Download Bloomfield B-406 Operating instructions

Transcript

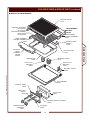

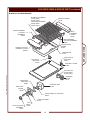

161 WELLS BLOOMFIELD, LLC 2 ERIK CIRCLE, P. O. Box 280 Verdi, NV 89439 telephone: 775-689-5707 fax: 775-689-5976 www.wellsbloomfield.com SUPPLEMENTAL SERVICE INSTRUCTIONS ELECTRIC CHARBROILERS COUNTERTOP MODELS B-40 B-44 B-50 BUILT-IN MODELS B-406 B-446 B-506 IMPORTANT: WELLS BLOOMFIELD, LLC PROPRIETARY INFORMATION. DISSEMINATION OF THIS INFORMATION TO ANYONE OTHER THAN WELLS AUTHORIZED SERVICE AGENTS IS STRICTLY PROHIBITED. TECHNICAL CONTENT OF THIS MANUAL IS DESIGNED FOR USE BY QUALIFIED PROFESSIONAL TECHNICIANS ONLY. PRINTED IN UNITED STATES OF AMERICA p/n SV161Rev.(-) S161 080910 cps PRECAUTIONS AND GENERAL INFORMATION GENERAL WARNING: RISK OF INJURY Installation procedures must be performed by a qualified technician with full knowledge of all applicable electrical and plumbing codes. Failure can result in personal injury and property damage. WARNING: ELECTRIC SHOCK HAZARD All servicing requiring access to non-insulated electrical components must be performed by a qualified technician. Some procedures involve exposed live circuits. Use all due caution to avoid contact with live electric circuits. Failure to follow this warning can result in severe electrical shock. CAUTION: RISK OF DAMAGE This appliance is intended for use in commercial establishments only. This appliance is intended to prepare food for human consumption. No other use is recommended or authorized by the manufacturer or its agents. Operators of this appliance must be familiar with the appliance use, limitations and associated restrictions. Operating instructions must be read and understood by all persons using or installing this appliance. Cleanliness of this appliance is essential to good sanitation. Read and follow all included cleaning instructions and schedules to ensure the safety of the food product. Disconnect this appliance from electrical power before performing any maintenance or servicing. Maintain 2" of water in drip pan at all times during operation. Do not pour water over elements to refill drip pan. DO NOT splash or pour water on, in or over any controls, control panel or wiring. DO NOT use water spray or steam jet to clean this appliance. This appliance is not jet stream approved. The technical content of this manual, including any wiring diagrams, schematics, parts breakdown illustrations and/or adjustment procedures, is intended for use by qualified technical personnel. Any procedure which requires the use of tools must be performed by a qualified technician. This appliance is made in the USA. Unless otherwise noted, this appliance has American sizes on all hardware. SV161 SvcManual Electric Char-Broilers DO NOT connect or energize this appliance until all installation instructions are read and followed. Damage to the appliance will result if these instructions are not followed. xi GENERAL Precautions & General Information …………….………… Specifications ..……………………………...................….. Features & Operating Controls ……………………………. SERVICING INSTRUCTIONS Troubleshooting Suggestions ......................................... Prepare the Broiler for Use ............................................. Replace Infinite Switch ................................................... Replace Pivot for Element Head .................................... Replace heating Element ............................................... Replace Sopport Rod Spring .......................................... EXPLODED VIEWS AND SERVICE PARTS Control Knob