Download Velleman K3511 Specifications

Transcript

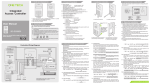

Remote controlled car alarm Total solder points: 88 + 68 + 367 Difficulty level: beginner 1 2 3 4 5 ⌧ advanced K3511 ILLUSTRATED ASSEMBLY MANUAL H3511IP-2 Features & specifications Features : Microprocessor technology. Multi-functional remote control operation. Audio and visual on/off indicators. Multifunction dashboard mounted LED. Automatic reset after alarm. Adjustable voltage drop (reaction to interior lighting). Voltage drop detection active immediately, or after 5 minutes. Direct alarm trigger input (direct alarm after triggering). Warning alarm trigger input (2 triggers within 15 seconds = alarm). Warning input can be switched off with the remote control. Adjustable shock detector (can be switched off with the remote control). Detector input for ventilator in order to avoid false alarms. Contact switches for bonnet and boot. Internal siren for on/off signal and alarm. Output for external siren and pager (5A). Alarm time: 30 seconds. Starter interrupter for ignition or diesel fuel pump (15A). Special starter motor interrupter relay (30A) supplied. Switch on protection if contact is on. Output to hazard lights (2 x 6A max.). Output for central locking (100mA). Selectable code for remote control transmitter and receiver (8.748 codes). An unlimited number of remote control transmitters can be used (K6706B or K6706G). Automatically resets in the event of accidental switch off (60 seconds). Connection for extra starter interrupter via security code lock module (SP150). Diagnosis facility to identify a triggered sensor at a later time. Specifications • • • • 2 Supply voltage: 12VDC. Consumption: 50mA in standby. Temperature range: -40 to +85°C. Battery for remote control unit: 12V type V23GA, V23A (not incl.). Assembly hints 1. Assembly (Skipping this can lead to troubles ! ) Ok, so we have your attention. These hints will help you to make this project successful. Read them carefully. 1.1 Make sure you have the right tools: • A good quality soldering iron (25-40W) with a small tip. • Wipe it often on a wet sponge or cloth, to keep it clean; then apply solder to the tip, to give it a wet look. This is called ‘thinning’ and will protect the tip, and enables you to make good connections. When solder rolls off the tip, it needs cleaning. • Thin raisin-core solder. Do not use any flux or grease. • A diagonal cutter to trim excess wires. To avoid injury when cutting excess leads, hold the lead so they cannot fly towards the eyes. • Needle nose pliers, for bending leads, or to hold components in place. • Small blade and Phillips screwdrivers. A basic range is fine. For some projects, a basic multi-meter is required, or might be handy 0.0 0 0 1.2 Assembly Hints : ⇒ Make sure the skill level matches your experience, to avoid disappointments. ⇒ Follow the instructions carefully. Read and understand the entire step before you perform each operation. ⇒ Perform the assembly in the correct order as stated in this manual ⇒ Position all parts on the PCB (Printed Circuit Board) as shown on the drawings. ⇒ Values on the circuit diagram are subject to changes. ⇒ Values in this assembly guide are correct* ⇒ Use the check-boxes to mark your progress. ⇒ Please read the included information on safety and customer service * Typographical inaccuracies excluded. Always look for possible last minute manual updates, indicated as ‘NOTE’ on a separate leaflet. 