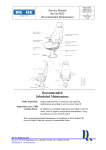

Download Operating Instructions Ontario - bei Karmann

Transcript