Download Agilent Technologies ENA Series User`s guide

Transcript

Caution

Do not exceed the operating input power, voltage, and current

level and signal type appropriate for the instrument being used, refer to

your instrument's Function Reference.

Electrostatic discharge(ESD) can damage the highly sensitive

microcircuits in your instrument. ESD damage is most likely to occur as

the test fixtures are being connected or disconnected. Protect them from

ESD damage by wearing a grounding strap that provides a high

resistance path to ground. Alternatively, ground yourself to discharge any

static charge built-up by touching the outer shell of any grounded

instrument chassis before touching the test port connectors.

Safety Summary

When you notice any of the unusual conditions listed below, immediately

terminate operation and disconnect the power cable.

Contact your local Agilent Technologies sales representative or

authorized service company for repair of the instrument. If you continue

to operate without repairing the instrument, there is a potential fire or

shock hazard for the operator.

- Instrument operates abnormally.

- Instrument emits abnormal noise, smell, smoke or a spark-like

light during operation.

- Instrument generates high temperature or electrical shock

during operation.

- Power cable, plug, or receptacle on instrument is damaged.

- Foreign substance or liquid has fallen into the instrument.

Herstellerbescheinigung

GERAUSCHEMISSION

LpA

< 70 dB

am Arbeitsplatz

normaler Betrieb

nach DIN 45635 T. 19

Manufacturer's Declaration

ACOUSTIC NOISE EMISSION

LpA

< 70 dB

operator position

normal operation

per ISO 7779

Regulatory compliance information

This product complies with the essential requirements of the following applicable European Directives, and

carries the CE marking accordingly:

The Low Voltage Directive 73/23/EEC, amended by 93/68/EEC

The EMC Directive 89/336/EEC, amended by 93/68/EEC

To obtain Declaration of Conformity, please contact your local Agilent Technologies sales office, agent or

distributor.

Safety notice supplement

・ This equipment complies with EN/IEC61010-1:2001.

・ This equipment is MEASUREMENT CATEGORY I (CAT I). Do not use for CAT II, III, or IV.

・ Do not connect the measuring terminals to mains.

・ This equipment is POLLUTION DEGREE 2, INDOOR USE product.

・ This equipment is tested with stand-alone condition or with the combination with the accessories supplied

by Agilent Technologies against the requirement of the standards described in the Declaration of

Conformity. If it is used as a system component, compliance of related regulations and safety requirements

are to be confirmed by the builder of the system.

Agilent E5070B/E5071B ENA Series RF Network Analyzers

User’s Guide

Eleventh Edition

FIRMWARE REVISIONS

This manual applies directly to instruments that have the firmware revision A.08.10.

For additional information about firmware revisions, see Appendix A.

Manufacturing No. E5070-90430

June 2007

Notices

The information contained in this document is subject to change without notice.

This document contains proprietary information that is protected by copyright. All rights

are reserved. No part of this document may be photocopied, reproduced, or translated to

another language without the prior written consent of Agilent Technologies.

Microsoft®,MS-DOS®,Windows®,Visual C++®,Visual Basic®,VBA® and Excel® are

registered

UNIX is a registered trademark in U.S. and other countries, licensed

exclusively through X/Open Company Limited.

Portions ©Copyright 1996, Microsoft Corporation. All rights reserved.

© Copyright 2002, 2003, 2004, 2005, 2006, 2007 Agilent Technologies

Manual Printing History

The manual’s printing date and part number indicate its current edition. The printing date

changes when a new edition is printed (minor corrections and updates that are incorporated

at reprint do not cause the date to change). The manual part number changes when

extensive technical changes are incorporated.

