Download Burnham Series V11 Brochure

Transcript

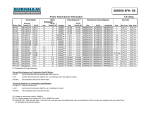

V11 Series Cast Iron Commercial Water or Steam Boiler 837 to 5733 MBH Input Oil, Gas, or Oil/Gas Combination 30, 50, or 80 PSI Cast Iron Sectional Design Water or Steam Top or Rear Venting Exclusive Optional SBC Boiler Controlª Ð M aximizes System Efficiency 1 V11 Series Cast Iron Commercial Water or Steam Boiler Your Commercial Heating Solution! Available in twenty sizes with gross output ratings from 667to4551MBH,theV11Seriesiscommonlyusedin schools, hospitals, and other large commercial applications where comfort and reliability are critical. The product meets theenergyefficiencyrequirementsofASHRAE90.1with combustion efficiencies up to 85%. Installation & Service Flexibility Cast iron construction, ease of assembly, two venting options, andstringenttestingmethodsmaketheV11Seriesboilerby Burnham Commercial your commercial heating solution. • Hassle-free Section Assembly ThecastironsectionaldesignoftheV11boilermakesiteasyto maneuver through doorways and into the boiler room. In addition to being shipped as loose sections, the boiler is available with factory-assembled sections or as a completely packaged and fire-tested unit. V11boilersectionshavereinforcedlugsthatareused to assemble the sections with individual draw rods resulting in fast, strain-free assembly. American-Made Cast Iron ConstructionÐ BC25-HSi Burnham CommercialÕ s unique BC25-HSicastironformulahas an extremely high silicon content, making it stronger and more flexible than the iron used in competitor's boiler sections. It offers better thermal shock resistance and greater heat transfer capabilities than other cast iron products. BC25-HSi'spropertiesallowBurnhamCommercialto maintain the highest level of quality from start to finish, and provide a product that is optimized for hydronic heating applications. The sections can be assembled using two common toolsÑ a 3/4" drive ratchet with a 1-1/16" deep socket and wrench. The sections are surface ground to ensure smooth surface mating. An elastic sealant and fiberglass rope are used on all section joints for a completely sealed and pressure-tight assembly. • extensive Testing Methods Each boiler section is hydrostatically tested at 2-1/2 times theratedworkingpressureatthefoundry.Factory- assembled sections are tested a second time at 1.5 times the rated working pressure. • Manufactured with Quality Cast iron sections are produced at BurnhamFoundryLLCinOhio, ensuring