Download Service manual Gryp 2006 GB - Energlo Diesel Heaters Inc.

Transcript

SPACE HEATERS WITH

COMPRESSOR

MAINTENANCE AND SERVICE MANUAL

1

THE MAINTENANCE OPERATIONS DESCRIBED IN THIS MANUAL MUST

ONLY BE CARRIED OUT BY QUALIFIED TECHNICIANS RESPECTING ALL

SAFETY RULES

USE ONLY ORIGINAL SPARE PARTS

RECOMMENDED BY THE MANUFACTURER

2

INDEX

!

"

#

!

$

%

$

$

$

$

$#

$$

$*

$+

$,

$ /

$

$

$

$

$ #

$ $

$ *

$ +

$ ,

$ /

$

*

4

+

5

"

"

"

"

()

"

"

"

"

"

&

&

&

&

"

"

"

"

"

&

&

& &

&

"

"

"

1

& &

&

'

&

&

&

& &

..

0

0

- 0

2

3

3

1. FUNCTIONING SCHEME OF DIRECT FIRED HEATERS

D

%

"

"

6

7

!

(

8

1

9

&

General functioning system

!

!

-

&

Detailed functioning system

5

'

::

!

;

)

!

..

'

- &

..

&!

'

!

)

&

..

&

-

'

'

.

.. -

)

)

:6

. !

:- &

)

&

!

&

)

2 &

.. '

.

-

'

/

3

'

'

-

'

-

'

:<:

!

'

!

4

/

'

-

)

&

-'

-'

)

-

.

2. FUNCTIONING SCHEME OF INDIRECT AND POST-VENTILATED HEATERS

S

F2

T

C1

E

R

M

U

B

V

F1

A

EV

F4

F3

%

"

"

6

7

!

(

8

1

4

&

..

)

(6

General functioning system

!

!

-

- &

&!

&

'

!

..

)

'

)

=

'

-

'

)

)

Detailed functioning system

5

'

::

!

&

;

!

..

&

&

&

'

-

'

.

..

!

&

-

)

)

&

)

2 &

.. 5

:6

. -!

.

-

:- &

)

'

/

3

'

'

-

'

:<:

-'

)

/

!

'

)

!

'

-

)

!

'

&

3. INSTALLING THE UNIT

Safety precautions

'

'=

=

=

&=

=

6

'

'

.

Ventilation

requirements

!

)-

=

//

>2?5

' 3

!

'=

# &5

&5

+ &5

&5

$/&5

/ #/ @

/ /

/ +/

/ /

/$//

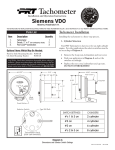

4. ROTARY COMPRESSOR

Exploded view

1

"

9

( )

&

A

B )

&

C

%

D

<

7

E

'

'

4

!

7

'

)

)

)

&

'

'

4.1

Assembling

sequence

"

!

'

4

'

.

!

'

2

'3 !

'

'

/

'

=

/#

&

-

/&

8

&

'

'

$//

'

'=

'

: :=

# / +

# / $/&5

F *

F

'

'

'

&

- '

:<:

/

'

-

4.2

Tuning

'

: :-

2

3

;

-

!

)

'

!

-

&

2

'

*

9

3-

/ /$

#

#

4.3

Cleaning the air

filter

!

#

%

$

#

"

"

$

"

$

!

' &

!

'

' &

'

&

"

4

=

//

#//

///

<

(

$ /

'

///

10

5. TROUBLESHOOTING

SWITCH ON

Check for correct voltage

rating (see data plate)

+/- 10% nom. value

Chech for the correct voltage

on the control panel

Check fuse (burn-outs,

damages,etc.)

THE UNIT DOES NOT

START

•

•

Check all connections

Replace with a new one with

identical ratings.

