Download Service Manual

Transcript

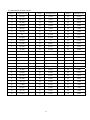

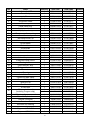

S/M No : DSA241L001 Service Manual Split System Air Conditioner Model: DSA-241L ✔ Caution : In this Manual, some parts can be changed for improving, their performance without notice in the parts list. So, if you need the latest parts information, please refer to PPL(Parts Price List) in Service Information Center. AUG., 2006 Contents 1. Features………………………………………………………………… 02 2. Specification………………………………………………………..……03 3. Dimensions…………………………………………………………..… 04 4. Refrigeration cycle diagram……………………………………………06 5. Capacity table…………………………………………………………...07 6. Wiring diagram…………………………………………………..………08 7. Troubleshooting………………………………….………….…………..11 8. Electronic function…………………………………………………… .17 9. Characteristic of temp. sensor…………………………………………23 1 1.Features 1.1 Compact design 1.2 LED display 2 16 54 P14RE5245 (Interna) 950 YDK36-4C Welling 150 2µ 1200/1120/1080/1000 1080/1020/960/880 1080X330X225 YDK53-6D Welling 800 2500 ≤ 56/60 R22 / 1450 ø m m °C °C ø 20 10 3.Dimensions 3.1 Indoor unit DSA-241L 4 3.2 Outdoor unit 12.5 DSA-241L 5 4.Refrigeration cycle diagram 6 5. Capacity table 5.1 DSA-241L SUMMER OUTDOOR TEMPERATURE DRY Indoor 25ºC 30ºC 35ºC 40ºC 45ºC 50ºC Total capacity kW 6.57 6.25 5.81 5.34 4.90 4.57 Sensitive capacity kW 4.61 4.47 4.28 4.06 3.85 3.69 Input kW. 2.30 2.50 2.71 2.95 3.13 3.35 Total capacity kW 7.04 6.73 6.35 5.94 5.55 5.22 Sensitive capacity kW 4.89 4.75 4.58 4.41 4.28 4.23 Input kW. 2.30 2.52 2.75 2.98 3.21 3.44 Total capacity kW 7.54 7.40 7.00 6.45 5.87 5.37 Sensitive capacity kW 5.30 5.19 5.12 4.75 4.51 4.30 Input kW. 2.34 2.58 2.80 3.05 3.29 3.52 Total capacity kW 7.98 7.80 7.69 7.42 7.08 6.73 Sensitive capacity kW 5.24 5.09 5.04 4.96 4.90 4.92 Input kW. 2.41 2.59 2.87 3.15 3.42 3.70 Conditions 21ºC D 15ºC W 24ºC D 17ºC W 27ºC D 19ºC W 32ºC D 23ºC W 7 6. Schematic diagram and wiring diagram 6.1 Schematic diagram IC3 1 C3 104 VCC WC SCL SDA 1 2 3 4 A0 A1 A2 GND +5V TRANS_OUT R7 12K C8 FUSE1 1000uF/25V L E1 D6 +5V 0.1uF/275VAC 1 3 2 R2 10K 2200uF/25V RST +5V C2 104 IC1 KIA7042 R1 10K J1 EEPROM R5 R6 10K SW1 J2 C7 104 J2 +12V D9 Model SW_TEST 10K TRANS_IN PTC1 82RM +5V D8 C1 104 2 t N POWER 104 12VAC1 1 C16 ZR1 14D681K 1 C5 CN5 3.15A/250V 470uF/16V +12V D5 L1 CN2 2 D4 12VAC2 1 E3 104 D7 3 +5V 3 Vout 104 5VAC1 4 2 C6 2 8 7 6 5 SCL SDA E2 D3 CN1 7805 Vin D2 5VAC2 IC2 24C04 R4 10K GND D1 IN4007*8 +5V R3 10K 无 冷暖 无掉电记忆 有 单冷 有掉电记忆 In_FanLL' J1 1 +5V In_FanLL +5V 2K In_FanLL' 2 C10 104 D13 IN4148 1 T1_room R11 2K T1_room R17 8.1K/1% CN8 D14 E4 C9 IN4148 10uF/16V 104 In_FanM In_FanH STEP_I1 STEP_I2 STEP_I3 STEP_I4 HEAT +5V SEG5 SEG1 SEG2 SEG3 SEG4 2 D15 IN4148 1 +5V T2_I.pipe R12 2K In_FanM In_FanH STEP_I1 STEP_I2 STEP_I3 STEP_I4 HEAT SEG5 SEG1 SEG2 SEG3 SEG4 T2_I.pipe R18 8.1K/1% D16 E5 C11 IN4148 10uF/16V 104 R19 1M IC4 T1 T1_room T2 T2_I.pipe SW SW_TEST Model Model 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 VSS VDD P25 P26 P00 P01 P02 P03 P04 VSS1 P05 P50 P51 P52 P53 AVDD AVREF ANI0 ANI1 ANI2 ANI3 X1 X2 RESET XT1 XT2 Vpp/IC P24 P23 P22 P21 VDD1 P20 P33 P32 P31 P30 P11 P10 AVSS ANI5 ANI4 X1 42 X1 41 X2 40 Reset 39 38 37 36 35 34 RXD20 33 TXD20 32 31 30 BUZ 29 In_FanL 28 In_FanLL 27 REC 26 SDA 25 SCL 24 23 22 RST REC C14 RxD20 TxD20 102 R22 3.5K/3W CN12 1 R24 5.1k D18 N ZD1 E6 C15 473 100uF/35V IN4749 R23 100K C17 471/250v STEP_I1 STEP_I2 In_FanH RxD20 C19 C20 101 4.7K R27 R25 330 IC6 L1 1N4007 R21 11K/2W 11K/2W DIS1 WT4021BG TxD20 2k +5 SEG3 DTA143 com1 com2 h g