traitement thermique

Heat Code

NuMro de SBrie du materiel

Material Senal Number

3037001

No de serie du r@l. forge

Forgmg Marl. Senal No.

TXAI A4734

87

I

Donnees sur le rnoteur 1module - Engine IModule Data

2004.07.28

Temps de

Cycles de

fonction.

foncfron.

Time Since New Cycles Smce New

0

0

D o n n b sur le maOriel - Material Data

foncz$sment

Temps de

Numero de sBrie

dU

module

Modele

Model

Ey&el$g,"'

eEngine

IModule

Serial Number

Material

Installed

D

mis le (A-M-J

Esue Date (Y-LD)

EPDEC

ROTOR-COMPRESSOR

qumero du materiel

Material Number

Temps de

fonctionnement

depuis

I'installation du

materiel

I

PCE-RKDlZ1

PT6A-66

renpvement

du materiel

En /Module

When

Material

Removed

TEN

0

Cumul. de cette installatiqn

Accumulated This Installabon

Temps -Time

Cycles

Cumul. jus u'a prbent

Total ~ccumiatedTo Date

-

Temps Time

Cycles

Obse~ation~

Installation d'entretien, de revision, bon de

trava~let bmbre du venficateur)

Remarks

(Maintenance/Ove~t~aul,

Facility Work

&

inspection

stampj

Order

I

Historique du materiel a duree de vie limitee

Life Limited Material History Record

Pratt & Whitney Canada Cie. 1

Pratt

1000.&~arie-victorin

Whitney Canada corp.

Pratt & Whitney Canada

Une so*

& UnnedTechmlopies/A UnitsdTecnndcqie. Crmpany

Numbro du dessin ST3582-01 - Drawing Number ST3582-01

Longueull Quebec

1Al

Canada J ~ G

&WC JR34834-E (68341(199805)

Iesignationdu matbriel

flakrial Name

Code de traitement thermique

Heat Code

DISC TURBINE

mis le (A-M-J

:sue Date (Y-h-D)

LARYB

Vu&ro du materiel

Watenal Number

Num6ro de sene du materiel

Material Senal Number

3037312

NO de sene du FYI. forge

Forging Mat'l. Ser~alNo.

A001K246

Donnks

sur le moteur Imodule - Engine IModule Data

Temps de

fonctionnement NuMro de sene

de uis

du moteur I

l'instal/km du

module

materiel

En ineIModule Engine IModule

QSN m e n

Serial Number

Material

Installed

I

I

Temps de

Cycles de

fon@on.

fonction.

Time S ~ n wNew Cycles Slnw New

0

0

Donnees sur le mat6riel- Material Data

Modele

Model

0727

2004.07.28

accumulee et r6siduelle du materiel,

consulter le Manuel d'entretien du

moteur ou le Bulletin de service

l a ~ ~ r o o r iselon

b , le cas.

Date

En /Module

T!N When

Inserer le Present historique dans le livre du moteur ou du module ou la piece est install&.

Observations

Installation d'entretien de r+&o

.in,

bon de

trava~let timbre du venficateur)

Remarks

stamp) Work

(MaintenancelOverhaul.

Order & inspectionFacility,

- This record must be kept with the enginelmodule logbook where this part is installed.

Historique du materiel a duree de vie limitee

Life Limited Material History Record

Uw todOte de UnitsdT.Fhrmlodas/AUnitsdTffihnolopiesCcinpany

Numero du dessin ST3582-01 - Drawing Number ST3582-C

.

.

DCignation du matbriel

Material Name

I

:ode de traitement thermique

ieat Code

DISC-TURBINE

-

-

N u M o du magriel

Mater~alNumber

Nume~ode eerie du magriel

Matenal Senal Number

3037313

LASWY

f de sene du marl. forge

-orglng Mat'l. Senal No.

A00 1K73F

I

I

I

1

Emis le (A-M-J

Issue Date (Y-h-D)

2004.07.28

Temps de

Cycles de

fonction.

foneon.

Time Since New Cycles S~nceNew

I

I

Longueull Quebec

1Al

Canada J ~ G

accumulee et rbiduelle du pateriel.

consulter le Manue! d'entreben du

moteur ou le Bulletin de servlce

a ~ ~ r o ~ selon

r i e , le cas.

I

I

Obsetvations

(Installation d'entretien, de revision, bon de

travail et timbre du venficateur)

Modele

Model

IModule

E ~ ~ $ N e / ~ ~Engine

l e Number

Serial

Material

Installed

1

n

l

n

Donn&es sur le maYriel - Material Data

0997

D o n n b sur le moteur 1 module - Engine 1 Module Data

Temps de

fonctionnement NuMro de serie

depuis

dUmodule

mteur I

I'installation du

mateliel

Pratt & Whitney Canada Cie. I

Pratt

1000,&~Whitney

a r i e - vCanada

e r i n Corp.

