Download Mitsubishi PU-5TJSA Service manual

Transcript

SPLIT-TYPE, COOLING AIR CONDITIONERS

No. OC134

REVISED EDITION-A

TECHNICAL & SERVICE MANUAL

Series PC Ceiling Suspended

Indoor unit

[Model names]

PC-2GJA

PC-2.5GJA

PC-3GJA

PC-4GJSA

PC-5GJSA

PC-6GJSA

[Service Ref.]

PC-2GJA1

PC-2.5GJA1

PC-3GJA1

PC-4GJSA1

1998 PC-5GJSA1

PC-6GJSA1

1997

This manual does not cover the

following outdoor units.

When

serving them, please refer to the

service

manual

No.OC127(REVISED EDITION-A) .

[Service Ref.]

PU-2VJA2

PU-2NJA1

PU-2.5VJA2

PU-2.5NJA1

PU-3NJA1

PU-3YJA3

PU-3VJA2

PU-4TJSA2

PU-4VLJSA2

PU-4YJSA3

PU-5YJSA

PU-5TJSA

PU-6YJSA

PU-6TJSA

CONTENTS

INDOOR UNIT

Revision:

●PC-5GJSA1,PC-6GJSA1

are added.

●The first edition has been partially modified.

●Please destroy OC134.

TIMER

TEMP

12

29

11

28

COOL

10

27

DRY

9

26

FAN

8

25

7

24

6

23

5

22

4

21

3

20

2

19

1

18

TIMER/TEMP.

UP

POWER

HIGH

ON/OFF

MODE

SELECT

LOW

FAN

SPEED

ON

LOUVER

1. FEATURES ···········································2

2. PART NAMES AND FUNCTIONS ········4

3. SPECIFICATIONS·································6

4. DATA ·····················································9

5. OUTLINES AND DIMENSIONS··········12

6. WIRING DIAGRAM·····························17

7. REFRIGERANT SYSTEM DIAGRAM ······18

8. OPERATION FLOW-CHART ··············20

9. MICROPROCESSOR CONTROL·······23

10. TROUBLE SHOOTING ·······················29

11. DISASSEMBLY PROCEDURE ···········30

12. PARTS LIST········································35

13. OPTIONAL PARTS ·····························46

DOWN

AUTO

STOP

START

TIMER

MODE

MITSUBISHI ELECTRIC

REMOTE CONTROLLER

The Slim Line.

From Mitsubishi Electric.

1

FEATURES

Series PC Ceiling Suspended

TIMER

TEMP

12

29

11

28

10

27

9

26

8

25

7

24

6

23

5

22

4

21

3

20

2

19

1

18

TIMER/TEMP.

POWER

COOL

DRY

FAN

UP

HIGH

ON/OFF

MODE

SELECT

LOW

FAN

SPEED

ON

LOUVER

DOWN

AUTO

STOP

START

TIMER

MODE

MITSUBISHI ELECTRIC

Indoor unit

Service Ref.

PC-2GJA1

PC-2.5GJA1

PC-3GJA1

PC-4GJSA1

PC-5GJSA1

PC-6GJSA1

Remote controller

Cooling Capacity (50 / 60Hz)

W

Btu/h

5,600/5,400

19,100/18,400

6,500/7,000

22,200/23,900

7,200/7,800

24,600/26,600

9,800/10,800

33,400/36,800

12,400/13,500

42,300/46,100

14,600/15,200

49,800/51,900

Note: Rating condition

Indoor : 27°C D.B., 19°C W.B.

Outdoor : 35°C D.B., 24°C W.B.

1. ADVANCED REMOTE CONTROLLER

(1) Ultra-thin 12mm (1/2”) remote controller

The streamelined, square controller is designed to blend with any interior. Also, the sophisticated microprocessor allows you to easily carry

TIMER/TEMP.

out a wide range of operations.

POWER

ON/OFF

12

29

(2) Attractive LED display

COOL

11

28

Every operation condition is indicated on the LED display.

MODE

DRY

10

27

SELECT

(3) Simultaneous display of set temperature and room temperature

FAN

9

26

8

25

The set temperature is indicated by continuous light and the room temUP

HIGH

FAN

7

24

SPEED

perature is indicated by a flashing light. In this way, accurate temperaLOW

6

23

DOWN

ture conditions are always available at a glance and fine temperature

5

22

ON

LOUVER

4

21

regulation is possible.

AUTO

3

20

STOP

(4) Convenient 12-hour ON-OFF timer

TIMER

2

19

MODE

START

1

18

The timer switches on and off automatically at the times you set. Once

the timer is set, the remaining time is shown on the LED display.

MITSUBISHI ELECTRIC

(5) Self-diagnostic feature indicates faults instantly

If a problem occurs, the unit will stop operating and the temperature

display will change to a self-diagnosis indicator, which shows the location of the trouble.

(6) Useful memory feature for storing instructions

The previous set value is memorized so that constant temperature control can be achived. For example, if a power failure occurs, the temperature will not have to be readjusted afterwards.

(7) Cables between remote controller and indoor unit

The polar, 12-core type remote controller cables makes installation simple and troublefree. Also, the cables can be

extended up to 50m. (optional)

TIMER

2

TEMP

1. AIR OUTLET

New PC series models have 1 air outlet (auto vane switching of horizontal air flow / down flow by switched by auto vane)

instead of 2 (horizontal, and down flows).

2. EASY TO CLEAN ; FLOCKLESS VANE

Protruding portion A

Unifies the air speed

with the vane.

B

+

With our original air current control mechanism, a flockless vane is

Flockless vane

newly adapted.

The flockless vane prevents the condensation on the vane.

A

By changing the vane to the flockless type, the unit can be cleaned

Air outlet

much easier with mild household detergent.

=

Protruding portion B

Sending the air to the upper

area of the vane

Prevents the air comes from

outside the unit

3. NEW MATERIALS FOR BETTER OIL RESISTANCE

We have changed the materials of grill, filer, fan and fan casing from ABS to P.P. (polypropylene) for better oil resistance. As

a result, oil crazing is cut in half.

4. SIMPLIFIED INSTALLATION WORK (DIRECT SUSPENDING METHOD)

Simplified the installation work by changing the suspending method to the direct suspending method (suspending the unit

directly from the suspension fixture).

In this way, the unit can be attached to the suspension fixture without removing the installation parts off (Only the side cover

is removed). This method is much simpler than the ¨One-time installation method¨.

5. IMPROVING EFFICIENCY OF PIPING WORK

New PC series models have 1 air outlet (auto vane switching of horizontal air flow / down flow by switched by auto vane)

instead of 2 (horizontal, and down flows).

1 Removed the knockout work by separating the piping space 2 Improved the flexibility by making it possible for drainage

from the air outlet for efficiency of the piping work.

pipe to exit not only from the right side back but also from

the left side back.

Side panel

Back panel

G

Open

L

U-cut

Drain pan

L

G

D

Open

D

L : Liquid pipe

G: Gas pipe

D: Drain pipe

w Knockout work is needed for the top part. When optional

drain-up machine is installed, the refrigerant pipe exits out

from the top.

Joint coupliy

(attached)

Insulation

cover

Band

(attached)

Rubber plug

Insulation cover

(attached)

Drain pipe

(purchased locally)

w Please move the rubber plug for the unit to the right joint

when drainage pipe exits from the left side.

3

6. QUITENESS ; 43dB : PC-3GJA1(HIGH NOTCH)

Quiteness of the New PC series product is significant. It is because we have adapted the new shape air outlet and changed

the air coures.

Auto vane

Swing

7. EASY MAINTENANCE ; NO MAINTENANCE NECESSARY FOR 2500 HOURS

The new long-life air filter can be used continuously 2500 hours without maintenance (at general office situation).

8. CHOICE OF FILTER

High performance filter can be purchased optionally for the special needs.

Locations

Busy

shops etc···

Regular

office, shops

2

Appropriate filter

High performance

filter

Standard longlife

filter

Capability

Weighing

method 70%

Weighing

method 30%

Filter

2500 hours

2500 hours

Maintenance

The filter can be used

again after cleaning.

The filter can be used

again after cleaning.

How to attach to the unit

Remove the standard long life filter

before attach this optional parts.

It is already attached to

the unit

PART NAMES AND FUNCTION

● Indoor (Main) Unit

Left/right guide vanes

Change the direction of airflow

from the horizontal blower.

Air outlet

Long-life filter

Removes dust and foreigh matter from air coming in

through the grille (Recommended cleaning interval :

Approx, every 2,500 operating hours)

Up/down guide vanes

Change the direction of airflow from the

vartical blower.

4

Air intake

Intake grille

● Remote controller

Settings remain in effect until changed. Air

conditioner can be operated by simply pushing

ON/OFF button once settings have been

made.

Display Panel

Operating panel

ON / OFF button

Pushing button starts

operation. Pushing again

stops operation. Green

lamp remains lit during

operation.

TIMER / TEMP.

This button is used to change

between display of room temperatue and display of remaining timer time durining “AUTO

STOP” operation. Green lamps

light in selected display mode.

Lamps display remaining

timer time or room temperature.

Remaining timer time display

Lamps indicate time remaining

until timer stops timed operation.

Green lamps corresponding to

remaining number of hours light.