Identification .............................................. B-40 and B-406 ............................................................... B-44 and B-446 .............................................................. B-50 and B-556 .............................................................. WIRING DIAGRAMS & SCHEMATICS B-40 and B-406 ............................................................... B-44 and B-446 .............................................................. B-50 and B-556 .............................................................. GENERAL TABLE OF CONTENTS xi 1 2 4 5 6 7 8 10 11 12 14 16 18 20 22 INTRODUCTION SV161 SvcManual Electric Char-Broilers This manual contains information needed to properly service and repair Wells Bloomfield electric charbroilers. This manual applies to the following Wells models: B-40(6), B-44(6), B-50(6) For installation, operation and maintenance instructions, refer to Operation Manual p/n 303672 (countertop models), or Operation Manual p/n 303673 (built-in models). SPECIFICATIONS AMPS PER LEG 3Ø L1 L2 L3 NEUT AMPS 1Ø 5.5 12.9 12.9 22.4 N/A 26.0 240 5.5 11.2 11.2 19.4 N/A 22.5 SINGLE ASSEMBLY 208 5.5 11.5 22.4 14.4 N/A 26.0 240 5.5 10.0 19.5 12.5 N/A 22.5 DUAL ASSEMBLIES 208 11.0 30.0 30.0 30.0 N/A - 240 11.0 26.0 26.0 26.0 N/A 45.0 MODEL ELEMENT VOLTS KW B-40 B406 SINGLE ASSEMBLY 208 B-44 B-446 B-50 B-506 1 POWER CORD (countertop only) OPTIONAL NEMA 6-30P NOT SUPPLIED NOT SUPPLIED FEATURES & OPERATING CONTROLS GENERAL COUNTERTOP ELECTRIC CHARBROILER IMPORTANT: B-40 grate mounts above the element. B-44 and B-50 grates can mount above or below the elements. Always remove a top-mounted grate before lifting the element assembly. IMPORTANT: Remember to dis-engage the support rod before lowering element assembly. IMPORTANT: DO NOT pour water over elements to refill drip pan. ITEM TEMPERATURE CONTROL The char-broiler is INFINITE SWITCH CONTROLLED. Power is applied to the heating elements in a timed sequence based on the control knob position. Light will glow when the infinite switch is in any position other that OFF. The char-broiler element assembly may be raised for cleaning, or to add water to HEATING ELEMENT the drip pan. Use the handle to manually lift the grate. It is held the “up” position by ASSEMBLY a support rod which automatically engages as the element is raised. ELEMENT GUARD/ GRATE ELEMENT SUPPORT ROD DRIP PAN DATA PLATE The grate is designed to protect the individual elements from food contact and spatula abrasion, resulting in prolonged element life and reduced carbonization. The grate is easily removed for cleaning. Holds element assembly in up position. Engages automatically when the element assembly is raised. Must be disengaged manually before lowering elements. The heavy-duty removable drip pan is located under the element assembly. The drip pan catches food particles and grease drippings during broiler operation. Maintain 2 inches of water in the drip pan at all times during operation of the broiler. The drip pan is easily removed for cleaning. Gives manufacturer, make, model and serial number. Also voltage and phase information, and agency approvals. ADJUSTABLE LEGS The char-broiler is equipped with adjustable 4” legs. 2 SV161 SvcManual Electric Char-Broilers INDICATOR LIGHT COMMENT FEATURES & OPERATING CONTROLS (continued) GENERAL BUILT-IN ELECTRIC CHARBROILER IMPORTANT: B-406 grate mounts above the element. B-446 and B-506 grates can mount above or below the elements. Always remove a top-mounted grate before lifting the element assembly. IMPORTANT: Remember to dis-engage the support rod