quality and availability of boiler sections. • Rear or Top Venting Asaforceddraftboiler,theV11 provides optimum draft for controlled efficiency, eliminating the need for high chimneys or induced draft fans. AuniquefeatureoftheV11boiler is that it can be vented from the rear or the top. This enables easy chimney or sidewall venting for maximum installation flexibility. Top outlet venting saves floor space and reduces installation time and materials. A plugged tapping is provided to take flue outlet pressure readings. • Cast Iron nipple Difference V11sectionsareheldtogether using cast iron nipples, which are well known as being of the highest standard for boiler construction. Unlike gaskets used by many other boiler manufacturers, cast iron nipples are impervious to flue gases, oils, petroleum-based chemicals and other contaminants, which means fewer costly repairs and a longer lasting boiler. 2 Commitment to Quality Burnham Commercial, "America's Boiler Company," has earned a reputation for quality and dependability. Built for a variety of applications,theV11Seriesisrightforyournextjob. Top or Rear Outlet with adjustable lock-type damper (not shown); includes plugged tapping for outlet pressure readings Front Mounted Controls for easy adjustment and maintenance Aluminized Steel Canopy Burner Mounting plate with flame observation port Cast Iron nipples ensure the integrity of the section assembly and resist petroleum based chemicals and flue gases Removable Side Jacket panels Easy access to all cleanouts and flue surfaces Cast Iron Sections Verticalfluedesignwith pinned heating surface for maximum heat extraction 4 Burner Manufacturers Rear Observation port Optionstobest fit your needs Includes plugged tapping for over-fire draft readings Individual Draw Rods Wet Base with reinforced lugs for strain free assembly Side wall insulation creates improved thermal circulation Optional Tankless Heater Providesdomestichotwater Also AvailableÉ SBC TM Integrated Boiler Control System Burnham CommercialÕ s SBC is a complete boiler monitoring and automation system. Available as an option, this exclusive feature wasdesignedanddevelopedbyBurnhamCommercial’sengineersandisavailableONLY on Burnham Commercial products. SBC Exclusives Designedtomaximizesystemefficiency and minimize energy usage Easily connected to building management systems Provencontrolplatform,usedsuccessfully for years at other Burnham companies Fail-safedesigninsuresboileroperation • AdvancedAdaptability • Peer-To-PeerNetwork •Fail-Safe System Operations • BoilerMonitoring&DiagnosticDisplays • ModulationRateandOn/OffModes • Outdoor Air Temperature Reset • Warm Weather Shutdown (WWSD) • Domestic Hot Water Priority (DHWP) • System Control Outputs 3 The SBC Boiler Control SystemÉ Only available from Burnham Commercial! V11 Series Dimensions BURneR DIMenSIOn - 'M' * BOILeR MODeL V1104 V1105 V1106 V1107 V1108 V1109 V1110 V1111 V1112 V1113 V1114 V1115 V1116 V1117 V1118 V1119 V1120 V1121 V1122 V1123 nUMBeR OF SeCTIOnS 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 BeCKeTT 'A' 26-5/8 32-3/4 38-7/8 45 51-1/8 57-1/4 63-3/8 69-1/2 75-5/8 81-3/4 87-7/8 94 100-1/8 106-1/4 112-3/8 118-1/2 124-5/8 130-3/4 136-7/8 143 'B' 18-7/8 25 31-1/8 37-1/4 43-3/8 49-1/2 55-5/8 61-3/4 67-7/8 74 80-1/8 86-1/4 92-3/8 98-1/2 104-5/8 110-3/4 116-7/8 123 129-1/8 135-1/4 'C' Ñ Ñ 31-1/8 37-1/4 43-3/8 49-1/2 24-3/4 37 37 37 24-3/4 24-3/4 30-7/8 30-7/8 30-7/8 30-7/8 30-7/8 30-7/8 30-7/8 30-7/8 'D' Ñ Ñ Ñ Ñ Ñ Ñ 30-7/8 24-3/4 30-7/8 37 24-1/2 24-1/2 36-3/4 36-3/4 24-1/2 24-1/2 24-1/2 24-1/2 24-1/2 24-1/2 'e' Ñ Ñ Ñ Ñ Ñ Ñ Ñ Ñ Ñ Ñ 30-7/8 37 24-3/4 30-7/8 24-1/2 24-1/2 36-3/4 36-3/4 24-1/2 24-1/2 'F' Ñ Ñ Ñ Ñ Ñ Ñ Ñ Ñ Ñ Ñ Ñ Ñ Ñ Ñ 24-3/4 30-7/8 24-3/4 30-7/8 24-1/2 24-1/2 'G' 'H' Ñ 13-13/16 Ñ 19-15/16 Ñ 26-1/16 Ñ 32-3/16 Ñ 38-5/16 Ñ 44-7/16 Ñ 50-9/16 Ñ 56-11/16 Ñ 56-5/8 Ñ 53-5/16 Ñ 53-5/16 Ñ 53-5/16 Ñ 53-5/16 Ñ 53-5/16 Ñ 53-5/16 Ñ 53-5/16 Ñ 53-5/16 Ñ 53-5/16 24-3/4 53-5/16 30-7/8 53-5/16 'J' 55 55 55 54 54 54 53 53 53 53 52 52 52 52 51 51 51 51 50 50 all dimensions in inches * Burnercontrolpanelconfigurationmaychangethisdimension FRONT OBSERVATION PORT 4 'K' 8 8 8 10 10 10 12 12 12 12 14 14 14 14 16 16 16 16 18 18 'L' 1 2 2 3 3 4 4 4 5 5 5 6 6 6 7 7 8 8 9 9 CF 24-3/4 24-3/4 24-3/4 24-1/4 24-1/4 24-1/4 24-1/4 24-1/4 25-3/4 25-3/4 27 27 26 Ñ Ñ Ñ Ñ Ñ Ñ Ñ CG 21-3/4 21-3/4 28-3/4 29-1/4 29-1/4 29-1/4 29-1/4 29-5/8 29-5/8 29-5/8 29-5/8 29-5/8 29-5/8 29-5/8 29-5/8 29-5/8 Ñ Ñ Ñ Ñ pOWeRFLAMe WeBSTeR CARLIn Ñ 19-3/4 19-3/4 20-1/2 20-1/2 20-1/2 25-5/8 25-5/8 25-5/8 26-1/8 26-1/8 26-1/8 26-1/8 26-1/8 Ñ Ñ Ñ Ñ Ñ Ñ CR 30 30 35 35 35 35 35 40 40 40 40 40 40 40 40 40 40 40 46 46 JR** 20-1/4 20-1/4 23-3/4 23-3/4 23-3/4 Ñ Ñ Ñ Ñ Ñ Ñ Ñ Ñ Ñ Ñ Ñ Ñ Ñ Ñ Ñ JB 25 25 25 25 25 25 25 29 29 29 29 29 29 29 29 29 29 29 29 29 AppROX. WeIGHT OF SeCTIOn (Assembly Only) 1833 2226 2618 3010 3403 3795 4188 4580 4972 5365 5757 6150 6542 6934 7327 7719 8112 8504 8896 9289 V11 Series Piping Recommendations Water Boiler pipe Sizing and notes nOTeS: 1. Allpipingisschedule40. 