f e d c b a SEG2 C20 104 +5 GND Q7 Vcc Q6 Q5 R59 9 10K 8 C16 101 SEG4 R60 10K SEG5 2 C17 101 E7 47UF/16V IC8 7 14 1 MR Q4 CP Q3 Q2 Dsb Q1 Dsa Q0 74HC164 13 +5 150 R19 12 11 10 6 5 4 3 R45 330 R46 330 R47 330 R48 330 R49 330 R54 330 R55 330 Q3 9014 In_FanM' L1 RY5 FAN_IN H 5 IN1 OUT1 IN2 OUT2 IN3 OUT3 IN4 OUT4 16 1 In_FanH' 15 2 OUT5 IN6 OUT6 11 In_FanM' IN7 OUT7 10 In_FanL' VDD 9 R9 1K 4 IN5 VSS CN10 1 HEAT_N 7 UJN2003 L1 LOAD_HEAT N 3 13 12 CN11 +12V 14 In_FanH' 5 RY6 HEAT N BUZ1 N +12VSWING LOAD_HEAT L R16 BUZ Q5 9014 REC1 C11 104 REC1 1 2 3 LED6 AUTO LED7 DEF. LED8 TIMER LED9 RUN 显示板原理图 8 CN13 1 HEAT_L RY7 HEAT L 2K HEAT' L R14 Q10 E8 100UF/16V 4 +12V NPN SEG1 Q9 DTA143 3 8 +5 Q8 DTA143 2 In_FanM 6 In_FanL Q4 R20 1 C12 104 PC851 D17 RY4 M IC7 STEP_I4 1N4007 L1 HEAT' IN4148 2K EEPROM 101 5 CON5 +12VD11 HEAT +5V +5 In_FanL' 104 STEP_I3 PC817 RY3 L R14 BUZ In_FanL In_FanLL REC SDA SCL R15 2k C13 104 S C18 4 N 1 2 3 4 5 6 7 8 +5V +5V IC_UPD789166(42PIN) IC5 R8 1K REC1 3 L1 CN9 SEG4 SEG3 SEG2 SEG1 SEG5 2 RY1 LL Q1 9014 R13 CN7 CN6 +12V IN4148 IC1 +12V 1 D2 E1 D3 7805 +5V 3 Vout CN4 E2 104 5VAC2 3 2 1 Vin C1 GND D1 IN4007*8 5VAC1 CN1 1 104 AC_L 1000uF/25V 470uF/16V L1 CN6 3.15A/250V ZR1 14D681K CN5 TRANS_OUT D5 4148 FUSE1 2 D4 L C2 C3 1 0.1uF/275VAC 2 t N 1 COMP COMP CN8 +12V 2 1 1 RL1 L1 TRANS_IN CN9 1 D6 4148 VALVE CN10 1 3 F_OUT1 2 R9 F_OUT1 CN11 1 Q5 9014 R15 RL4 2k 2K R5 8.1K/1% D9 E4 C6 IN4148 10uF/16V 104 CN13 IC2 IC/UPD78F9116 +5V +5V C7 104 R8 Current C5 104 相序C 相序B 相序A T3 Current D10 1N4148 R6 2K 5.1K/1% D11 R7 1N4148 16K R10 1K/1% E3 100uF/16V R39 330 CT1 0057U +5V LED1 压力开关 F_OUT2 相序C 相序B 相序A 1 2 3 4 5 T3 CURRENT 6 7 8 9 10 指示灯 11 12 13 14 压力开关 1 P23/INTP0 P22/RxD20 P24/INTP1 P21/TxD20 P25/INTP2 P20/ASCK20 AVDD P11 P60/AN10 P10 P61/AN11 VDD P62/AN12 VSS P63/AN13 X1 AVSS X2 P50 IC P51 RESET P52 P03 P53 P02 P00 P01 28 27 26 25 24 23 22 21 20 19 18 17 16 15 RX TX RX TX 单相启动 曲轴箱 +5V 单相启动 曲轴箱 X1 F_OUT2 R12 1M X1 X2 Reset COMP VALVE F_OUT1 RL5 D13 4148 Q4 9014 R14 F_OUT2 L1 2k CN12 1 2 RST COMP VALVE F_OUT1 D12 4148 F_OUT2 曲轴箱 Q3 9014 R13 曲轴箱 2k +5V 10K 相序C IC3 R19 相序C C10 104 +5V R16 R24 D14 R11 12K 1 3 2 IC6 KIA7042 D17 4148 RST C11 104 单相启动 68K/2W 2K C8 104 PC817 2k 相序B IC4 10K R20 PC817 R18 相序A J10 R25 68K/2W 2K C9 104 相序A N D15 L Q7 NPN R27 TX TX CN14 相序B 2K IC8 1 2 3 4 RX RX IC7 R28 2k R35 5.1K +5V R32 10K 压力开关 C15 104 CN16 F2 压力开关 J9 1 9 PC817 471/250V R29 D18 1N4007 104 CN3 1 C12 5.1K C18 101 +5V 1 R31 3.5k/3W C13 +5 C17 101 CN15 F1 PC851 R38 330 4007 R23 5.1K +5V 10K Q6 9014 R30 单相启动 4007 R22 5.1K +5V R17 F_OUT2 L1 T3 1 T3 F_OUT1 L1 D7 4148 +5V 4 D8 IN4148 333 L1 RL3 R4 10K R3 VALVE 51/1W C4 Q2 9014 R2 VALVE RL2 2k CN2 COMP 2k PTC1 82RM AC_N CN7 Q1 9014 R1 S N N 曲轴箱 6.2 Wiring diagram 6.2.1 Cooling only DSA-241L WIRING DIAGRAM (INDOOR UNIT) UNIT2 TRANS1 CN1 XS2 XP2 CN8 UNIT1 FUSE 3.15A/250V RT1 CN2 CN6 CN10 CN11 RT2 CN7 RED BLUE WHITE Y/G XT1 CN CN9 1 5 FAN1 M ~ SWING SWING S AG CAP1 TO OUTDOOR UNIT CN1 CN2 CN11 CN10 CN6 UNIT1 CN3 CN4 CN5 CN8 TO INDOOR UNIT POWER SUPPLY 10 Y/G 7.troubleshooting The following tables will help to find where error happened (LED on indoor unit): For models adopting electrical function Operation Timer Defrosting lamp lamp lamp ☆ ☆ ☆ ☆ X ☆ X X ☆ X X X X X ☆ X X X ☆ ☆ EEROM error X ☆ X ☆ Indoor unit communication err X X X ☆ Failure phenomenon Over current protection of the compressor occurs 4 times Indoor room temp. sensor is open circuit or short circuit Temp. sensor on indoor evaporator is open circuit or short circuit Auto lamp Temp. sensor on outdoor condenser is open circuit or short circuit (without for cooling only models) Outdoor unit protects(outdoor temp sensor, phase order etc) r Extinguish ☆ Flash at 5Hz NOTE: For cool only model, the defrosting lamp is replaced with fan lamp, but malfunction display remains. 