August 2002

First Edition (part number: E5070-90030)

March 2003

Second Edition (part number: E5070-90040, changes for firmware

version A.03.50)

July 2003

Third Edition (part number: E5070-90050)

January 2004

Fourth Edition (part number: E5070-90060, changes for firmware

version A.03.60)

March 2004

Fifth Edition (part number: E5070-90070)

August 2004

Sixth Edition (part number: E5070-90080, changes for firmware

version A.04.00)

May 2005

Seventh Edition (part number: E5070-90090, changes for firmware

version A.05.00)

November 2005

Eighth Edition (part number: E5070-90400, changes for firmware

version A.06.00)

May 2006

Ninth Edition (part number: E5070-90410, changes for firmware

version A.06.50)

February 2007

Tenth Edition (part number: E5070-90420, changes for firmware

version A.08.00)

June 2007

Eleventh Edition (part number: E5070-90430, changes for firmware

version A.08.10)

2

Safety Summary

The following general safety precautions must be observed during all phases of operation,

service, and repair of this instrument. Failure to comply with these precautions or with

specific WARNINGS elsewhere in this manual may impair the protection provided by the

equipment. Such noncompliance would also violate safety standards of design,

manufacture, and intended use of the instrument. Agilent Technologies assumes no liability

for the customer’s failure to comply with these precautions.

NOTE

The E5070B/E5071B complies with INSTALLATION CATEGORY II as well as

POLLUTION DEGREE 2 in IEC61010-1. The E5070B/E5071B is an INDOOR USE

product.

NOTE

The LEDs in the E5070B/E5071B are Class 1 in accordance with IEC60825-1,

CLASS 1 LED PRODUCT.

•

Ground the Instrument

To avoid electric shock, the instrument chassis and cabinet must be grounded with the

supplied power cable’s grounding prong.

•

DO NOT Operate in an Explosive Atmosphere

Do not operate the instrument in the presence of inflammable gasses or fumes.

Operation of any electrical instrument in such an environment clearly constitutes a

safety hazard.

•

Keep Away from Live Circuits

Operators must not remove instrument covers. Component replacement and internal

adjustments must be made by qualified maintenance personnel. Do not replace

components with the power cable connected. Under certain conditions, dangerous

voltage levels may remain even after the power cable has been disconnected. To avoid

injuries, always disconnect the power and discharge circuits before touching them.

•

DO NOT Service or Adjust the Instrument Alone

Do not attempt internal service or adjustment unless another person, capable of

rendering first aid and resuscitation, is present.

•

DO NOT Substitute Parts or Modify the Instrument

To avoid the danger of introducing additional hazards, do not install substitute parts or

perform unauthorized modifications to the instrument. Return the instrument to an

Agilent Technologies Sales and Service Office for service and repair to ensure that

safety features are maintained in operational condition.

•

Dangerous Procedure Warnings

Warnings, such as the example below, precede potentially dangerous procedures

throughout this manual. Instructions contained in the warnings must be followed.

WARNING

Dangerous voltage levels, capable of causing death, are present in this instrument.

Use extreme caution when handling, testing, and adjusting this instrument.

3

Safety Symbols

General definitions of safety symbols used on the instrument or in manuals are listed

below.

Instruction Manual symbol: the product is marked with this symbol when it is necessary for

the user to refer to the instrument manual.

Alternating current.

Direct current.

On (Supply).

Off (Supply).

In-position of push-button switch.

Out-position of push-button switch.

A chassis terminal; a connection to the instrument’s chassis, which includes all exposed

metal structure.

Stand-by.

WARNING

This warning sign denotes a hazard. It calls attention to a procedure, practice, or

condition that, if not correctly performed or adhered to, could result in injury or

death to personnel.

CAUTION

This Caution sign denotes a hazard. It calls attention to a procedure, practice, or condition

that, if not correctly performed or adhered to, could result in damage to or destruction of

part or all of the instrument.

NOTE

This Note sign denotes important information. It calls attention to a procedure, practice, or

condition that is essential for the user to understand.