Pratt & Whitney Canada

remps - Time

Remarks

(MaintenancelOverhaul. Facility, Work

Order & inspection stamp)

I

Inserer le present historique dans le livre du moteur ou du module ou la piece est install&.

- This record must be kept with the enginelmodule logbook where this part is installed.

Historique du materiel a duree de vie limitee

Life Limited Material History Record

Pratt & Whitney Canada

Une s&&6

&a Unitsd TwhrwlodesIA UnitsdTechnolwiesCompany

-

Pratt & Whitney Canada Cie. 1

Pratt & Whitney Canada Corp.

1000, Marie-Victorin

L0ngueull Quebec

1Al

Canada J ~ G

Numero du dessin ST3582-01 Drawing Number ST3582-01

LWC JR3-6834-E I68341 (199806)

Iesignation du materiel

Aaterial Name

Code de traitement thermique

Heat Code

ROTOR - COMPRESSOR

2004.07.28

EPDDH

4umero du materiel

vlatenal Number

Numb~ode sene du materiel

Matenal Senal Number

3040942

EAAAOOOF800

-

No de sene du mat'l. forge

Forging Mat'l. Senal No.

130

Cycles de

Temps de

fonction.

fonction.

Time Since New Cycles Since New

0

-

D o n n k sur le moteur / module Engine I Module Data

Temps de

ionctionnement

depuis

I'installatipn du

matenel

mis le (A-M-J

t s u e Date ( Y - k ~ )

0

Donn6es sur le materiel Material Data

foncz$sment

Temps de

de serie

I

module

dU

Ey$f$i'e

Material

Engine / Module

Serial Number

0

PCE-RKO12I

Modele

Model

Installed

PT6A-66

renl&vement

du mat6nel

En IModule

men

Material

Removed

TEN

Cumul. de cette installatiqn

Accumulated This Installabon

Temps -Time

Cycles

Cumul. jus u'a present

Total ~ccumiatedTo Date

Temps -Time

Cycles

Note: For.determination of accumulated

and remalnln lives on thls material, refer

to the en Ine%aintenance Manual or

Service 8ulletin. as applicable.

Date

Observations,

(Installation d'entretien de revision, bon de

trava~let timbre du verificateur)

Remarks

(MaintenancelOverhauI,Facility, Work

Order & inspection stamp)

0

Inserer le present historique dans le livre du moteur ou du module ou la pibce est install&. -This record must be kept with the enginelmodule logbook where Mis part is installed.

Historique du materiel a duree de vie limitee

Life Limited Material History Record

Pratt & Whitney Canada

Une d 6 t d de United T.ohmldstrlA UnltodTochndonies Company

Numero du dessin ST3582-01 - Drawing Number ST3582-01

Pratt & Whitney Canada Cie. I

Pratt & Whitney Canada Corp.

1000. Marie-Victorin

Longueull Quebec

Canada J ~ G

1Al

P&WC JRM834-E 168341 (1998-06)

r~bsignationdu magriel

Material Name

Code de traitement thermique

Heat Code

ROTOR - COMPRESSOR

Num4ro de sene du magriel

Material Senal Number

3040944

EAAAOOOF494

0

0

.

Temps de

dU

module

I

Modele

Model

Engine 1 Module

Serial Number

PCE-RK0121

PT6A-66

..

DonnCs sur le rnatbriel Material Data

foncz$Sment

de serie

Installed

0

126

Cydes de

Temps de

foneon.

fon@on.

Time Slnce New Cycles Slnce New

-

-

Donnbes sur le mteur Imodule Engine IModule Data

'T!{fi:Material

le

No de sene du rn?'I. forge

Forging Mat'l. Senal No.

accumulee et rbiduelle du magriel,

wnsulter le Manue! d'entreben du

moteur ou le Bullebn de servlce

a ~ ~ r w r iselon

e . le cas.

2004.07.28

EPCZU

Nu&ro du materiel

Material Number

Temps de

fonctionnernent

de uis

hxtalttion du

materiel

mis le (A-M-J

i s u e Date (Y-&-D)

renlevement

du materiel

En IModule

T ~m

Ne n

Material

Removed

Cumul. de cette installation

Accumulated This Installabon

Cumul. jus u'd prbsent

Total ~ccumiatedTo Date

)A:!$

Temps - Time

Cycles

Temps -Time

Cydes

Date

Observations,

(Installation d'entretien de revision, bon de

trava~let bmbre du venficateur)

Remarks

(MaintenanceIOverhaul Facility, Work

Order & inspectiohstamp)

0

Inserer le prbsent historique dans le livre du moteur ou du module ou la piece est installee. -This record must be kept with the enginelmodule logbook where this part is installed.

