Download Mazda 2006 RX-8 Specifications

Transcript

2006

Mazda

RX-8

Service

Highlights

FOREWORD

This manual explains components, system

operations and functions for the Mazda RX-8.

For proper repair and maintenance, a thorough

familiarization with this manual is important,

and it should always be kept in a handy place

for quick and easy reference.

All the contents of this manual, including

drawings and specifications, are the latest

available at the time of printing.

As modifications affecting repair or

maintenance occur, relevant information

supplementary to this volume will be made

available at Mazda dealers.

This manual should be kept up-to-date.

Mazda Motor Corporation reserves the right to

alter the specifications and contents of this

manual without obligation or advance notice.

All rights reserved. No part of this book may be

reproduced or used in any form or by any

means, electronic or mechanical—including

photocopying and recording and the use of any

kind of information storage and retrieval

system—without permission in writing.

Mazda Motor Corporation

HIROSHIMA, JAPAN

APPLICATION:

This manual is applicable to vehicles

beginning with the Vehicle Identification

Numbers (VIN), and related materials shown

on the following page.

CONTENTS

Title

Section

GENERAL INFORMATION

00

ENGINE

01

SUSPENSION

02

DRIVELINE/AXLE

03

BRAKES

04

TRANSMISSION/TRANSAXLE

05

STEERING

06

HEATER, VENTILATION &

AIR CONDITIONING (HVAC)

07

RESTRAINTS

08

BODY & ACCESSORIES

09

© 2005 Mazda Motor Corporation

PRINTED IN U.S.A., OCTOBER 2005

Form No. 3409–1U–05J

Part No. 9999–95–102F–06

VEHICLE IDENTIFICATION NUMBERS (VIN)

JM1 FE173✻6#

JM1 FE17N✻6#

200001—

200001—

RELATED MATERIALS

Material Name

MNAO Part No.

Mazda Material No.

2004 Mazda RX-8 Service Highlights

9999–95–102F–04

3378–1U–03C

2005 Mazda3, Mazda MX-5 Miata/MX-5, MAZDASPEED MX-5,

Mazda MPV, Mazda RX-8 Service Highlights

9999–95–MODL–05

3400–1U–04H

1995, 1996, 1997, 1998, 1999, 2000 OBD-II Service Highlights

9999–95–OBD2–00

3344–1U–99K

2006 Mazda RX-8 Workshop Manual

9999–95–064B–06

1857–1U–05J

Engine Workshop Manual 13B-MSP

9999–95–E13B–MSP

1773–1U–03C

9999–95–T15M–D

1774–1U–03C

Automatic Transmission Workshop Manual RC4A-EL

9999–95–RC4A–EL

1775–1U–03C

2004 Mazda RX-8 Bodyshop Manual

9999–95–120F–04

3379–1U–03D

2006 Mazda RX-8 Wiring Diagram

9999–95–040G–06

5650–1U–05J

Manual Transmission Workshop Manual Y16M-D

00

GENERAL INFORMATION

SECTION

Toc

of SCT INFORMATION . . . . 00-00

GENERAL

Toc of SCT

00–00

GENERAL INFORMATION

Conversion to SI Units (Système

International d'Unités) . . . . . . . . . . . .

Rounding Off . . . . . . . . . . . . . . . . . . . .

Upper and Lower Limits . . . . . . . . . . . .

SAE STANDARD . . . . . . . . . . . . . . . . . . .

VEHICLE IDENTIFICATION NUMBER

(VIN) CODE . . . . . . . . . . . . . . . . . . . . . . 00–00–1

VEHICLE IDENTIFICATION NUMBER

(VIN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 00–00–1

UNITS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 00–00–2

00–00–2

00–00–2

00–00–2

00–00–3

End of Toc

VEHICLE IDENTIFICATION NUMBER (VIN) CODE

EHU000000000105

J M1 FE17N *6 # 1 2 3 4 5 6

Serial No.

Plant

0= Hiroshima

1= Hofu

Model year

4=2004, 5=2005...

Check Digit

*=0 to 9, X

Engine

Body style

Restraint system

Carline, series

World manufacturer identification

N= 13B-Standard power

3= 13B-High power

7= Coupe

1=Driver, Passenger Airbag,

Side Airbag, Curtain Airbag

FE= Mazda RX-8

JM1= Mazda/passenger car

EHU000ZW8008

End Of Sie

VEHICLE IDENTIFICATION NUMBER (VIN)

EHU000000000106

JM1 FE173*6# 200001—

JM1 FE17N*6# 200001—

End Of Sie

00–00–1

00–00

GENERAL INFORMATION

UNITS

Electrical current

Electric power

Electric resistance

Electric voltage

Length

Negative pressure

Positive pressure

Torque

Volume

Weight

EHU000000000103

A (ampere)

W (watt)

ohm

V (volt)

mm (millimeter)

in (inch)

kPa (kilo pascal)

mmHg (millimeters of mercury)

inHg (inches of mercury)

kPa (kilo pascal)

kgf/cm2 (kilogram force per square

centimeter)

psi (pounds per square inch)

N·m (Newton meter)

kgf·m (kilogram force meter)

kgf·cm (kilogram force centimeter)

ft·lbf (foot pound force)

in·lbf (inch pound force)

L (liter)

US qt (U.S. quart)

Imp qt (Imperial quart)

ml (milliliter)

cc (cubic centimeter)

cu in (cubic inch)

fl oz (fluid ounce)

g (gram)

oz (ounce)

Conversion to SI Units (Système International d'Unités)

• All numerical values in this manual are based on SI units. Numbers shown in conventional units are converted

from these values.

Rounding Off

• Converted values are rounded off to the same number of places as the SI unit value. For example, if the SI unit

value is 17.2 and the value after conversion is 37.84, the converted value will be rounded off to 37.8.

Upper and Lower Limits

• When the data indicates upper and lower limits, the converted values are rounded down if the SI unit value is

an upper limit and rounded up if the SI unit value is a lower limit. Therefore, converted values for the same SI

unit value may differ after conversion. For example, consider 2.7 kgf/cm2 in the following specifications:

210—260 kPa {2.1—2.7 kgf/cm2, 30—38 psi}

270—310 kPa {2.7—3.2 kgf/cm2, 39—45 psi}

• The actual converted values for 2.7 kgf/cm2 are 265 kPa and 38.4 psi. In the first specification, 2.7 is used as

an upper limit, so the converted values are rounded down to 260 and 38. In the second specification, 2.7 is

used as a lower limit, so the converted values are rounded up to 270 and 39.

End Of Sie

00–00–2

GENERAL INFORMATION

SAE STANDARD

EHU000000000104

• In accordance with new regulations, SAE (Society of Automotive Engineers) standard names and abbreviations

are now used in this manual. The table below lists the names and abbreviations that have been used in Mazda

manuals up to now and their SAE equivalents.

Abbreviation

AP

APP

ACL

A/C

BARO

B+

CMP sensor

CAC

CLS

CTP

CPP

CIS

CKP sensor

DLC

DTM

DTC

DI

DLI

EI

ECT

EM

EVAP

EGR

FC

FF

4GR

GEN

GND

HO2S

IAC

IAT

KS

MIL

SAE Standard

Remark

Name

Accelerator Pedal

Accelerator Pedal Position

Air Cleaner

Air Conditioning

Barometric Pressure

Battery Positive Voltage

Camshaft Position Sensor

Charge Air Cooler

Closed Loop System

Closed Throttle Position

Clutch Pedal Position

Continuous Fuel Injection System

Crankshaft Position Sensor

Data Link Connector

Diagnostic Test Mode

#1

Diagnostic Test Code(s)

Distributor Ignition

Distributorless Ignition

Electronic Ignition

#2

Engine Coolant Temperature

Engine Modification

Evaporative Emission

Exhaust Gas Recirculation

Fan Control

Flexible Fuel

Fourth Gear

Generator

Ground

Heated Oxygen Sensor

Idle Air Control

Intake Air Temperature

Knock Sensor

Malfunction Indicator Lamp

With

heater

Abbreviation

MAP

MAF sensor

MFL

OBD

OL

OC

O2S

PNP

PSP

PCM

SAE Standard

Name

Manifold Absolute Pressure

Mass Air Flow Sensor

Multiport Fuel Injection

On-board Diagnostic System

Open Loop

Oxidation Catalytic Converter

Oxygen sensor

Park/Neutral Position

Power Steering Pressure

Powertrain Control Module

Remark

#3

PAIR

Pulsed Secondary Air Injection

Pulsed

injection

AIR

Secondary Air Injection

Injection

with air

pump

SAPV

SFI

3GR

TWC

TB

TP sensor

TCC

Secondary Air Pulse Valve

Sequential Multiport Fuel

Injection

Third Gear

Three Way Catalytic Converter

Throttle Body

Throttle Position Sensor

Torque Converter Clutch

TCM

Transmission (Transaxle) Control

Module

TR

TC

VSS

VR

VAF sensor

Transmission (Transaxle) Range

Turbocharger

Vehicle Speed Sensor

Voltage Regulator

Volume Air Flow Sensor

WU-TWC

WOP

Warm Up Three Way Catalytic

Converter

#4

Wide Open Throttle

#1: Diagnostic trouble codes depend on the diagnostic test mode.