11 Cur r ent p rotectio n (LED indi cates) Check t he indoor air filt er. Check the out door condenser. Che ck t he positio n and wiring of tem p sen sor (all of the m). Check sp eed of in door motor. Che ck speed of o utdoo r mo tor. Recycle the refrigerant and recharge . Yes Does ind oor heat exchan g er frosted? If wro ng, t he unit w ill result in current prote ction, not tem p. Yes D oes it occur in C ool mode? No Does outdo o r heat exchanger fr osted? Yes It is n orma l under tha t ambient temp . Yes Doe s the ind oor o temp low than 1 0 C? No Doe s the outdoo r o temp over 48 C? Yes No No No Check t he overcurre n t prot ect or of comp ressor. Check t he solenoid coil o f reve rse valve. Check t h e soft starter m ou ld. C heck the soft st arter mou ld. Re place the ma in PCB board . C heck t he ove rc urre nt prot ect or of c ompressor. Re place the co mpressor. Replace th e main PCB board. R eplace the re verse v alve. Recycle the ref rig erant and rec h arge. Indoor /Outdoor Units C ommunic ation Pr otection No Is the L&N c onnections betwe en indoor and outdoor units corr ec t? Re conne ct cor re ctly. Yes No Is the c omm unic ation conne ction good? Re conne ct cor re ctly. Yes Re place the outdor PC B, the n run th e m ac hine. Is the com mu nica ti on pro tec tion re lie ved? Yes It m ean s t h at t h e mal fu n c t i o n i s fr om indoor unit. Re pla ce the indoor PC B. 12 Che ck t he dra inage sys tem of out door unit. T he unit does not o per ate Per f orm the related inst ruct io ns. Yes Do th e LED lamps indicat es ERR? Ye s Does the power LED light af ter turning the switch on? No Ch eck t he bat ter y of the remot er. Check the po wer supplie r. Check t he displa y board . Chec k wirin g. No Is th ere beep from the unit when using remoter? Yes Yes Replace the disp lay boa rd . Does the unit run in Forced Co ol m ode? No Rep lace the ma in PCB b oard. Ch eck t he soft sta rter No No C heck t he elect rical so urce. Does the volt ag e bet wee n inpu t terminat es o f transformer i s corre ct? Yes Does the volt ag e bet wee n outp ut terminat es o f transformer i s corre ct? No Replace the transfo rmer. Yes No D oes the power tr ansfer to t he di sp lay boa rd ? Yes Replace the disp lay boa rd . No Does it just happ en in th e beginning of coolin g or heat in g mode? Yes It is b ecaus e of the h eat rub be tween plastics parts. It is n orma l. Abnormal n o ise from the indoor unit Check t he swing mo to r. Yes Does it happ en with aut o swing? Yes Does it happ e n in Fan On ly mod e? No Check t he swing lou ver . Check t he fa n motor . No Check the inp ut and output pip e. Check t he cross flow fan . R ecycle the ref rig er ant and recha rge. Replace the b ear. Ab normal noise fro m the outdoo r uni t Check t he motor. Yes Do th e fan blade rub with t he shroud? No Check t he fan blad e. Check t he motor supporter. C heck t he fixing nut s of outdoo r unit. Yes D oes it happ en in C ool mode? No Check t he capillary. C heck t he co mpressor. 