Historique du materiel a duree de vie limitee

Life Limited Material History Record

Pratt & Whitney Canada

Une s&O

d.UniUdT.ohmlodes/AUnbdToohndwis. Company

Nurnero du dessin ST3582-01 - Drawing Number ST3582-01

Pratt & Whitney Canada Cie. I

~ r a t&t Whitney Canada Corp.

1000 Marie-Victorin

L ~ ~ Q ' U ~Quebec

U~I

Canada J ~ G

IAl

PWC JR34834-E [MU41(199806)

)&signation du materiel

daterial Name

Code de traitement thermique

Heat Code

SHAFT-STUB,COMPRESSOR ROTOR

qumero du materiel

daterial Number

EPDBK

NuMro de sene du matbriel

Material Senal Number

3043063

No de sene du marl. forge

Forgmg Marl. Ser~alNo.

PKAAOOOL492

D o n n h sur le moteur Imodule - Engine IModule Data

Temps de

fonctionnement

de uis

l'instal&ion du

materiel

ET!t(,","Ie

mis le (A-MJ

:sue Date (Y-AD)

47

2004.07.28

Temps de

Cycles de

fonction.

foneon.

Time Since New Cycles Slnce New

0

-

0

accumul6e et r6siduelle du materiel,

consulter le Manuel d'entretien du

moteur ou le Bulletin de service

Note: For,determinationof accumulated

and remalnln lives on this material refer

to the en ine%aintenance Manual br

Service &letin, as applicable.

Donnees sur le matbriel Material Data

I

de serie

dUmodule I

Engine

IModule

Serial Number

Modele

Model

Installed

Inserer le prhsent historique dans le livre du moteur ou du d u l e ou la piece est install&.

- This record must be kept with the enginelmodulelogbook where this part is installed.

Historique du materiel a duree de vie limitee

Life Limited Material History Record

Pratt & Whitney Canada

Une sodw da unitsdT.Ehnoio~sr/A

UniWTechnologiasC a p a n y

Nurnero du dessin ST3582-01 - Drawing Number ST3582-01

NC JR36834-E [6834] (199806)

Bsignation du materiel

atenal Name

I

DISC - TURBINE

um6ro du maOriel

atenal Number

Numero de sene du materiel

Material Serial Number

3053740-01

A001K78L

mbes sur le motet Imodule - Engine IModule Data

Temps de

mtionnement

depuis

installation du

matenel

.n inelModule

QSN m e n

Material

Installed

Num6ro de serie

du moteur I

module

Engine IModule

Serial Number

I

Code de traitemnt thermique

Heat Code

32

mis le (A-M-J

k.ue Date (Y-lh-D)

1

EPDEM

No de sene du m+t'I. forge

Forgmg Mat'l. Senal No.

Pratt & Whitney Canada Cie. I

Pratt & Whitney Canada Corp.

1000 Marie-Victorin

L W ~ ~ Quebec

U ~ I

G

Canada J ~ 1Al

2004.07.28

l a ~ ~ r o ~ selon

r i e , le cas.

I

Temps de

Cycles de

fonction.

fonction.

Time Since New Cycles S~ncaNew

0

0

Donnees sur le materiel - Material Data

I

Modele

Model

Temps de

fonctionnement

Cumul. de cette installation

depuis

Accumulated This Installation

I'enlevement

du materiel

En 1Module

T

N

!

When

Material

Temps - T i m

Cycles

Removed

Cumul. jus u'A present

Total ~ccum8atedTo Date

I

Temps - T i m

Cycles

Observations

(Installation d'entretien de,rcvision, ban de

trava~let hmbre du venficateur)

Remarks

(MaintenanceQverhafl, Facility, Work

stamp)

Order & ~nspechon

Inserer le present historique dans le livre du mteur ou du module oh la piece est install&. -This record must be kept with the enginelmodule logbook where this part is installed.

Page no :

PRATT & WHITNEY CANADA

ENGINE BUILD RECORD STATUS

THE FOLLOWING SERVICE BULLETINS ARE BASIC TO :

ENGINE SERIATJ NO.

PCE-RKO121

ENGINE MODEL

PT6A- 6 6

BUILD SPEC

676

SERVICE BULLETINS

1

ENGINE SERVICE AND

MAINTENANCE RECORD

1

\

I

operation.