MODE SELECT button

TIMER

TEMP

12

29

11

28

COOL

10

27

DRY

9

26

FAN

8

25

7

24

6

23

5

22

4

21

3

20

2

19

1

18

TIMER/TEMP.

UP

POWER

HIGH

ON/OFF

MODE

SELECT

LOW

FAN

SPEED

ON

LOUVER

DOWN

AUTO

STOP

START

TIMER

MODE

Room Temperature display

Lamps display temperatue setings and actual room temperatues.

Temperatue settings.

Green lamps light.

Temperatue in room.

Green lamps flash.

MITSUBISHI ELECTRIC

UP and DOWN buttons

(Example display readings are

for explanations only; actual display readings will differ.)

Temperature control (While ”TEMP” green lamp is

lit.)

Use UP and DOWN buttons to set desired temperature between 18 and 29oC.

Timed operation (While green “TIMER” lamp is lit.)

Use UP and DOWN buttons to set timed operation

between one and twelve hours.

This button is used to

change between cooling.

ventilation and DRY(or heating)operation modes.One of

three green lamps light to

indicate mode in effect.

FAN SPEED button

This button is used to

change between low and

high fan speeds. One of

two green lamps lights to

indicade fan speed in

effect.

Swing Louver Button

Used to automatically

disperse airflow vertically.

Air is blown in one

direction when louver is

not turning. Lamp lights

effect.

TIMER MODE button

Used for selecting timed

starting or stopping.Green

lamp light to indicate

timer mode selected.

Attention:

Pushing UP and DOWN buttons together for more than two seconds will initate “trial run” or “inspection” mode. Avoid

pushing these buttons simultaneously during normal operation. Push ON / OFF button to cancel trial run or inspection

mode if initiated by accident.

All green lamps turn off when air conditioner is stopped.

Avoid operation of buttons with fingernails or other sharp object. Sharp object may scratch operating panel.

*Heating operation mode is only available for models with built-in electric heater.

5

3

SPECIFICATIONS

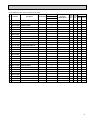

1. STANDARD SPECIFICATIONS

Service Ref.

Item

W

Btu/h

W

Btu/h

W

Btu/h

50Hz

Cooling capacity w1

60Hz

Cooling capacity w4

60Hz

Total input (50/60Hz) w2

Service Ref.

External finish

Fan motor output

50Hz

Outdoor unit

Indoor unit

Airflow Lo-Hi

60Hz

External static pressure

Operation control & Thermostat

50Hz

Noise level Low-High

60Hz

O.D.

Cond. drain connector

W

D

Dimensions

H

Weight

Service Ref.

External finish

Refrigerant (R-22) control

50/60Hz

Crankcase Heater w3

50/60Hz

Compressor output

Protection devices

Fan motor output

50Hz

Airflow

60Hz

50/60Hz

Noise level

W

D

Dimensions

H

Weight

m/min

CFM

m/min

CFM

Pa(mmAq)

dB(A)

dB(A)

mm(in.)

mm(in.)

mm(in.)

mm(in.)

kg(lbs.)

W

kW

kW

K/min(CFM)

K/min(CFM)

dB(A)

mm(in.)

mm(in.)

mm(in.)

kg(lbs.)

PC-2GJA1

Models

50Hz

60Hz

O

O

O

O

O

O

O

PC-2,2.5,3

1ph220V / 1ph220V

1ph220V / 1ph220V

6,500

7,200

9,800

22,200

24,600

33,400

7,000

7,800

10,800

23,900

26,600

36,800

6,200

6,500

9,300

21,200

22,200

31,700

2.58/3.07

3.30/3.60

3.49/4.47

PC-2.5GJA1

PC-3GJA1

PC-4GJSA1

Munsell 0.70Y 8.59/0.97

0.054

0.07

0.07

0.09

10-13

14-18

14-18

20-25

353-459

494-635

494-635

706-883

10-13

14-18

14-18

20-25

353-459

494-635

494-635

706-883

0 (Direct blow)

Remote control & Built-in

37-42

37-43

37-43

40-45

37-42

37-43

37-43

40-45

26 (1)

26 (1)

26 (1)

26 (1)

1000 (39-3/8)

1310 (51-9/16)

1310 (51-9/16)

1310 (51-9/16)

680 (26-3/4)

680 (26-3/4)

680 (26-3/4)

680 (26-3/4)

210 (8-1/4)

210 (8-1/4)

210 (8-1/4)

270 (10-5/8)

27 (60)

34 (75)

34 (75)

37 (82)

PU-2VJA2,PU-2NJA1 PU-2.5VJA2,PU-2.5NJA1 w9 PU-3JA-type w10 PU-4JSA-type

Munsell 5Y 7/1

Capillary tube

32/32/32/38

32/38

2.0/1.5

2.0/1.7

2.7/2.7

2.2/2.2

w5

w5

w7(V)/w6(Y,T)

w5

0.065

0.085

0.065+0.065

0.085

45 (1588)

50 (1765)

95 (3352)

50 (1765)

45 (1588)

50 (1765)

95 (3352)

50 (1765)

49/50

52/53

54/55

52/53

870 (34-1/4)

870 (34-1/4)

870 (34-1/4)

870 (34-1/4)

295+24 (11-5/8 add 1)

650 (25-5/8)

850 (33-7/16)

1258 (49-1/2)

850 (33-7/16)

60 (132)

71 (157)

94 (207)

73 (161)

PC-4,5,6

1ph220V / 3ph380V

1ph220V / 3ph220V

Rating conditions (JISB8616)

w3. The capacity of crankcase heater (W)

6

PC-4GJSA1

PC-3GJA1

5,600

19,100

5,400

18,400

4,300

14,700

2.54/2.60

PC-2GJA1

Notes : w1. Rating condition (JISB8616)

Indoor : 27 C (80 F) D.B., 19 C (66 F) W.B.

Outdoor : 35 C (95 F) D.B., 24 C (75 F) W.B.

Refrigerant piping length (one way) : 5m (16ft)

w2. Total input based indicated voltage (In/Out)

O

PC-2.5GJA1

w4. Rating condition (SSA385, 386)

Indoor : 29 C (84 F) D.B., 19 C (66 F) W.B.

Outdoor : 46 C (115 F) D.B., 24 C (75 F) W.B.

Refrigerant piping lenght (one way ) : 5m (16ft)

O

O

O

O

O

O

O

O

w5. Inner thermostart, HP switch, LP switch

w6. Thermal switch, Reversed-phase protector, HP switch, LP

switch

Thermal relay

w7. Thermal switch, HP switch, LP switch,

Inner thermostat

w8. Thermal switch, HP switch,Inner thermostat

w9. PU-3JA-type···PU-3VJA2, PU-3YJA3, PU-3NJA1,

w10. PU-4JSA-type···PU-4VLJSA2, PU-4YJSA3, PU-4TJSA2

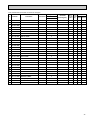

Service Ref.

Item

50Hz

Cooling capacity w1

60Hz

Cooling capacity w4

60Hz

W

Btu/h

W

Btu/h

W

Btu/h

Total input (50/60Hz) w2

Service Ref.

External finish

Fan motor output

Airflow Lo-Hi

Indoor unit

PC-6GJSA1

12,400

42,300

13,500

46,100

11,600

39,600

4.76/5.89

PC-5GJSA1

14,600

49,800

15,200

51,900

13,400

45,700

5.31/6.41

PC-6GJSA1

Munsell 0.70Y 8.59/0.97

50Hz

Outdoor unit

PC-5GJSA1

60Hz

External static pressure

Operation control & Thermostat

50Hz

Noise level Low-High

60Hz

O.D.

Cond. drain connector

W

D

Dimensions

H

Weight

Service Ref.

External finish

Refrigerant (R-22) control

50/60Hz

Crankcase Heater w3

50/60Hz

Compressor output

Protection devices

Fan motor output

50Hz

Airflow

60Hz

50/60Hz

Noise level

W

D

Dimensions

H

Weight

0.15

27-34

953-1,200

27-34

953-1,200

K/min

CFM

K/min

CFM

Pa(mmAq)

dB(A)

dB(A)

mm(in.)

mm(in.)

mm(in.)

mm(in.)

kg(lbs.)

W

kW

kW

K/min(CFM)

K/min(CFM)

dB(A)

mm(in.)

mm(in.)

mm(in.)

kg(lbs.)

0.15

27-34

953-1,200

27-34

953-1,200

0 (Direct blow)

Remote control & Built-in

41-46

42-48

41-46

42-48

26(1)

26(1)

1,620(63-3/4)

1,620(63-3/4)

680(26-3/4)

680(26-3/4)

270(10-5/8)

270(10-5/8)

43(95)

45(99)

PU-5YJSA,PU-5TJSA

PU-6YJSA,PU-6TJSA

Munsell 5Y 7/1

Capillary tube

—

—

3.5

4.2/4.0

w8

w8

0.10+0.10

0.10+0.10

100(3530)

100(3530)

100(3530)

100(3530)

55

56

970(38-3/16)

970(38-3/16)

345+24(13-9/16+1)

345+24(13-9/16+1)

1,258(49-1/2)

1,258(49-1/2)

114

117

2. POWER SUPPLY & MODEL NAMES

Power supply

50Hz

60Hz

1ph.