3 Assembly hints 1.3 Soldering Hints : 1- Mount the component against the PCB surface and carefully solder the leads 2- Make sure the solder joints are cone-shaped and shiny 3- Trim excess leads as close as possible to the solder joint REMOVE THEM FROM THE TAPE ONE AT A TIME ! AXIAL COMPONENTS ARE TAPED IN THE CORRECT MOUNTING SEQUENCE ! Velleman hereby certifies that the device K3511 meets the essential requirements and all other relevant stipulations of directive 1999/5/ EG and 1995/5/EC. For the complete conformity declaration check out : http://www.velleman.be/downloads/DoC/CE_K3511.pdf 4 Construction IMPORTANT The car alarm consist of three PCB’s, 1 for the remote control transmitter, 1 for the receiver and 1 for the main PCB. The receiver PCB is fitted to the main PCB. Tip: The pictures on the packaging can be used as a guideline. However, due to possible changes it is not 100% reliable. (A) Construction of the P6706 remote control transmitter Before mounting the components to the PCB it must first be checked that the PCB fits in the housing. Be careful of the small notch next to LD1. Should it not fit the edge of the PCB can be sanded down with fine sandpaper. 1. Jumperwire 4. Resistors (check the color code) J R... 2. Diodes (Check the polarity) D... R1: 100K R2: 100K R3: 33K R4: 100 R5: 1K (1 - 0 - 4 - B) (1 - 0 - 4 - B) (3 - 3 - 3 - B) (1 - 0 - 1 - B) (1 - 0 - 2 - B) CATHODE 5. Axial coil D1 : BAT85 D2 : BAT85 L2 L... 3. Zener diode. Check the polarity! ZD... ZD1 : 6V8 CATHODE L2 : 10µH (1-0-0-A) 6. Push button SW1 SW2 5 Construction 7. Capacitive trimmer 12. LED (Check the polarity) CV : 1,5 - 5pF CV... 8. IC socket (Watch the position of the notch) + - IC1 : 18p 1 IC... 13. IC (Watch the position of the notch !) 9. Capacitors C1 : 2pF (2,2) C2 : 2pF (2,2) C3 : 330pF (331) C... IC1 : UM3758 - 120A 14. Sticker 10. Transistor Affix the supplied sticker to the housing. T1 : BF199 Velleman 433,92 MHz 7mm SRFCE 11. LED (Check the polarity) LD1 : 3mm RED 6 11mm Construction 15. Create your code The code can be set for a transmitter/receiver combination. There is a row of 9 coding islands for setting the code. The closest is near the IC legs. The code can be set by connecting one or more of these coding islands to a neighbouring island or a neighbouring + island using a jumper, or by not connecting them at all (leaving open). No connection Code connection to ‘-’ Code connection to ‘+’ Example of a possible code Note: certain points cannot be connected to ‘+’ 16. Final assembly Place the PCB in its housing, check for the position of the battery lips. The cover may only be fitted after mounting and adjustment. Place the 12V battery (type V23GA) in the housing (check the polarity). 7 Construction (B) Construction of the remote control receiver P3511R 1. Zener diode (Check the polarity) 4. IC socket. Watch the position of the notch. ZD... ZD1 : 4V3 ZD2 : 5V1 ZD3 : 5V1 IC1 : 8p IC... 2. Resistors (check the color code) 5. Capacitors C1 : 2pF (2,2) C2 : 2pF (2,2) C3 : 22pF C4 : 82pF C5 : 330pF (331) C6 : 330pF (331) C7 : 1µF (105 - 1µ) R... R1 : 270 R2 : 2K2 R3 : 18K R4 : 18K R5 : 33K R6 : 5K6 R7 : 2K7 R8 : 6K8 R9 : 6M8 R10 : 1K R11 : 1K R12 : 1K R13 : 4K7 1 CATHODE (2 - 7 - 1 - B) (2 - 2 - 2 - B) (1 - 8 - 3 - B) (1 - 8 - 3 - B) (3 - 3 - 3 - B) (5 - 6 - 2 - B) (2 - 7 - 2 - B) (6 - 8 - 2 - B) (6 - 8 - 5 - B) (1 - 0 - 2 - B) (1 - 0 - 2 - B) (1 - 0 - 2 - B) (4 - 7 - 2 - B) C... 6. Transistor T1 : BF199 7mm 7. Pin contacts 3. Axial coil Rx : 3p (+9V) L2 L... L1 : 1µH (1 - 0 - B - A) cut 8 18mm Construction 8. Capacitive trimmer Solder side CV... Fig.8 CV1 : 5pF 9. LED (Check the polarity) 