Download Toshiba SR-1054HSP Robotics User Manual

Transcript

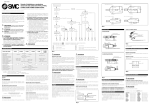

STE 58764 CHAPTER 2 INSTALLATION 2.1 INSTALLATION ENVIRONMENT Table 2.1 shows the environmental conditions for the location in which the SR-HSP Series Robot and SR7000 Controller are to be installed. Table 2.1 Environmental Conditions for the Robot and Controller Specifications In operation : 0 to 40 ℃ In storage : -10 to 50 ℃ Humidity 20 to 90 % (Non-condensing) Do not install the robot where it may be subject to fluids such as water. Altitude 1000 m or less 2 Vibration In operation : Within 0.98m/s 2 In transport : Within 9.8m/s Dust There is to be no inductive dust. Please consult with Toshiba first should you wish to use the robot and controller in an especially dusty environment. Gas There is to be no corrosive or combustible gas. Sunlight The robot must not be subject to direct sunlight. Electromagnetic There are to be no devices in the area which produce an excessive noise amount of electromechanical noise. Field There are to be no devices in the area that generate a strong field. Item Temperature Danger Do not place the robot near combustible matters. Doing so could lead to fires if the matter ignites due to a fault, etc. ・ 2.2 ROBOT INSTALLATION Before actually installing the robot, you must plan a layout and take into consideration such matters as the working space, coordinate system and space for maintenance. 2.2.1 External Dimensions An outline drawing of the robot is shown in Figs. 2.1 to 2.5. - 2-1 - STE 58764 Fig. 2.1 External view of SR-504HSP robot - 2-2 - STE 58764 Fig. 2.2 External view of SR-554HSP robot - 2-3 - STE 58764 Fig. 2.3 External view of SR-654HSP robot - 2-4 - STE 58764 Fig. 2.4 External view of SR-854HSP robot - 2-5 - STE 58764 Fig. 2.5 External view of SR-1054HSP robot - 2-6 - STE 58764 Working Space Figs. 2.6 to 2.10 show the working space of the robot. Each axis can operate within the working space. To keep the robot from moving out of the working space by mis-operation, the robot is equipped with mechanical stoppers outside the moving range. In addition, soft limits are provided which may be set as desired by the user. 110° R500 R184 137° 137° 110° 150 R250 100 2.2.2 Fig. 2.6 SR-504HSP robot working space - 2-7 - STE 58764 115° R193 R550 200 120° 120° 100 115° Fig. 2.7 SR-554HSP robot working space 115° R227 140° 140° 200 R650 100 115° Fig. 2.8 SR-654HSP robot working space - 2-8 - STE 58764 115° R350 145° R850 200 145° 110 115° Fig. 2.9 SR-854HSP robot working space 115° R333 145° 115° 150 145° 200 R1050 Fig. 2.10 SR-1054HSP working space - 2-9 - STE 58764 Coordinate System The robot's joint angle zero point (0° or 0mm position) has been calibrated before shipment in respect to the base reference planes. The base coordinate system will be determined according to this calibration. Figs. 2.11 to 2.15 show the base coordinate system and the zero positions of each axis joint angle. (-) XB Axis 4 0° (+) (-) 0° (-) 0° (+) Axis 2 250 Reference plane 180 Reference plane (+) Axis 1 90 250 YB ZB Axis 3 Origin of base coordinate system (+) 0mm ◎ 100 2.2.3 Fig. 2.11 SR-504HSP base coordinate system and joint angle zero point -2-10- STE 58764 Reference plane (-) (-) 210 (-) XB Axis 4 (+) Reference plane Axis 2 (+) 300 (+) Axis 1 250 105 YB ZB Axis 3 XB (+) Origin of base coordinate system 0mm ◎ View A 100 View A Fig. 2.12 SR-554HSP base coordinate system and joint angle zero point - 2-11 - STE 58764 Reference plane 0° XB (-) (-) 210 (-) Reference plane 0° 0° Axis 4 (+) (+) Axis 2 Axis 1 300 (+) 105 350 YB ZB XB Axis 3 (+) Origin of base coordinate system View A 0mm 100 ◎ View A Fig. 2.13 SR-654HSP base coordinate system and joint angle zero point -2-12- STE 58764 Reference plane (-) 0° XB Axis 4 0° (+) (+) Axis 2 210 (-) Reference plane (-) 0° Axis 1 (+) 300 105 550 YB ZB Axis 3 XB (+) View A 0mm ◎ 110 View A Origin of base coordinate system Fig. 2.14 SR-854HSP base coordinate system and joint angle zero point -2-13- STE 58764 Reference plane (-) 300 (-) (-) 0° 0° XB Reference plane 0° (+) Axis 4 Axis 2 (+) Axis 1 (+) 150 470 580 YB ZB Axis 3 XB (+) 0mm ◎ Origin of base coordinate system 150 View A View A Fig. 2.15 SR-1054HSP base coordinate system and joint angle zero point -2-14- STE 58764 2.2.4 Installing the Robot The robot is fastened down using the mounting holes in the base. Use M12 hexagon socket bolts for the SR-504HSP and M16 hexagon socket bolts for the SR-554HSP, SR-654HSP, SR-854HSP and SR-1054HSP. The robot installation method is shown in Figs. 2.16 to 2.18. A reference plane is prepared on the base section and is marked with "xxx". To align the robot's base coordinate system position or when the robot must be replaced, prepare an adequate reference plane. Then, contact that reference plane to the base reference plane and fasten. The reference plane has been coated with anticorrosive agents before shipment, so wipe the agent off with thinner before using. Caution ・ ・ The robot will suddenly accelerate and decelerate during operation, so when installing it on a frame, make sure that the frame has sufficient strength and rigidity. If the robot is installed on a frame that does not have sufficient rigidity, the vibration will occur while the robot is operating, and could lead to faults. When installing the robot on the floor, fasten the robot down securely with foundation bolts. Install the robot on a level place. Failure to do so could lead to a drop in performance or faults. Reference plane 180 130 65 ×× M12 hexagon socket bolt 4-φ14hole φ24depth counterbore 130 × ×× Reference plane 90 30 20 × 140 Fig. 2.16 Installing the SR-504HSP robot -2-15- STE 58764 Reference plane M16 hexagon socket bolt 160 4-φ18 hole,counterbore 26 ××× 105 160 105 × × ××105 40 104 160 25 Reference plane Fig. 2.17 Installing the SR-554HSP,SR-654HSP, SR-854HSP robot Reference plane 240 4-φ18 hole,counterbore 26 ××× × × 150 240 150 M16 hexagon socket bolt ×××× 150 148 40 Reference plane 25 × × 185 Fig. 2.18 Installing the SR-1054HSP robot -2-16- STE 58764 INSTALLING THE CONTROLLER External Dimensions 20.5 An external view of the controller is shown in Fig 2.19. 