4

Certification

Agilent Technologies certifies that this product met its published specifications at the time

of shipment from the factory. Agilent Technologies further certifies that its calibration

measurements are traceable to the United States National Institute of Standards and

Technology, to the extent allowed by the Institution’s calibration facility or by the

calibration facilities of other International Standards Organization members.

Documentation Warranty

The material contained in this document is provided "as is," and is subject to being

changed, without notice, in future editions. Further, to the maximum extent permitted by

applicable law, Agilent disclaims all warranties, either express or implied with regard to

this manual and any information contained herein, including but not limited to the implied

warranties of merchantability and fitness for a particular purpose. Agilent shall not be

liable for errors or for incidental or consequential damages in connection with the

furnishing, use, or performance of this document or any information contained herein.

Should Agilent and the user have a separate written agreement with warranty terms

covering the material in this document that conflict with these terms, the warranty terms in

the separate agreement will control.

Exclusive Remedies

The remedies provided herein are Buyer’s sole and exclusive remedies. Agilent

Technologies shall not be liable for any direct, indirect, special, incidental, or

consequential damages, whether based on contract, tort, or any other legal theory.

Assistance

Product maintenance agreements and other customer assistance agreements are available

for Agilent Technologies products.

For any assistance, contact your nearest Agilent Technologies Sales and Service Office.

Addresses are provided at the back of this manual.

5

Typeface Conventions

Sample (bold)

Boldface type is used when a term is defined or

emphasis.

Sample (Italic)

Italic type is used for emphasis.

key

Indicates a hardkey (key on the front panel or

external keyboard) labeled “Sample.” “key” may

be omitted.

Sample menu/button/box

Indicates a menu/button/box on the screen labeled

“Sample” which can be selected/executed by

clicking. “menu,” “button,” or “box” may be

omitted.

Sample block/toolbar

Indicates a block (group of hardkeys) or a toolbar

(setup toolbar) labeled “Sample.”

Sample 1 - Sample 2 - Sample 3

Indicates a sequential operation of Sample 1,

Sample 2, and Sample 3 (menu, button, or box).

“-” may be omitted.

6

Documentation Map

The following manuals are available for the Agilent E5070B/E5071B.

•

User’s Guide (Part Number E5070-904x0, attached to Option ABA)

This manual describes most of the basic information needed to use the

E5070B/E5071B. It provides a function overview, detailed operation procedure for

each function (from preparation for measurement to analysis of measurement results),

measurement examples, specifications, and supplemental information. For

programming guidance on performing automatic measurement with the

E5070B/E5071B, please see the Programming Manual.

•

Installation and Quick Start Guide (Part Number E5070-900x1, attached to Option

ABA)

This manual describes installation of the instrument after it is delivered and the basic

procedures for applications and analysis. Refer to this manual when you use the

E5070B/E5071B for the first time.

•

Programmer’s Guide (Part Number E5070-900x2, attached to Option ABA)

This manual provides programming information for performing automatic

measurement with the E5070B/E5071B. It includes an outline of remote control,

procedures for detecting measurement start (trigger) and end (sweep end), application

programming examples, a command reference, and related information.

•

VBA Programmer’s Guide (Part Number E5070-900x3, attached to Option ABA)

This manual describes programming information for performing automatic

measurement with internal controller. It includes an outline of VBA programming,

some sample programming examples, a COM object reference, and related

information.

NOTE

The number position shown by “x” in the part numbers above indicates the edition number.

This convention is applied to each manual, CD-ROM (for manuals), and sample programs

disk issued.

7

VBA Macro

The Agilent folder (D:\Agilent) on the hard disk of the E5070B/E5071B contains the VBA

macros (VBA Projects) used in this manual.

The customer shall have the personal, non-transferable rights to use, copy, or modify the

VBA macros for the customer’s internal operations.

The customer shall use the VBA macros solely and exclusively for their own purposes and

shall not license, lease, market, or distribute the VBA macros or modification of any part

thereof.

