Download Avanti Model Specifications

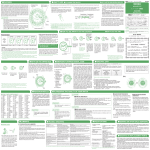

Transcript