ITT Trim:

T5 Trim resistance:

0.0 C'

00

Ohms

I

TSN

Description of all operations pertaining to Airworthiness Directives,

Service Documents, Overhaul, Major or Minor Repair, and Inspections.

TSO

.

. ..

Page 1

Date

Propeller

TSN TSO

AIC

Hrs

Description of all operations pertaining to Airworthiness Directives,

Service Documents, Overhaul, Major or Minor Repair, and Inspections.

RECORD OF ENGINE

AIRWORTHINESS DIRECTIVES IA/Dl, SERVICE BULLETINS (W,

CF-9624 TO PRECLUDEMALFUNCTION OF THE COMPRESSOR BLEED OFF VALVE

FAAAD. SB 1538R2,3344,42M. 12134, 13287 & 14251 OR THEIR LATER REVlSlO

97-04-12 OR SUPERSEDING SB INCORPORATED AT MANUFACTURE.

FOR LIST OF SB'S INCORPORATED SEE ATTACHED ENGINE BUILD RECOR

STATUS REPORT SHEET.

NAME PRINTED:

-

1

SPECIAL INSPECTIONS (SYIJ AND MODIFICATIONS (MODS]

IUN

DATE

HIS.

BROUGHT

FORWIRD

"IN.

ENGINE SERVICE AND

MAINTENANCE RECORD

I

T l Y C SINCE

INITALLITIOML.

OVERHAUL

NOTE

S

.

USE m.7~

P A a E s r-O

INSPECTIONS,

r l M A N Y L I N E S -1 . I E O Y I " T O

-0-

REPAIRS.

Y0OIFICAIIOH.I

YNU.CD

LINL. I N D A T E A N D

1

10

,,""Be"

New engine final acceptance test and

inhibiting run completed satisfactorily and is

in condition for safe operation.

1

This Gas Generator module is combined with

Power Section.

sm: PS&

ma/

1

I

ITT Trim:

fl.0

I

C"

I

I

--T O T A L THIS PAGE

Y I X l Y U Y HOURS BETWEEN O V E R H A U L S

T O T A L FROM

PFtEVI0U.I I Y Y I A R I

s

TOT*L

SINCE YFO.

LlCEHCL

s'=YAT"RE

TSYE C~LUYN$.

"IN.

(

~ U L Y /0~ &

1 0Y I1 0

ADIUSIYCNTI.

ENT

D ~

~ AI

W

1L

O I &I

S.

D U L L LlUL I H I O U G Y .U1

COY-LSIE

1

1

H0UI.L.

I

Page No.

TOTAL

TOTAL

TACH OR

DESCRIPTION OF WORK PERFORMEDSIGNATURE & CERTIFICATE NO. OF PERSON PERFORMING WORK

TIME

R M N S AVIATION lNC

GREENVILLE. SC

-

3/30/2005

LEFT ENGINE

101 Serviced engine with Mobile Jet I1 per Maintenance Manual Specifications.

The Maintenance Identified In This Work Order Package Has Been Inspected And The Item(s) Are

Approved For Return To Service. Pertinent Details Of The Repair@)Are On File At This Agency

Under Work Order No. GYH.33758/I25.

SIGNED

A ~ A T Z O NZNC...

.

GREENVZLLE.SC CRS VZBR368K

1-1

4/3/05 P ~ 6 ~ - 11

6 SN-PCE-RKO122.

6

/I #1

ENGTT: 146.4

i

CYCLES: 109

"THIS ENGINE IS PRESENTLY INSTALLED ON AIRCRAFT P-180, N-307L, SN-1091"

t-

COMPLETED 150 HOUR ENGINE MINOR INSPECTION. INSTALLED A PT6 O-RING KIT AND SERVICED ENGINE

WITH MOBIL JET I1 TURBINE OIL. SECURITY LEAK AND FUNTION CHECK PERFORMED NO FAULTS FOUND.

MAINTENANCE DONE V A N PRATT & WAITNEY PT6A-66 M/M REV-26 (9-17-04) AND THE AVANTAIR P-180 AAIP

SECTION 2 PAGE 2.

ENGINE APPROVED FOR SERVICE.

AUTHORIZED SIGNATURE

APIA

I

SUB-TOTALS this page

I

I

I

(

TOTALS-Carry forward to next page

Page No.

TOTAL

DATE

TIME

IN

SERVICE

x\

TOTAL

TIME

SINCE

OVERHAUL

TACH OR

RECORDING

METER

TIME

DESCRIPTION OF WORK PERFORMEDSIGNATURE &CERTIFICATE NO. OF PERSON PERFORMING WORK

SEEK AVIATION INC

GREENVILLE. SC

N307SL

SN 1091

3/30/2005

RIGHT ENGINE

101 Serviced engine with Mobile Jet I1 per Maintenance Manual Specifications.

The Maintenance Identified In This Work Order Package Has Been Inspected And The Item@)Are

Approved For Return To Service. Pertinent Details Of The Repair(s) Are On File At This Agency

Under Work Order No. GYH.33758A25.

