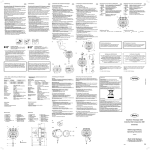

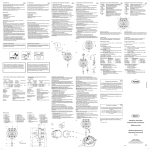

Download MarTest. Test Indicators MarCator. Dial Indicators Millimess®. Dial

Transcript