Indoor unit Service Ref.

PC-2GJA1

PC-2.5GJA1

PC-3GJA1

PC-4GJSA1 PC-5GJSA1

PC-6GJSA1

Outdoor unit Service Ref.

220,230,240V

PU-2VJA2

PU-2.5VJA2

PU-3VJA2

PU-4VLJSA2

—

—

—

—

PU-3YJA3

PU-4YJSA3

PU-5YJSA

PU-6YJSA

3ph.

380/220, 400/230, 415/240V

1ph.

220V

PU-2NJA1

PU-2.5NJA1

PU-3NJA1

—

—

—

3ph.

220V

—

—

—

PU-4TJSA2

PU-5TJSA

PU-6TJSA

Notes : 1. Power supply key N

: 1ph, 220V/60Hz

T : 3ph, 220V/60Hz

V(L) : 1ph, 220, 230, 240V/50Hz Y : 3ph, 380/220, 400/230, 415/240V, 50Hz, 4wires

2. Primary power supplies for all indoor units are single-phase.

7

3. ELECTRICAL SPECIFICATIONS

Rating conditions — JIS B8616 Indoor : 27°C (80°F) D.B., 19°C (66°F) W.B.

Outdoor : 35°C (95°F) D.B., 24°C(75°F) W.B.

Serises PC Indoor unit (Single phase)

Power supply (1 Phase)

V : 220V , 50Hz

Service Ref.

Current

Input

Starting current

PC-2GJA1 PC-2.5GJA1 PC-3GJA1 PC-4GJSA1 PC-5GJSA1 PC-6GJSA1

A

0.38

0.51

0.51

0.68

0.96

0.96

kW

0.10

0.12

0.12

0.14

0.20

0.20

A

1.10

1.17

1.17

1.36

2.00

2.00

PU-2

PU-2.5

PU-3

PU-4

PU-5

PU-6

Outdoor unit to be connected

Power supply (1 Phase)

V : 230V , 50Hz

Service Ref.

Current

Input

Starting current

PC-2GJA1 PC-2.5GJA1 PC-3GJA1 PC-4GJSA1 PC-5GJSA1 PC-6GJSA1

A

0.41

0.53

0.53

0.69

1.01

1.01

kW

0.12

0.13

0.13

0.15

0.22

0.22

A

1.15

1.22

1.22

1.42

2.10

2.10

PU-2

PU-2.5

PU-3

PU-4

PU-5

PU-6

Outdoor unit to be connected

Power supply (1 Phase)

V : 240V , 50Hz

Service Ref.

Current

Input

Starting current

PC-2GJA1 PC-2.5GJA1 PC-3GJA1 PC-4GJSA1 PC-5GJSA1 PC-6GJSA1

A

0.43

0.55

0.55

0.70

1.06

1.06

kW

0.14

0.15

0.15

0.16

0.25

0.25

A

1.20

1.27

1.27

1.48

2.20

2.20

PU-2

PU-2.5

PU-3

PU-4

PU-5

PU-6

Outdoor unit to be connected

Power supply (1 Phase)

N : 220V , 60Hz

Service Ref.

Current

Input

Starting current

PC-2GJA1 PC-2.5GJA1 PC-3GJA1 PC-4GJSA1 PC-5GJSA1 PC-6GJSA1

A

0.61

0.70

0.70

0.95

1.20

1.20

kW

0.15

0.16

0.16

0.20

0.26

0.26

A

Outdoor unit to be connected

1.03

1.11

1.11

1.27

1.91

1.91

PU-2

PU-2.5

PU-3

PU-4

PU-5

PU-6

Rating conditions — SSA385, 386

Indoor : 29°C (84°F) D.B., 19°C (66°F) W.B.

Outdoor : 46°C (115°F) D.B., 24°C(75°F) W.B.

Power supply (1 Phase)

N : 220V , 60Hz

Service Ref.

Current

Input

Starting current

PC-2GJA1 PC-2.5GJA1 PC-3GJA1 PC-4GJSA1 PC-5GJSA1 PC-6GJSA1

A

0.61

0.70

0.70

0.95

1.20

1.20

kW

0.15

0.16

0.16

0.20

0.26

0.26

A

1.03

1.11

1.11

1.27

1.91

1.91

PU-2

PU-2.5

PU-3

PU-4

PU-5

PU-6

Outdoor unit to be connected

8

4

DATA

1. PERFORMANCE DATA

Cooling capacity 50Hz

Service Ref.

Temperature

Outdoor D.B.

Indoor W.B.

16°C (60.8°F)

18°C (64.4°F)

21°C

19°C (66.2°F)

(69.8°F)

19.4°C (67°F)

20°C (68°F)

22°C (71.6°F)

16°C (60.8°F)

18°C (64.4°F)

25°C

19°C (66.2°F)

(77°F)

19.4°C (67°F)

20°C (68°F)

22°C (71.6°F)

16°C (60.8°F)

18°C (64.4°F)

30°C

19°C (66.2°F)

(86°F)

19.4°C (67°F)

20°C (68°F)

22°C (71.6°F)

16°C (60.8°F)

18°C (64.4°F)

32.2°C

19°C (66.2°F)

(90°F)

19.4°C (67°F)

20°C (68°F)

22°C (71.6°F)

16°C (60.8°F)

18°C (64.4°F)

35°C

19°C (66.2°F)

(95°F)

19.4°C (67°F)

20°C (68°F)

22°C (71.6°F)

16°C (60.8°F)

18°C (64.4°F)

40°C

19°C (66.2°F)

(104°F)

19.4°C (67°F)

20°C (68°F)

22°C (71.6°F)

16°C (60.8°F)

18°C (64.4°F)

40.6°C

19°C (66.2°F)

(105°F)

19.4°C (67°F)

20°C (68°F)

22°C (71.6°F)

16°C (60.8°F)

18°C (64.4°F)

45°C

19°C (66.2°F)

(113°F)

19.4°C (67°F)

20°C (68°F)

22°C (71.6°F)

16°C (60.8°F)

18°C (64.4°F)

46°C

19°C (66.2°F)

(115°F)

19.4°C (67°F)

20°C (68°F)

22°C (71.6°F)

16°C (60.8°F)

18°C (64.4°F)

50°C

19°C (66.2°F)

(69.8°F)

19.4°C (67°F)

20°C (68°F)

22°C (71.6°F)

16°C (60.8°F)

18°C (64.4°F)

52°C

19°C (66.2°F)

(125.5°F)

19.4°C (67°F)

20°C (68°F)

22°C (71.6°F)

PC-2GJA1

C.F.

T.C.

(T.I.)

0.81

5.6

0.82

6.0

0.83

6.2

0.83

6.2

0.84

6.4

0.86

6.7

0.84

5.5

0.85

5.9

0.86

6.0

0.86

6.1

0.87

6.2

0.89

6.6

0.90

5.3

0.92

5.6

0.93

5.8

0.93

5.9

0.94

6.0

0.96

6.4

0.93

5.2

0.95

5.5

0.96

5.7

0.97

5.8

0.97

5.9

0.99

6.3

0.96

5.1

0.99

5.4

1.00

5.6

1.00

5.7

1.01

5.8

1.04

6.2

1.03

4.9

1.06

5.2

1.07

5.4

1.08

5.4

1.08

5.5

1.11

5.9

1.04

4.8

1.06

5.2

1.08

5.3

1.08

5.4

1.09

5.5

1.12

5.9

1.10

4.6

1.12

4.9

1.14

5.1

1.15

5.2

1.16

5.3

1.20

5.7

1.11

4.6

1.14

4.9

1.15

5.1

1.16

5.1

1.17

5.2

1.21

5.6

1.16

4.4

1.19

4.7

1.21

4.9

1.22

4.9

1.23

5.0

1.28

5.4

1.19

4.3

1.22

4.6

1.24

4.7

1.25

4.8

1.26

4.9

1.31

5.3

PC-2.5GJA1

T.C.

C.F.

(T.I.)

6.5

0.81

6.9

0.82

7.2

0.83

7.3

0.83

7.4

0.84

7.8

0.86

6.4

0.84

6.8

0.85

7.0

0.86

7.1

0.86

7.2

0.87

7.7

0.89

6.1

0.90

6.6

0.92

6.8

0.93

6.9

0.93

7.0

0.94

7.4

0.96

6.0

0.93

6.4

0.95

6.6

0.96

6.7

0.97

6.9

0.97

7.3

0.99

5.9

0.96

6.3

0.99

6.5

1.00

6.6

1.00

6.7

1.01

7.2

1.04

5.6

1.03

6.0

1.06

6.2

1.07

6.3

1.08

6.4

1.08

6.9

1.11

5.6

1.04

6.0

1.06

6.2

1.08

6.3

1.08

6.4

1.09

6.8

1.12

5.4

1.10

5.7

1.12

5.9

1.14

6.0

1.15

6.1

1.16

6.6

1.20

5.3

1.11

5.7

1.14

5.9

1.15

6.0

1.16

6.1

1.17

6.5

1.21

5.1

1.16

5.4

1.19

5.6

1.21

5.7

1.22

5.8

1.23

6.3

1.28

4.9

1.19

5.3

1.22

5.5

1.24

5.6

1.25

5.7

1.26

6.1

1.31

PC-3GJA1

C.F.