before lowering element assembly. IMPORTANT: DO NOT pour water over elements to refill drip pan. ITEM SV161 SvcManual Electric Char-Broilers TEMPERATURE CONTROL INDICATOR LIGHT COMMENT The char-broiler is INFINITE SWITCH CONTROLLED. Power is applied to the heating elements in a timed sequence based on the control knob position. Light will glow when the infinite switch is in any position other that OFF. The char-broiler element assembly may be raised for cleaning, or to add water to HEATING ELEMENT the drip pan. Use the handle to manually lift the grate. It is held the “up” position by ASSEMBLY a support rod which automatically engages as the element is raised. ELEMENT GUARD/ GRATE ELEMENT SUPPORT ROD DRIP PAN The grate is designed to protect the individual elements from food contact and spatula abrasion, resulting in prolonged element life and reduced carbonization. The grate is easily removed for cleaning. Holds element assembly in up position. Engages automatically when the element assembly is raised. Must be disengaged manually before lowering elements. The heavy-duty removable drip pan is located under the element assembly. The drip pan catches food particles and grease drippings during broiler operation. Maintain 2 inches of water in the drip pan at all times during operation of the broiler. The drip pan is easily removed for cleaning. DATA PLATE Gives manufacturer, make, model and serial number. Also voltage and phase information, and agency approvals. WELLSLOKS The broiler is equipped with WELLSLOKS, uniquely designed turnout tabs, which help secure the broiler to the countertop. 3 SERVICING INSTRUCTIONS TROUBLESHOOTING SUGGESTIONS SYMPTON Won’t heat- - no indicator lights POSSIBLE CAUSE SUGGESTED REMEDY SERVICING Not plugged in, or Circuit breaker tripped. Check plug Check / reset circuit breaker Temperature control not set Set temperature control knob to desired temperature 240V unit run on 208V Verify proper voltage Damaged infinite switch Check/replace infinite switch Check/repair wiring and terminals Damaged heating element(s) Check/replace heating elements Check/repair wiring and terminals Temperature control not set Set temperature control knob to desired temperature 208V unit run on 240V Verify proper voltage Damaged infinite switch Check/replace infinite switch Element assy loose, or difficult to raise or lower Damaged hinge Repair/replace hinge Element assy does not latch in up position Damaged support rod assembly Clean/repair support rod assembly Replace support rod spring One or more section won’t heat—or not hot enough One or more section too hot SV161 SvcManual Electric Char-Broilers 4 SERVICING INSTRUCTIONS (continued) PREPARE THE CHAR-BROILER FOR USE CAUTION: When using the broiler for the first time, and after major repairs, wipe the entire unit with a clean damp cloth or sponge and mild detergent. Rinse thoroughly clean water. Dry with a soft clean cloth. HOT SURFACE IMPORTANT: DO NOT attempt to raise the element assembly without first removing the grate. Damage to the hinges will result. Such damage is NOT covered by warranty. Remove the GRATE and raise the ELEMENT ASSEMBLY. Install the DRIP PAN and add 2” (5cm) of tap water. Release the ELEMENT SUPPORT ROD by lifting the element assembly slightly, then pulling the lower portion of the support rod forward. Gently lower the ELEMENT ASSEMBLY. MODEL B-40(6): Grate must be installed ABOVE elements. Install the GRATE, front edge first. The TANGS of the grate go DOWN and point toward the FRONT. The grooves on the underside of the grate align with the elements. The rear edge of the