2. Pipesizelistedarebasedona20°For40°F differential (temperature drop). Select one to match application. 3. Whenspecifiedreturnpipingsizeislessthan3", install 3" x 12" nipple and appropriate size bell reducer directly into boiler return tapping as shown. 4. Drainvalve-ballvalvepreferable,gatevalveacceptable alternative (supplied by others). MinimumvalvesizeperASMEcodeis3/4"NPT. 5. Swing joints on two riser systems may be piped over the top of the boiler if space is limited. 6. Boilers require protection from flue gas condensation and thermal shockwhenoperatingbelow135°Freturnwatertemperatures BOILeR MODeL V1104 V1105 V1106 V1107 V1108 V1109 V1110 V1111 V1112 V1113 V1114 V1115 V1116 V1117 V1118 V1119 V1120 V1121 V1122 V1123 SUppLy pIpInG SIZe In InCHeS (1B) (1A) SUppLy RISeR SUppLy (1) (QTy.) SIZe HeADeR SUppLy 20¡ F 40¡ F 20¡ F 40¡ F 20¡ F 40¡ F DROp DROp DROp DROp DROp DROp Ñ Ñ Ñ Ñ 2 2-1/2 Ñ Ñ Ñ Ñ 2 2-1/2 Ñ Ñ Ñ Ñ 2 2-1/2 Ñ Ñ Ñ Ñ 2 3 Ñ Ñ Ñ Ñ 2 3 Ñ Ñ Ñ Ñ 2-1/2 4 Ñ Ñ Ñ Ñ 2-1/2 4 Ñ Ñ Ñ Ñ 2-1/2 4 Ñ Ñ Ñ Ñ 3 4 Ñ Ñ Ñ Ñ 3 4 Ñ Ñ Ñ Ñ 3 4 Ñ Ñ Ñ Ñ 3 4 Ñ (2) 3 Ñ 3 3 5 Ñ (2) 3 Ñ 3 3 5 Ñ (2) 4 Ñ 4 4 5 Ñ (2) 4 Ñ 4 4 5 Ñ (2) 4 Ñ 4 4 5 Ñ (2) 4 Ñ 4 4 5 Ñ (2) 4 Ñ 4 4 5 Ñ (2) 4 Ñ 4 4 5 5 ReTURn pIpInG SIZe In InCHeS (2B) (2A) ReTURn BRAnCH ReTURn (2) (QTy.) SIZe HeADeR ReTURn 20¡ F 40¡ F 20¡ F 40¡ F 20¡ F 40¡ F DROp DROp DROp DROp DROp DROp Ñ Ñ Ñ Ñ 2 2-1/2 Ñ Ñ Ñ Ñ 2 2-1/2 Ñ Ñ Ñ Ñ 2 2-1/2 Ñ Ñ Ñ Ñ 2 3 Ñ Ñ Ñ Ñ 2 3 Ñ (2) 3 Ñ 3 2-1/2 4 Ñ (2) 3 Ñ 3 2-1/2 4 Ñ (2) 3 Ñ 3 2-1/2 4 Ñ (2) 3 Ñ 3 3 4 Ñ (2) 3 Ñ 3 3 4 Ñ (2) 3 Ñ 3 3 4 Ñ (2) 3 Ñ 3 3 4 Ñ (2) 3 Ñ 3 3 5 Ñ (2) 3 Ñ 3 3 5 (2) 3 (3) 3 3 4 4 5 (2) 3 (3) 3 3 4 4 5 (2) 3 (3) 3 3 4 4 5 (2) 3 (3) 3 3 5 4 5 (2) 3 (3) 3 3 5 4 5 (2) 3 (3) 3 3 5 4 5 V11 Series Piping Recommendations Steam Boiler pIpInG SIZe In InCHeS (1) RISeR (2) (3) (4) BOILeR MODeL (QTy.) SIZe ReTURn HeADeR eQUALIZeR 2-1/2 4 2 (1) 4 V1104 2-1/2 4 2 (1) 4 V1105 2-1/2 6 2-1/2 (2) 4 V1106 2-1/2 6 2-1/2 (2) 4 V1107 2-1/2 6 2-1/2 (2) 4 V1108 2-1/2 6 2-1/2 (2) 4 V1109 2-1/2 6 2-1/2 (3) 4 V1110 4 8 3 (3) 4 V1111 4 8 3 (3) 4 V1112 4 8 3 (3) 4 V1113 4 8 3 (4) 4 V1114 4 8 3 (4) 4 V1115 4 8 3 (4) 4 V1116 4 8 3 (4) 4 V1117 4 8 3 (5) 4 V1118 4 10 3 (5) 4 V1119 4 10 3 (5) 4 V1120 4 10 3 (5) 4 V1121 4 10 3 (6) 4 V1122 4 10 3 (6) 4 V1123 RISeR SpACInG In InCHeS ÔAÕ Ñ Ñ 31-1/8 37-1/4 43-3/8 49-1/2 24-3/4 37 37 37 24-3/4 24-3/4 30-7/8 30-7/8 30-7/8 30-7/8 30-7/8 30-7/8 30-7/8 30-7/8 ÔBÕ Ñ Ñ Ñ Ñ Ñ Ñ 30-7/8 24-3/4 30-7/8 37 24-1/2 24-1/2 36-3/4 36-3/4 24-1/2 24-1/2 24-1/2 24-1/2 24-1/2 24-1/2 ÔCÕ Ñ Ñ Ñ Ñ Ñ Ñ Ñ Ñ Ñ Ñ 30-7/8 37 24-3/4 30-7/8 24-1/2 24-1/2 36-3/4 36-3/4 24-1/2 24-1/2 ÔD Õ Ô eÕ Ñ Ñ Ñ Ñ Ñ Ñ Ñ Ñ Ñ Ñ Ñ Ñ Ñ Ñ Ñ Ñ Ñ Ñ Ñ Ñ Ñ Ñ Ñ Ñ Ñ Ñ Ñ Ñ Ñ 24-3/4 Ñ 30-7/8 Ñ 24-3/4 Ñ 30-7/8 24-1/2 24-3/4 24-1/2 30-7/8 nOTeS: 1. Allpipingisschedule40. 