13 Re cycle the ref rig eran t and recharg e. PROBLEM Not operating Indoor abnormal noise. CAUSE Power failure Wiring failure Transformer failure Indoor PCB failure Cross flow fan failure Loose screws Worn bearings Motor failure Fan blade failure Loose screws Outdoor abnormal Motor failure noise. Compressor failure Copper tubing REMEDY Check the power cord. Check the wiring. Replace the terminates or wires if failure. Check the input and the output on transformer. Replace if failure. Replace after checked failure. Replace the fan if cracked, out of balance, or partially missing Tighten them. Replace after checked failure. Replace the motor if knocking sounds continue when running or loose, or the motor hums or noise appears to be internal while running. Replace the fan blade if cracked, out of balance, or partially missing. Tighten them. Replace the motor if knocking sounds continue when running or loose, or the motor hums or noise appears to be internal while running. Replace the compressor if sounds coming from inner of the compressor. Remove the cabinet and carefully rearrange tubing not to contact cabinet, compressor. Display board or indoor PCB failure Remote control failure. Compressor protection Replace the display board. If it is still false, replace the PCB. Check the voltage of battery. Replace batteries if the voltage Battery failure is lower than 2.3V. Normally, the remote control is not easy to damage. If the Remote control failure above two methods are not effectual, replace the remote control. Check leakage. Recycle the refrigerant. Correct and Lack of refrigerant recharge if there is any leakage in the refrigerant system. Check the module and the capacitor connected to the Soft starter module failure module. Replace if failure. Overcurrent protector Check the resistance of compressor overcurrent protector. failure Replace if failure. Outdoor PCB failure Replace after checked failure. 14 PROBLEM Open or short circuit of outdoor temperature sensor Room temp or evap temp sensor open or short circuit Over load or too low voltage protection Fan speed beyond control Zero-crossing error Insufficient cooling or heating. CAUSE Temperature sensor failure Connector failure or loose Outdoor PCB failure Temperature sensor failure Connector failure or loose Indoor PCB failure REMEDY Replace after checked failure. Repair or replace the sensor. Replace after checked failure. Replace after checked failure. Repair or replace the sensor. Replace after checked failure. Check the module and the capacitor connected to the Soft starter module failure module. Replace if failure. Power failure Wait if checked the power voltage is really too low. Wiring failure Correct if indoor fan motor wiring is loose. Indoor fan motor failure Check the input of fan motor. Replace if failure. Indoor PCB failure Replace after checked failure. Indoor PCB failure Replace after checked failure. Air filter Clean or replace if restricted. Determine if the unit is properly sized for the area to be Unit undersized cooled or heated. Condenser and Clean or replace if restricted. Evaporator Take proper measures to make the door and windows Room structure sealed well if gap is found. Clean or remove if any barrier is found to block the Air flow inlet/outlet wind flow of the unit. Sunlight Add a awning if the outdoor unit is exposed to the sunlight. Check the fan capacitor on outdoor power control board and replace the board if not within +/-10% of manufacturer's Outdoor fan motor rating. Replace the motor if the speed is not within +/-10% of manufacturer's rating but not because of the capacitor. indoor fan motor Less refrigerant Capillary tube Compressor Heat sources reverse valve For electrical function 2.3 models. Check the fan capacitor in indoor electric box (for some models, the capacitor is on main PCB.) and