•

•

See charter 6.20

Replace the control unit

Check that the red lock-out

warning light is not alight

•

Switch on “O”, wait 10 seconds

and switch on “1”

Check that the overheat

thermostat has not been

activated

•

•

Leave the unit to cool

Position on “0” and then on”1”.

Check that the remote

thermostat is properly

connected and adjusted.

Only on AP and PV models

•

•

Check connections

Turn the thermostat tap

For operation without remote

thermostat, check that the

thermostat socket cover is

correctly inserted in the socket.

Only on AP and PV models

•

•

Check the metal jumper

Reinsert and block

•

Replace if not functioning

correctly

Check the burner control unit

Check that following parts are

working:

- Motor and capacitor

- Electrical cable and

plug

- Internal cables

11

•

•

Replace if not functioning

See chapter 6.16

•

•

Tighten the oil line fittings

Check for damages/craks in the

oil hoses

Check that the nozzle is clean

•

Check charter “ Cleaning the

combustion head”

Check that the combustion

head is clean

•

Clean the combustion head with

compressed air or a brush

dipped in oil

Check that the electrovalve

opens after the prepurge

sequence.

Only on AP and PV models

•

•

Check the electrical tester.

See chapter 6.13

Check for the presence of

external (spurious) lights

(sunlight, lamps)

•

Look for – and eliminate – light

reflectors due to sunrays, lamps,

etc. that could disturb the flame

sensor

Look for fires inside the

machine

Check the following parts are

working:

• Ignition transformer

• HT cables

• Ignition electrode

Check that the oil tank is full

Check for air bubbles in the

air filter

THE HEATER STARTS, THE

PREPURGE SEQUENCE

STARTS BUT THEN THE

HEATER STOPS WITHOUT

IGNITION

•

Check that oil flows to the

nozzle

12

•

•

Check the position of air and oil

hoses on the combustion head

Check that the o-ring on the

nozzle is not damaged

THE HEATER START,

IGNITES AND THEN STOPS

Check that the photocell is not

damaged, clean and fixed to

the combustion head

•

•

Clean the photocell with alcohol

Replace if necessary

Check that the nozzle is clean

•

•

See chapter 6.9

Replace oil nozzle

•

Wrong air pressure of the

compressor

Look for correct nozzle size on the

setting chart

Check the nozzle size

THE HEATER STARTS, THE

FLAME IGNITES BUT

COMBUSTION IS NOT

GOOD

Measure and regulate pressure

Check the nozzle is clean

•

•

See chaper6.9

Replace oil nozzle

Check that the oil filter is clean

•

See chapter 6.7

Check that there are no air

bubbles in the fuel line

•

•

Tighten fittings

Replace the faulty pipes/hoses

Wrong air pressure of the

compressor

•

Measure and regulate pressure

Oil is not correct, dirty,

polluted or contains water

•

Empty tank and refill with

correct fuel

Pulsating combustion

•

•

•

13

Check and clean oil nozzle

Check if o-ring on nozzle is

damaged

Check that the nozzle holder is

not damaged

Photocell activated

•

•

Dirty photocell: clean with

alcohol

No flame caused by:

• Dirty nozzle

• No oil

THE HEATER STOPS

SUDDENLY

Overheat

thermostatincorrectly

activated

•

•

Wrong location of overheat

thermostat (after incorrect

servicing, repairs, etc.)

Damaged electrical connection

cable

OK

Excessive overheating of

combustion chamber (overheat

thermostat activated)

•

•

•

•

•

•

•

•

14

Wrong nozzle (too large) (see

specification chart)

Wrong fuel pressure (too high)

– see specification chart

Insufficient ventilation due to

motor fault

Insufficient ventilation due to

fan failure

Blockage of airways due to dirt

or foreign objects

Exhaust pipe partially

obstructed

Combustion chamber clogged

by soot (see charter 3.10)

Room temperature too high

6. MAINTENANCE AND SERVICE

OPERATIONS

&'

'*

(

'

'

+'

& *(

'

+)' *

',

,-0

&

&'

','

*

*

/

'1

,*'

' (('

' *) ' )

)'

*

, ( * +'

. ,/'

( ),

'

, * /' ,

*1

6.1 CHECKING THE SUPPLY VOLTAGE

!