#2: Controlled by the PCM

#3: Device that controls engine and powertrain

#4: Directly connected to exhaust manifold

End Of Sie

00–00–3

00–00

2006 Mazda RX-8 Service Highlights (3409–1U–05J)

01

ENGINE

SECTION

01–00

Toc

of SCT . . . . . . . . . . . . . . . . . . 01-00

OUTLINE

INTAKE-AIR SYSTEM . . . . . . . 01-13

ON-BOARD DIAGNOSTIC . . . . 01-02

Toc of SCT

01–00

OUTLINE

ENGINE ABBREVIATIONS . . . . . . . . . . . 01–00–1

ENGINE FEATURES . . . . . . . . . . . . . . . . 01–00–1

ENGINE SPECIFICATIONS. . . . . . . . . . . 01–00–2

End of Toc

ENGINE ABBREVIATIONS

A/C

APV

CCM

DC

CSERS

FP1

KOEO

KOER

L/F

L/R

MT

RP1

SSV

SW

T/F

T/R

VDI

VFAD

EHU010002000101

Air Conditioner

Auxiliary Port Valve

Comprehensive Component Monitor

Drive Cycle

Cold Start Emission Reduction Strategy

Front Primary 1

Key On Engine Off

Key On Engine Running

Leading Front

Leading Rear

Manual Transmission

Rear Primary 1

Secondary Shutter Valve

Switch

Trailing Front

Trailing Rear

Variable Dynamic Effect Intake

Variable Fresh Air Duct

End Of Sie

ENGINE FEATURES

To meet OBD-II regulations

EHU010002000102

• Modes 01, 02, 03, and 06 of diagnostic test modes changed

End Of Sie

Revised 4/2006 (Ref. No. R027/06)

01–00–1

2006 Mazda RX-8 Service Highlights (3409–1U–05J)

OUTLINE

ENGINE SPECIFICATIONS

EHU010002000103

Specification

2006MY Mazda RX-8

2005MY Mazda RX-8

13B-MSP

13B-MSP

13B-MSP

13B-MSP

(Standard

(High

(Standard

(High

power)

power)

power)

power)

Item

MECHANICAL

Engine type

Rotor arrangement and number

Combustion chamber type

Displacement

Compression ratio

Compression pressure

Open

IN

Port timing

Close

Rotary

In-line 2-rotor, longitudinal

Bathtub

(ml {cc, cu in})

654 {654, 40.0}×2

10.0

830 {8.5, 120}[250]

←

3°

12°

3°

←

←

←

←

←

←

←

←

Force-fed type

Trochoid gear

←

←

441—490

{4.5—5.0, 64.0—71.0}

←

Full-flow

←

(kPa {kgf/cm psi}

)

78—118

{0.8—1.2, 11.4—17.1}

←

(kPa {kgf/cm2, psi} [rpm] )

350 {3.57, 50.8} [3,000]

←

3.3 {3.5, 2.9}

3.5 {3.7, 3.1}

4.7 {5.0, 4.1}

5.7 {6.0, 5.0} 6.4 {6.7, 5.6}

SL

5W–20

GF–3

←

←

←

←

←

←

←

Water-cooled, forced

circulation

9.8 {10.4, 8.6}

Centrifugal, V-ribbed beltdriven

Wax

80—84 {176—183}

95 {203}

8.5 {0.33} or more

Corrugated fin

←

(kPa {kgf/cm2, psi} [rpm])

Primary port

Secondary port ATDC

Auxiliary port

Primary port

Secondary port ABDC

Auxiliary port

BBDC

BTDC

Open

Close

LUBRICATION SYSTEM

Type

Type

Oil pump

Relief valve opening pressure

(approx. quantity)

EX

(kPa {kgf/cm2, psi}

)

Type

Oil filter

Relief valve opening pressure

(approx. quantity)

Oil pressure (approx.

quantity)

[oil temperature 100°C

{212°F}]

2,

Oil replacement

Oil capacity

(approx. quantity)

Oil and oil filter replacement

(L {US qt, lmp qt}) Engine overhaul

Total (dry engine)

API service

Recommended oil

SAE viscosity

ILSAC

COOLING SYSTEM

Type

Coolant capacity

(L {US qt, lmp qt})

Water pump

Type

Opening temperature

(°C {F°})

Thermostat

Full-open temperature

(°C {F°})

Full-open lift

(mm {in})

Radiator

Type

Cap valve opening pressure

Cooling system cap

(kPa {kgf/cm2, psi} )

01–00–2

←

←

←

←

←

–

60°

45°

–

40°

38°

65°

36°

80°

50°

73.3—103.3 {0.748—

1.053, 10.63—14.98}

←

←

←

←

←

←

←

←

←

OUTLINE

Item

Type

Cooling fan

Number of blades

Outer diameter

(mm {in})

Specification

2006MY Mazda RX-8

2005MY Mazda RX-8

13B-MSP

13B-MSP

13B-MSP

13B-MSP

(High

(Standard

(High

(Standard

power)

power)

power)

power)

Electronic

←

Cooling fan No.1: 5,

←

Cooling fan No.2: 7

300 {11.8}

←

FUEL SYSTEM

Injector

Type

Type of fuel delivery

Type of drive

Pressure regulator control

pressure

Fuel pump type

Fuel tank capacity (approx.

quantity)

(kPa {kgf/cm2, psi})

(L {US gal, lmp gal})

Fuel type

EMISSION SYSTEM

AIR system

←

←

←

Approx. 390 {3.98, 56.6}

←

Electric

←

60 {15.9, 13.2}

←

Unleaded premium

(unleaded high-octane)

gasoline

←

Air pump, air control valve

Three-way catalyst

(monolithic)

Canister design

Closed design

Catalyst type

EVAP control system

PCV system

CHARGING SYSTEM

Voltage

Battery

Type and capacity

(5 hour rate)

Out-put

Generator

Regulated voltage

Self diagnosis function

IGNITION SYSTEM

(V)

12

(A·h)

75D23L (52)

(V–A)

(V)

12—100

Controlled by PCM

Distributorless Ignition

(DLI)

Electronic

When idling:

T/F-L/F-T/R-L/R

Except for idling:

L/F-T/F-L/R-T/R

(Independent ignition

control)

Type

Spark advance

Ignition system

Firing order

Spark plug

Multiple hole design

Top-feed

Electronic

←

←

←

←

←

←

50D20L (40), 55D23L (48)

75D23L (52), 75D26L (52)

←

←

←

←

←

←

Leading side

N3H5 18 110 (RE7C-L)*1,

N3Y8 18 110 (RE7C-L)*1,

N3Y9 18 110 (RE6C-L)*2

N3H2 18 110C

(RE7A-L)*1,

N3Y2 18 110 (RE7A-L)*1,

N3Y3 18 110 (RE6A-L)*2,

N3H5 18 110 (RE7C-L)*1,

N3Y8 18 110 (RE7C-L)*1,

N3Y9 18 110 (RE6C-L)*2

Trailing side

N3H1 18 110C

(RE9B-T)*1,

N3Y1 18 110 (RE9B-T)*1

←

Type

STARTING SYSTEM

Type

Starter

Output

Coaxial reduction

(kW)

2.0

←

AT: 1.8*3, MT: 1.4*3

2.0*4

01–00–3

01–00

OUTLINE

Item

CONTROL SYSTEM

Neutral switch (MT)

CPP switch (MT)

SSV switch

APV position sensor

ECT sensor

IAT sensor

TP sensor

APP sensor

MAF sensor (Inside MAF)

Front HO2S

Rear HO2S

BARO sensor

KS

Eccentric shaft position sensor

Metering oil pump switch

Brake switch

Throttle valve actuator

APV motor

Fuel injector (primary 1)

Fuel injector (secondary)

Fuel injector (primary 2)

Stepping motor (in metering oil pump)

Specification

2006MY Mazda RX-8

2005MY Mazda RX-8

13B-MSP

13B-MSP

13B-MSP

13B-MSP

(High

(Standard

(High

(Standard

power)

power)

power)

power)

ON/OFF

ON/OFF

ON/OFF

–

Hall element

Thermistor

Thermistor

Hall element

Hall element

Hot-wire

Zirconia element (all range

air/fuel ratio sensor)

Zirconia element

(Stoichiometric air/fuel

ratio sensor)

Piezoelectric element

Piezoelectric element

Magnetic pickup

ON/OFF

ON/OFF

DC motor

–

DC motor

Multiple hole type (12

holes)

Multiple hole type (4 holes)

Multiple hole

–

type

(4 holes)

Stepping motor

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

*1 : Standard equipment

*2 : Hot type plug: Available only for customers who often drive their car at very low speed which causes the plugs

to foul easily.