T.C.

(T.I.)

0.81

7.2

0.82

7.7

0.83

7.9

0.83

8.0

0.84

8.2

0.86

8.7

0.84

7.1

0.85

7.5

0.86

7.8

0.86

7.9

0.87

8.0

0.89

8.5

0.90

6.8

0.92

7.3

0.93

7.5

0.93

7.6

0.94

7.7

0.96

8.2

0.93

6.7

0.95

7.1

0.96

7.4

0.97

7.5

0.97

7.6

0.99

8.1

0.96

6.5

0.99

7.0

1.00

7.2

1.00

7.3

1.01

7.4

1.04

7.9

1.03

6.2

1.06

6.7

1.07

6.9

1.08

7.0

1.08

7.1

1.11

7.6

1.04

6.2

1.06

6.6

1.08

6.9

1.08

6.9

1.09

7.1

1.12

7.6

1.10

5.9

1.12

6.4

1.14

6.6

1.15

6.7

1.16

6.8

1.20

7.3

1.11

5.9

1.14

6.3

1.15

6.5

1.16

6.6

1.17

6.7

1.21

7.2

1.16

5.6

1.19

6.0

1.21

6.2

1.22

6.3

1.23

6.5

1.28

6.9

1.19

5.5

1.22

5.9

1.24

6.1

1.25

6.2

1.26

6.3

1.31

6.8

PC-4GJSA1

C.F.

T.C.

(T.I.)

0.81

9.8

0.82

10.5

0.83

10.8

0.83

10.9

0.84

11.1

0.86

11.8

0.84

9.6

0.85

10.2

0.86

10.6

0.86

10.7

0.87

10.9

0.89

11.6

0.90

9.3

0.92

9.9

0.93

10.2

0.93

10.3

0.94

10.5

0.96

11.2

0.93

9.1

0.95

9.7

0.96

10.0

0.97

10.2

0.97

10.3

0.99

11.0

0.96

8.9

0.99

9.5

1.00

9.8

1.00

9.9

1.01

10.1

1.04

10.8

1.03

8.5

1.06

9.1

1.07

9.4

1.08

9.5

1.08

9.7

1.11

10.3

1.04

8.4

1.06

9.0

1.08

9.3

1.08

9.5

1.09

9.6

1.12

10.3

1.10

8.1

1.12

8.6

1.14

8.9

1.15

9.1

1.16

9.3

1.20

9.9

1.11

8.0

1.14

8.6

1.15

8.9

1.16

9.0

1.17

9.2

1.21

9.8

1.16

7.6

1.19

8.2

1.21

8.5

1.22

8.6

1.23

8.8

1.28

9.4

1.19

7.4

1.22

8.0

1.24

8.3

1.25

8.4

1.26

8.6

1.31

9.2

PC-5GJSA1

T.C.

C.F.

(T.I.)

12.4

0.81

13.3

0.82

13.7

0.83

13.8

0.83

14.1

0.84

14.9

0.86

12.2

0.84

13.0

0.85

13.4

0.86

13.6

0.86

13.8

0.87

14.7

0.89

11.7

0.90

12.5

0.92

12.9

0.93

13.1

0.93

13.3

0.94

14.2

0.96

11.5

0.93

12.3

0.95

12.7

0.96

12.8

0.97

13.1

0.97

13.9

0.99

11.2

0.96

12.0

0.99

12.4

1.00

12.6

1.00

12.8

1.01

13.6

1.04

10.7

1.03

11.5

1.06

11.9

1.07

12.0

1.08

12.3

1.08

13.1

1.11

10.7

1.04

11.4

1.06

11.8

1.08

12.0

1.08

12.2

1.09

13.0

1.12

10.2

1.10

10.9

1.12

11.3

1.14

11.5

1.15

11.7

1.16

12.5

1.20

10.1

1.11

10.8

1.14

11.2

1.15

11.3

1.16

11.5

1.17

12.4

1.21

9.1

1.16

9.8

1.19

10.2

1.21

10.3

1.22

10.5

1.23

10.9

1.28

8.1

1.19

8.7

1.22

9.0

1.24

9.1

1.25

9.3

1.26

9.7

1.31

PC-6GJSA1

T.C.

C.F.

(T.I.)

14.7

0.81

15.6

0.82

16.1

0.83

16.3

0.83

16.6

0.84

17.6

0.86

14.3

0.84

15.3

0.85

15.8

0.86

16.0

0.86

16.3

0.87

17.3

0.89

13.8

0.90

14.7

0.92

15.2

0.93

15.4

0.93

15.7

0.94

16.7

0.96

13.6

0.93

14.5

0.95

14.9

0.96

15.1

0.97

15.4

0.97

16.4

0.99

13.2

0.96

14.1

0.99

14.6

1.00

14.8

1.00

15.1

1.01

16.1

1.04

12.6

1.03

13.5

1.06

14.0

1.07

14.2

1.08

14.4

1.08

15.4

1.11

12.6

1.04

13.4

1.06

13.9

1.08

14.1

1.08

14.4

1.09

15.3

1.12

12.0

1.10

12.9

1.12

13.3

1.14

13.5

1.15

13.8

1.16

14.7

1.20

11.9

1.11

12.7

1.14

13.1

1.15

13.3

1.16

13.5

1.17

14.6

1.21

10.7

1.16

11.5

1.19

12.0

1.21

12.1

1.22

12.4

1.23

12.8

1.28

9.5

1.19

10.2

1.22

10.6

1.24

10.7

1.25

11.0

1.26

11.4

1.31

Cooling Capacity Correction Factors 50Hz

Service Ref.

PC-2GJA1

PC-2.5GJA1

PC-3GJA1

PC-4GJSA1

PC-5GJSA1

PC-6GJSA1

5m(16ft)

1.0

1.0

1.0

1.0

1.0

1.0

Refrigerant piping length (one way)

10m(33ft) 15m(49ft) 20m(66ft) 25m(82ft) 30m(98ft) 35m(115ft) 40m(131ft) 45m(148ft) 50m(164ft)

—

—

—

—

0.985

0.975

0.964

0.954

0.944

—

—

—

—

0.983

0.972

0.961

0.951

0.940

—

—

—

—

0.978

0.962

0.948

0.934

0.921

—

0.935

0.926

—

0.984

0.974

0.964

0.954

0.944

0.962

0.908

0.896

0.884

0.875

0.948

0.934

0.921

0.978

0.880

0.864

0.850

0.840

0.950

0.931

0.912

0.896

0.970

9

Cooling capacity

60Hz

PC-3GJA1

PC-4GJSA1

PC-2GJA1

PC-2.5GJA1

PC-5GJSA1

Service Ref.

T.C.

C.F.

C.F.

C.F.

C.F.

T.C.

T.C.

T.C.

C.F.

T.C.

Temperature

(T.I.)

(T.I.)

(T.I.)

(T.I.)

(T.I.)

Outdoor D.B.

Indoor W.B.

13.6

0.81

0.81

0.81

0.81

7.0

7.8

10.8

0.81

5.4

16°C (60.8°F)

14.4

0.82

0.82

0.82

0.82

7.5

8.3

11.5

0.82

5.8

18°C (64.4°F)

21°C

14.9

0.83

0.83

0.83

0.83

7.7

8.6

11.9

0.83

6.0

19°C (66.2°F)

(69.8°F)

15.1

0.83

0.83

0.83

0.83

7.8

8.7

12.0

0.83

6.0

19.4°C (67°F)

(68°F)

15.3

0.84

0.84

0.84

0.84

7.9

8.9

12.3

0.84

6.1

20°C

(

)

16.2

0.86

0.86

0.86

0.86

8.4

9.4

13.0

0.86

6.5

22°C

71.6°F

16°C (60.8°F)

13.2

0.84

0.84

0.84

0.84

6.9

7.7

10.6

5.3

0.84

18°C (64.4°F)

14.1

0.85

0.85

0.85

0.85

7.3

8.2

11.3

5.6

0.85

25°C

19°C (66.2°F)

14.6

0.86

0.86

0.86

0.86

7.6

8.4

11.7

5.8

0.86

(77°F)

19.4°C (67°F)

14.8

0.86

0.86

0.86

0.86

7.7

8.5

11.8

5.9

0.86

(68°F)

20°C

15.0

0.87

0.87

0.87

0.87

7.8

8.7

12.0

6.0

0.87

22°C (71.6°F)

16.0

0.89

0.89

0.89

0.89

8.3

9.2

12.8

6.4

0.89

12.8

0.90

0.90

0.90

0.90

6.6

7.4

10.2

0.90

5.1

16°C (60.8°F)

13.6

0.92

0.92

0.92

0.92

7.1

7.9

10.9

0.92

5.4

18°C (64.4°F)

30°C

(

)

14.0

0.93

0.93

0.93

0.93

7.3

8.1

11.2

0.93

5.6

19°C

66.2°F

(86°F)

14.2

0.93

0.93

0.93

0.93

7.4

8.2

11.4

0.93

5.7

19.4°C (67°F)

(68°F)

14.5

0.94

0.94

0.94

0.94

7.5

8.4

11.6

0.94

5.8

20°C

15.4

0.96

0.96

0.96

0.96

8.0

8.9

12.3

0.96

6.2

22°C (71.6°F)