Agilent Technologies shall not be liable for any infringement of any patent, trademark,

copyright, or other proprietary right by the VBA macros or their use. Agilent Technologies

does not warrant that the VBA macros are free from infringements of such rights of third

parties. However, Agilent Technologies will not knowingly infringe or deliver software

that infringes the patent, trademark, copyright, or other proprietary right of a third party.

8

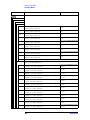

Contents

1. Precautions

Software Installed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Before contacting us . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2. Overview of Functions

Front Panel: Names and Functions of Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

1. Standby Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2. LCD Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3. ACTIVE CH/TRACE Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4. RESPONSE Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5. STIMULUS Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6. Floppy Disk Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7. NAVIGATION Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

8. ENTRY Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

9. INSTR STATE Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

10. MKR/ANALYSIS Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

11. Test Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

12. Front USB Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

13. Ground Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Screen Area: Names and Functions of Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

1. Menu Bar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

2. Data Entry Bar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3. Softkey Menu Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4. Instrument Status Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5. Channel Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Rear Panel: Names and Functions of Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

1. Handler I/O Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

2. Ethernet Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

3. External Monitor Output Terminal (Video). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

4. GPIB Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

5. External Trigger Input Connector (Ext Trig) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

6. Fan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

7. Line Switch (Always ON). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

8. Power Cable Receptacle (to LINE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

9. High Stability Frequency Reference Output Connector (Ref Oven, Option 1E5 only) . . . . . . . . . . . . 56

10. External Reference Signal Input Connector (Ref In) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

11. Internal Reference Signal Output Connector (Ref Out) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

12. Serial Number Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

13. Certificate of Authenticity Label. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

14. Rear USB port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

15. Reserved Port (Reserved) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

16. Printer Parallel Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

17. Mini-DIN Keyboard Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

18. Mini-DIN Mouse Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

19. USB (USBTMC) Interface Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

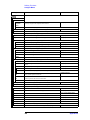

3. Setting Measurement Conditions

Initializing Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

9

Contents

Setting Channels and Traces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting upper limits of number of channels/traces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting channel display (layout of channel windows) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting trace display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Active channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Active trace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parameter setting for each setup item (analyzer, channel, trace) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting the System Z0. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Stimulus Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting sweep type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting the Sweep Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Turning stimulus signal output on/off. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting fixed frequency at power sweep . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting power level with Auto Power Range set function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting power range manually . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting the number of points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting the sweep time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting Measurement Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Definition of S-parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting up S-parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting a Data Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rectangular display formats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Polar format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Smith chart format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting a data format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting the Scales . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Auto scale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual scale adjustment on a rectangular display format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual scale adjustment on the Smith chart/polar format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting the value of a reference line using the marker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Window Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximizing the specified window/trace display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Turning off the display of graticule labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hiding Frequency Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Labeling a window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting display colors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

61

61

62

64

66

66

67

69

70

70

70

73

73

74

77

78

78

80

80

80

81

81

82

83

84

85

85

85

87

87

88

88

88

89

89

91

4. Calibration

Measurement Errors and their Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Drift Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Random Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Systematic Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Calibration Types and Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Checking Calibration Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Execution status of error correction for each channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Execution status of error correction for each trace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Acquisition status of calibration coefficient for each channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Selecting Calibration Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Setting the trigger source for calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

10

Contents

OPEN/SHORT Response Calibration (reflection test) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

THRU Response Calibration (transmission test) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

1-Port Calibration (reflection test) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Enhanced Response Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Full 2-Port Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Full 3-Port Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Full 4-Port Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

ECal (electronic calibration) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

1-Port Calibration Using a 2-Port ECal Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Full 2-Port Calibration Using the 2-Port ECal Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Unknown Thru Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Turning off ECal auto-detect function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Full 3-Port and Full 4-Port Calibration using 2-Port ECal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Operational procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Calibration Using 4-port ECal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Operational procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

2-port TRL calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Operational procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

3-port TRL calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Operational procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