2. To prevent condensate from being trapped in header, do not reduce equalizer elbow at header connection. 3. Drain/blowoffvalve—ballvalvepreferable,gatevalveacceptable alternative (supplied by others). -MinimumvalvesizeperASMEcodeis1"NPT(V1104-1106),1-1/4" NPT(V1107-1112),1-1/2"NPT(V1113-1123). - Increasing the valve size will improve the blowdown operation - In all cases, piping connecting blowoff valve to boiler shall be full size to the point of discharge. 4. Headerpipingmayberunoverthetopofboilerifspacedoesnot allow for piping arrangement shown. However,increasedservicerequirementswillresult. 5. Supply from boiler header must be connected between the first boiler riserandtheheaderdrip(orhartfordloop).Donotconnectsupply between risers or opposite end of boiler header. 6. Forpumpedreturnsystems,seeV11installationmanual. 'A' 'B' 'A' V1106 THRU V1109 V1104 AND V1105 V1 110 THRU V1113 'A' 18" MIN. 'A' 'A' 'B' 'B' 'C' 'C' 'B' 'C' 'D' 'D' 24" MIN. 'E' 1 RISER 3 HEADER 4 EQUALIZER CLOSE NIPPLE V1114 THRU V1117 V1118 THRU V1121 6 WATER LINE 2" TO 4" REAR OF BOILER HARTFORD LOOP (REQ'D ON GRAVITY RETURN SYSTEM) SUPPLY (SEE NOTE 5) 2 RETURN V1122 AND V1123 5 BLOWOFF/DRAIN VALVE (SEE NOTE 3) V11 Series Burner Schedule OIL BURneRS BeCKeTT CARLIn pOWeR FLAMe WeBSTeR BOILeR nUMBeR BURneR MODeL H.p. BURneR MODeL H.p. BURneR MODeL H.p. BURneR MODeL H.p. V1104 CF1400 1/2 Ñ Ñ CR1-OS 1/2 JB1O-03 1/3 V1105 CF1400 1/2 702CRD 1/2 CR1-OS 1/2 JB1O-03 1/3 V1106 CF1400 1/2 702CRD 1/2 CR2-OAS 3/4 JB1O-03 1/3 V1107 CF2300 3/4 801CRD 3/4 CR2-OAS 3/4 JB1O-05 1/2 V1108 CF2300 3/4 801CRD 3/4 CR2-OAS 3/4 JB1O-05 1/2 V1109 CF2300 3/4 801CRD 3/4 CR2-OAS 3/4 JB1O-07 3/4 V1110 CF2300 3/4 1050FFD 1 CR2-OAS 1-1/2 JB1O-07 3/4 V1111 CF2300 3/4 1050FFD 1 CR3-O 2 JB2O-10 1 V1112 CF2500 2 1050FFD 1-1/2 CR3-O 2 JB2O-10 1 V1113 CF2500 2 1050FFD 1-1/2 CR3-O 2 JB2O-10 1 V1114 CF3500 2 1150FFD 1-1/2 CR3-O 2 JB2O-10 1 V1115 CF3500 2 1150FFD 1-1/2 CR3-O 2 JB2O-10 1 V1116 CF3500 2 1150FFD 1-1/2 CR3-O 3 JB2O-15 1-1/2 V1117 Ñ Ñ 1150FFD 1-1/2 CR3-O 3 JB2O-30 3 V1118 Ñ Ñ Ñ Ñ CR3-OB 3 JB2O-30 3 V1119 Ñ Ñ Ñ Ñ CR3-OB 3 JB2O-30 3 V1120 Ñ Ñ Ñ Ñ CR3-OB 3 JB2O-30 3 V1121 Ñ Ñ Ñ Ñ CR3-OB 3 JB2O-50 5 V1122 Ñ Ñ Ñ Ñ CR4-OA 5 JB2O-50 5 V1123 Ñ Ñ Ñ Ñ CR4-OA 5 JB2O-50 5 STANDARD