SIGNED

IhC,GREENVILLE, SC CRS VIBR368K

4/3/05 PT6A-66 I/ SN-PCE-RKO121. 11 #2

ENGTT: 146.4

CYCLES: 109

*THISENGINE IS PRESENTLY INSTALLED ON AIRCRAFT P-180, N-307SL, SN-1091"

COMPLETED 150 HOUR ENGINE MINOR INSPECTION. INSTALLED A PT6 O-RING KIT AND SERVICED ENGINE

WITH MOBIL JET I1 TURBINE OIL. SECURITY LEAK AND FUNTION CHECK PERFORMED NO FAULTS POUND.

MAINTENANCE DONE IIAIW PRATT & WHITNEY PT6A-66 hUM REV-26 (9-17-04) AND THE AVANTAIR P-180 AAIP

SECTION 2 PAGE 2.

SUB-TOTALS this page

TOTALS-Carry forward to next page

Page No. RK PERFORMED-

HARTZELL PROPELLER N PN-HC-ESN-3AL 11 SN-HF184. I/ 146.4 {PROPTT}

*THIS PROPELLER IS PRESENTLY INSTALLED ON AIRCRAFT N-307SL, SN-10911

1

1

COMPLIED WITH 150 HOUR INSPECTION OF THE #2 RIB:PROPELLER YAlW

PIAGGIO P-180 M/MREV C7 (11130104) CHAPTER 61 AND THE AVANTAIR P-180 AAIP

SECTION 2 PAGE 2. CLEANED AND DRESSED LEADING EDGES. PAINTED PROPELLER AS

REQUIRED. SECURITY AND FUNCTION CHECK PERWORMED NO FAULTS FOUND.

PROPELLER APPROVED FOR SERVICE.

1

I

I

.

SUB-TOTALS t h ~ spage

TOTALS-Carry

forward to next page

I

3

I

I

4-03-05

HARTZELL PROPELLER N PN-HC-E5N3A /I SN-KU041. /I 146.4 {PROPTT}

"THIS PROPELLER IS PRESENTLY INSTALLED ON AIRCRAFT N-307SL, SN-1091*

COMPLIED WITH 150 HOUR INSPECTION OF THE #1 WH PROPELLER YAlW

PIAGGIO P-180 M/M REV C7 (llN0104) CHAPTER 61 AND THE AVANTAIR P-180 AMP

SECTION 2 PAGE 2. CLEANED AND DRESSED LEADING EDGES. PAINTED PROPELLER AS

REQUIRED. SECURITY AND FUNCTION CHECK PERFORMED NO FAULTS FOUND.

PROPELLER APPROVED FOR SERVICE.

AUTHORIZED SIGNATURE:

*

SUB-TOTALS this page

I

r

I

I

1

TOTALS-Carry

forward to next page

Page No. -

DATE

TOTAL

TACH OR

TIME

RECORDING

IN

METER

TIME

SERVICE

I

DESCRIPTION OF WORK PERFORMEDSIGNATURE 8 CERTIFICATE NO. OF PERSON PERFORMING WORK

I

TOTAL brought forward from previous page

Date: 4-3-05

N#: 307SL

ACTT: 146.4

CYCLES: 109

LANDINGS: 109

Complied with a 150 hr "A"Check and 150 hour minor inspections on the

#1 and #2 engines in accordance with the Avantair P-180 AMP Section 11,

Page 2 and Piaggio P-180 chap-5 and Pratt & Whitney PT6A-66

Maintenance Manuals chapt-72-00-00.

1) C/W AD 2000-07-1 1 Leaking Brake Fluid by inspection satisfactory. Next d u e 296.4

2) C/W FAR 91.207 @) by inspection satisfactoty. Next due@ 4/06

10) REPLACED L/H MAIN TIRE. INSTALLED A NEW UNIT. PN= 028-357-0,

SN- 4247W00201.

11) REPLACED R/H MAIN TIRE. INSTALLED A NEW UNIT PN= 028-357-0,

SN-4247WOO188.

12) REPLACED #2 PROP, BETA BLOCK. PN= A3026.

I certify that this airframe has been inspected in accordance with a h A

Check inspection and determined to be in airworthy condition and approved

for return to service.

Signature:

-

SUB-TOTAL this page

TOTAL--Carry forward to next page