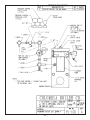

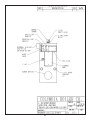

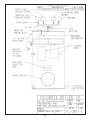

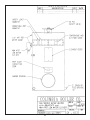

Download Columbia WL-60 Specifications

Transcript