*3 : Applied VIN (Assumed)

JM1 FE173*5# 100001–150736

JM1 FE17N*5# 100001–150736

*4 : Applied VIN (Assumed)

JM1 FE173*5# 150737–

JM1 FE17N*5# 150737–

End Of Sie

01–00–4

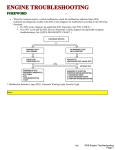

ON-BOARD DIAGNOSTIC

01–02

ON-BOARD DIAGNOSTIC

ON-BOARD DIAGNOSTIC OUTLINE . . .

Features . . . . . . . . . . . . . . . . . . . . . . . .

ON-BOARD DIAGNOSTIC

WIRING DIAGRAM . . . . . . . . . . . . . . . .

DIAGNOSTIC TEST MODE. . . . . . . . . . .

On-board system readiness test . . . . .

OBD-II Freeze Frame Data

(Mode 02). . . . . . . . . . . . . . . . . . . . . .

01–02–1

01–02–1

01–02–2

01–02–4

01–02–4

01–02–4

OBD-II Diagnostic Trouble Code

(Mode 03) . . . . . . . . . . . . . . . . . . . . . . 01–02–5

OBD-II Diagnostic Monitoring System

Test Results (Mode 06) . . . . . . . . . . . . 01–02–8

DTC DETECTION LOGIC AND

CONDITIONS . . . . . . . . . . . . . . . . . . . . . 01–02–8

KOEO/KOER SELF-TEST . . . . . . . . . . . . 01–02–9

PID/DATA MONITOR AND RECORD . . . . 01–02–12

SIMULATION TEST . . . . . . . . . . . . . . . . . 01–02–14

End of Toc

ON-BOARD DIAGNOSTIC OUTLINE

EHU010200000101

Features

To meet OBD-II regulations

• Modes 02, 03, and 06 of diagnostic test modes changed

End Of Sie

01–02–1

01–02

ON-BOARD DIAGNOSTIC

ON-BOARD DIAGNOSTIC WIRING DIAGRAM

EHU010200000107

IG2

IG1

FUEL PUMP RELAY

STARTER RELAY

5A

5P

START

ACC

FUEL PUMP

SPEED CONTROL RELAY

5J

MAIN RELAY

4M

4E

5AC

FUEL PUMP RESISTOR

5AF

BATTERY

FUEL INJECTOR (FP)

IGNITION RELAY

2M

FUEL INJECTOR (FS)

4Q

2G

DRIVE-BY-WIRE RELAY

FUEL INJECTOR (RP)

2J

5H

4C

FUEL INJECTOR (RS)

2D

2

CPP SWITCH *

FUEL INJECTOR (FP2) *1

4F

3A

NEUTRAL SWITCH *2

FUEL INJECTOR (RP2) *1

2O

3D

BRAKE SWITCH *3

4P

PCM

2AD

IGNITION COIL (T/F)

2AC

IGNITION COIL (T/R)

2AA

IGNITION COIL (L/F)

2Z

IGNITION COIL (L/R)

CRUISE CONTROL SWITCH *3

5V

4U

METERING OIL PUMP SWITCH

2N

METERING OIL PUMP

SSV SWITCH

1D

2W

REFRIGERANT PRESSURE SWITCH

2V

A/C

AMPLIFIER

HI, LO

MIDDLE

4W

2AB

4Z

OIL LEVEL SWITCH

2Y

2R

OIL-PRESSURE SWITCH

4H

2E

COOLANT LEVEL SWITCH

4T

d

c

a

b

4D

EVAP SYSTEM

LEAK DETECTION

PUMP

*1: 13B-MSP (HIGH POWER)

*2: MT

*3: WITH CRUISE CONTROL SYSTEM

EHU140ZT8003

01–02–2

ON-BOARD DIAGNOSTIC

c

a

b

c

d

ECT SENSOR

VFAD SOLENOID VALVE *1

2K

MAF SENSOR

5Z

5U

VDI SOLENOID VALVE

1W

5N

01–02

SSV SOLENOID VALVE

5K

1L

IAT SENSOR

PURGE SOLENOID VALVE

BARO SENSOR

2P

5S

AIR SOLENOID VALVE

1O

4K

KS

AIR PUMP RELAY

1T

4O

1F

1G

AIR PUMP

1U

APP SENSOR

4Y

NO.1

2I

5F

GENERATOR

2T

5AE

4X

NO.2

A/C AMPLIFIER

5W

5C

5AB

THROTTLE BODY

TP SENSOR

A/C RELAY

1Q

NO.1

1J

NO.2

1M

PCM

5AA

COOLING FAN RELAY NO.1

5X

2F

THROTTLE ACTUATOR

1C

COOLING FAN RELAY NO.2

5AD

1B

APV MOTOR *1

APV

POSITION

SENSOR

APV MOTOR

COOLING FAN RELAY NO.3

1S

3B

3J

4V

CAN_H

3G

ECCENTRIC SHAFT POSITION SENSOR

2U

4S

2X

CAN_L

OTHER MODULE

·EPS CONTROL MODULE

·TCM

·ABS HU/CM

·DSC HU/CM

·KEYLESS CONTROL MODULE

·TPMS CONTROL MODULE

·STEERING ANGLE SENSOR

·INSTRUMENT CLUSTER

2H

2B

4A

2C

4J

1V

5D

FRONT HO2S

REAR HO2S

5O

2Q

5R

2A

5T

*1: 13B-MSP (HIGH POWER)

EHU140ZT8004

End Of Sie

01–02–3

ON-BOARD DIAGNOSTIC

DIAGNOSTIC TEST MODE

• The diagnostic test mode is essentially carried over from that of the 2005 MY except for following.

— To meet OBD-II regulations, modes 02, 03, and 06 have been changed.

Diagnostic test mode

Mode 01

Mode 02

Mode 03

Mode 04

Mode 06

Mode 07

Mode 08

Mode 09

EHU010200000102

Item

Sending diagnostic data (PID data monitor/On-board system readiness test)

Sending freeze frame data

Sending emission-related malfunction code (DTC)

Clearing/resetting emission-related malfunction information

Sending intermittent monitoring system test results (DMTR)

Sending continuous monitoring system test results (pending code)

On-board device control (simulation test, active command mode)

Request vehicle information

On-board system readiness test

• The items supported by the on-board system readiness test are shown below.

Continuous monitoring system

— HO2S heater

— Thermostat

— Fuel system

— Misfire

— CCM

Intermittent monitoring system

— HO2S

— AIR system

— Catalyst

— EVAP system

— Engine cooling system

— CSERS

OBD-II Freeze Frame Data (Mode 02)

• Differences between the 2006 MY and 2005 MY Freeze Frame Data monitor items are shown below.

Freeze Frame Data monitor table

X: Applicable

—: Not applicable

2006 MY

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

01–02–4

2005 MY

X

X

X

X

X

X

X

X

X

X

X

X

X

—

X

X

X

X

X

X

X

X

X

Full names

DTC that caused required Freeze Frame Data storage

Fuel system status

Calculated LOAD Value

Engine Coolant Temperature

Short term fuel trim

Long term fuel trim

Engine RPM

Vehicle Speed Sensor

Ignition Timing Advance

Intake Air Temperature

Air Flow Rate from Mass Air Flow Sensor

Absolute Throttle Position

Commanded Secondary Air Status

Rear HO2S

Time since engine start

Commanded Evaporative Purge

Fuel Level Input

Number of warm-ups since DTCs cleared

Distance travelled since DTCs cleared

Barometric Pressure

Catalyst Temperature

Control module voltage

Absolute load value

Unit

—

Refer to list below.

%

°C

°F

%

%

rpm

km/h

mph

°

°C

°F

g/s

%

—

%

s

%

%

—

km

miles

kPa

°C

°F

V

%

ON-BOARD DIAGNOSTIC

2006 MY

X

X

X

X

X

X

X

2005 MY

X

X

X

X

X

X

X

Full names

Commanded Equivalence Ratio

Relative Throttle Position

Ambient air temperature

Absolute Throttle Position No.2

Accelerator Pedal Position No.3

Accelerator Pedal Position No.4

Commanded Throttle Actuator Control

Unit

—

%

°C

%

%

%

%

01–02

Meaning of fuel system loop status

• The following information is displayed on the tester.

— Feedback operating: HO2S being used for feedback is normal.

— Feedback stops: ECT is lower than the determined feedback zone.

— Feedback stops: Open loop due to driving condition.

— Feedback stops: Open loop due to detected system fault.