grate can now be lowered until it rests firmly on the elements. ELEMENT SUPPORT ROD ELEMENT HANDLE FRONT GRATE TANG B-40(6) GRATE INSTALLATION SV161 SvcManual Electric Char-Broilers MODELS B-44(6) and B-50(6): Grate(s) can be installed above or below the elements. ABOVE: Gently lower grate over elements. The end with flush tabs goes toward the front. BELOW: Install one wing bolt in each tab. The notch in the wing rests on the lip of the drip pan. The end with flush tabs must go toward the front Adjust the wing bolts so that , when the element assembly is lowered, the top of the element is 1/4" (6mm) below the top of the grate fins. B-44(6) and B-50(6) GRATE INSTALLATION 5 IMPORTANT: Allow drip pan to cool before removing from the broiler. DO NOT operate the broiler without the drip pan installed. DO NOT operate the broiler without 2” (5cm) of water in the drip pan. IMPORTANT: DO NOT attempt to lower the element assembly without first releasing the support rod. Damage to the hinges will result. Such damage is NOT covered by warranty. SERVICING Exposed surfaces can be hot to the touch and may cause burns. SERVICING INSTRUCTIONS (continued) CAUTION: REPLACE INFINITE SWITCH HOT SURFACE COUNTERTOP UNITS: Exposed surfaces can be hot to the touch and may cause burns. 1. Disconnect unit from electric power and allow to cool. 2. Remove control knob. Remove screws holding trim ring to cabinet. Withdraw trim ring and switch. SERVICING 3. Note orientation of switch to trim ring. Mark location of wires on switch. Remove wires from switch. Remove and discard infinite switch. 4. Mount new switch to trim ring, being careful to maintain proper orientation. Connect wiring to switch. Remount trim ring and switch in cabinet. 5. Reconnect to electric power and test for proper operation. BUILT-IN UNITS: 1. Disconnect unit from electric power and allow to cool. 2. Remove control knob. Remove screws holding control panel to cabinet. Withdraw control panel and switches. 3. Note orientation of switch on control panel. Mark location of wires on switch. Remove wires from switch. Remove and discard infinite switch. 4. Mount new switch to panel, being careful to maintain proper orientation. Connect wiring to switch. Remount control panel and switches into cabinet. 5. Reconnect to electric power and test for proper operation. KNOB INFINITE SWITCH INDICATOR LIGHT L1 L2 P L1 H1 L2 H2 LOAD 6 SV161 SvcManual Electric Char-Broilers TRIM RING (OR CONTROL PANEL) SERVICING INSTRUCTIONS (continued) REPLACE PIVOT FOR ELEMENT ASSEMBLY CAUTION: HOT SURFACE 2. Support the element head near the pivot to be replaced. Remove the rear element cover. Note and mark the location of the supply wires to the elements. Disconnect the supply wires from the elements. 3. Remove the pivot cover. Store the pivot cover in a safe place. Withdraw the element supply wires from the pivot. Remove the screws holding the pivot to the cabinet. Withdraw the old pivot. 4. Clean all old sealant from the cabinet at the pivot. Apply a thin coat of high-temp food-grade lubricant to the pin of the new pivot. Apply food-grade silicone sealant to the bottom of the pivot. Slide the pin of the pivot into the element head assembly, then attach the pivot to the cabinet. 5. Thread the element supply wires through the pivot and re-connect to the elements. Reattach the pivot cover. For pivots with wires, be sure insulation for pivot cover screw is in place. Reattach the rear element cover. Exposed surfaces can be hot to the touch and may cause burns. IMPORTANT: DO NOT attempt to raise the element assembly without first removing the grate. Damage to the hinges will result. Such damage is NOT covered by warranty. IMPORTANT: DO NOT attempt to lower the element assembly without first releasing the support rod. Damage to the hinges will result. Such damage is NOT covered by warranty. 