replace the capacitor (or main PCB) if not within +/-10% of manufacturer's rating. Replace the motor if the speed is not within +/-10% of manufacturer's rating but not because of the capacitor. Check the tubes for reasons of leakage. Recycle the refrigerant, correct the leakage points and recharge. Regulate the flow if capillary tube is blocked. Make the evaporating temperature appropriate if the evaporator is frosted. The inlet and outlet valve of the compressor is damaged, making the low pressure connected with the high pressure. The refrigerating system is difficult to produce high pressure and low pressure. Replace the compressor after checking for the reason. Reduce if over loaded. The two paths for refrigerant are connected, making the low pressure connected with the high pressure. The refrigerating system is difficult to produce high pressure and low pressure. Replace the reverse valve after checking for the reason 15 PROBLEM No display on indoor unit. CAUSE LED failure Remote control shut the display No power Wiring Temperature setting Mode setting REMEDY Replace the display if checked failure. Push the button to turn the display on. Check the voltage. Call an electrician if not within the limit. Check the terminals. Repair and correct if loose. Check and adjust the temperature setting. Check and adjust the mode setting. Check the module and the capacitor connected to the No cooling or Soft starter module failure module. Replace if failure. heating. Reverse valve solenoid Check the reverse valve solenoid coil. Replace the coil if coil short, open or damaged. If the reverse valve is blocked, the heating mode will not Reverse valve perform. Replace the reverse valve after checking the reason. Water drainage failure Check the drainage pipe and repair if failure. The indoor unit is incorrect Correct the installation if not correct. Water drops from installed indoor unit Drainage pipe blocked Correct it. The humidity in room is It's normal if the humidity in the room is over 85%. too high Wiring failure Check wiring. Correct if wrong wiring or loosen. Check wiring. Correct if the commucication wire is not Wire EMC shielded wire or twisted with other wires. Zero-crossing Outdoor PCB failure Replace if the LED is not on. error Outdoor transformer Replace if failure. failure Insufficient Replace the PCB if the photon coupling on indoor PCB is Indoor PCB failure cooling or heating. failure. Indoor PCB failure Replace after checked failure. 16 8. Electronic Control Principle of Large Cooling Capacity Split Model A/C 8.1 Fan only mode Fan speed is high/mid/low/ Auto 8.2 Cooling mode The 4-way valve is closed at cooling mode. The action of the compressor and the outdoor fan: T: Room temp. Ts: Setting temp. Condition Temp. up Temp. down Compressor Outdoor fan T> Ts+1 On On T<Ts+1 Off Off T> Ts On On T<Ts Off Off Auto fan Condition(T=Indoor Temp.-Setting Temp.) Temp. up Temp. down Indoor fan speed T<1℃ Low 1℃ <T<4℃ Med. T>5℃ High T> 4℃ High 1℃ <T<4℃ Med. T<1℃ Low Anti-freezing control to indoor evaporator Condition Temp. Temp. up Compressor T> TE6 T< TE6 Temp. down >4 Minutes T> TE5 T< TE5 >4 Minutes On On Off Off On On Off Off Condenser high temp. protection( only for heat pump) Temp. Condition Temp. up Temp. down Compressor T> TE10 Off T< TE10 On T> TE11 Off T< TE11 On The outdoor fan motor speed control in the cooling mode. T3 32 High speed 30 Low speed 8.3 Dehumidifying mode 8.3.1 Indoor fan speed at low speed. 