BURNER MOTOR VOLTAGE: Beckett–CF1400,andCF2300are120/60/1.CF2500andCF3500are240/60/3.Carlin–Allsizes240/60/1.power Flame–CR1-OSis 120/60/1.CR2-OASis240/60/1.Allothersare240/60/3.Webster–JB10-03,JB10-05andJB10-07are120/60/1.JB20-10is240/60/1.Allothersare240/60/3. GAS BURneRS* BeCKeTT pOWeR FLAMe - 'CR'= pOWeR FLAMe - 'JR'= WeBSTeR BOILeR BURneR MIn. GAS BURneR BURneR BURneR MIn. GAS nUMBeR MODeL H.p. pReSS. (In.) MODeL H.p. MODeL H.p. MODeL H.p. pReSS. (In.) V1104 CG10.6S 1/3 4.6 CR1-G-12 1/3 JR30A-10 1/3 JB1G-03 1/3 6 V1105 CG10.6S 1/3 6.6 CR1-G-12 1/2 JR30A-12 1/3 JB1G-03 1/3 4 V1106 CG15.4S 1/2 6.2 CR2-G-15 1/2 JR50A-15 1/3 JB1G-03 1/3 6 V1107 CG25.2S 3/4 5.2 CR2-G-15 1/2 JR50A-15 1/2 JB1G-05 1/2 5 V1108 CG25.3S 3/4 5.0 CR2-G-15 1/2 JR50A-15 1/2 JB1G-05 1/2 5 V1109 CG25.4S 3/4 5.2 CR2-G-15 1/2 Ñ Ñ JB1G-07 3/4 8 V1110 CG25.5S 3/4 5.2 CR2-G-20A 1 Ñ Ñ JB1G-07 3/4 8 V1111 CG50.2S 2 5.7 CR3-G-20 1-1/2 Ñ Ñ JB2G-10 1 8 V1112 CG50.3S 2 4.3 CR3-G-20 1-1/2 Ñ Ñ JB2G-10 1 6 V1113 CG50.3S 2 5.7 CR3-G-20 1-1/2 Ñ Ñ JB2G-10 1 7 V1114 CG50.4S 2 5.7 CR3-G-20 1-1/2 Ñ Ñ JB2G-15 1-1/2 8 V1115 CG50.5S 2 5.0 CR3-G-20 1-1/2 Ñ Ñ JB2G-30 3 8 V1116 CG50.5S 2 5.3 CR3-G-25 3 Ñ Ñ JB2G-30 3 8 V1117 CG50.5S 2 6.1 CR3-G-25 3 Ñ Ñ JB2G-30 3 9 V1118 CG50.5S 2 6.9 CR3-G-25B 3 Ñ Ñ JB2G-30 3 10 V1119 CG50.5S 2 7.3 CR3-G-25B 3 Ñ Ñ JB2G-30 3 11 V1120 Ñ Ñ Ñ CR3-G-25B 3 Ñ Ñ JB2G-30 3 12 V1121 Ñ Ñ Ñ CR3-G-25B 3 Ñ Ñ JB2G-50 5 14 V1122 Ñ Ñ Ñ CR4-G-25 3 Ñ Ñ JB2G-50 5 15 V1123 Ñ Ñ Ñ CR4-G-25 3 Ñ Ñ JB2G-50 5 16 STANDARD BURNER MOTOR VOLTAGE: power Flame C Series–CR1-G-12andCR2-G-15are120/60/1.CR2-G-20Ais240/60/1.Allothersare240/60/3.power Flame JR Series –Allburnersare120/60/1.Webster–JB1G-03,JB1G-05andJB1G-07are120/60/1.JB2G-10is240/60/1.Allothersare240/60/3. *Forinletgasconnectionsize,seeGas/OilBurnerChart=Forminimumgaspressurerequirements,seeGas/OilBurnerChart. GAS/OIL BURneRS pOWeR FLAMe - 'CR' SeRIeS WeBSTeR BOILeR BURneR InLeT GAS MIn. GAS BURneR InLeT GAS MIn. GAS nUMBeR MODeL H.p. COnneCTIOn (In.) pReSS. (In.) MODeL H.p. COnneCTIOn (In.) pReSS. (In.) V1104 CR1-GO-12 1/2 1 4.7 JB1C-03 1/3 1 7.0 V1105 CR1-GO-12 1/2 1 4.8 JB1C-03 1/3 1-1/4 4.9 V1106 CR2-GO-15 3/4 1 5.4 JB1C-03 1/3 1-1/4 7.0 V1107 CR2-GO-15 3/4 1 6.4 JB1C-05 1/2 1-1/4 6.2 V1108 CR2-GO-15 3/4 1 7.5 JB1C-05 1/2 1-1/2 6.9 V1109 CR2-GO-15 3/4 1-1/4 6.4 JB1C-07 3/4 1-1/2 7.0 V1110 CR2-GO-20A 1-1/2 1-1/4 5.8 JB1C-07 3/4 1-1/2 7.0 V1111 CR3-GO-20 2 2 5.8 JB2C-10 1 2 6.3 V1112 CR3-GO-20 2 1-1/2 6.0 JB2C-10 1 2 5.6 V1113 CR3-GO-20 2 1-1/2 6.8 JB2C-10 