8mm SOLDER SIDE LD1 : 3mm RED 10. IC (Watch the position of the notch !) IC1 : RV4558, LM258, LM2904 9 Construction (C) Construction of the main PCB 3511 1. Jumperwire J 2. Diodes (Check the polarity) D... CATHODE D1 D2 D3 D4 D5 D6 D7 D8 D9 D10 D11 D12 : 1N4148 : 1N4148 : 1N4148 : 1N4148 : 1N4148 : 1N4148 : 1N4000 … 1N4007 : 1N4000 … 1N4007 : 1N4000 … 1N4007 : 1N4000 … 1N4007 : 1N4000 … 1N4007 : 1N4000 … 1N4007 3. Zener diode. Check the polarity! ZD1 : 2V4 ZD2 : 5V1 ZD3 : 18V ZD4 : 18V ZD5 : 18V ZD... CATHODE 4. Resistors (check the color code) R... R1 : 100K (1 - 0 - 0 - 3 - 1) R2 : 100K (1 - 0 - 0 - 3 - 1) R3 : 100K (1 - 0 - 0 - 3 - 1) 10 R4 : 100K R5 : 10 R6 : 220 R7 : 4K7 R8 : 4K7 R9 : 4K7 R10 : 4K7 R11 : 1K R12 : 1K R13 : 1K R14 : 1K R15 : 1K R16 : 1K R17 : 1K R18 : 1K R19 : 1K R20 : 47K R21 : 47K R22 : 47K R23 : 47K R24 : 47K R25 : 47K R26 : 47K R27 : 47K R28 : 47K R29 : 10K R30 : 10K R31 : 10K R32 : 10K R33 : 10K R34 : 10K R35 : 10K R36 : 10K R37 : 10K R38 : 10K R39 : 10K R40 : 10K R41 : 10K R42 : 10K R43 : 10K R44 : 10K R45 : 100K R46 : 100K (1 - 0 - 0 - 3 - 1) (1 - 0 - 0 - B) (2 - 2 - 1 - B) (4 - 7 - 2 - B) (4 - 7 - 2 - B) (4 - 7 - 2 - B) (4 - 7 - 2 - B) (1 - 0 - 2 - B) (1 - 0 - 2 - B) (1 - 0 - 2 - B) (1 - 0 - 2 - B) (1 - 0 - 2 - B) (1 - 0 - 2 - B) (1 - 0 - 2 - B) (1 - 0 - 2 - B) (1 - 0 - 2 - B) (4 - 7 - 3 - B) (4 - 7 - 3 - B) (4 - 7 - 3 - B) (4 - 7 - 3 - B) (4 - 7 - 3 - B) (4 - 7 - 3 - B) (4 - 7 - 3 - B) (4 - 7 - 3 - B) (4 - 7 - 3 - B) (1 - 0 - 3 - B) (1 - 0 - 3 - B) (1 - 0 - 3 - B) (1 - 0 - 3 - B) (1 - 0 - 3 - B) (1 - 0 - 3 - B) (1 - 0 - 3 - B) (1 - 0 - 3 - B) (1 - 0 - 3 - B) (1 - 0 - 3 - B) (1 - 0 - 3 - B) (1 - 0 - 3 - B) (1 - 0 - 3 - B) (1 - 0 - 3 - B) (1 - 0 - 3 - B) (1 - 0 - 3 - B) (1 - 0 - 4 - B) (1 - 0 - 4 - B) Construction 5. Axial coil C9 : 100nF C10 : 100nF L2 L... 10. Transistors L1 : 100µH (1 - 0 - 1 - A) 6. IC sockets (Watch the position of the notch) IC1 : 8p IC2 : 18p IC3 : 18p 1 IC... 7. Potentiometer RV1 RV1 : 4K7 / 5K (µ1 - 104) (µ1 - 104) T1 T2 T3 T4 T5 T6 T7 T8 T9 T10 T11 T12 T13 T14 : BC547 or eq. : BC547 or eq. : BC547 or eq. : BC547 or eq. : BC547 or eq. : BC547 or eq. : BC547 or eq. : BC547 or eq. : BC337 or eq. : BC337 or eq. : BC337 or eq. : BC337 or eq. : BC557 or eq. : BC557 or eq. 11. Female connector 8. LED (Check the polarity) J3 : 3p .. J. LD1 : 3mm RED LD1 .. J. CATHODE 9. Capacitors cut c... 12. Male Pin connector C1 C2 C3 C4 C5 C6 C7 C8 : 100pF : 330pF : 100nF : 100nF : 100nF : 100nF : 100nF : 100nF (101) (331) (µ1 - 104) (µ1 - 104) (µ1 - 104) (µ1 - 104) (µ1 - 104) (µ1 - 104) J1 : 10p J2 : 12p 11 Construction 13. Pin contacts 16. Voltage regulators VR1 : 7809 VR2 : 7805 cut 18mm JP1 : 3p JP2 : 3p JP3 : 3p JP4 : 3p 14. Electrolytic capacitors. Watch the polarity ! C11 : 1µF C12 : 1µF C13 : 1µF C14 : 1µF C15 : 1µF C17 : 1µF C18 : 1µF C19 : 22µF C20 : 220µ F C21 : 1000µF VR... 17. Fuse F1 : 15A Thin the PCB track with extra solder 18. Relays C... RY1 : FRA2C RY2 : FRA2C RY3 : V23033, FRA2C Thin the PCB track with extra solder 15. Diodes (Check the polarity) 19. IC’s. Watch the position of the notch ! D... CATHODE D13 : 6A2, 6A6 or eq. D14 : 6A2, 6A6 or eq. IC1 : RV4558, LM258, LM158 IC2 : UM3758 - 120A IC3 : VK3511, PIC16C54RCE 12 Test & adjustment 20. Create your code See point 15 in transmitter construction “P6706”. (Pag. 7) 21. Final assembly Mount the receiver PCB “P3511R” on the main PCB “P3511” using the 20mm treaded rod. Check that the components of the main PCB and the receiver PCB do not touch each other. 