OBD-II Diagnostic Trouble Code (Mode 03)

• The following DTCs have been adopted.

— P0116, P0134, P0137, P0411, P050A

• Differences between the 2006 MY and 2005 MY DTCs are shown below.

DTC table

DTC No.

2006 MY 2005 MY

P0030

←

P0031

←

P0032

←

P0037

←

P0038

←

P0076

←

P0077

←

P0101

←

P0102

←

P0103

←

P0107

←

P0108

←

P0111

←

P0112

←

P0113

←

P0116*3

×: Applicable

—: Not applicable

MIL

DC

Front HO2S heater control circuit problem

Front HO2S heater control circuit low

Front HO2S heater control circuit high

Rear HO2S heater control circuit low

Rear HO2S heater control circuit high

VDI solenoid valve control circuit low

VDI solenoid valve control circuit high

MAF sensor circuit range/performance problem

MAF sensor circuit low input

MAF sensor circuit high input

BARO sensor circuit low input

BARO sensor circuit high input

IAT sensor circuit range/performance problem

IAT sensor circuit low input

IAT sensor circuit high input

ON

ON

ON

ON

ON

OFF

OFF

ON

ON

ON

ON

ON

ON

ON

ON

2

2

2

2

2

2

2

2

1

1

1

1

2

1

1

—

Engine coolant temperature circuit range/

performance

ON

2

P0117

P0118

P0122

P0123

←

←

←

←

ECT sensor circuit low input

ECT sensor circuit high input

TP sensor No.1 circuit low input

TP sensor No.1 circuit high input

ON

ON

ON

ON

1

1

1

1

P0125

←

Insufficient coolant temperature for closed loop fuel

control

ON

2

P0126

P0130

P0131

P0132

P0133

←

←

←

←

←

Insufficient coolant temperature for stable operation

Front HO2S circuit problem

Front HO2S circuit low voltage

Front HO2S circuit high voltage

Front HO2S circuit slow response

ON

ON

ON

ON

ON

2

2

2

2

2

Monitor

item*1

HO2S heater

HO2S heater

HO2S heater

HO2S heater

HO2S heater

Other

Other

CCM

CCM

CCM

CCM

CCM

CCM

CCM

CCM

Engine

cooling

system

CCM

CCM

CCM

CCM

Engine

cooling

system

Thermostat

HO2S

HO2S

HO2S

HO2S

P0134*3

—

Front HO2S no activity detected

ON

2

*3

—

Rear HO2S circuit low input

ON

←

Rear HO2S circuit high voltage

ON

P0137

P0138

Condition

Self -test Memory

function

type*4

C, O, R

×

C, O, R

×

C, O, R

×

C, O, R

×

C, O, R

×

C, O, R

×

C, O, R

×

C

×

C, O, R

×

C, O, R

×

C, O, R

×

C, O, R

×

C

×

C, O, R

×

C, O, R

×

C

×

C, O, R

C, O, R

C, O, R

C, O, R

×

×

×

×

C

×

C

C, O, R

C, O, R

C, O, R

C

×

×

×

×

×

HO2S

C, R

×

2

HO2S

C

×

2

HO2S

C, R

×

01–02–5

ON-BOARD DIAGNOSTIC

DTC No.

2006 MY 2005 MY

P0139

←

P0171

←

P0172

←

P0222

←

P0223

←

Condition

Rear HO2S circuit slow response

System too lean

System too rich

TP sensor No.2 circuit low input

TP sensor No.2 circuit high input

P0300

←

Random misfire detected

P0301

←

Front rotor misfire detected

P0302

←

Rear rotor misfire detected

P0327

P0328

P0335

←

←

←

P0336

←

P0410

←

MIL

DC

ON

ON

ON

ON

ON

Flas

h/ON

Flas

h/ON

Flas

h/ON

ON

ON

ON

2

2

2

1

1

1 or

2

1 or

2

1 or

2

1

1

1

ON

Monitor

item*1

HO2S

Fuel system

Fuel system

CCM

CCM

Self -test Memory

function

type*4

C, R

×

C, R

×

C, R

×

C, O, R

×

C, O, R

×

Misfire

C

×

Misfire

C

×

Misfire

C

×

CCM

CCM

CCM

C, O, R

C, O, R

C

×

×

×

1

CCM

C, R

×

ON

2

AIR system

C, R

×

ON

2

AIR system

C

×

ON

ON

ON

ON

ON

ON

2

2

2

2

2

2

Catalyst

EVAP system

EVAP system

CCM

EVAP system

EVAP system

C

C, R

C, R

C, R

C, R

C, R

×

×

×

×

×

×

ON

2

EVAP system

C, R

×

P0420

P0441

P0442

P0443

P0446

P0455

←

←

←

←

←

←

KS circuit low input

KS circuit high input

Eccentric shaft position sensor circuit problem

Eccentric shaft position sensor circuit range/

performance problem

Secondary air injection system problem

Secondary air injection system incorrect upstream

flow

Catalyst system efficiency below threshold

EVAP system incorrect purge flow

EVAP system leak detected (small leak)

Purge solenoid valve circuit problem

EVAP system vent control circuit problem

EVAP system leak detected (large leak)

P0456*2

←

EVAP system leak detected (very small leak)

P0461

←

ON

2

CCM

C

×

P0462

P0463

P0480

P0481

P0500

P0505

P0506

P0507

←

←

←

←

←

←

←

←

Fuel gauge sender unit circuit range/performance

problem

Fuel gauge sender unit (main) circuit low input

Fuel gauge sender unit (main) circuit high input

Cooling fan No.1 control circuit problem

Cooling fan No.2 control circuit problem

VSS circuit problem

Idle air control system problem

Idle air control system RPM lower than expected

Idle air control system RPM higher than expected

ON

ON

OFF

OFF

ON

OFF

ON

ON

2

2

2

2

2

—

2

2

CCM

CCM

Other

Other

CCM

—

CCM

CCM

C, O, R

C, O, R

C, O, R

C, O, R

C

R

C

C

×

×

×

×

×

—

×

×

P050A*3

P0562

P0564

P0571

P0601

P0602

P0604

P0610

—

Cold start idle air control system performance

ON

2

CSERS

C

×

←

←

←

←

←

←

←

ON

OFF

OFF

ON

ON

ON

ON

1

1

1

1

1

1

1

CCM

Other

Other

CCM

CCM

CCM

CCM

C, O, R

C, O, R

C, O, R

C, O, R

C, O, R

C, O, R

C, O, R

×

×

×

×

×

×

×

P0638

←

ON

1

CCM

C

×

P0661

P0662

P0703

←

←

←

System voltage low (KAM)

Cruise control switch input circuit problem

Brake switch input circuit problem

PCM memory check sum error

PCM programming error

PCM random access memory error

PCM vehicle options error

Throttle actuator control circuit range/performance

problem

SSV solenoid valve control circuit low

SSV solenoid valve control circuit high

Brake switch input circuit problem

ON

ON

ON

2

2

2

CCM

CCM

CCM

C, O, R

C, O, R

C

×

×

×

P0704*3

←

CPP switch input circuit problem

ON

2

CCM

C

×

*3

P0850

P1260

←

Neutral switch input circuit problem

ON

2

CCM

C

×

←

OFF

1

Other

C, O

—

P1686

←

Immobilizer system problem

Metering oil pump control circuit low flow side

problem

ON

1

CCM

C, R

×

P0411

*3

01–02–6

—

ON-BOARD DIAGNOSTIC

DTC No.