16°C (60.8°F)

12.5

0.93

0.93

0.93

0.93

6.5

7.2

10.0

0.93

5.0

18°C (64.4°F)

13.4

0.95

0.95

0.95

0.95

6.9

7.7

10.7

0.95

5.3

32.2°C

19°C (66.2°F)

13.8

0.96

0.96

0.96

0.96

7.2

8.0

11.0

0.96

5.5

(90°F)

19.4°C (67°F)

14.0

0.97

0.97

0.97

0.97

7.3

8.1

11.2

0.97

5.6

(68°F)

20°C

14.3

0.97

0.97

0.97

0.97

7.4

8.2

11.4

0.97

5.7

22°C (71.6°F)

15.2

0.99

0.99

0.99

0.99

7.9

8.8

12.1

0.99

6.1

16°C (60.8°F)

12.2

0.96

0.96

0.96

0.96

6.3

7.1

9.8

4.9

0.96

18°C (64.4°F)

13.1

0.99

0.99

0.99

0.99

6.8

7.5

10.5

5.2

0.99

35°C

19°C (66.2°F)

13.5

1.00

1.00

1.00

1.00

7.0

7.8

10.8

5.4

1.00

(95°F)

(

)

19.4°C

67°F

13.7

1.00

1.00

1.00

1.00

7.1

7.9

10.9

5.5

1.00

(68°F)

20°C

13.9

1.01

1.01

1.01

1.01

7.2

8.1

11.1

5.6

1.01

22°C (71.6°F)

14.9

1.04

1.04

1.04

1.04

7.7

8.6

11.9

5.9

1.04

11.7

1.03

1.03

1.03

1.03

6.1

6.8

9.4

1.03

4.7

16°C (60.8°F)

12.5

1.06

1.06

1.06

1.06

6.5

7.2

10.0

1.06

5.0

18°C (64.4°F)

40°C

12.9

1.07

1.07

1.07

1.07

6.7

7.5

10.3

1.07

5.2

19°C (66.2°F)

(104°F)

13.1

1.08

1.08

1.08

1.08

6.8

7.6

10.5

1.08

5.2

19.4°C (67°F)

(68°F)

13.4

1.08

1.08

1.08

1.08

6.9

7.7

10.7

1.08

5.3

20°C

14.3

1.11

1.11

1.11

1.11

7.4

8.2

11.4

1.11

5.7

22°C (71.6°F)

(

)

16°C

60.8°F

11.6

1.04

1.04

1.04

1.04

6.0

6.7

9.3

1.04

4.7

18°C (64.4°F)

12.4

1.06

1.06

1.06

1.06

6.4

7.2

9.9

1.06

5.0

40.6°C

19°C (66.2°F)

12.9

1.08

1.08

1.08

1.08

6.7

7.4

10.3

1.08

5.1

(105°F)

19.4°C (67°F)

13.0

1.08

1.08

1.08

1.08

6.8

7.5

10.4

1.08

5.2

(

)

20°C

68°F

13.3

1.09

1.09

1.09

1.09

6.9

7.7

10.6

1.09

5.3

22°C (71.6°F)

14.2

1.12

1.12

1.12

1.12

7.4

8.2

11.3

1.12

5.7

16°C (60.8°F)

11.1

1.10

1.10

1.10

1.10

5.8

6.4

8.9

1.10

4.4

18°C (64.4°F)

11.9

1.12

1.12

1.12

1.12

6.2

6.9

9.5

1.12

4.8

45°C

19°C (66.2°F)

12.3

1.14

1.14

1.14

1.14

6.4

7.1

9.9

1.14

4.9

(113°F)

19.4°C (67°F)

12.5

1.15

1.15

1.15

1.15

6.5

7.2

10.0

1.15

5.0

(68°F)

20°C

12.7

1.16

1.16

1.16

1.16

6.6

7.4

10.2

1.16

5.1

22°C (71.6°F)

13.6

1.20

1.20

1.20

1.20

7.1

7.9

10.9

1.20

5.5

11.0

1.11

1.11

1.11

1.11

5.7

6.4

8.8

1.11

4.4

16°C (60.8°F)

(

)

11.8

1.14

1.14

1.14

1.14

6.1

6.8

9.4

1.14

4.7

18°C

64.4°F

46°C

12.1

1.15

1.15

1.15

1.15

6.3

7.1

9.8

1.15

4.9

19°C (66.2°F)

(115°F)

12.3

1.16

1.16

1.16

1.16

6.4

7.1

9.9

1.16

4.9

19.4°C (67°F)

(68°F)

12.5

1.17

1.17

1.17

1.17

6.5

7.3

10.1

1.17

5.0

20°C

(

)

13.5

1.21

1.21

1.21

1.21

7.0

7.8

10.8

1.21

5.4

22°C

71.6°F

16°C (60.8°F)

9.9

1.16

1.16

1.16

1.16

5.5

6.1

8.4

1.16

4.2

18°C (64.4°F)

10.7

1.19

1.19

1.19

1.19

5.9

6.5

9.0

1.19

4.5

50°C

19°C (66.2°F)

11.1

1.21

1.21

1.21

1.21

6.1

6.8

9.4

1.21

4.7

(69.8°F)

19.4°C (67°F)

11.2

1.22

1.22

1.22

1.22

6.2

6.9

9.5

1.22

4.7

(68°F)

20°C

11.4

1.23

1.23

1.23

1.23

6.3

7.0

9.7

1.23

4.8

22°C (71.6°F)

11.8

1.28

1.28

1.28

1.28

6.7

7.5

10.4

1.28

5.2

16°C (60.8°F)

8.8

1.19

1.19

1.19

1.19

5.3

5.9

8.2

1.19

4.1

18°C (64.4°F)

9.4

1.22

1.22

1.22

1.22

5.7

6.4

8.8

1.22

4.4

52°C

(

)

19°C

66.2°F

9.8

1.24

1.24

1.24

1.24

5.9

6.6

9.2

1.24

4.6

(125.5°F)

19.4°C (67°F)

9.9

1.25

1.25

1.25

1.25

6.0

6.7

9.3

1.25

4.6

(68°F)

20°C

10.1

1.26

1.26

1.26

1.26

6.1

6.9

9.5

1.26

4.7

22°C (71.6°F)

10.5

1.31

1.31

1.31

1.31

6.6

7.3

10.2

1.31

5.1

Notes:1.T.C. : Total capacity (x kW)...Btu/h=(W)x0.86

C.F. (T.I.) : Correction factors of Total input + Outdoor unit input)

2.(oF)=32+9/5(oC)

Lower limit...Indoor 21oC(70oF) D.B.,15.5oC(60oF) W.B., Outodoor 21oC(70oF) D.B.

3.Guaranteed operating range (cooling):

Upper limit...Indoor 35oC(95oF) D.B.,22.5oC(72.5oF) W.B.,Outodoor 52oC(125.5oF) D.B.

{

Cooling Capacity Correction Factors

Service Ref.

PC-2GJA1

PC-2.5GJA1

PC-3GJA1

PC-4GJSA1

PC-5GJSA1

PC-6GJSA1

10

5m(16ft)

1.0

1.0

1.0

1.0

1.0

1.0

PC-6GJSA1

T.C.

C.F.

(T.I.)

15.3

0.81

16.2

0.82

16.8

0.83

17.0

0.83

17.3

0.84

18.3

0.86

14.9

0.84

15.9

0.85

16.4

0.86

16.6

0.86

16.9

0.87

18.0

0.89

14.4

0.90

15.3

0.92

15.8

0.93

16.0

0.93

16.3

0.94

17.4

0.96

14.1

0.93

15.1

0.95

15.5

0.96

15.7

0.97

16.0

0.97

17.1

0.99

13.8

0.96

14.7

0.99

15.2

1.00

15.4

1.00

15.7

1.01

16.7

1.04

13.2

1.03

14.1

1.06

14.6

1.07

14.7

1.08

15.0

1.08

16.0

1.11

13.1

1.04

14.0

1.06

14.5

1.08

14.7

1.08

15.0

1.09

16.0

1.12

12.5

1.10

13.4

1.12

13.9

1.14

14.1

1.15

14.4

1.16

15.3

1.20

12.4

1.11

13.3

1.14

13.7

1.15

13.8

1.16

14.1

1.17

15.2

1.21

11.2

1.16

12.0

1.19

12.4

1.21

12.6

1.22

12.9

1.23

13.3

1.28

9.9

1.19

10.6

1.22

11.0

1.24

11.2

1.25

11.4

1.26

11.8

1.31

}

60Hz

Refrigerant piping length (one way)

10m(33ft) 15m(49ft) 20m(66ft) 25m(82ft) 30m(98ft) 35m(115ft) 40m(131ft) 45m(148ft) 50m(164ft)

0.985

0.975

0.964

0.954

0.944

—

—

—

—

0.978

0.963

0.948

0.934

0.921

—

—

—

—

0.971

0.950

0.931

0.913

0.896

—

—

—

—

0.980

0.966

0.952

0.939

0.826

0.914

0.902

—

—

0.971

0.950

0.931

0.913

0.896

0.880

0.864

0.850

0.840

0.960

0.933

0.908

0.885

0.864

0.845

0.828

0.812

0.800

2. STANDARD OPERATION DATA

Service Ref.

