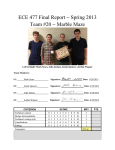

Download EE 477 Final Report

Transcript