Download Community SLS Owner`s manual

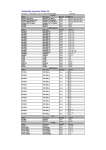

Transcript