6. Reconnect to electric power and test for proper operation. PIVOT COVER SCREW INSULATION SV161 SvcManual Electric Char-Broilers RIGHT PIVOT CENTER PIVOT LEFT PIVOT CENTER PIVOT COVER NT O FR PIVOT COVER NOTE: B-50(6) dual pivot shown. Other units do not use the center pivot components. Pivot cover screw insulation is used, where wiring passes through the pivot, to minimize abrasion and chafing of the power wires. 7 SERVICING 1. Disconnect unit from electric power and allow to cool. SERVICING INSTRUCTIONS (continued) CAUTION: HOT SURFACE Exposed surfaces can be hot to the touch and may cause burns. SERVICING IMPORTANT: DO NOT attempt to raise the element assembly without first removing the grate. Damage to the hinges will result. Such damage is NOT covered by warranty. IMPORTANT: DO NOT attempt to lower the element assembly without first releasing the support rod. Damage to the hinges will result. Such damage is NOT covered by warranty. REPLACE HEATING ELEMENT 1. Disconnect unit from electric power and allow to cool. Remove grate. 2. Remove front and rear element covers. Note location of jumpers and wires. SUGGESTION: Removing a pivot will allow the element head to be tipped on its side for better access to the element connection screws. 3. Disconnect jumpers and wires from element to be removed. Remove short jumpers from the front of all elements. Remove element nuts from the front end of all elements. Slide the front element support frame off of the elements. 4. Remove the rear element nut from all elements to be replaced. Withdraw the old element from the rear element support frame and discard. 5. Apply a small amount of anti-sieze to the element threads, then attach the element to the rear element support frame. NOTE: The element mounts such that the end with the shoulder is positioned at the rear, the "flat" of the element is down, and the electrical connection pad is toward the bottom. 6. Examine all rear elements for proper alignment, and all rear element nuts for tightness. 7. Thread an element nut on the front end of the new element. Run the nut inboard until a single thread remains exposed. Examine all the other inboard element nuts to verify that only a single thread remains exposed on each. IMPORTANT: Review page 7 for procedure on reinstalling pivots. 9. Reconnect all jumpers and wiring. Reinstall element covers. If any pivots were removed or loosened, be sure element support bar is fully forward before reinstalling the element assembly on the pivots. 10. Reconnect to electric power and test for proper operation. Reinstall grate. 8 SV161 SvcManual Electric Char-Broilers SUGGESTION: At the rear element connections, install upper group of jumpers first, then install lower group. Installing jumpers in this order will ease accessibility conflicts. 8. Slide the front element support frame over the elements. NOTE: Position front element support frame such that the cover mounting holes on its face are at the top, and the edge with the cover mounting slot and threaded tabs is at the bottom. Loosely reinstall all front element nuts. Adjust front and inboard element nuts until the front and rear element support frames are the same distance apart on right and left ends. Tighten front and inboard element nuts evenly. SERVICING INSTRUCTIONS (continued) REAR ELEMENT SUPPORT FRAME REAR ELEMENT NUT SERVICING NOTE: SHOULDER AT REAR END HEATING ELEMENT NOTE: NO SHOULDER AT FRONT END T ON FR LONG JUMPER (REAR) NOTE: ALL JUMPER SCREWS INSERT FROM BOTTOM INBOARD ELEMENT NUT FRONT ELEMENT SUPPORT FRAME FRONT ELEMENT NUT SV161 SvcManual Electric Char-Broilers SHORT JUMPER (FRONT) FRONT INSTALL FIRST 15 REAR 2 INSTALL LAST NOTE: B-44(6) shown. B-50(6) utilizes two identical element heads. B-40(6) is similar. 