2006 MY 2005 MY

Condition

Metering oil pump control circuit high flow side

problem

Metering oil pump control circuit initial check

problem

Self -test Memory

function

type*4

MIL

DC

Monitor

item*1

ON

1

CCM

C, R

×

ON

1

CCM

C, R

×

P1687

←

P1688

←

P2004*3

←

APV stuck open

ON

2

CCM

C, O, R

×

*3

P2006

←

APV motor control driver IC problem

ON

2

CCM

C

×

P2009*3

←

APV motor control circuit low

ON

2

CCM

C, O, R

×

P2010*3

←

APV motor control circuit high

ON

2

CCM

C, O, R

×

*3

←

APV position sensor circuit low

ON

2

CCM

C, O, R

×

P2016

P2017

P2067

P2068

P2070

P2096

P2097

P2102

P2103

←

APV position sensor circuit high

ON

2

CCM

C, O, R

×

←

←

←

←

←

←

←

ON

ON

ON

ON

ON

ON

ON

2

2

2

2

2

1

1

CCM

CCM

CCM

Fuel system

Fuel system

CCM

CCM

C, O, R

C, O, R

C, O, R

C, R

C, R

C, O, R

C, O, R

×

×

×

×

×

×

×

P2106

←

ON

1

CCM

C

×

P2107

P2108

←

←

ON

ON

1

1

CCM

CCM

C, O, R

C

×

×

P2109

←

ON

1

CCM

C

×

P2112

←

ON

1

CCM

C

×

P2119

←

ON

2

CCM

C, O, R

×

P2122

P2123

P2127

P2128

P2135

←

←

←

←

←

ON

ON

ON

ON

ON

1

1

1

1

1

CCM

CCM

CCM

CCM

CCM

C, O, R

C, O, R

C, O, R

C, O, R

C, O, R

×

×

×

×

×

P2136

←

ON

1

CCM

C, O, R

×

P2138

←

ON

1

CCM

C, O, R

×

P2195

P2196

P2257

P2258

P2259

P2260

P2270

P2271

←

←

←

←

←

←

←

←

ON

ON

ON

ON

ON

ON

ON

ON

2

2

2

2

2

2

2

2

HO2S

HO2S

AIR system

AIR system

AIR system

AIR system

HO2S

HO2S

C, R

C, R

C, O, R

C, O, R

C, O, R

C, O, R

C, R

C, R

×

×

×

×

×

×

×

×

P2401

←

ON

2

EVAP system

C, O, R

×

P2402

←

ON

2

EVAP system

C, O, R

×

P2404

←

ON

2

EVAP system

C

×

P2405

←

ON

2

EVAP system

C, O, R

×

P2407

←

Fuel gauge sender unit (sub) circuit low input

Fuel gauge sender unit (sub) circuit high input

SSV stuck open

Target A/F feedback system too lean

Target A/F feedback system too rich

Drive-by-wire relay control circuit low

Drive-by-wire relay control circuit high

Throttle actuator control system-forced limited

power

Throttle actuator control module processor error

Throttle actuator control module performance error

TP sensor minimum stop range/performance

problem

Throttle actuator control system range/performance

problem

Throttle actuator control throttle body range/

performance problem

APP sensor No.1 circuit low input

APP sensor No.1 circuit high input

APP sensor No.2 circuit low input

APP sensor No.2 circuit high input

TP sensor No.1/No.2 voltage correlation problem

TP sensor No.1/No.3 (calculation value in PCM)

voltage correlation problem

TP sensor No.3 (calculation value in PCM)/No.4

(calculation value in PCM) voltage correlation

problem

Front HO2S signal stuck lean

Front HO2S signal stuck rich

AIR pump relay control circuit low

AIR pump relay control circuit high

AIR solenoid valve control circuit low

AIR solenoid valve control circuit high

Rear HO2S signal stuck lean

Rear HO2S signal stuck rich

EVAP system leak detection pump control circuit

low

EVAP system leak detection pump control circuit

high

EVAP system leak detection pump sense circuit

range/performance problem

EVAP system leak detection pump sense circuit

low

EVAP system leak detection pump sense circuit

intermittent/erratic problem

ON

2

EVAP system

C, O, R

×

*3

01–02–7

01–02

ON-BOARD DIAGNOSTIC

DTC No.

Condition

2006 MY 2005 MY

P2502

←

Charging system voltage problem

P2503

←

Charging system voltage low

P2504

←

Charging system voltage high

*1

*2

*3

*4

MIL

DC

OFF

OFF

OFF

1

1

1

Monitor

item*1

Other

Other

Other

Self -test Memory

function

type*4

C, R

×

C, R

×

C, R

×

: Indicates the applicable item in the On-Board System Readiness Test as defined by CARB.

: California emission regulation applicable model

: 13B-MSP (HIGH POWER)

: C: CMDTC self-test, O: KOEO self-test, R: KOER self-test

OBD-II Diagnostic Monitoring System Test Results (Mode 06)

• Differences between the 2006 MY and 2005 MY diagnostic monitoring system test results are shown below.

DMTR table

Test ID

2006 MY

10:01:80

10:01:81

10:01:82

10:01:83

10:02:03

10:02:04

10:02:05

10:21:80

10:3A:80

10:3B:80

2005 MY

←

←

—

—

←

←

←

←

←

←

←

10:3C:80*1

10:3D:80

10:71:80

10:71:81

←

←

—

10:A2:0B

←

10:A2:0C

←

10:A3:0B

←

10:A3:0C

10:E1:81

←

←

*1

Description

Response lean to rich

Response rich to lean

Response lean to rich delayed

Response rich to lean delayed

Low sensor voltage for switch time calculation

High sensor voltage for switch time calculation

Rich to lean sensor switching time

Front and rear HO2S switching time ratio

Large leak check

Small leak check

Very small leak check

Purge flow monitor

Secondary airflow test 1 (secondary air functional check)

Secondary airflow test 2 (secondary airflow rate check)

Exponentially weighted moving average misfire counts for

last 10 driving cycles

Misfire counts for last/current driving cycles

Exponentially weighted moving average misfire counts for

last 10 driving cycles

Misfire counts for last/current driving cycles

ECT

Related system

HO2S (front HO2S)

HO2S (rear HO2S)

Catalyst

EVAP system

AIR system

Misfire

Thermostat

: California emission regulation applicable model

End Of Sie

DTC DETECTION LOGIC AND CONDITIONS

EHU010200000103

• The following DTCs have been adopted detection condition.

— P0116, P0134, P0137, P0411, P050A

• The following DTCs have been changed detection condition.

— P0030

• Detection conditions are shown below.

P0030 Front HO2S heater control circuit problem

• The PCM monitors the front HO2S impedance when under the front HO2S heater control for 190 s. If the

impedance is more than 44 ohms while PCM turns front HO2S heater on, the PCM determines that there is a

front HO2S heater control circuit problem.

P0116 Engine coolant temperature circuit range/performance

• The PCM monitors the maximum value and minimum value of engine coolant temperature when the engine is

started and 5 min have been passed after leaving the vehicle 6 h or more. If difference between maximum and

minimum values of engine coolant temperature is below 5.6 °C {42.1 °F} the PCM determines that there is an

ECT circuit range/performance problem.

01–02–8

ON-BOARD DIAGNOSTIC

P0134 Front HO2S no activity detected

• The PCM monitors the front HO2S element impedance when the following conditions are met. If the front

HO2S element impedance is 50 ohms or more, the PCM determines that front HO2S is not activated.

MONITORING CONDITIONS

— HO2S, HO2S heater and TWC Repair Verification Drive Mode

— Following conditions are met

• Time from engine start is above 40 s (ECT when engine start is 20 °C {68 °F}).

P0137 Rear HO2S circuit low input

• The PCM monitors input voltage from rear HO2S. If the input voltage from the rear HO2S is below 0.1 V for

35.2 s the PCM determines that circuit input is low.

MONITORING CONDITIONS

— HO2S, HO2S heater and TWC repair verification drive mode

— Following conditions are met.

• Engine speed is above 1,500 rpm.

• Engine coolant temperature is above 70 °C {158 °F}.

• Fuel injector control in rear HO2S closed loop control.

• The PCM monitors the input voltage from the rear HO2S when the following conditions are met. Under the

following monitoring conditions, if the input voltage from the rear HO2S does not even exceed 0.1 V though

the short term fuel trim is controlled, the PCM determines that sensor circuit input is low.

P0411 Secondary air injection system incorrect upstream flow

• The PCM monitors the front HO2S output current when the Secondary air injection system is operating. If the

output current is less than the specification, the PCM determines that there is a Secondary air injection system

problem.

P050A Cold start idle air control system performance

• The PCM monitors actual idle speed while fast idle up correction operating. If the idle speed is out of specified

range, the PCM determines that the idle air control has performance problem.

End Of Sie

KOEO/KOER SELF-TEST

• Differences between the 2006 MY and 2005 MY KOEO/KOER self-test items are shown below.

KOEO/KOER self-test table

EHU010200000104

×: Applicable

—: Not applicable

DTC No.

2006 MY

2005 MY

P0030

←

P0031

←

P0032

←

P0037

←

P0038

←

P0076

←

P0077

←

P0101

←

P0102

←

P0103

←

P0107

←

P0108

←

P0111

←

P0112

←

P0113

←

P0116

—

P0117

←

P0118

←

P0122

←

P0123

←

P0125

←

P0126

←

P0130

←

P0131

←

P0132

←

Condition

Front HO2S heater control circuit problem

Front HO2S heater control circuit low

Front HO2S heater control circuit high

Rear HO2S heater control circuit low

Rear HO2S heater control circuit high

VDI solenoid valve control circuit low

VDI solenoid valve control circuit high

MAF sensor circuit range/performance problem

MAF sensor circuit low input

MAF sensor circuit high input

BARO sensor circuit low input

BARO sensor circuit high input

IAT sensor circuit range/performance problem

IAT sensor circuit low input

IAT sensor circuit high input

Engine coolant temperature circuit range/performance

ECT sensor circuit low input

ECT sensor circuit high input

TP sensor No.1 circuit low input

TP sensor No.1 circuit high input

Insufficient coolant temperature for closed loop fuel control

Insufficient coolant temperature for stable operation

Front HO2S circuit problem

Front HO2S circuit low voltage

Front HO2S circuit high voltage

Test condition

KOEO

KOER

×

×

×

×

×

×

×

×

×

×

×

×

×

×

—

—

×

×

×

×

×

×

×

×

—

—

×

×

×

×

—

—

×

×

×

×

×

×

×

×

—

—

—

—

×

×

×

×

×

×

01–02–9

01–02

ON-BOARD DIAGNOSTIC

DTC No.