8.3.2 Protection is same as cooling mode. 8.4 Outdoor fan Time Heating mode 17 8.4.1 8.4.2 8.4.3 Generally, the 4-way valve is open in heating mode, but it is closed in defrosting mode. Generally, the outdoor fan is turned off with the on-off action of compressor in heating mode, except for the defrosting mode or the end of defrost. Action conditions of compressor at heating mode: compressor must run for 4 minutes after starting and then judge temperature. Meanwhile other protections are still valid. Condition Room temp. up Room temp. down 8.4.4 Compressor Outdoor fan T> Ts+4 Off Off T<Ts+4 On On T< Ts+3 On On T>Ts+3 Off Off Indoor Fan actions at heating mode Indoor Fan can be set at HIGH/MID/LOW/AUTO by using a remote controller, Anti-cold wind function 1. Condition Indoor fan speed T= Indoor exchanger temp. Indoor exchanger temp. up Indoor exchanger temp. down T<TE1 Off TE1<T<TE2 Low speed T>TE2 Setting fan speed T>TE3 Setting fan speed TE4<T<TE3 Low speed T>TE4 Off Anti- cold air protection 2 ( when the room temp. satisfy the setting temp.) T=evaporator pipe sensor temp. Indoor fan speed Room temp. up T<TE14+2℃ Low speed or stop T> TE14+2℃ Setting speed. Room temp. down T> TE14 Setting speed. T< TE14 Stop after 15 seconds Low speed Condition Indoor fan speed Auto wind T=Indoor Temp.-Setting Temp. Room Room temp. up temp. down T<2℃ Med. speed T>2℃ Low speed. T> 0℃ Low speed. T<0℃ Med. speed Indoor evaporator high-temperature protection Condition Compressor Outdoor fan T= Indoor exchanger temp. Indoor exchanger temp. up Indoor exchanger temp. down T<TE15=54℃ On On(high speed) TE15<T<TE8 On On(low speed) TE8<T<TE7 On Off T>TE7 Off Off T>TE9 Off Off T<TE9 On On 8.5 Defrosting mode 8.5.1 Conditions of defrost: Defrosting starts when either of the following : T3 lower than 0°c, lasts for more than 40 minutes, provided that the time period when the temperature is lower than -3°c consecutively reaches 3 minutes. Calculate from the end of latest defrost, evaporator high temp. protection only closes outdoor fan with 18 the compressor still running. Add up to 90 minutes . 8.5.2 Conditions of defrost ending: Defrosting ends when either of the following : The time gets to 10 minutes; T3>20°c 19 8.5.3 Time sequence of the whole defrosting procedure is as follows: Defrost 10or 6minutes 55S 55S Compressor 4-way Valve 50S 50S Outdoor Fan Indoor Fan 15S Remark: when the evaporator pipe sensor temp. more than TE16, The indoor fan start to run. 8.6 8.6.1 Auto mode When running in automatic mode, the air conditioner automatically selects one of the following operation modes: cooling, heating or ventilation according to the difference between room temp. (TA) and set temp. (TS). TA—TS Operation mode TA—TS>2℃ Cooling -1℃ ≤TA—TS≤+2℃ Air-only TA—TS<-1℃ Heating (air-only for cooling only type) 8.6.2 8.6.3 At auto mode, the indoor fan blows automatically in selected mode. One mode should be carried out for at least 15 minutes once selected. If the compressor cannot start for 15 minutes, reselect the operation mode according to the room temp. and set temp., or reselect when the setting temp. changed 8.7 Economic mode Cooling: The set temperature rise 1℃ per hour. Two hours later, the set temperature will maintain as a constant and the air circulation is kept at low speed,and the air condition will stop work after 7 hours. Heating: The set temperature decrease 1℃ per hour. Two hours later, the set temperature will maintain as a constant and the air circulation is kept at low speed, and the air condition will stop work after 7 hours. (Cold air proof function takes priority over all). 