9 1 SERVICING INSTRUCTIONS (continued) CAUTION: HOT SURFACE Exposed surfaces can be hot to the touch and may cause burns. SERVICING IMPORTANT: DO NOT attempt to raise the element assembly without first removing the grate. Damage to the hinges will result. Such damage is NOT covered by warranty. IMPORTANT: DO NOT attempt to lower the element assembly without first releasing the support rod. Damage to the hinges will result. Such damage is NOT covered by warranty. REPLACE SUPPORT ROD SPRING 1. Disconnect unit from electric power and allow to cool. Remove grate. 2. Remove rear element cover. Remove one pivot , then slide the element head off of the other pivot. 3. Use a flat blade screwdriver to pry open the split end of the support bar. Withdraw and discard all segments of the broken spring 4. Swing the support rod to the rear until the slot in the rod's split end is vertical. 5. Slide the new spring into the support rod slot. The long finger must be toward the outside and pointing toward the front. 6. Position the spring so that the short finger is fully seated in the support rod slot. Then, use pliers to pinch the split end, capturing the spring. 7. Rotate the long finger of the spring clockwise until it is captured by the vertical walls at the back and side of the frame support casting. 8. Swing the support rod forward until it is against the elements, then reinstall the element head on its pivots. Reinstall pivot. 9. Test the support rod for proper operation. It should spring into position to support the element head when the head is raised. 10. Reinstall rear element cover. 11. Reconnect unit to elctric power and test for proper operation. Reinstall grate. SUPPORT ROD REMOVE OLD SPRING 10 INSTALL NEW SPRING TENSION NEW SPRING SV161 SvcManual Electric Char-Broilers SUPPORT ROD SPRING EXPLODED VIEWS & SERVICE PARTS CONTROL KNOB IDENTIFICATION All versions of the Wells Electric Char-Broiler use control knob p/n 50371. OFF WELLS 2 8 LO HI 7 3 5 6 SV161 SvcManual Electric Char-Broilers EXPLODED VIEWS 4 11 EXPLODED VIEWS & SERVICE PARTS B-40 COUNTERTOP CHAR-BROILER BROILER GRATE 21707 REAR ELEMENT CASTING ASSEMBLY 57509 ELEMENT ASSEMBLY 52722 (208V) 52723 (240V) INDIVIDUAL ELEMENT 50007 (208V) 50005 (240V) REAR ELEMENT COVER 52728 SUPPORT ROD 52729 FRONT ELEMENT CASTING ASSEMBLY 57508 EXPLODED VIEWS HANDLE & FRONT ELEMENT COVER 500686 SUPPORT ROD SPRING 52428 GREASE PAN 20202 TERMINAL BLOCK 50131 LEFT PIVOT BRACKET 52840 RIGHT PIVOT BRACKET 52841 BRACKET COVER 52806 WE LL SV161 SvcManual Electric Char-Broilers AMBER LIGHT SIGNAL 50516 S TRADEMARK LABEL 53848 POP RIVET 54284 4” ADJUSTABLE FEET (PK 4) 20563 STAINLESS 20314 PLASTIC CONTROL KNOB 50371 TRIM RING ASSEMBLY 50256 INFINITE SWITCH CONTROL 54593 12 EXPLODED VIEWS & SERVICE PARTS (continued) B-406 BUILT-IN CHAR-BROILER BROILER GRATE 21707 ELEMENT ASSEMBLY 52722 (208V) 52723 (240V) INDIVIDUAL ELEMENT 50007 (208V) 50005 (240V) REAR ELEMENT COVER 52728 REAR ELEMENT CASTING ASSEMBLY 57509 FRONT ELEMENT CASTING ASSEMBLY 57508 HANDLE & FRONT ELEMENT COVER 500686 SUPPORT ROD 52729 GREASE PAN 20202 TERMINAL BLOCK 50131 LEFT PIVOT BRACKET 52840 RIGHT PIVOT BRACKET 52841 SV161 SvcManual Electric Char-Broilers BRACKET COVER 