4-port TRL calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Operational procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Simplified calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Simplified full 3/4-port calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Simplified 3/4-port TRL calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Partial overwrite . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Improving accuracy of measurement using partial overwrite (thru calibration) along with ECal . . . . . 152

Unknown Thru Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Calibration between Ports of Different Connector Types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Operating procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Adapter Characterization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Concept . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

How to execute adapter characterization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Execution procedure of characterization for test fixture using probe . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Adapter Removal-Insertion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

About Adapter Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

About Adapter Insertion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Procedure for Adapter Removal / Insertion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

User-characterized ECal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Precautions to take in using VBA macros. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

11

Contents

Storing user characteristics to the ECal module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Backup and recovery of ECal module's built-in flash memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Executing User-characterized ECal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Confidence Check on Calibration Coefficients Using ECal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operational procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Changing the Calibration Kit Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Definitions of terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Defining parameters for standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Redefining a calibration kit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Example of defining the TRL calibration kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting options for TRL calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting a media type for the calibration kit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Saving and loading definition file of calibration kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Default settings of pre-defined calibration kits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifying Different Standard for Each Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Defining different standard for each frequency band . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Defining standard for each subclass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disabling standard defined for a subclass. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Notes on how frequency ranges are dealt when using subclasses . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Turning ON or OFF power level error correction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preparing power meter and sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting target port of error correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting loss compensation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting a tolerance for power calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Measuring calibration data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Receiver Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Turning ON/OFF receiver error correction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting target port for error correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Measuring the calibration data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Vector-Mixer Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview of vector-mixer calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Measured mixer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibration mixer (with IF filter) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Characterizing calibration mixer (with IF filter) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Characterizing procedure for calibration mixer (with IF filter) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How to execute characterization of calibration mixer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Characterizing calibration mixer (with IF filter) for balance mixer measurement. . . . . . . . . . . . . . . . .

How to execute characterization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Scalar-Mixer Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Confirming calibration status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operational Procedure (when using mechanical calibration kit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operational procedure (when using ECal module). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

172

176

177

179

179

181

182

183

185

188

190

191

192

193

202

202

203

204

205

208

208

209

215

215

218

218

220

220

221

221

223

223

224

224

224

225

226

230

230

233

234

235

238

5. Making Measurements

Setting Up the Trigger and Making Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sweep Order in Each Channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Trigger Source. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Trigger Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

242

242

243

243

12

Contents

Setting Up the Trigger and Making Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

Setting the Point Trigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Procedure to Set the Point Trigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Setting the low-latency external trigger mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

Procedure to set the low-latency external trigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

External trigger delay time and point trigger interval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Setting the Averaging Trigger Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Using the averaging trigger function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Executing a Trigger Only for Active Channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

Procedure to set the range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

6. Data Analysis

Analyzing Data on the Trace Using the Marker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

About marker functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

Reading values on the trace. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

Reading the Relative Value From the Reference Point on the Trace . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

Reading only the actual measurement point/Reading the value interpolated between measurement points

257

Setting up markers for each trace/Setting up markers for coupled operations between traces . . . . . . . . 258

Listing all marker values in all channels displayed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

Specifying the display position of marker values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

Aligning maker value displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

Displaying all marker values for displayed traces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

Searching for Positions that Match Specified Criteria . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

Setting search range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

Automatically executing a search each time a sweep is done (search tracking). . . . . . . . . . . . . . . . . . . 264

Searching for the maximum and minimum measured values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

Searching for the target value (target search) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

Searching for the peak. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

Determining the Bandwidth of the Trace (Bandwidth Search). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

Executing a Bandwidth Search . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

Obtaining the bandwidth of a trace (notch search) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

Executing a notch Search . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273

Determining the Mean, Standard Deviation, and p-p of the Trace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

Displaying Statistics Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

Comparing Traces/Performing Data Math . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

Performing Data Math Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

Performing Parameter Conversion of Measurement Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