2006 MY

2005 MY

P0133

←

P0134

—

P0137

—

P0138

←

P0139

←

P0171

←

P0172

←

P0222

←

P0223

←

P0300

←

P0301

←

P0302

←

P0327

←

P0328

←

P0335

←

P0336

←

P0410

←

P0411

—

P0420

←

P0441

←

P0442

←

P0443

←

P0446

←

P0455

←

P0456

←

P0461

←

P0462

←

P0463

←

P0480

←

P0481

←

P0500

←

P0505

←

P0506

←

P0507

←

P050A

—

P0562

←

P0564

←

P0571

←

P0601

←

P0602

←

P0604

←

P0610

←

P0638

←

P0661

←

P0662

←

P0703

←

P0704

←

P0850

←

P1260

←

P1686

←

P1687

←

P1688

←

P2004

←

01–02–10

Condition

Front HO2S circuit slow response

Front HO2S no activity detected

Rear HO2S circuit low input

Rear HO2S circuit high voltage

Rear HO2S circuit slow response

System too lean

System too rich

TP sensor No.2 circuit low input

TP sensor No.2 circuit high input

Random misfire detected

Front rotor misfire detected

Rear rotor misfire detected

KS circuit low input

KS circuit high input

Eccentric shaft position sensor circuit problem

Eccentric shaft position sensor circuit range/performance problem

Secondary air injection system problem

Secondary air injection system incorrect upstream flow

Catalyst system efficiency below threshold

EVAP system incorrect purge flow

EVAP system leak detected (small leak)

Purge solenoid valve circuit problem

EVAP system vent control circuit problem

EVAP system leak detected (large leak)

EVAP system leak detected (very small leak)

Fuel gauge sender unit circuit range/performance problem

Fuel gauge sender unit (main) circuit low input

Fuel gauge sender unit (main) circuit high input

Cooling fan No.1 control circuit problem

Cooling fan No.2 control circuit problem

VSS circuit problem

Idle air control system problem

Idle air control system RPM lower than expected

Idle air control system RPM higher than expected

Cold start idle air control system performance

System voltage low (KAM)

Cruise control switch input circuit problem

Brake switch input circuit problem

PCM memory check sum error

PCM programming error

PCM random access memory error

PCM vehicle options error

Throttle actuator control circuit range/performance problem

SSV solenoid valve control circuit low

SSV solenoid valve control circuit high

Brake switch input circuit problem

CPP switch input circuit problem

Neutral switch input circuit problem

Immobilizer system problem

Metering oil pump control circuit low flow side problem

Metering oil pump control circuit high flow side problem

Metering oil pump control circuit initial check problem

APV stuck open

Test condition

KOEO

KOER

—

—

—

×

—

—

—

×

—

×

—

×

—

×

×

×

×

×

—

—

—

—

—

—

×

×

×

×

—

—

—

×

—

×

—

—

—

—

—

×

—

×

—

×

—

×

—

×

—

×

—

—

×

×

×

×

×

×

×

×

—

—

—

×

—

—

—

—

—

—

×

×

×

×

×

×

×

×

×

×

×

×

×

×

—

—

×

×

×

×

—

—

—

—

—

—

×

—

—

×

—

×

—

×

×

×

2006 Mazda RX-8 Service Highlights (3409–1U–05J)

ON-BOARD DIAGNOSTIC

DTC No.

2006 MY

2005 MY

P2006

←

P2009

←

P2010

←

P2016

←

P2017

←

P2067

←

P2068

←

P2070

←

P2096

←

P2097

←

P2102

←

P2103

←

P2106

←

P2107

←

P2108

←

P2109

←

P2112

←

P2119

←

P2122

←

P2123

←

P2127

←

P2128

←

P2135

←

P2136

←

P2138

←

P2195

P2196

P2257

P2258

P2259

P2260

P2270

P2271

P2401

P2402

←

←

←

←

←

←

←

←

←

←

P2404

←

P2405

←

P2407

←

P2502

P2503

P2504

←

←

←

Condition

APV motor control driver IC problem

APV motor control circuit low

APV motor control circuit high

APV position sensor circuit low

APV position sensor circuit high

Fuel gauge sender unit (sub) circuit low input

Fuel gauge sender unit (sub) circuit high input

SSV stuck open

Target A/F feedback system too lean

Target A/F feedback system too rich

Drive-by-wire relay control circuit low

Drive-by-wire relay control circuit high

Throttle actuator control system-forced limited power

Throttle actuator control module processor error

Throttle actuator control module performance error

TP sensor minimum stop range/performance problem

Throttle actuator control system range/performance problem

Throttle actuator control throttle body range/performance problem

APP sensor No.1 circuit low input

APP sensor No.1 circuit high input

APP sensor No.2 circuit low input

APP sensor No.2 circuit high input

TP sensor No.1/No.2 voltage correlation problem

TP sensor No.1/No.3 (calculation value in PCM) voltage correlation

problem

TP sensor No.3 (calculation value in PCM)/No.4 (calculation value

in PCM) voltage correlation problem

Front HO2S signal stuck lean

Front HO2S signal stuck rich

AIR pump relay control circuit low

AIR pump relay control circuit high

AIR solenoid valve control circuit low

AIR solenoid valve control circuit high

Rear HO2S signal stuck lean

Rear HO2S signal stuck rich

EVAP system leak detection pump control circuit low

EVAP system leak detection pump control circuit high

EVAP system leak detection pump sense circuit range/performance

problem

EVAP system leak detection pump sense circuit low

EVAP system leak detection pump sense circuit intermittent/erratic

problem

Charging system voltage problem

Charging system voltage low

Charging system voltage high

Test condition

KOEO

KOER

—

—

×

×

×

×

×

×

×

×

×

×

×

×

×

×

—

×

—

×

×

×

×

×

—

—

×

×

—

—

—

—

—

—

×

×

×

×

×

×

×

×

×

×

×

×

×

×

×

×

—

—

×

×

×

×

—

—

×

×

×

×

×

×

×

×

×

×

×

×

—

—

×

×

×

×

—

—

—

×

×

×

End Of Sie

01–02–11

01–02

2006 Mazda RX-8 Service Highlights (3409–1U–05J)

ON-BOARD DIAGNOSTIC

PID/DATA MONITOR AND RECORD

• Differences between the 2006 MY and 2005 MY PID/DATA monitor items are shown below.

PID/DATA monitor item table

EHU010200000105

—: Not applicable

Item

2006 MY

Definition

2005 MY

Unit/Condition

PCM terminal

AC_REQ*1

ACCS

—

Refrigerant pressure switch (high, low)

On/Off

4W

←

A/C relay control signal in PCM

On/Off

5AA

ACSW*2

AIP RLY

ALTF

ALTT V

APP

←

Input signal from A/C switch

On/Off

4W

AIR pump relay control signal in PCM

Generator field coil control signal in PCM

Input voltage from generator

APP

APP from APP sensor No.1

Input voltage from APP sensor No.1

APP from APP sensor No.2

Input voltage from APP sensor No.2

APV motor control signal in PCM

Input voltage from APV position sensor

Target engine speed

On/Off

%

V

%

%

V

%

V

Opening/Closing

V

RPM

4O

2I

2T

5C, 5F

APV

APV_POS

ARPMDES

←

←

←

←

←

←

←

←

←

←

←

B+*2

←

Input voltage from battery

V

5J

BOO

CATT11_DSD

CHRGLP

←

←

←

←

←

COLP

←

BARO

Input voltage from BARO sensor

Input signal from brake switch No.2

Estimated catalyst converter temperature

Generator warning light control signal in PCM

Input signal from refrigerant pressure switch

(medium-pressure)

CPP*3

CPP/PNP

DEI

DTCCNT

←

Input signal from CPP switch

←

←

←

←

←

Input signal from neutral switch

VDI solenoid valve control signal in PCM

DTC count (includes those needing no action)

