Download Sentry™ Visibility Sensor User's Guide

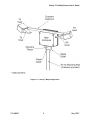

Transcript