1 2 6.3 V1114 CR3-GO-20 2 1-1/2 7.4 JB2C-10 1 2 7.0 V1115 CR3-GO-20 2 1-1/2 7.3 JB2C-10 1 2 6.8 V1116 CR3-GO-25 3 2 6.6 JB2C-15 1-1/2 2 7.0 V1117 CR3-GO-25 3 2 7.1 JB2C-30 3 2 7.3 V1118 CR3-GO-25B 3 2 7.7 JB2C-30 3 2-1/2 8.1 V1119 CR3-GO-25B 3 2-1/2 6.5 JB2C-30 3 2-1/2 9.2 V1120 CR3-GO-25B 3 2-1/2 7.0 JB2C-30 3 2-1/2 10.0 V1121 CR3-GO-25B 3 2-1/2 7.0 JB2C-50 5 2-1/2 11.0 V1122 CR4-GO-25 5 2-1/2 6.3 JB2C-50 5 2-1/2 12.4 V1123 CR4-GO-25 5 2-1/2 6.9 JB2C-50 5 2-1/2 13.1 STANDARD BURNER MOTOR VOLTAGE: power Flame-CR1-GO-12is120/60/1.CR-2-GO-15andCR2-GO-20Aare240/60/1.Allothersare240/60/3.Webster–JB1C-03,JB1C05,JB1C-07are120/60/1.JB2C-10is240/60/1.Allothersare240/60/3. **Forminimumgaspressurerequirements,seeGasBurnerChart.NOTES:1.TheminimumgaspressuresshownareforstandardULburnerswiththestandardfiringsequence.IRI,FM andCSD-1requirementsmayresultindifferentpressuresandprices. 7 Specifications V11 RATInGS BOILeR MODeL (1) V1104 V1105 V1106 V1107 V1108 V1109 V1110 V1111 V1112 V1113 V1114 V1115 V1116 V1117 V1118 V1119 V1120 V1121 V1122 V1123 GROSS OUTpUT MBH BOILeR (2) H.p. 667 19.9 857 25.6 1069 31.9 1281 38.3 1517 45.3 1729 51.7 1941 58.0 2154 64.3 2334 69.7 2503 74.8 2730 81.6 2957 88.3 3129 93.4 3353 100.2 3580 106.9 3739 111.7 3957 118.2 4174 124.7 4334 129.5 4551 136.0 I=B=R neT RATInG (3) STeAM MBH 500 643 802 963 1159 1335 1507 1672 1812 1943 2120 2296 2427 2603 2780 2903 3072 3241 3365 3533 SQ. FT. 2083 2679 3342 4013 4829 5563 6279 6967 7550 8096 8833 9567 10113 10846 11583 12096 12800 13504 14021 14721 WATeR MBH 580 745 930 1114 1319 1503 1688 1873 2030 2177 2374 2571 2718 2916 3113 3251 3441 3630 3769 3957 BURneR InpUT OIL GpH (4) 5.8 7.4 9.2 11.0 13.0 14.8 16.6 18.4 20.0 21.5 23.5 25.5 27.0 29.0 31.0 32.5 34.5 36.5 38.0 40.0 GAS MBH 837 1068 1328 1588 1876 2136 2396 2656 2887 3103 3392 3680 3897 4186 4474 4691 4979 5268 5485 5733 neT FIReBOX VOLUMe (In. WTR. COLUMn) 7.9 10.6 13.2 15.9 18.5 21.1 23.8 26.5 29.1 31.8 34.4 37.1 39.7 42.4 45.0 47.7 50.3 53.0 55.6 58.3 pReSSURe In FIReBOX (In. WTR. COLUMn) .35 .36 .37 .42 .42 .39 .42 .40 .42 .40 .38 .36 .38 .41 .39 .38 .38 .40 .41 .43 I=B=R VenT DIA. (In.) 8 8 8 10 10 10 12 12 12 12 14 14 14 14 16 16 16 16 18 18 AppROX. SHIppInG AnD LIFTInG WeIGHT (LBS.) 2105 2510 2920 3325 3733 4147 4557 4964 5374 5771 6184 6601 7008 7417 7823 8231 8638 9053 9456 9865 1. Suffix“S”indicatessteamboiler,“W”indicateswaterboiler.Suffix“G”indicatesgas-fired,“O”indicatesoilfiredand“GO”indicatescombination gas/oil fired. 