22. Test and adjustment IMPORTANT: • To tune the remote control transmitter to the receiver, the plastic tuning screwdriver supplied is needed (sometimes it will be necessary to make the point a little bit finer by using sandpaper) • The transmitter must be in its housing without the cover on. • The receiver may not be in the vicinity of any metal objects • The transmitter and receiver must have the same code • Use the right hand button of the transmitter (SW2) 1. Tuning the receiver : • Connect 12V in to the + and - of a stable supply or battery. Check the polarity • Set the tuning capacitor of the receiver to around its mid point (see figure 8). Check that the tuning LED of the receiver is not, or almost not, lit up. If it is lit the capacitor must be set a little bit further on. Do not touch the circuit with your hand 2. Tuning one or more transmitters to the receiver: • Activate the transmitter (do not touch any other components other than the push button) and turn (very carefully) the tuning capacitor until the tuning LED of the receiver lights up. If all is well one of the relays will energise - if the transmitter and receiver codes are the same. (Between 2 operations a pause of at least 5 seconds is required) • Now take the transmitter at least 10 metres away from the receiver and repeat the setting. Then take the transmitter to around 20 metres away and repeat (perhaps ask somebody to help you). • Should it not be possible to tune the receiver to the transmitter, then it might be that the tuner capacitor of the receiver should be set into a different position. Clip the cover of the housing of the transmitter back into place. See user instructions for further operation. 13 PCB 23. PCB P6706 24. PCB P3511R 14 PCB 25. Main PCB P3511 15 16 BATTERY 12V - + NC A10 A9 A8 A7 A6 A5 A4 A3 A2 A1 IC1 18 SW2 A11 11 NC D1 D2 VSS TX OSC A12 12 14 17 13 16 RX MODE 15 UM3758-120A SW1 10 9 8 7 6 5 4 3 2 1 VDD R3 C3 R1 R2 C2 C1 R4 T1 CV L2 R5 ZD1 LD1 L1 Diagram 26. Diagram Remote Transmitter R6 R5 C5 C3 C4 R7 T1 L2 R3 R1 L1 C1 CV1 R4 C6 R8 ZD1 C7 A1 R9 1 A1,A2 = IC1 3 2 R10 C2 4 8 7 LD1 A2 ZD2 6 5 R11 R13 R12 R2 ZD3 GND Rx OUT +9V Diagram 27. Diagram Remote Receiver 17 Diagram 28. Main diagram +V1 6 8 Rx IN IR Rx IN 1 16 2 R45 +V RF GND IR GND A1,A2 = IC1 +12V OUT 18 R39 7 4 3 R46 +V3 4 OSC C21 C2 +V1 D7 VR1 L1 +12V IN I R3 R1 GND I C4 C11 RV1 +V C12 C5 +V3 LD1 R11 +V R12 9 OUT +V +V3 +V R43 D2 OSC DIRECT SENSORS IN RB0 C14 +V R44 A10 1 6 RA3 R22 RA2 +V 5MIN NC DIRECT R6 DASHBOARD LED + R38 T5 +V3 DASHBOARD LED INSIDE SIREN + RB4 R9 RB6 R10 INSIDE SIREN T10 2 T1 R23 ZD2 C15 RY1 NC LEFT DIRECTION LIGHTS RIGHT IC3 VK3511 10 CONTACT1 D10 NC A11 T9 +V RA1 JP3 ARM TIME 16 (PIC16C54’RC) R31 R32 A8 A9 D14 C1 T14 R40 A7 R37 18 +V RY2 R18 7 R30 R21 A6 C9 D13 D11 RA0 14 17 RB2 8 +V R13 11 A4 A5 14 15 12 VSS MODE +V3 VDD 3 RB1 C13 17 A2 A3 A12 T13 R29 10 A1 T8 RTCC +V R20 D1 R28 WARNING SENSORS IN 12 WARNING OUT T6 ZD4 +V +V3 CONTACT2 D9 R33 T12 D3 RST ZD3 R24 +V R14 R8 11 NC OFF ON +V3 R25 T2 JP2 POS R35 T3 C8 R26 NEG JP4 BLOWER T4 R34 FAN SENS IN D6 5 RB7 +V D4 R16 R15 13 R36 C17 D5 R27 C18 RB5 R19 RB3 R7 RY3 OUTSIDE SIREN / PAGER T11 +V CODELOCK CODELOCK IN C10 D12 4 C16 18 8 ZD1 C6 C19 D8 7 C7 R4 R2 6 UM3758-120A O NC VOLTAGE DROP JP1 +V OFF 3 ON A1 1 R42 R41 2 GND IC2 VR2 O C3 C20 5 13 R5 F1 +V VDD RF Rx IN A2 5 +V RF +9V IR +9V +V1 9 VSS DOOR LOCK OUT SIGNAL T7 R17 ZD5 VELLEMAN KIT NV Legen Heirweg 33 9890 Gavere Belgium Europe Info ?: http://www.velleman.be Modifications and typographical errors reserved © Velleman Kit nv H3511IP - 2003 - ED2 (rev 3) 5 410329 291518