ECT

Input voltage from ECT sensor

←

APP1

APP2

BARO

kPa

Bar

V

On/Off

psi

5F

5C

3G, 3J

3B

—

5S

On/Off

4P

—

—

On/Off

4Z

On/Off

4F

Drive/Neutral

On/Off

—

°C

°F

V

2O

1W

—

Lambda

—

2B

—

Target lambda

—

—

°

%

°

%

On/Off

On/Off

%

On/Off

FPRR

←

On/Off

4M

FUELPW

←

Throttle valve opening angle

Target throttle valve position

Target throttle valve opening angle

Purge solenoid valve control signal in PCM

Cooling fan relay No.1 control signal in PCM

Cooling fan relay No.2 control signal in PCM

Fuel tank level

Fuel pump relay control signal in PCM

Fuel pump speed control relay control signal in

PCM

Fuel injection duration in PCM

1J, 1M

EVAPCP

FAN1

FAN2

FLI

FP

←

←

←

←

←

←

←

←

2J, 2M

FUELSYS

←

Fuel system loop status

GENVDSD

HTR11

HTR12

IAC

IASV

←

←

←

←

←

Target generator voltage

Front HO2S heater control signal in PCM

Rear HO2S heater control signal in PCM

Throttle actuator control signal in PCM

VFAD solenoid valve control signal in PCM

ms

OL/CL/OL Drive/

OL Fault/CL Fault

V

On/Off

On/Off

%

On/Off

ECT

EQ_RAT11

EQ_RAT11_DS

D*1

ETC_ACT

ETC_DSD

01–02–12

°C

°F

2K

—

2P

5X

5AD

—

5P

—

—

1V

2A

1B, 1C

5Z

Revised 10/2006 (Ref. No. R153/06)

ON-BOARD DIAGNOSTIC

Item

2006 MY

INGEAR

IVS

KNOCKR

2005 MY

←

←

←

←

←

LDP_MON

←

LDP_REF

←

LDP_IDL

←

LDP_SLDV

←

LDP_VSLDV*4

←

LDP_EVAPCP

←

LOAD

LONGFT1

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

IAT

MAF

MIL

MIL_DIS

MOP_POS

MOP_SW

O2S11

O2S12

PACNTV

PCM_T

RO2FT1

RPM

SC_SET

SCCS

SELTESTDTC

SHRTFT1

SHRTFT12

SPARK-L

SPARK-T

SSV

Test

TIRESIZE

TP

TP REL

TP1

TP2

TPCT

←

VPWR*1

—

VSS

←

*1

*2

*3

*4

Definition

IAT

Input voltage from IAT sensor

In gear

Idle validation

Spark retard value to prevent knocking

Indicates EVAP System leak detection pump

monitoring current

Indicates EVAP System leak detection pump

reference current

Indicates EVAP System leak detection pump idle

current

Indicates EVAP Control system small leak

detection value

Indicates EVAP Control system very small leak

detection value

Indicates EVAP Control system incorrect purge

flow detection value

LOAD

Long term fuel trim

MAF

Input voltage from MAF sensor

MIL control signal in PCM

Distance travelled while MIL is activated

Metering oil pump control status

Input signal from metering oil pump switch

Front HO2S output current

Input voltage from rear HO2S

AIR solenoid valve control signal in PCM

Input voltage from PCM temperature sensor

Target A/F feedback system status

Engine speed

Cruise indicator light control signal in PCM

Input voltage from cruise control switch

DTC count by KOEO/KOER self-test

Short term fuel trim

Target A/F fuel trim

Spark advance (L/F) in PCM

Spark advance (T/F) in PCM

SSV solenoid valve control signal in PCM

Test mode

Tire revolution per mile

Input voltage from TP sensor

Relative TP

TP from TP sensor No.1

Input voltage from TP sensor No.1

TP from TP sensor No.2

Input voltage from TP sensor No.2

Minimum input voltage from TP sensor at throttle

closing

Input voltage from battery (battery positive

voltage)

Vehicle speed

Unit/Condition

°C

°F

V

On/Off

Idle/Off Idle

°

PCM terminal

5K

—

1J, 1M

1T

mA

4D

mA

4D

mA

4D

mA

4D

mA/sec

4D

mA

4D

%

%

g/s

V

On/Off

—

—

5N

km

mile

—

On/Off

mA

V

On/Off

V

—

RPM

On/Off

V

—

%

%

°

°

On/Off

On/Off

rev/mile

V

%

%

V

%

V

KPH

—

—

2V, 2W, 2Y, 2AB

2N

2B

2Q

1O

—

—

—

—

5V

—

—

—

2AA

2AD

1L

—

—

1J, 1M

1J, 1M

1J

1M

V

1J, 1M

V

5J

MPH

—

: 13B-MSP (HIGH POWER)

: 13B-MSP (STANDARD POWER)

: MT model

: California emission regulation applicable model

01–02–13

01–02

ON-BOARD DIAGNOSTIC

End Of Sie

SIMULATION TEST

EHU010200000106

• Differences between the 2006 MY and 2005 MY simulation items are shown below.

Simulation item table

Item

Applicable component

Unit/condition

A/C relay

AIR pump relay

Generator (field coil)

APV motor

Target engine speed

VDI solenoid valve

Target throttle valve opening angle

Purge solenoid valve

Cooling fan relay No.1

Cooling fan relay No.2

Fuel pump relay

Fuel pump speed control relay

Fuel injector (FP1, RP1)

Target generator voltage

Rear HO2S heater

VFAD solenoid valve

On/Off

On/Off

%

opening/closing

RPM

On/Off

°

%

On/Off

On/Off

On/Off

On/Off

%

V

On/Off

On/Off

2006 MY

ACCS

AIP RLY

ALTF

APV

ARPMDES

DEI

ETC_DSD

EVAPCP

FAN1

FAN2

FP

FPRR

FUELPW1

GENVDSD

HTR12

IASV

2005 MY

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

MOP_POS

←

Metering oil pump

PACNTV

SSV

test

←

←

←

Time_DR_LR*1

—

Time_DR_RL*1

—

AIR solenoid valve

SSV solenoid valve

Test mode

Lean-to-rich Delayed Response

Time

Rich-to-lean Delayed Response

Time

Time_SR_LR*1

—

*1

—

Time_SR_RL

*1

: 13B-MSP (HIGH POWER)

End Of Sie

01–02–14

×: Applicable

—: Not applicable

Test condition

KOEO

KOER

×

×

×

×

—

×

×

×

×

×

×

×

×

×

×

×

×

×

×

×

×

×

×

×

—

×

—

×

×

×

×

×

PCM terminal

—

×

×

On/Off

On/Off

On/Off

×

×

×

×

×

×

5AA

4O

2I

3G, 3J

—

1W

—

2P

5X

5AD

5P

4M

2J, 2M

—

2A

5Z

2V, 2W, 2Y,

2AB

1O

1L

—

sec

—

×

—

sec

—

×

—

Lean-to-rich Slow Response Time

sec

—

×

—

Rich-to-lean Slow Response Time

sec

—

×

—

2006 Mazda RX-8 Service Highlights (3409–1U–05J)

INTAKE-AIR SYSTEM

01–13

INTAKE-AIR SYSTEM

INTAKE-AIR SYSTEM DIAGRAM . . . . . . 01–13–1

INTAKE-AIR SYSTEM HOSE

ROUTING DIAGRAM . . . . . . . . . . . . . . . 01–13–3

End of Toc

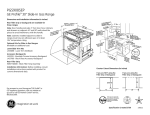

INTAKE-AIR SYSTEM DIAGRAM

EHU011300000101

Applied VIN (assumed):

JM1 FE173*6# 200001—JM1 FE173*6# 200011

JM1 FE17N*6# 200001—JM1 FE17N*6# 200011

TO CHARCOAL CANISTER

AIR

SOLENOID

VALVE

VDI

SOLENOID

VALVE

SSV

SOLENOID

VALVE

CATCH TANK

VFAD

THROTTLE

VALVE

C

A

B

TO METERING OIL NOZZLE

AIR CLEANER

TO FUEL TANK

VACUUM

CHAMBER

CHECK

VALVE

SSV

VDI ACTUATOR

TO REAR

PRIMARY/SECONDARY

PORTS

VDI VALVE

TO POWER

BRAKE UNIT

D

AUXILIARY

PORT

/APV

B

SSV ACTUATOR

FRONT

HOUSING

PRIMARY PORT

INTERMEDIATE

HOUSING

VACUUM

CHAMBER

VFAD

ACTUATOR

VFAD

SOLENOID

VALVE

C

D

CHECK VALVE

APV

MOTOR

13B-MSP

(HIGH POWER)

13B-MSP

(HIGH POWER)

SECONDARY

PORT

A

JET AIR FUEL MIXING NOZZLE

TO PCM

(ILLUSTRATION SHOWS 13B-MSP (HIGH POWER))

CHU0113W001

Added 4/2006 (Ref. No. R027/06)

01–13–1

01–13

2006 Mazda RX-8 Service Highlights (3409–1U–05J)

INTAKE-AIR SYSTEM

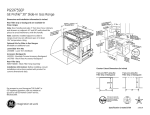

Applied VIN (assumed):

