Download Sioux Tools LOW VIBRATION AIR HAMMER 5276 User's Manual

Transcript

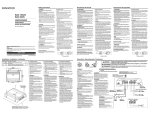

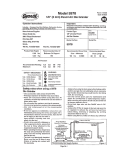

Form # ZCE701 Date 5-02JA Operator Instructions accessible plack Product Type Low VIb d o n Air Hammer ManufacturerBuppIier Sioux Tools, lnc. 250 Snapon Drive P.0. sox 1596 Murpb, NC 28906 U.S.A. Tel No. 828-835-9765 Product Net Weight 5-10 I& 2.32 kg Mcdel %/Nos Fax No. 828-835-9635 Recommended Use Of W a n c e r Or Support NO 62 6.2 RecommendedMax. Hose Length 30Ft IOM Noise Level: Sound Pressure Level 943dB(A) Sound Power Level 106.6 dB(A) Air Pressure -RecommendedWorking Maximum , Recornmded Hose Bore Size - Minimum 916 ins 8m Serial No- -bar bar 90 90 PSI PSI Tesi Method: Tested in accordance with Pneump test code PNBNTCI and IS0 Standard 3744 Wbration Level 9.56 Meters 1 S& Test Method: Tested in accordance with IS0 standards 8662 Farl I Safety rules when using a 5276 Air Hammer -Always wear s a w goggles as use of tool may cause flyingakqeck. - Prolonged exposure to vibration may cause injury-Read all instructions before using this tool. All operalots must be fully trained in its use and aware of these safety rules. - Do not exceed the maximum working air pressure. - Use personal protectii equipmentas recommended- Some dust created by fixed to the tool- - The tool is not electrically insulated, Never we the tool if there is any chance of coming into wntacl with live electricity. -Always when using the t d , adopt a firm footing andtor position and grip the tool sufkienlly only to u v e r m e any reaction forces that may result from the tool doing wok. Do not overgrip. -Use only correct spa?e parts for maintenance and repair. Do not improvise or make temporary repairs. Major servicing and repairs should only be carried out by person$ trained to do so. - Do not lock, tape, wire, ek.the '0n/Off' valve in 'On' position. The WggerAever, etc. must always be free to return to the 'OW position when released. p e r s n c h g , sawing, grhding, drilling, and other construction actjvities contains &@mi& knmntocause m e r , birih defects and other reproduhe harm-Use only compressed air at the recommended conditions. -If the toot appears to malfunction, remove from use immediately and arrange b r sewice and repair- If it is not practical to remove tool from .kttlsuikkl~ sewice, then shul off rhe air supply T 0 M a i U a i i ~ to the tool and write or haw-writlena warning note and attach it to the tool. - If tool is to be used with a balancer or other suspension device, ensure that the tool is firmly attached to the suspensiontsupport device. -When opefating lhe tool. always keep the body and pariicularly the hands RecomrnenddAir Supply System away from the working attachment 7 Fgure 1 -Always shut off the air supply to the tool and press the '0n/Off' valve 10 exhaust the air from the feed hose before figing, removing or adjusting the working attachment filted to the W. Before using h e t d , mike sure that a shut off device has been fitted to the air supply line and the positim is known and easily accessible so that the air supply to the 1001 can be &ut off in an emergency. -Check hose and fitlings regularly for wearTake care against entangtement of the moving park of the t d w-Wi cbthing, hair, ties, cleaning rags, rings, jewelry, watches, bracelets, etc- This could cause the . body of parts of the body to be drawn towards and in contact with the moving parts of the tool and could be very dangerous. -It is expected that users will adopt safe working praclices and observe all local, rdimal and country legal requirements when installing, using or maintaining the tool. -Take care that the exhaust air does not point towards any other person or material or substance that could be contaminated by oil droplets. When first lubricating a 1001 or if the tool exhaust has a high oil content, do not allow the exhaust air to come near very h.ot surfaces or flames. -Never Iay the tool down until the wor!4ng attachment has stopped fnm*ngM e n ttw tool is nat in use, shut offthe air supply and press the triggernever to drain the supply line. If the tool is not 10 be used for a periodof time, first lubricate, disconnect from Ar supply and store in a dry average room tertyeralure environment. -If the tool is passed from one user to a new or inexperienced user, m a b sure these instructions are passed with the tool. - Do not r e m e any manufacturer a t i d safely dwhere fitted, i-e., wheel guards. safety trigger, speed governors, etc. -WMrever possible, secure workpiece with clamps, a , vise, etc- t o make it rigidso it does not mwe during the work operation. Keep good balance at all times. Do rmt stfetch or overreach. - Try to match tfw tml to the work operalion. Do not use a tml that is too light or heavy for the work operation. If in doubL seek adGce. -In general terms, this tool i s not suitable for undewater use or use in explm*ve e ~ m n m e n t s seek advice from mndaclurer. -Try to make sure that the work area is clear to enable the work task to be performed safely. If practical and possible; try to clear unnecessary obsmctim b b t 9 skrtjng work. -Always use air hose and couplings with minimum working pressure ratings at least 1 1/2 times ?he maximum working p r e G r e raling of the W. - - - Putting Into Service Air Suppiy Use a dmn lubiiated air supply that will give a measured air p ~ r at e tool d90 ps.iJ6.2 bar h e n the too4 is mning with lhe t-erAever fully depressed. Use m m m e m d hose size and Ie+. It is r m m n d d that the tool is connected to me air supplyasshw~~ mQure I.Oa notmnmct the tool to 4he air G n e systemwithout ifmporatingan isy to reachand operate air shut off valve. The air supply should be lubricated. It is strongly r m r n a e d that an air Mer, regulator. lubricator (FRL) is used as shown in F ~ u r I e as Wis will supply clean, lubrbted air at me correct ~ e s s u r eto the tod. Details d such equipment m n be obtained from your s-ier. lf swh equipment is not used, lhen the tod shu!d be lubmted by ofl the air supply to the tad, dq~essurizMgthe I'mt q p&ng the biggerfiever on the W. Disconnect the air line and pour into the W e adaptor a teaspmnful (5ml) of a suitable pneumatic motor l u b m l i q oil &urn preferably iworpraiing a net inh'#)iior. Reconnect t d to air supply and run tool slowly for a few seconds to allow air lo circulate the oil- If &I is used frequenw. lubricate cn daiiy basis and iltool starts to slow or Ipower. 11is r w m m d e d -1 tbe a~pressure at the tool while the t d is wnniq is 90 psU6.2 bar. - - Foreseen Use Uf TheToot 5276 Page No 2