8.8 Manual operation Manual operation is controlled by touching buttons and divided into force cooling and forced auto mode. It transfers between these two modes by pressing the buttons, the cycling order of the button press is: Remote mode Forced auto Forced cooling 8.8.1 Forced Cooling 8.8.1.1 In forced cooling mode, the remote signal is not accepted. 8.8.1.2 The compressor is unconditionally turned on, after 30 minutes cooling operation whose fan mode is set as low, the A/C operates in the forced auto mode under the requirements of the forced auto mode. 8.8.1.3 During the start-up and operation, all of the following protecting functions work: 3minutes start-up delay protection, overload protection, outdoor protection, evaporator Protection against low temperature. If any of the protection functions, the comparative protecting action is executed. The forced cooling mode is closed by one touch on the button, meanwhile the operation light is off, the buzzer buzzes lasts for 1 seconds, then A/C turns to be closedown status. 20 8.8.2. Forced Auto 8.8.2.1 Remote control signal can be received in forced auto mode. When receiving the signals, the forced auto mode will be canceled and the A/C changes to remote control status and performs operation as the signals indicates. 8.8.2.2 The system performs control according to the remote control auto mode with a set temperature of 24°c. 8.9 Timer 24 hours timer on or off. 8.10 Protecting Function 8.10.1 Compress with a delay of 3 minutes. 8.10.2 Sensor open and break protection 8.10.3 EEPROM error protection. 8.10.4 Current protection function. Condition Current up Indoor fan Compressor Outdoor fan Remark I< IRESTORE On On On IRESTORE <I< IFAN On On Off Heating mode Low speed On On Cooling mode IFAN <I<I5MIN Off Off After 5 Minutes I5MIN<I< I3SEC Off Off After 3 Seconds Current I5MIN<I< I3SEC Off Off After 3 Seconds down IFAN <I<I5MIN Off Off After 5 Minutes On On Off Heating mode Low speed On On Cooling mode On On On IRESTORE <I< IFAN I< IRESTORE 8.11 Auto restart Function In case of a sudden power failure, this function automatically sets the unit to previous settings before the power failure when power returns. 21 Models and Parameters Model DSA-241L I3SEC 14A I5MIN 20A IFAN 22A IRESTORE IDEFROST TE1 TE2 TE3 TE4 TE5 2°C TE6 12°C TE7 TE8 TE9 ANGLCOOL 67 ANGLHEAT ANGLOFF 130 THDEFROST TMDEFROST TLDEFROST 22 9. Characteristic of temp. sensor Temp.℃ Resistance KΩ Temp.℃ Resistance KΩ Temp.℃ Resistance KΩ -10 62.2756 17 14.6181 44 4.3874 -9 58.7079 18 13.918 45 4.2126 -8 56.3694 19 13.2631 46 4.0459 -7 52.2438 20 12.6431 47 3.8867 -6 49.3161 21 12.0561 48 3.7348 -5 46.5725 22 11.5 49 3.5896 -4 44 23 10.9731 50 3.451 -3 41.5878 24 10.4736 51 3.3185 -2 39.8239 25 10 52 3.1918 -1 37.1988 26 9.5507 53 3.0707 0 35.2024 27 9.1245 54 2.959 1 33.3269 28 8.7198 55 2.8442 2 31.5635 29 8.3357 56 2.7382 3 29.9058 30 7.9708 57 2.6368 4 28.3459 31 7.6241 58 2.5397 5 26.8778 32 7.2946 59 2.4468 6 25.4954 33 6.9814 60 2.3577 7 24.1932 34 6.6835 61 2.2725 8 22.5662 35 6.4002 62 2.1907 9 21.8094 36 6.1306 63 2.1124 10 20.7184 37 5.8736 64 2.0373 11 19.6891 38 5.6296 65 1.9653 12 18.7177 39 5.3969 66 1.8963 13 17.8005 40 5.1752 67 1.830 14 16.9341 41 4.9639 68 1.7665 15 16.1156 42 4.7625 69 1.7055 16 15.3418 43 4.5705 70 1.6469 23 Exploded View Parts for Model DSA-241L 220~240V, 60Hz: Indoor Unit 24 No 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 Name Indicator for LED Panel Ass’y air filter Air cleaner Air cleaner holder Screw cap Panel frame assy display board holder display board assy Window cover for