PC-2GJA1

Total

Electrical circuit

PC-6GJSA1

W

5,600 4,300 6,500 6,200 7,200 6,500 9,800 9,300 12,400 11,600 14,600 13,400

Input

kW

2.54

3.12

2.58

3.60

3.30

Indoor unit Service Ref.

PC-2GJA1

PC-2.5GJA1

phase, Hz

1,50

1,60

1,50

1,60

1,50

4.25

PC-3GJA1

3.43

5.17

4.76

6.94

5.31

7.54

PC-4GJSA1

PC-5GJSA1 PC-6GJSA1

1,60

1,50

1,60

1,50

1,60

1,50

1,60

Volts

V

220

220

220

220

220

220

220

220

220

220

220

220

Amperes

A

0.38

0.61

0.51

0.70

0.51

0.70

0.68

0.95

0.96

1.20

0.96

1.20

PUPU- PUPU- PUPU- PU- PU- PU- PU- PU- PU2VJA2 2NJA1 2.5VJA2 2.5NJA1 3VJA2 3NJA1 4YJSA3 4TJSA2 5YJSA 5TJSA 6YJSA 6TJSA

Outdoor unit Service Ref.

phase, Hz

Amperes

Refrigerant circuit

PC-4GJSA1 PC-5GJSA1

Capacity

Volts

Indoor side

PC-3GJA1

Cooling Cooling Cooling Cooling Cooling Cooling Cooling Cooling Cooling Cooling Cooling Cooling

MODE

Outdoor

side

PC-2.5GJA1

1,50

1,60

1,50

1,60

1,50

1,60

3,50

3,60

3,50

3,60

3,50

3,60

V

220

220

220

220

220

220

380

220

380

220

380

220

A

11.3

13.6

11.4

15.8

15.1

20.9

5.7

14.0

8.15 19.61 8.63 21.45

MPa.G

(kgf/F•G)

MPa.G

(kgf/F•G)

1.93

(19.7)

0.44

(4.5)

2.49

(25.4)

0.53

(5.4)

1.96

(20.0)

0.5

(5.1)

2.68

(27.3)

0.52

(5.3)

1.96

(20.0)

0.44

(4.5)

2.54

(25.9)

0.44

(4.5)

1.80

(18.3)

0.51

(5.2)

2.40

(24.4)

0.51

(5.2)

1.83

(18.7)

0.46

(4.7)

2.41

(24.6)

0.43

(4.4)

1.96

(20.0)

0.41

(4.2)

2.41

(24.6)

0.42

(4.3)

Discharge temperature

°C

68.6

77.7

72.3

94.3

63.9

82.0

67.5

88.4

72.9

94.8

75.4

94.8

Condensing temperature

°C

51.6

60.5

52.4

57.6

52.3

61.6

48.3

54.5

48.8

60.1

51.1

60.3

Suction temperature

°C

3.3

8.3

8.6

10.2

3.7

3.6

7.3

6.0

3.1

1.7

2.3

1.6

Ref. pipe length

m

5

5

5

5

5

5

5

5

5

5

5

5

D.B.°C

27

29

27

29

27

29

27

29

27

29

27

29

W.B.°C

19

19

19

19

19

19

19

19

19

19

19

19

D.B.°C

9.7

13.8

12.0

15.3

10.7

12.8

10.5

11.7

13.7

14.9

12.2

12.6

D.B.°C

35

46

35

46

35

46

35

46

35

46

35

46

W.B.°C

24

24

24

24

24

24

24

24

24

24

24

24

Discharge pressure

Suction pressure

Intake air temperature

Discharge air temperature

Intake air temperature

The unit of pressure has been changed to MPa based on SI(International System of unit) in accordance with I.S.O.(International

Organization for Standardization).

The conversion factor is : 1(MPa•G)=10.2(kgf / F•G)

60Hz

50Hz

Frequency

3. OUTLET AIR SPEED AND COVERAGE RANGE

Configuration

Ceiling suspended

Service Ref.

PC-2GJA1

PC-2.5GJA1

PC-3GJA1

PC-4GJSA1

3

PC-5GJSA1 PC-6GJSA1

Airflow

m /min

13

18

18

25

34

34

Air speed

m/sec.

3.7

3.8

3.8

4.1

4.38

4.38

Coverage

m

8.8

10.4

10.4

12.6

15.2

15.2

range

ft

29

34.5

34.5

41.6

50.0

50.0

Airflow

m /min

13

18

18

25

34

34

Air speed

m/sec.

3.7

3.8

3.8

4.1

4.38

4.38

Coverage

m

8.8

10.4

10.4

12.6

15.2

15.2

range

ft

29

34.5

34.5

41.6

50.0

50.0

3

The air coverage range is the value up to the position

where the air speed is 0.25 m/sec. when air is blown out

horizontally from the unit at Hi notch position.

The coverage range should be used as a general guideline since it varies according to the size of the room and

furniture inside the room.

11

When electrical

box is pulled

down

6-7

928

1

Electrical box 70

525

Celling

8

Electrical box [FRONT VIEW]

32

161

3

2

226

86

2

138

171

263

352

5

1 4

Gap to ceiling

Air intake

Air outlet

918

1000

904

983

933 (suspension bolt pitch)

140

6

70

15

85

(3/8F) liquid

(5/8F) gas

(Drainage)

182

201

241

NOTES:

1. Use M10 or W3/8 screws for anchor bolt.

2. Please be sure when installing the drain-up machine (option parts).

refrigerant pipe will be only upper drain pipe arrangement.

5 Refrigerant-pipe connection (liquid pipe side/flared connection)

6 Knock out hole for upper drain pipe arrangement

7 Knock out hole for left drain pipe arrangement

8 Knock out hole for wiring arrangement

131

17

150

Drainage pipe connection (26mm I.D.)

Drainage pipe connection (for the left arrangement)

Knock out hole for left drain-piping arrangement

Refrigerant-pipe connection (gas pipe side/flared connection)

179

42

3879

38

1

46 175

80

320

180

210

1

2

3

4

81 76

254

1. INDOOR UNIT

PC-2GJA1

680

12

157

5

OUTLINES AND DIMENSIONS

When electrical

box is pulled

down

2

1235

1

Electrical box

525

Celling

70

8

[ FRONT VIEW ]

226

2

86

138

171

263

416

5

1 4

Air outlet

Gap to ceiling

Air intake

131

Electrical box

32

161

3

179

42

3879

38

1

46 175

17

6~7

150

1228

1310

1214

1290

1240 (suspension bolt pitch)

140

70

6

210

80

15

85

(3/8F liquid)

(5/8F gas)

(Drainage)

182

201

241

NOTES:

1. Use M10 or W3/8 screws for anchor bolt.

2. Please be sure when installing the drain-up machine (option parts).

refrigerant pipe will be only upper drain pipe arrangement.

5 Refrigerant-pipe connection (liquid pipe side/flared connection)

6 Knock out hole for upper drain pipe arrangement

7 Knock out hole for left drain pipe arrangement

8 Knock out hole for wiring arrangement

81 76

254

320

180

680

Drainage pipe connection (26mm I.D.)

Drainage pipe connection (for the left arrangement)

Knock out hole for left drain-piping arrangement

Refrigerant-pipe connection (gas pipe side/flared connection)

157

1

2

3

4

PC-2.5GJA1

PC-3GJA1

13

3

239

2

When electrical

box is pulled

down

42

93

1

Electrical box

525

160

70

229

1235

Celling

8

[ FRONT VIEW ]

38 140

2

687

38

86

138

171

263

5

4

Gap to ceiling

192

Air intake

Air outlet

1

1

236

17

1228

1310

1214

1240 (suspension bolt pitch)

150

Electrical box

140

70

6

320

207

680

45

80

6~7

16

87

(3/8F liquid)

(5/8F gas)

(Drainage)

182

198

245

5 Refrigerant-pipe connection (liquid pipe side/flared connection)

6 Knock out hole for upper drain pipe arrangement

7 Knock out hole for left drain pipe arrangement

NOTES:

8 Knock out hole for wiring arrangement

1. Use M10 or W3/8 screws for anchor bolt.

2. Please be sure when installing the drain-up machine (option parts).

refrigerant pipe will be only upper drain pipe arrangement.

81 96

254

Drainage pipe connection (26mm I.D.)

Drainage pipe connection (for the left arrangement)

Knock out hole for left drain-piping arrangement

Refrigerant-pipe connection (gas pipe side/flared connection)

217

14

270

1

2

3

4

PC-4GJSA1

239

When electrical

box is pulled

down

42

Electrical box

93

6~7

1

Electrical box

525

160

3

2

229

1545

70

Celling

[ FRONT VIEW ]

2

8

38 140

38

86

138

171

263

687

5

1

4

1

236

Gap to ceiling

192

Air intake

Air outlet

45

1535

1620

1524

1547(suspension bolt pitch)

18

140

70

6

16

87

(3/8F liquid)

(3/4F gas)

(Drainage)

182

198

245

NOTES:

1. Use M10 or W3/8 screws for anchor bolt.

2. Please be sure when installing the drain-up machine (option parts).

refrigerant pipe will be only upper drain pipe arrangement.

