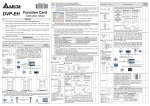

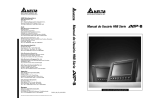

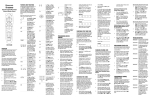

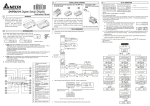

Download Delta - InduProgress

Transcript