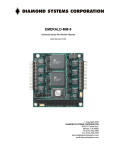

Download PMC520 User`s Manual

Transcript