JM1 FE173*6# 200012—

JM1 FE17N*6# 200012—End Of Sie

TO CHARCOAL CANISTER

AIR SOLENOID

VALVE

VDI SOLENOID

VALVE

SSV

SOLENOID

VALVE

CATCH TANK

C

A

B

TO METERING OIL NOZZLE

AIR CLEANER

TO FUEL TANK

VACUUM

CHAMBER

VFAD

THROTTLE

VALVE

CHECK

VALVE

SSV

VDI ACTUATOR

TO REAR

PRIMARY/SECONDARY

PORTS

VDI VALVE

TO POWER

BRAKE UNIT

AUXILIARY

PORT/APV

B

SSV ACTUATOR

D

FRONT

HOUSING

PRIMARY PORT

INTERMEDIATE

HOUSING

VACUUM

CHAMBER

VFAD

ACTUATOR

VFAD

SOLENOID

VALVE

C

D

CHECK VALVE

APV

MOTOR

13B-MSP (HIGH

POWER)

13B-MSP (HIGH

POWER)

SECONDARY PORT

A

JET AIR FUEL MIXING NOZZLE

TO PCM

(ILLUSTRATION SHOWS 13B-MSP (HIGH POWER))

EHU113ZS4A02

01–13–2

Added 4/2006 (Ref. No. R027/06)

2006 Mazda RX-8 Service Highlights (3409–1U–05J)

INTAKE-AIR SYSTEM

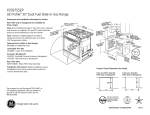

INTAKE-AIR SYSTEM HOSE ROUTING DIAGRAM

EHU011300000102

Applied VIN (assumed):

JM1 FE173*6# 200001—JM1 FE173*6# 200011

JM1 FE17N*6# 200001—JM1 FE17N*6# 200011

VDI ACTUATOR

SSV ACTUATOR

01–13

AIR SOLENOID

VALVE

INTAKE MANIFOLD

METERING

OIL NOZZLE

EXTENSION MANIFOLD

(UPPER)

PURGE

SOLENOID VALVE

AIR PUMP

METERING

OIL NOZZLE

VACUUM

CHAMBER

ONE-WAY

CHECK VALVE

SSV SOLENOID

VALVE

AIR CONTROL VALVE

EXHAUST MANIFOLD

VDI SOLENOID VALVE

ONE-WAY CHECK VALVE

(13B-MSP (HIGH POWER))

VFAD SOLENOID VALVE

(13B-MSP (HIGH POWER))

VACUUM CHAMBER

(13B-MSP (HIGH POWER))

VFAD ACTUATOR

(13B-MSP (HIGH POWER))

(ILLUSTRATION SHOWS 13B-MSP (HIGH POWER))

CHU0113W002

Added 4/2006 (Ref. No. R027/06)

01–13–3

2006 Mazda RX-8 Service Highlights (3409–1U–05J)

INTAKE-AIR SYSTEM

Applied VIN (assumed):

JM1 FE173*6# 200012—

JM1 FE17N*6# 200012—End Of Sie

VDI ACTUATOR

SSV ACTUATOR

AIR SOLENOID

VALVE

INTAKE MANIFOLD

METERING OIL

NOZZLE

EXTENSION MANIFOLD

(UPPER)

PURGE SOLENOID

VALVE

AIR PUMP

METERING

OIL NOZZLE

VACUUM

CHAMBER

ONE-WAY

CHECK VALVE

SSV SOLENOID

VALVE

AIR CONTROL VALVE

EXHAUST MANIFOLD

VDI SOLENOID VALVE

ONE-WAY CHECK VALVE

(13B-MSP (HIGH POWER))

VFAD SOLENOID VALVE (13B-MSP

(HIGH POWER))

VACUUM CHAMBER (13B-MSP

(HIGH POWER))

VFAD ACTUATOR (13B-MSP

(HIGH POWER))

(ILLUSTRATION SHOWS 13B-MSP (HIGH POWER))

EHU113ZS4A01

01–13–4

Added 4/2006 (Ref. No. R027/06)

TRANSMISSION/TRANSAXLE

05

SECTION

Toc

of SCT . . . . . . . . . . . . . . . . . . 05-00

OUTLINE

ON-BOARD DIAGNOSTIC

[SJ6A-EL] . . . . . . . . . . . . . . . . 05-02

AUTOMATIC

TRANSMISSION

[SJ6A-EL] . . . . . . . . . . . . . . . 05-13

AUTOMATIC TRANSMISSION

SHIFT MECHANISM . . . . . . . 05-14

Toc of SCT

05–00

OUTLINE

TRANSMISSION/TRANSAXLE

ABBREVIATIONS. . . . . . . . . . . . . . . . . . 05–00–1

TRANSMISSION/TRANSAXLE

FEATURES . . . . . . . . . . . . . . . . . . . . . . . 05–00–1

05–00

TRANSMISSION/TRANSAXLE

SPECIFICATIONS . . . . . . . . . . . . . . . . . 05–00–2

Automatic Transmission . . . . . . . . . . . . 05–00–2

End of Toc

TRANSMISSION/TRANSAXLE ABBREVIATIONS

AAS

ATF

AT

CAN

CPU

DC

EC-AT

PPF

1GR

2GR

3GR

4GR

5GR

6GR

EHU050000000101

Active Adaptive Shift

Automatic Transmission Fluid

Automatic Transmission

Controller Area Network

Central Processing Unit

Drive Cycle

Electronically Controlled Automatic Transmission

Power Plant Frame

First Gear

Second Gear

Third Gear

Fourth Gear

Fifth Gear

Sixth Gear

End Of Sie

TRANSMISSION/TRANSAXLE FEATURES

6-SPEED AT [SJ6A-EL]

Improved fuel economy

Improved marketability

Superior shift quality

Improved driveability

EHU050000000108

• Six-speed SJ6A-EL automatic transmission has been adopted.

• Six-speed SJ6A-EL automatic transmission has been adopted.

• The Sport AT has been adopted. With this feature up and downshifting can be performed with

either the shift control switch on the steering wheel or with the one-touch operation of the

selector lever.

• A 5-6 shift inhibit control has been adopted for rapid engine warming.

• Torque reduction control and line pressure control has been adopted.

• Shift learning control has been adopted.

• To improve drivetrain rigidity, a closed section power plant frame (PPF) has been adopted.

• A control feature for climbing/descending hills has been adopted, improving driveability when

climbing/descending.

End Of Sie

05–00–1

OUTLINE

TRANSMISSION/TRANSAXLE SPECIFICATIONS

EHU050000000106

Automatic Transmission

Item

Transmission type

Gear ratio

1GR

2GR

3GR

4GR

5GR

6GR

Reverse

Type

ATF

Capacity (Approx. quantity)

(L {US qt, lmp qt})

Torque converter stall torque ratio

Low clutch

High clutch

Reverse clutch

2-4 brake

Low and reverse brake

C1 clutch

Hydraulic system

C2 clutch

(Number of drive/driven plates)

C3 clutch

C4 clutch

B1 brake

B2 brake

B3 brake

B4 brake

Sun gear

Pinion gear

Pinion gear (inner)

Front planetary gear (Number of teeth)

Pinion gear (outer)

Internal gear

Ring gear

Sun gear

Middle planetary gear (Number of teeth) Pinion gear

Ring gear

Sun gear

Pinion gear

Rear planetary gear (Number of teeth)

Internal gear

Ring gear

End Of Sie

05–00–2

2005MY RX-8

RC4A-EL

2.785

1.545

1.000

0.694

—

—

2.272

ATF M-III or

equivalent

(e.g. Dexron®III)

←

←

←

←

←

—

—

←

2006MY RX-8

SJ6A-EL

3.538

2.060

1.404

1.000

0.713

0.582

3.168

←

JWS3309

8.7 {9.2, 7.7}

←

7.9 {8.4, 7.0}

2.04:1

5/5

6/6

2/2

4/4

4/5

—

—

—

—

—

—

—

—

33

21

—

—

75

—

—

—

—

42

17

75

—

←

←

←

←

←

←

—

—

—

—

—

—

—

—

←

←

—

—

←

—

—

—

—

←

←

←

—

1.85:1

—

—

—

—

—

4/4

5/5

4/3

4/4

3/3

4/3

4/4

5/4

←

—

19

18

—

75

26

20

66

26

20

—

66

ON-BOARD DIAGNOSTIC [SJ6A-EL]

05–02

ON-BOARD DIAGNOSTIC [SJ6A-EL]

ON-BOARD DIAGNOSTIC (OBD)

SYSTEM OUTLINE [SJ6A-EL] . . . . . . . 05–02–1

ON-BOARD DIAGNOSTIC (OBD)

SYSTEM BLOCK DIAGRAM

[SJ6A-EL] . . . . . . . . . . . . . . . . . . . . . . . 05–02–1