2. Boilerratingsarebasedon13%CO2onoil;10.0%CO2ongas,and+.10in.watercolumnpressureatboilerflueoutlet. 3. I=B=Rnetratingsshownarebasedonpipingandpickupallowanceswhichvaryfrom1.333to1.288forsteamand1.15forwater.Consult manufacturer for installations having unusual piping and pick up requirements, such as intermittent system operation, extensive piping systems, etc. 4. TheI=B=RburnercapacityinGPHisbasedonoilhavingaheatvalueof140,000BTUpergallon. Ratingsshownaboveapplytoaltitudesupto1000feetforoiland2000feetforgas.Foraltitudesabovethoseindicated,theratingsshouldbereduced attherateof4%foreach1000feetabovesealevel. nOTe: Maximumallowableworkingpressure(MAWP): Steam: 15PSI Water–USA: 80PSI(Standardreliefvalveprovidedis50PSI)(80PSI/30PSIOptional) Water–Canada: 50PSI(Standardreliefvalveprovidedis50PSI)(30PSIOptional) STAnDARD eQUIpMenT ALL BOILeRS:Sectionsunassembled,flushinsulatedjacket,burnermountingplate,rearobservationportcover,firewallplates,targetwall(V1104-1106 only), rear flue outlet damper (top outlet optional), flue canopy, trim, and miscellaneous plugs, bushing and fittings STeAM TRIM:15PSIsafetyvalve,L404Fpressuretrol,gaugeglassassembly,steamgauge WATeR TRIM:50PSIsafetyreliefvalve,L4006Ahighlimit,pressuretemperaturegauge OIL BOILeRS:Flangemountedflameretentionoilburnerfurnishedwith2stagefuelunit,primarycontrolanddualoilvalves GAS BOILeRS:FlangemountedgasburnerwithstandardcontrolsmeetingthelatestULrequirements,dualgasvalves,gas-electricignitionwithproven gaspilot,flamerodonJRburner,ultravioletflamedetectoronothers,electronicprogrammingcontrolsandcomponentsarefactorywiredinaburner mountedcontrolpanel(exceptJR-panelavailableasanoption) GAS/OIL BURneRS:Flangemountedcombinationgas/oilburnerwithstandardcontrolsmeetinglatestULrequirements,manuallyoperatedfueltransfer switch for dual fuel changeover, dual gas valves and oil valves, electric ignition with proven gas pilot on both fuels (direct spark ignition of oil is optional), ultra-violet flame detector, electronic programming controls and components are factory wired in a burner mounted control panel OpTIOnAL eQUIpMenT Assembled sections; completely packaged (includes manual reset high limit and manual reset low water cutoff); packaged and fire-tested; top outlet flue damper;tanklessheaters;sideinspectiontappingswithbrassplugs;pressurereliefdoor;30PSIand80PSIsafetyreliefvalves;combustionandhydronic controlstomeetspecialapplicationsincludingF.M.,I.R.I.,andASMECSD-1. BurnhamCommercial-Lancaster,PA Phone:-888-791-3790 www.burnhamcommercial.com 8