repairing Air out frame assy Horizontal louver, up Horizontal louver, down Air out frame Drain Hose Grille holder Vertical louver Louver motor evaporator Indoor temp sensor Evaporator temp sensor Bearing holder Cross flow fan, assy Fixing part for motor Fan motor Chassis Installation Plate Connecting pipe clamp Fan motor capacitor Wire joint, 5p Transformer E-Parts box Main control board (including Program chip) Wire clamp for power cord Cover for E-parts box Remote Controller Holder, Remote Controller connector for watering seal Copper nut, TLM-B02 Copper nut,TLM-D04 Quanlity 1 1 2 1 1 3 1 1 1 1 1 1 1 1 1 3 15 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 25 Sale code 13518111001 13528111001 13528111002 10109121226 10109121225 13528111003 13528111004 13518111007 13518111008 15021111006 13821111002 13528111006 13528111007 13528111010 10118121223 10321121006 13528111012 10105111047 10924121003 15021111014 10109121242 10321111008 10321111009 10321111013 13521311001 15021111015 10321111011 10321111015 50309121808 10124121203 10118121232 15021111016 13821111005 13407111026 10121121234 15021111017 11608111003 10718121009 11609121003 31009321021 10909121013 11324113804 BOM code 2113029215 2113079316 2113079315 2113010212 2113010217 2113079313 2113079317 2113029159 2333029078 2113079250 2113079320 2113079568 2113079569 2113079567 2110109002 2113079145 2113079570 2240020004 2153079031 2243079040 2243069051 2273079001 2110029010 2113079045 2240040720 2113079242 2123079017 2123079016 2240119015 2230145023 2230099003 2113079200 2133079129 2130073660 2113070033 2113079249 2335506565 2113139022 2110102011 2272009001 2160032001 2160032003 Remark Exploded View Parts for Model DSA-241L 220~240V, 60Hz : Outdoor Unit 26 No. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 Part Name Clamp for front net Front net Front clapboard Propeller fan Fan Motor Holder for fan motor Foam over holder for motor Front right clapboard Chassis Compressor Separating board Little Handle Cover Condenser Left clapboard Rear Net Rear right clapboard Big Handle Installation plate for valves Water collector Capacitor Clamp Compressor capacitor Fan motor capacitor Wire joint Washer for wire joint Clamp for wiring Installation board for E-parts Contactor Wire joint for multiplexer Main control board Transformer High Pressure Valve Ass’y Liquid pipe valve Low Pressure Valve Ass’y Low Pressure Valve Copper nut, TLM-B02 Copper nut,TLM-D04 Quantity 8 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 27 Sale code 10112121801 10118121801 10924121801 10118121804 13521311801 10118121809 10118121807 10118121803 10122113803 10122123804 10118111806 10830121811 10118121827 13521111801 10924121808 10924121809 10118113804 10118121817 10118113805 10118121832 10112121814 10122123801 10109121819 11812113810 10112121817 10118121823 13821111803 10121121806 10121121809 13528111802 11018121010 10124111815 10124121812 10122113804 10124121814 10909121013 11324113804 BOM code 2113511801 2124550017 2124550030 2114550002 2240041637 2124550020 2224550001 2124551101 2124550022 2140061720 2123530551 2115029006 2124550031 2153549096 2124550032 2114550004 2123549024 2114550003 2123500018 2113529005 2120010002 2240100805 2240110351 2230145021 2113500004 2124540027 2123549049 2230085004 2230145035 2133549001 2230090080 2163549418 2160074223 2163549312 2160072219 2160032001 2160032003 Remark PH360X3CS-3KUU1 DAEWOO ELECTRONICS CORP. 686, AHYEON-DONG MAPO-GU SEOUL, KOREA C.P.O. BOX 8003 SEOUL, KOREA TELEX: DWELEC K28177-8 CABLE: “DAEWOOELEC” PRINTED DATE: AUG., 2006