52806 TOP ASSEMBLY 52730 CONTROL PANEL 54015 RED LIGHT SIGNAL 50385 OUTLET BOX 53859 INFINITE SWITCH CONTROL 54593 CONTROL KNOB ASSEMBLY 50371 POP RIVET 54284 13 EXPLODED VIEWS SUPPORT ROD SPRING 52428 EXPLODED VIEWS & SERVICE PARTS (continued) B-44 COUNTERTOP CHAR-BROILER BROILER GRATE 21706 REAR ELEMENT COVER 52740 ELEMENT ASSEMBLY 52737 (208V) 52738 (240V) INDIVIDUAL ELEMENT 50020 (208V) 50019 (240V) REAR ELEMENT CASTING ASSEMBLY 57507 SUPPORT ROD SPRING 52428 EXPLODED VIEWS HANDLE & FRONT ELEMENT COVER 500687 FRONT ELEMENT CASTING ASSEMBLY 57506 GREASE PAN 20174 RIGHT PIVOT BRACKET 52841 LEFT PIVOT BRACKET 52840 BRACKET COVER 52806 ACCESS COVER 57893 CONTACTOR 57779 (208V) 57780 (240V) TRADEMARK LABEL 53848 TRIM RING ASSEMBLY 50256 TIMER WIRE TUBING (24”) 52128 WE LL S CONTROL KNOB 50371 4” ADJUSTABLE FEET (PK 4) 20563 STAINLESS 20314 PLASTIC POP RIVET 54284 INFINITE SWITCH CONTROL 54593 AMBER LIGHT SIGNAL 50516 14 SV161 SvcManual Electric Char-Broilers TERMINAL BLOCK 50131 EXPLODED VIEWS & SERVICE PARTS (continued) B-446 BUILT-IN CHAR-BROILER ELEMENT ASSEMBLY 52737 (208V) 52738 (240V) INDIVIDUAL ELEMENT 50020 (208V) 50019 (240V) BROILER GRATE 21706 FRONT ELEMENT CASTING ASSEMBLY 57506 REAR ELEMENT COVER 52740 SUPPORT ROD SPRING 52428 HANDLE & FRONT ELEMENT COVER 500687 GREASE PAN 20174 RIGHT PIVOT BRACKET 52841 LEFT PIVOT BRACKET 52840 BRACKET COVER 52806 SV161 SvcManual Electric Char-Broilers CONTACTOR 57779 (208V) 57780 (240V) TERMINAL BLOCK 50131 MOUNTING BRACKET 60843 CONTROL BOX 51033 RED LIGHT SIGNAL 50385 INFINITE SWITCH CONTROL 54593 CONTROL PANEL 51023 CONTROL KNOB ASSEMBLY 50371 POP RIVET 54284 15 EXPLODED VIEWS REAR ELEMENT CASTING ASSEMBLY 57507 EXPLODED VIEWS & SERVICE PARTS (continued) B-50 COUNTERTOP CHAR-BROILER BROILER GRATE 21706 SUPPORT ROD SPRING 52428 REAR ELEMENT CASTING ASSEMBLY 57507 REAR ELEMENT COVER 52740 ELEMENT ASSEMBLY 52737 (208V) 52738 (240V) INDIVIDUAL ELEMENT 50020 (208V) 50019 (240V) EXPLODED VIEWS SUPPORT ROD 52741 FRONT ELEMENT CASTING ASSEMBLY 57506 GREASE PAN 20174 HANDLE & FRONT ELEMENT COVER 500687 CENTER PIVOT ASSEMBLY 53895 DOUBLE PIVOT COVER 53245 PIVOT BRACKET COVER 52806 CONTACTOR 57779 (208V) 57780 (240V) LEFT PIVOT BRACKET 52840 AMBER LIGHT SIGNAL 50516 TRADEMARK LABEL 53848 WE LL S POP RIVET 54284 CONTROL KNOB 50371 TRIM RING ASSEMBLY 50256 INFINITE SWITCH CONTROL 54593 16 4” ADJUSTABLE FEET (PK 4) 20563 STAINLESS 20314 PLASTIC SV161 SvcManual Electric Char-Broilers TERMINAL BLOCK 50131 RIGHT PIVOT BRACKET 52841 EXPLODED VIEWS & SERVICE PARTS (continued) B-506 BUILT-IN CHAR-BROILER BROILER GRATE 21706 REAR ELEMENT CASTING SUPPORT ASSEMBLY ROD SPRING 57507 52428 SUPPORT ROD 52741 HANDLE & FRONT ELEMENT COVER 500687 FRONT ELEMENT CASTING ASSEMBLY 57506 GREASE PAN 20174 DOUBLE PIVOT COVER 53245 CENTER PIVOT ASSEMBLY 53895 CONTACTOR 57779 (208V) 57780 (240V) PIVOT BRACKET COVER 52806 TERMINAL BLOCK 50412 SV161 SvcManual Electric Char-Broilers LEFT PIVOT BRACKET 52840 RIGHT PIVOT BRACKET 52841 CONTROL PANEL 54015 TOP ASSEMBLY 52759 RED LIGHT SIGNAL 50385 OUTLET BOX 53859 INFINITE SWITCH CONTROL 54593 CONTROL KNOB ASSEMBLY 50371 POP RIVET 54284 17 EXPLODED VIEWS REAR ELEMENT COVER 52740 ELEMENT ASSEMBLY 52737 (208V) 52738 (240V) INDIVIDUAL ELEMENT 50020 (208V) 50019 (240V) WIRING DIAGRAMS TERMINAL BLOCK 1ø LONG JUMPERS (20) 1 L1 3 2 L2 4 HEATING ELEMENTS (24) TERMINAL BLOCK 3ø SHORT JUMPERS (12) L1 1 2 L3 3 WIRING L2 4 9 LIGHT SIGNAL HEATING LIGHT SIGNAL HEATING 18 B-406 ONLY 17 INFINITE SWITCH P 17 L1 L2 P INFINITE SWITCH H1 H2 7 18 8 L1 L2 H1 H2 5 6 JUMPER INSTALLATION FRONT SV161 SvcManual Electric