'

2 /63 !

/6

/6

'

• %

&

'

=

• "

&

• "

&

D

'

23

&

=<

>

-

'

.

6.2 CHECKING AND REPLACING THE

POWER CORD

• "

&

• 8

'

)

'

• 8

!

• <

'

=

B/* D

'

• 9

-

•

•

)

'

)

'

)

'

2

'

=#

•

)

• "

• " &

•

)3

6.3 CHECKING AND REPLACING THE

MOTOR

• ()

• " &

• "

&

-

!

• 8

• 9

•

• 8

&-

'

&

=

'

$ %#

'

•

)

&

• "

•

•

• 9

• 8

!

• 8

'

&

'

16

'

&

=

'

&

"

'

)

•

• ()

• 9

•

'

• "

-

&

6.4 CHECKING AND REPLACING THE

FAN

• "

&

&

&

!

• 8

•

• "

'

=

'

)

'

&

'

'

•

• "

&

)

•

)

6.5 EXHAUST GAS ANALYSIS (only for

indirect heaters)

7

1

• 8

)

4

&

'

*

17

)

• 5

34

/

( '* '5

2( )

'

&

&

,-3'

• ()

2

'

&

!

)

9

/

4

1

F

'

&

&

"

&

>'

&

&

-

F

)

2

'

3

&

=

"

2

)

&

2

3

'

<

9

G

)

)

$ *-$ +-$ ,3

.. 2

C &

-

6.7 CHECKING AND REPLACING THE

FUEL FILTER

'

'

6.6 CLEANING THE TANK

!

• C

• 7

• 8

&=

'

'

'

&

&

• 8

18

'

• "

&

-

!

• 9

=

•

6.8 CHECKING AND REPLACING THE

FUEL HOSE

"

&

!

&

"

&

'

• ()

'

&'

'

&

'

• 8

• "

6.9

CHECKING

REPLACING

CLEANING THE NOZZLE

..

..

AND

•

•

•

2

• "

•

•

.. <

3

&

<

'

..

( 6

%

$

19

..

#

%

•

•

3

7

'

)

6.10 CHECKING AND CLEANING THE

COMPRESSOR

!

"

=

'

•

•

•

'

=

//

#//

///

%

%

•

•

()

•

'

20

()

'

"

&

'

&

•

)

'

%

'

'

6.11 REPLACING AND ADJUSTING THE

AIR COMPRESSOR

!

'

•

•

•

()

'

%#

'

•

'

%#

•

'

'

' %

•

'

!

•

•

=

0

)

7

'

/ /#

H

2

3

#

"

! ""

%

$

"

#

%

" #

# 6 %

•

21

)

)

%#

'

•

FIX IN THE

CORRECT

POSITION!

•

•

•

•

)

'

)

8

•

•

%#

8

"

%

"

•

'

2

=/ /$

3

9

0

•

"

•

<

>

&

'

&

)

>

'

&

4

6.12

CHECKING

ADJUSTING VALVE

!

8

.

&

'

0

7

'

•

•

&

4'

'

22

•

•

•

•

0

4 '

D

4

1

THE

=

PRESSURE

•

•

=

"

"

&

!

• 9

>

•

•

9

'

)

•

6.13 CHECKING AND REPLACING THE

AIR SOLENOID VALVE (only for indirect

and post-ventilation models)

•

=

! !

$

4'

2

&

-2/ 3

6.14

CHECKING,

CLEANING

CONTROLLO,

ADJUSTING

AND

REPLACING

IGNITION

ELECTRODES

• ()

•

&

'

" &

93:

•

-

'

•

6

$

'

3

"

'

'

"

'

• "

23

&

•

'

• "

&

'

'

•

..

