Download Santerno SUNWAY M XS User manual

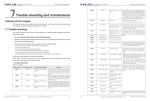

Transcript