80

320

207

680

150

5 Refrigerant-pipe connection (liquid pipe side/flared connection)

6 Knock out hole for upper drain pipe arrangement

7 Knock out hole for left drain pipe arrangement

8 Knock out hole for wiring arrangement

217

Drainage pipe connection (26mm I.D.)

Drainage pipe connection (for the left arrangement)

Knock out hole for left drain-piping arrangement

Refrigerant-pipe connection (gas pipe side/flared connection)

270

1

2

3

4

81 96

254

PC-5GJSA1

PC-6GJSA1

15

2.REMOTE CONTROLLER

12(15/32)

96.5

90.5

3

3.6

Upper side wiring

arrangement

opening

12(15/32)

8

Rear side wiring

arrangememt opening

6

COOL

10

27

DRY

9

26

FAN

8

25

7

24

6

23

5

22

4

21

3

20

2

19

1

18

TIMER/TEMP.

UP

POWER

HIGH

ON/OFF

46

28

MODE

SELECT

LOW

FAN

SPEED

ON

LOUVER

DOWN

AUTO

STOP

START

TIMER

MODE

4.6

29

11

83.5(3-9/32)

TEMP

12

108(4-1/4)

117(4-5/8)

69

TIMER

3

75

3

3

11.6

9.2

MITSUBISHI ELECTRIC

108(4-1/4)

117(4-5/8)

Fixing hole

Remote controller cable installation

●For exposed remote controller cable installation

●For recessed remote controller cable installation

Exposed remote controller

cable

Remote controller cable

Conduit tube

(local arrangement)

TIMER

TEMP

12

29

11

28

COOL

10

27

DRY

9

26

8

25

7

24

6

23

5

22

4

21

3

20

2

19

1

18

TIMER/TEMP.

POWER

FAN

UP

HIGH

ON/OFF

MODE

SELECT

LOW

FAN

SPEED

ON

LOUVER

DOWN

AUTO

STOP

START

TIMER

MODE

MITSUBISHI ELECTRIC

Switch box

(local arrangement)

Cable connection is only from the top.

(right, left and bottom not possible)

Set screw (match with switch box),

local arrangement.

Note:The cable for the remote controller is 5m (16ft)and 12-core with connection O.D. 5.8.

16

6

WIRING DIAGRAM

PC-2GJA1 / PC-2.5GJA1 / PC-3GJA1 / PC-4GJSA1 / PC-5GJSA1 / PC-6GJSA1

SYMBOL

NAME

C

SYMBOL

FAN MOTOR CAPACITOR

NAME

SYMBOL

NAME

SYMBOL

NAME

RUN INDICATOR LED

SWC<I.B>

OPTION SWITCH

CN120<I.B> REMOTE CONTROLLER TRANS- LD3<R.B>

COOLING INDICATOR LED

SW1<I.B>

FUNCTION SWITCH

MISSION WIRE CONNECTOR

LD4<R.B>

FAN MODE INDICATOR LED

SW2<I.B>

UNIT SWITCH

CN2<I.B>

TIMER ADAPTOR CONNECTOR

LD5<R.B>

FAN HIGH INDICATOR LED

SW3<I.B>

EMERGENCY OPERATION SWITCH

CN2A<I.B>

TRANSMISSION WIRE No.1

LD6<R.B>

LOUVER RUN INDICATOR LED

SW1<R.B>

ON / OFF SWITCH

CONNECTOR

LD7<R.B>

INDICATOR MODE TEMPERATURE LED

SW2<R.B>

OPERATION MODE SWITCH

TRANSMISSION WIRE No.2

LD8<R.B>

INDICATOR MODE TIMER LED

SW3<R.B>

FAN HIGH/LOW SWITCH

X1<I.B>

DRAIN-UP MACHINE RELAY

CN2B<I.B>

LD1<R.B>

TB4

INDOOR / OUTDOOR CONNECTING WIRE TERMINAL BLOCK

RT1

ROOM TEMPERATURE THERMISTOR

(0 /15k ,25 /5.4k

RT2

DETECT)

INDOOR COIL THERMISTOR

(0 /15k ,25 /5.4k

DETECT)

CONNECTOR

LD9<R.B>

DRY INDICATOR LED

SW4<R.B>

LOUVER ON / OFF SWITCH

X4<I.B>

FAN MOTOR RELAY

CNP<I.B>

DRAIN-UP MACHINE CONNECTOR

LD10<R.B>

FAN LOW INDICATOR LED

SW5<R.B>

INDICATOR SWITCH

ZNR

VARISTOR

CN28<I.B>

TIME SHORTENING CONNECTOR LD11<R.B>

OFF TIMER INDICATOR LED

SW6<R.B>

TEMPERATURE / TIMER

DP

OPTION DRAIN-UP MACHINE

CN50<I.B>

DRAIN SENSOR CONNECTOR

LD12<R.B>

SETTING UP SWITCH

DS

OPTION DRAIN SENSOR

CN51<I.B>

MULTIPLE CONNECTOR

LD13-24<R.B> TEMPERATURE / TIMER RE-

TEMPERATURE / TIMER

W/B

OPTION WIRELESS REMOTE

ON TIMER INDICATOR LED

CN120<R.B> REMOTE CONTROLLER TRANS-

SW7<R.B>

CONTROLLER BOARD

SETTING DOWN SWITCH

MAINING TIME INDICATOR LED

MISSION WIRE CONNECTOR

MF

FAN MOTOR

SW8<R.B>

TIMER CONTINUOUS ON / OFF SWITCH CNB(W.B)

F1,2<I.B>

FUSE (6.3A 250V)

MV

VANE MOTOR

R.B

REMOTE CONTROLLER BOARD

LED1(W.B)

RUN INDICATOR LED

CN70<I.B>

WIRELESS REMOTE CONT-

SWA<I.B>

HIGH CELING TYPE SWITCH

T

TRANSFOMER

SW2(W.B)

COOL OPERATION SWITCH

ROLLER CONNECTOR

JR<I.B>

FUNCTION SELECTOR

TB2

POWER SUPPLY TERMINAL BLOCK RU(W.B)

I.B

L

N

RED

ORN

YLW

1 3 5

CNP 1 3

D.U.M

CND 1 3

6

RED

RED

BRN

BRN

TRANS

ON

OFF

1 2 34 5 6 7 8

ON

OFF

1 2 34 5 6 7 8

1 2 34 5 6 7 8

LD8

LD7

SW5

SW1

CN120

LD1

SW2

SW3

SW4

SW8

LD3

LD9

LD4

LD5

LD6

LD10

LD11

RT1

SW6

SW7

RT2

LD12

STD

OP

BLK

BLK

2

1

R.B

LD13

LD14

LD15

LD16

LD17

LD18

LD19

LD20

LD21

LD22

LD23

LD24

12345

YLW

TO OUTDOOR UNIT

CONNECTING WIRES

DC12V

CN28

12345678

L.TEST

1 2 34 5 6

INTAKE

3

2

1

OUTDOOR UNIT

ORN TB4

2 1

SW2

CN2

TWIN-1

SW1

ON

OFF

TIMER

TWIN-2

JR

SWC

CN2A

CN20

SWA

CN2B

1 2 34 5 6 7 8

6GJSA1

Remote control transmissing wire 12VDC with 12 core connector

2 1

PIPE

WIRELESS

123

1 2 34 5 6 7 8

5GJSA1

REMOTE CONTROLLER

12

1 3 2 1

CN21

2 1

CN50

DRAIN

CN30

OUTDOOR

CN51

MULTIPLE

5 4 3 2 1

CN70

1 2 34 5 6 7 8

4GJSA1

INDOOR UNIT

12

TO.RC

1

CN6V

SW3

ON

OFF

TRANS

ZNR

ON

OFF

3GJA1

2.5GJA1

ON

OFF

ON

OFF

SW1

fig:*3

F1

VANE

X1

MV

4 3 2 1 CN4T

X1

X4

2GJA1

ON

OFF

SW1

Service Ref.

6

T

6

X4

Service Ref.

TB2

CN120

F2

GRN/YLW

1 3 CNT

POWER

POWER SUPPLY

(1 PHASE)

AC220-240V 50Hz

AC220V 60Hz

14.7VAC

WHT

YLW

RED

BLU

RED

WHT

BLK

C

11.8VAC

220V

230V

240V

MF

FAN1

BEAM RECIEVE UNIT

JUMPER RESISTORS

INDOOR CONTROLLER BOARD

I.B

INDOOR BOARD CONNECTOR

[Emergemcy operation procedure]

(2) Turn on outdoor unit side circuit breaker, then indoor unit side circuit breaker in this order.

(3) During emergency operation, indoor fan runs at high speed but automatic vane remains stop.

(4) If vane closed, open the vane by hand slowly.

(5) Thermostat will not function.

(6) Emergency cooling should be limited to 10 hours maximum (The Indoor unit heat exchanger may freeze).

(7) If the ,microcomputer doctor detects the abnomality of the drain-up machine during cool mode. do not execute emergency operation (It causes drain overflow).

NOTES :

1. Since the indoor fan motor (MF) is connected with 220V power, using 230, 240V power will require a setting change of the dip switch (SW1<I.B>) on the indoor controller board

as shown in fig : w1.

fig : w1

SW1

ON

ON

Indoor fan motor (MF) for 230, 240V.