Operational Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

Using the Equation Editor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

Procedure to start the equation editor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

Procedure to use the equation editor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

Enabling/Disabling the equation editor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

Entering the equation label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

7. Fixture Simulator

Overview of Fixture Simulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

Functions for single-ended (unbalanced) port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

13

Contents

Balance-unbalance conversion (option 313, 314, 413, or 414) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Functions for balanced port (option 313, 314, 413, or 414) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Extending the Calibration Plane Using Network De-embedding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Network De-embedding Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Converting the Port Impedance of the Measurement Result . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Converting the Port Impedance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Determining Characteristics After Adding a Matching Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Matching Circuit Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Obtaining Characteristics After Embedding/De-embedding 4-port Network . . . . . . . . . . . . . . . . . . . . . .

Operational Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Evaluating Balanced Devices (balance-unbalance conversion function). . . . . . . . . . . . . . . . . . . . . . . . . .

Measurement parameters of balanced devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Steps for Balance-Unbalance Conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Steps for Measurement Parameter Setups. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checking device type and port assignment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Converting Reference Impedance of Balanced Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Converting port reference impedance in differential mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Converting port reference impedance in common mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Determining the Characteristics that Result from Adding a Matching Circuit to a Differential Port . . . .

Example of Using Fixture Simulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Measurement circuit example for a DUT with balanced port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Evaluation using an actual test fixture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Problems in measurement with an actual test fixture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DUT evaluation using the E5070B/E5071B’s fixture simulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Advantages of balanced DUT evaluation using fixture simulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

286

286

287

287

288

288

289

289

292

293

295

297

300

301

301

302

303

303

305

308

308

308

309

310

312

8. Frequency-Offset Measurement (Option 008)

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview of Frequency-Offset Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Measurement of Mixers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Measurement flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1. Setting Frequency-Offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. Setting External Signal Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. Avoid Spurious Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. Changing Frequency Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. Implementing Mixer Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6. Conversion Loss Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Measurement of Harmonic Distortion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Measurement flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1. Setting Frequency-Offset Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. Implementing Receiver Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. Setting Absolute Measurement Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. Harmonic Distortion Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

314

314

315

315

315

318

322

323

325

325

328

328

328

329

329

330

9. Analysis in Time Domain (Option 010)

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 334

Overview of time domain measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 334

Comparison to time domain reflectometry (TDR) measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 334

14

Contents

Time domain function of E5070B/E5071B. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 335

Transformation to time domain. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 336

Measurement flow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 336

Selecting a type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 337

Setting the window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 339

Calculating necessary measurement conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 340

Setting the frequency range and the number of points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 344

Setting display range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 345

Enabling transformation function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 345

Deleting Unnecessary Data in Time Domain (gating) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 347

Measurement Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 347

Setting gate type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 347

Setting gate shape . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 348

Setting gate range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 349

Enabling gating function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 350

Characteristics of Response in Time Domain. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 351

Masking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 351

Identifying mismatch type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 352

10. Data Output

Saving and Recalling Instrument State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 354

Compatibility of files related to saving and recalling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 354

Save procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 356

Recall Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 359

Recall Procedure Using “Recall by File Name” Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 360

Priority of recalling the configuration file at startup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 360

Saving/Recalling Instrument State for Each Channel into/from Memory . . . . . . . . . . . . . . . . . . . . . . . . . 361

Operational Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 361

Saving Trace Data to a File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 362

Saving data as a CSV file . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 362

Saving data in Touchstone format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 363

Saving the Screen Image to a File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 368

Saving the Screen Image to a File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 368

Organizing Files and Folders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 369

To Open Windows Explorer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 369

To Copy a File or Folder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 369

To Move a File or Folder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 370

To Delete a File or Folder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 370

To Rename a File or Folder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 370