0

'

•

•

•

!

&

•

)

• 9

&

6.15 CHECKING AND REPLACING HIGH

VOLTAGE IGNITON CABLES

=

• "

• "

• 9

• 4'

• 6

&

&

)

'

&

&

• "

'

&

%

','

%

6=1/ $

! %

•

•

!

, *&

;

% # $

$

'

"$

3<

%

%

• 9

• 8

"

• 9

• 9

2

'

8

#

6.16 CHECKING AND REPLACING THE

IGNITION TRANSFORMER

)

'

%

#

% 1

8

"

#

'

24

•

• ()

-

'

"

6.17 REPLACING THE FUSE

• <

• ()

H

&

"

• "

•

'=

&

'

• 4

• ()

• H

6.18

CHECKING,

CLEANING

REPLACING THE FLAME SENSOR

• ()

-

AND

!

• 9

I

&

•

•

25

=

'

&

'

-

6.19 CHECKING AND REPLACING THE

SAFETY THERMOSTAT

•

• "

!

• 9

•

•

&

% &

'

6.20 CHECKING AND REPLACING THE

FLAME CONTROL UNIT

)

=

!

&

-

'

"

8

!

4

=

'

>

2

"

=

3

&

'

&

3

'

"

!

'

-

-

'

)

'

=

'

'

7 '

7

J

'

'

!

4

'

!

2

>

2

"

!

2)

& 3

2) '

-

&

3

4

'

'

&

'

26

&

3

'

' 2'

"

&

'

-

3

9

2

!

C &

• !

•

'

9

'

'2

-

& '

#/3

'

6.21 BURNER HEAD (OLD TYPE)

!

'

'

..

'

•

!

&

9

9

=

27

<

..

'

&

&

..

'

-

<

•

•

•

•

..

K

K

K

K

'

'

'

'

2

L

M

&

&

'

.. 3-

..

28

7. SETTING CHARTS

Indirect fired heaters

+

'

&'

,

;

=

( ) '**

* >'

#

NF /

O

3? )

=

LCM

&

7? )

/

=

<4 )

&

#

NF #

) '**

/ ',

>>,'

* /' &' ( *

/ *'

/ /P/

9(C 6 D

/ /A7B

/$/,

$#O"

! &

/ P/

9(C 6 D

/*# A7B

/$/,+

$#O"

#

! &

/ P/

9(C 6 D

//A7B

/$/,

$#O"

#

! &

*

O

#

NF #

+O

'

#

Direct fired heaters

+

'

&'

,

3?

/

( ) '**

* >'

D

#

N F ,/

#O

D

#

N F ,/

O

! &

#

NF /

O

! &

=

74

;

! &

) '**

'

/ ',

>>,'

* /' &' ( *

/ *'

/ + P/ /

9(C 6 D

/ /A7B

/$/,

>>

#

*

/ + P/ ,

9(C 6 D

/$# A7B

/$/,*

$#O"

#

*

/ /P/

9(C 6 D

/*# A7B

/$/,+

$#O"

#

/ P/

9(C 6 D

//A7B

/$/,

$#O"

*

A1

=

D

7@

A1

=

<4

D

#

NF #

+O

! &

A1

30

#

Direct fired heaters with post-ventilation

+

'

&'

,

;

=

( ) '**

* >'

#

NF #

>>

<4)=

/

) '**

! &

/ P/

9(C 6 D

//A7B

/$/,

! &

/ P/ #

9(C 6 D

#/A7B

/$/, ,

O

=

LCM

A4)=

-

&

N F #/

O

'

/ ',

>>,'

31

* /' &' ( *

/ *'

$#O"

#

$#O"

#

8. WIRING DIAGRAMS

Direct fired heaters

"

4

D

%

'

!

!4

"

32

Indirect fired heaters and direct fired heaters with postventilation

"

4

D

%

(6

'

!

!4

"

!B

33