OFF

1 2 3 4 5 6 7 8

OFF

1 2 3 4 5 6 7 8

2. Since the indoor transformer (T) is connected with 220V power, if 230, 240V power used. Change the wiring connection showing fig : W2.

fig : w2

When power supply is

240V

230V

240

YELLOW

230

ORANGE

220

RED

3. Since the outdoor side electric wiring may change be sure to check the outdoor unit electric wiring for servicing.

4. Symbols used in wiring diagram above are.

: Connector ,

: Terminal block

5. Emergency operation

If remote controller or microcomputer fails but there is no other trouble,. emergency operation is possible by setting dip switch (SW3<I.B>) on the indoor controller board.

[Check items]

(1)Compressor and fan.

(2)Check the abnomality using self diagnostic function. When the result of self diagnosis indicates protective device such as freeze protection, emergency operation is not possible

unless the cause is removed.

(3)Emergency operation will be continuous operation mode due to power ON/OFF (ON/OFF with remote controller is not possible).

[Emergency operation procedure]

(1)Set the dip switch(SW3<I.B>) on the indoor controller board to1 2 onand 3 off for cooling.

17

7

REFRIGERANT SYSTEM DIAGRAM

PC-2GJA1 / PU-2NJA1, PU-2VJA2

Refrigerant pipe 15.88 (5/8)

(With insulator) option

Flexible tube

Low pressure

switch

Ball

valve

Check

plug

High

pressure

switch

Charge

plug

Outdoor heat

exchanger

Indoor heat

exchanger

Flared

connection

Strainer

Flared

connection

Distributor

with strainer

Accumulator

Compressor

Capillary tube

for injection

O.D.4

Ball valve

(with service port)

I.D.2 –R430

flow of refrigerant

Refrigerant pipe 9.52 (3/8)

(With insulator) option

PC-2.5GJA1, PC-3GJA1, PC-4GJSA1 / PU-2.5NJA1, PU-2.5VJA2, PU-3NJA1,PU-3VJA2,

PU-3YJA3,PU-4TJSA2, PU-4VLJSA2, PU-4YJSA3

PC-2.5/3GJA

PC-4GJA

Refrigerant pipe 15.88 (5/8)

Refrigerant pipe 19.05 (3/4)

Flexible tube

Low pressure

switch

Ball

valve

Indoor heat

exchanger

Indoor coil

thermistor

RT2

Thermal switch

(Only PU-4VLJSA)

Charge

plug

High pressure

switch

Check

plug

Strainer

Flared

connection

Outdoor heat

exchanger

Flared

connection

Accumulator

Compressor

Capillary tube for

injection

Distributor

with strainer

w

Capillary

tube

Only PU-2.5

PU-3

PU-4YJSA,

4TJSA

Ball valve

(with service port)

Refrigerant pipe 9.52 (3/8)

(With insulator) option

18

flow of refrigerant

w

Capillary tube size

PU-2.5 (O.D.3.2 I.D.1.6 –R760) 2pcs

PU-3 (O.D.3.2 I.D.1.8 –R800) 2pcs

PU-4YJSA, 4VLJSA, 4TJSA (O.D.3.2 I.D.2.0 –R840)

2pcs

PC-5GJSA1, 6GJSA1 / PU-5YJSA, PU-5TJSA

PU-6YJSA, PU-6TJSA

INDOOR UNIT

Refrigerant pipe 19.05 (3/4F)

(With insulator) option

Flexible tube

Distributor

with strainer

Check plug

Charge

plug

Ball

valve

Indoor heat

exchanger

OUTDOOR UNIT

Thermal

switch

Outdoor heat

exchanger

High

pressure

switch

Flared

connection

Flared

connection

Accumulator

Compressor

Capillary tube

PU-5Y·TJSA

(O.D. 4.0 oI.D. 2.4 –R840)o2pcs

PU-6YJSA

(O.D. 4.0 oI.D. 2.4 –R1200)o2pcs

PU-6TJSA

(O.D. 4.0 oI.D. 2.4 –R740)o2pcs

Ball valve

(with service port)

Refrigerant pipe 9.52 (3/8F)

(With insulator) option

Strainer

DPR

Capillary tube

PU-5Y·TJSA (O.D. 4.0 oI.D. 2.4 –R400)

PU-6Y·TJSA (O.D. 4.0 oI.D. 2.4 –R200)

: flow of refrigerant

19

8

OPERATION FLOW-CHART

Models : PC-GJA

1. Main operation

Start

1

NO

POWER SUPPLY

Live

YES

<w1>

TIMER MODE

button ON

YES

NO

During

operation

<w2>

NO

Protection device

Self hold reset

ON/OFF

button ON

YES

YES

STOP

<w3>

YES

Protection device

Self hold

Abnormal

operation mode

NO

NO

AUTO STOP lamp ON

AUTO START lamp ON

Auto stop timer

1 12Hr up/ press

12 1Hr down/ press

Auto start timer

1 12Hr up/ press

12 1Hr down/ press

Set time Elapsed time=0

Set time Elapsed time=0

YES

POWER lamp ON

Self-diagnostic function

Indicate & Memory

EMERGENCY

ALL STOP

NO

STOP

<w4>

<w5>

MODE SELECT

button

DRY

COOL

COOL OPERATION

w1

w2

w3

w4

20

DRY OPERATION

Refer to page 26 for timer mode details.

The unit starts operation by pressing the ON / OFF switch when unit is OFF.

The factors which cause "abnormal operation mode" are as follows.

●Outdoor unit abnormal operation.

●Fault of room temperature thermistor (RT1).

●Fault of indoor coil thermistor (RT2).

●Indoor coil frost protection mode.

●Drain water overflow prevention mode.

Refer to page 28 for abnormal operation mode details.

The compressor will not start for 3 minutes after the stop.

YES

NO

COOLING OPERATION

COOL operation

NO

Initial

COOLING

w8

YES

Vane initial

setting

NO

Fan speed

LOW

YES

NO

Downward discharge

1 hour

YES

Vane horizontal

airflow

Vane setting notch

w9

NO

Compressor

thermostat

ON

NO

Allowance

cancel

NO

YES

YES

3-minute

time delay

YES

6-minute

time delay

NO

3-minute

compressor

operation

NO

NO

w10

YES

Allowance

period

NO

6 minute

time delay

Allowance set

YES

Coil frost protection

YES

Coil frost

prevention

NO

w11

NO

Cooling area

NO

YES

10-minute

compressor

operation

YES

NO

1 min continue

YES

Allowance cancel

FAN speed

LOW

Coil frost

protection

NO

YES

NO

16-minute

compressor

operation

Indoor coil NO

tempreature is

10°C or higher

YES

Indoor pipe

temperature is

1°C or lower

NO

Compressor ON

YES

YES

Coil frost

prevention

FAN speed

LOW 5 min

elapse

NO

YES

Outdoor unit

trouble

3-minute

time delay

Coil frost

prevention release

Compressor OFF

1

w8 When operation stops or changes to cooling or dry mode, the auto vane turns to a horizontal angle. If operation changes

during auto vane SWING, the auto vane will continue to swing.

w9 When operating TEST RUN, the thermostat will be continuously ON.

w10 After 3 minute compressor operation, if the indoor coil thermistor reads -15°C or below for 3 minutes, the compressor will

stop for 6 minutes.

w11 Cooling area : Indoor coil temperature is more than 5 degrees above the room temperature.

FAN area

: Indoor coil temperature is within 5 degrees either way of the room temperature.

21

DRY OPERATION

DRY

operation

NO

Initial dry

operation

w8

YES

Vane

setting notch

Vane initial setting

YES

Room tempereature is

18°C or lower

w12

NO

NO

During

compressor ON

YES

3-minute

compressor

operation

NO

NO

YES

NO

w9

Compressor &

thermostat ON

YES

Compressor &

thermostat

ON

NO

Compressor ON

time completes

10-minute

compressor

OFF

NO

YES

YES

w13

10-minute compressor

OFF timer start

Compressor ON

time set

Compressor OFF

Compressor ON

w14

w14

Fan speed LOW

1

w8—9 Refer to page 24~25.

w12

When room temperature is 18°C or below, the compressor cannot operate.

When room temperature rises over 18°C, the compressor starts after a 3-minute time delay.

w13

Compressor ON time is decided by room temperature. Refer to page 24~25.

w14

In dry operation, compressor ON makes the fan speed LOW and compressor OFF stops the fan.

It is not possible to set the fan speed with the remote controller

22

w9

NO

YES

Fan STOP

YES

3-minute

time delay

9

MICROPROCESSOR CONTROL

1.OUTLINE OF MICROPROCESSOR CONTROL

REMOTE CONTROLLER

INPUT to remote controller

OUTPUT to remote controller

● Transmits and receives orders.

● OFF-ON switching.

● COOL/DRY-FAN selector switching.

● Thermostat setting.

● HIGH-LOW fan speed switching.

● Swing louvers SWING-FIXED switching.

● TIMER mode selector switching.

● Timer setting.

● Self diagnostic troubleshooting.

● Test run switching.

● Indication LED lights.

TIMER

TEMP

12

29

11

28

COOL

10

27

DRY

9

26

FAN

8

25

7

24

6

23

5

22

4

21

3

20

2

19

1

18