381 330 Right side Top 230 241 430 11 2.3.1 30.5 2.3 Front Rear Fig. 2.19 External view of the controller -2-17- STE 58764 2.3.2 Rack Mounting Dimensions When mounting the SR-7000 robot controller in a rack, set the side brackets using the screw holes provided on both ends of the front panel, and secure the controller to the rack. (① in Fig. 2.20: Side brackets are optional.) 10 460 10 40 4-R3 ① ① 11 40 150 Adaptive screw diameter 5mm Fig. 2.20 Dimensions of controller rack mounting holes 2.3.3 Precautions for Rack Mounting Pay attention to the following when rack mounting the SR-7000 robot controller. (1) When mounting the controller in a rack, use the screw holes provided at both ends of the front panel, and fix the controller. (Optional side brackets are required.) Caution ・ If the rack is completely sealed, provide holes to allow the air to be let out, forcibly ventilate the rack with a fan or cool it indirectly so that the heat will not be trapped in the rack. If the heat is trapped in the rack or controller, faults could occur. (2) The cable connectors are connected to the rear side of the controller, so provide a space of 110mm at the rear side. -2-18- STE 58764 (3) The upper cover must be removed during maintenance. (See Fig. 2.21.) Keep this in mind when installing the controller. Specifically, the controller should be easily removable from the rack. Practically, be careful of the following points. (a) Arrange the cables around the rear panel of the controller (so that the controller can be removed). (b) Arrange the cables between the controller and the control panel when the control panel is separated (so that the controller can be removed). (c) Connect all the cables in a position where the robot can be operated even if the controller is removed from the rack. Upper cover SR70 00 Robo t Cont roll er Fig. 2.21 Upper cover (4) When the controller is mounted on the rack, the weight of the controller should be supported with the legs of the controller. Screw holes for rack mounting the controller are used for securing the controller panel, and the weight of the controller cannot be supported only with the screws. (5) On the front of the controller, a clearance of approx. 90 mm should be provided for connecting the connector of the teach pendant. Even if the teach pendant is not used, a clearance of approx. 50 mm is required for connecting a dummy plug. 35mm 90mm Fig. 2.22 Clearance of front panel of controller -2-19- 50mm STE 58764 2.3.4 Precautions for Direct Installation When two or more controllers are used, it is necessary to provide a clearance of 50 mm or more in the horizontal direction and a clearance of 100 mm or more in the vertical direction between the controllers. Caution ・ ・ Provide a ventilation space at the side of the controller so that the air vent holes are not blocked. The space equal to the length of the support should be kept below the lower surface. Failure to do so could cause the cooling performance to drop or to faults. Do not stack the controllers or place objects in front of it. SERVO POWER OFF EMERGENCY J1 ON POWER J2 50mm or more 50mm or more PC STOP START FAULT BATTERY ALARM POWER CC24V C.P. EXT INT MANU FDD CYCLE STOP TP 10AT 11mm Fig. 2.23 Controller ventilation space 2.4 PRECAUTIONS FOR HANDLING THE TEACH PENDANT Be careful of the following when handling the teach pendant. Caution ・ ・ ・ ・ ・ Do not drop the teach pendant or hit it against anything. Do not pull on the cable protruding from the teach pendant. Do not press the switches on the teach pendant with anything sharp (like the tip of a knife, pencil, ball-point pen, etc.). Do not place or use the teach pendant near open flames. Do not leave the teach pendant in direct sunlight for a long period of time. -2-20- STE 58764 2.5 SAFETY MEASURES (1) When installing the robot, provide sufficient space to carry out the work safely. (2) Clarify the hazard zone, and provide a safety fence so that other persons cannot enter the zone easily. The hazard zone is the zone near the robot's working space where a hazardous state could occur if a person enters. (3) Provide a limit switch, photo switch or foot switch, etc., at the entrance of the safety fence to provide an emergency stop function that will stop the robot if a person enters the hazard zone. The emergency stop function should be an electrically independent b contact (closed in normal operation) with compulsive opening function and must not be automatically recovered. Limit switch Door Warning light Robot unit Safety fence Controller Photo switches Foot switch Robot working space Line Foot switch Line Photo switches Safety fence Warning light Limit switch Door (4) The controller must be installed at a place outside the hazard zone where the operator can view the robot movement. -2-21-