Char-Broilers INSTALL FIRST REAR 6 7 5 8 NOMINAL AMPS PER LINE B-40 and B-406 208V, 240V VOLTS KW AMPS 3ø L1 208 240 p/n 31269 issue I 18 5.4 5.4 L2 L3 12.9 12.9 24.4 11.2 11.2 19.4 AMPS 1ø 26.0 22.5 WIRING DIAGRAMS (continued) L1 B-40 and B-406 208V 240V L2 S1-2 H2 3ø H1 S1-1 L3 L2 L3 L2 L1 P LIGHT SIGNAL HEATING L1 S2-1 H1 H2 S2-2 P LIGHT SIGNAL HEATING SV161 SvcManual Electric Char-Broilers B-40 and B-406 208V WIRING HEATING ELEMENTS L1 L2 240V 1ø LIGHT SIGNAL HEATING P L1 S1-1 L1 S2-1 H1 H1 P HEATING ELEMENTS 19 H2 S1-2 L2 H2 S2-2 L2 LIGHT SIGNAL HEATING WIRING DIAGRAMS (continued) TERMINAL BLOCK 1ø LONG JUMPERS (15) 9 11 L1 12 6 L2 HEATING ELEMENTS (18) 13 8 TERMINAL BLOCK 3ø SHORT JUMPERS (9) 9 L1 12 L3 11 6 CONTACTOR 13 L2 8 16 WIRING B-446 ONLY LIGHT SIGNAL HEATING C 18 17 P INFINITE SWITCH L1 L2 H1 H2 CAPACITOR 2 1 15 JUMPER INSTALLATION FRONT REAR 1 2 15 INSTALL LAST NOMINAL AMPS PER LINE B-44 and B-446 208V, 240V VOLTS KW AMPS 3ø L1 208 240 p/n 31278 issue M 20 5.5 5.5 L2 L3 11.5 22.4 14.4 10.0 19.5 12.5 AMPS 1ø 26.0 22.5 SV161 SvcManual Electric Char-Broilers INSTALL FIRST WIRING DIAGRAMS (continued) L1 L3 B-44 and B-446 208V C1 COIL P 240V LIGHT SIGNAL HEATING C L1 S1-1 H1 L2 3ø H2 C1-3 S1-2 L2 C1-2 WIRING C1-1 HEATING ELEMENTS SV161 SvcManual Electric Char-Broilers L1 L3 B-44 and B-446 P L1 S1-1 H1 208V C1 COIL C 240V L2 1ø LIGHT SIGNAL HEATING H2 C1-3 S1-2 C1-2 C1-1 HEATING ELEMENTS 21 L2 22 L2 L3 L1 19 7 11 17 10 13 8 17 12 9 11 22 7 19 22 12 13 8 B-506 ONLY 23 TERMINAL BLOCK 3ø L2 L1 9 L1 L2 H1 H2 P 18 CONTACTOR p/n 31226 issue S B-50 and B-506 208V, 240V INFINITE SWITCH 16 16 LIGHT SIGNAL HEATING C 20 CAPACITOR SHORT JUMPERS (9) LEFT SECTION HEATING ELEMENTS (18) LONG JUMPERS (15) SV161 SvcManual Electric Char-Broilers 10 1 2 KW 10.8 10.8 VOLTS 208 240 3 INFINITE SWITCH 16 16 L1 L2 21 L2 L3 30.0 30.0 30.0 26.0 26.0 26.0 L1 AMPS 3ø 45.0 AMPS 1ø NOMINAL AMPS PER LINE H1 H2 P CONTACTOR C 20 CAPACITOR SHORT JUMPERS (9) RIGHT SECTION HEATING ELEMENTS (18) LONG JUMPERS (15) LIGHT SIGNAL HEATING WIRING TERMINAL BLOCK 1ø (240V ONLY) 4 5 6 WIRING DIAGRAMS (continued) INSTALL FIRST 23 4 5 2 WIRING 3 1 6 INSTALL LAST LEFT REAR INSTALL FIRST RIGHT FRONT RIGHT REAR LEFT FRONT B-50 AND B-506 JUMPER INSTALLATION SV161 SvcManual Electric Char-Broilers INSTALL LAST WIRING DIAGRAMS (continued) WIRING DIAGRAMS (continued) L1 L3 B-50 and B-506 208V 240V L2 3ø P C1 COIL LIGHT SIGNAL HEATING H1 S1-1 L1 C L2 S1-2 H2 C1-3 C1-1 WIRING C1-2 LEFT SECTION HEATING ELEMENTS P L1 S2-1 H1 C2 COIL LIGHT SIGNAL HEATING C H2 S2-2 L2 C2-2 RIGHT SECTION HEATING ELEMENTS 24 SV161 SvcManual Electric Char-Broilers C2-3 C2-1 WIRING DIAGRAMS (continued) L1 L3 B-50 and B-506 240V ONLY L2 1ø P C1 COIL LIGHT SIGNAL HEATING H1 S1-1 L1 C L2 S1-2 H2 C1-3 WIRING C1-1 C1-2 LEFT SECTION HEATING ELEMENTS P L1 S2-1 H1 C2 COIL LIGHT SIGNAL HEATING SV161 SvcManual Electric Char-Broilers C H2 S2-2 L2 C2-3 C2-1 C2-2 RIGHT SECTION HEATING ELEMENTS 25 IMPORTANT: WELLS BLOOMFIELD PROPRIETARY INFORMATION. DISSEMINATION OF THIS INFORMATION TO ANYONE OTHER THAN WELLS AUTHORIZED SERVICE AGENTS IS STRICTLY PROHIBITED. TECHNICAL CONTENT OF THIS MANUAL IS DESIGNED FOR USE BY QUALIFIED PROFESSIONAL TECHNICIANS ONLY. Commercial Food Equipment Service Association Wells Bloomfield proudly supports CFESA Commercial Food Equipment Service Association SERVICE TRAINING - QUALITY SERVICE Genuine Parts Protect - YOU - All - Ways CUSTOMER SATISFACTION WELLS BLOOMFIELD, LLC 2 ERIK CIRCLE, P. O. Box 280 Verdi, NV 89439 telephone: 775-689-5703 fax: 775-689-5976 www.wellsbloomfield.com PRINTED IN UNITED STATES OF AMERICA