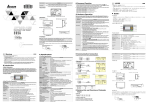

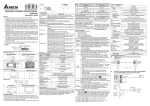

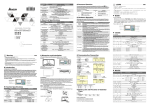

Download Delta Electronics TP08 User manual

Transcript