To Format a Floppy Disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 370

Printing Displayed Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 371

Supported printers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 371

Printed/saved images. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 372

Print Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 372

11. Limit Test

Limit Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 376

Concept of limit test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 376

15

Contents

Displaying judgment result of limit test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Defining the limit line. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Turning the limit test ON/OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Limit line offset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Initializing the limit table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ripple Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Concept of ripple test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Displaying ripple test results. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring ripple limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Turning on/off ripple test and displaying results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Initializing the limit table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bandwidth Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Displaying Bandwidth Test Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Set up bandwidth test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Turning On/Off Bandwidth Test and Displaying Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

377

378

382

383

384

385

385

386

387

390

391

392

393

394

394

12. Optimizing Measurements

Expanding the Dynamic Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lowering the receiver noise floor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reducing Trace Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Turning on Smoothing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Improving Phase Measurement Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Delay. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Phase offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifying the velocity factor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Port Extensions and Loss Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting port extensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting loss values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Enabling port extensions and loss values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the auto port extension function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reducing Measurement Error in High Temperature Environments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Improving Measurement Throughput. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using Fast Sweep Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Turning off the updating of information displayed on the LCD screen . . . . . . . . . . . . . . . . . . . . . . . . .

Turning off system error correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performing a Segment-by-Segment Sweep (segment sweep) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Concept of Segment Sweep . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Conditions for setting up a segment sweep . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Items that can be set for each segment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sweep delay time and sweep time in a segment sweep . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Frequency base display and order base display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

396

396

398

398

400

400

402

402

403

403

404

405

406

411

411

412

412

416

416

417

417

418

418

419

419

421

13. Setting and Using the Control and Management Functions

Setting the GPIB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 428

Setting talker/listener GPIB address of E5070B/E5071B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 428

Setting system controller (USB/GPIB interface) when c drive volume label in hard disk is less than CP801

16

Contents

428

Setting system controller (USB/GPIB interface) when c drive volume label in hard disk is more than CP810

431

Setting the Internal Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 433

Setting the Date and Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 433

Setting the Date/Time Display ON/OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 434

Setting the Mouse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 435

Setup Step . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 435

Configuring the Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 438

Enabling/disabling network. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 438

Setting IP address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 439

Specifying computer name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 441

Remote Control Using HTTP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 443

Required Modification of Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 443

How to Start VNC Server Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 443

Accessing Hard Disk of E5070B/E5071B from External PC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 444

Enabling the access form the external PC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 444

Accessing hard disk of E5070B/E5071B from external PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 446

Disabling USB Mass Storage Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 447

Steps for Setting Modification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 447

Locking the Front Keys, Keyboard, and/or Mouse (Touch Screen) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 448

Locking the Front Keys, Keyboard, and/or Mouse. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 448

Setting the Beeper (Built-in Speaker) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 449

Setting the Operation Complete Beeper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 449

Setting the Warning Beeper. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 449

Turning off the LCD Screen Backlight. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 450

Turning off the LCD Screen Backlight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 450

Checking the product information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 451

Checking the serial number. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 451

Checking other product information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 451

Setting the preset function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 453

Showing/hiding the confirmation buttons when presetting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 453

Setting the user preset function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 453

Saving a user-preset instrument state . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 454

System Recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 455

Types of system recoveries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 455

Notes on executing system recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 455

Procedure to execute the factory function (1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 456

Procedure to create the user backup image (1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 459

Procedure to execute the user recovery function (1). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 462

Procedure to execute the factory recovery function (2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 465

Procedure to create the user backup image (2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 468

Procedure to execute the user recovery function (2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 471

Calibration of the Touch Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 474

Initial Source Port Control function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 475

14. Controlling E5091A

Connecting E5070B/E5071B and E5091A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 478

Required devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 478

17

Contents

Connecting E5070B/E5071B and E5091A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Powering on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting the E5091A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting ID for E5091A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting the E5091A Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Assigning test ports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Displaying the E5091A properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting control line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Enabling control of E5091A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performing Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Trigger state and switching the setting of the E5091A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .