Download Gilibrator User Manual - Enviro

Transcript

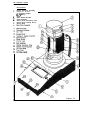

Instruction Manual for the Gilian” Primary Standard Airflow Calibrator with Interchangeable Flow Cell Assemblies Flow Cell Assembly Ranges Low : 1 to 250 cc/min. Standard : 20 cc/min. to 6 LPM High : 2 to 30 LPM On-Site Instruments l-8OO-7-On-Site (l-800-766-7483) 689 North James Road - Columbus, Ohio 43219 Prologue This Instruction Manual describes the basic principles, installation, operation/controls and maintenance for the Cilibrator, Primary Standard Airflow Calibrator manufactured by Cilian Instrument Corp. Table of Contents The Gil ibrator Page # Section # 1 Introduct ion 2 2 General Description 2-6 3 Theory 4 Operating Procedures Initial Set-up & O p e r a t i o n 8-12 5 Storage 13-17 6 The Printer Module Introduction E General Description Theory of Operation Operation Procedures Storage and Maintenance 7 of E Operation Maintenance 7 18 18-19 19 19-21 21 Spec if icat ions The Gil ibrator The Printer Module 22 23 8 Cilibrator Parts List 23 9 Warranty E Service Policy 24 1 Section 1 Introductih The Gilibrator is a high accuracy, electronic bubble flowmeter that provides instantaneous air flow readings and a cumulative averaging of The Gilibrator system provides a large dynamic range multiple samples. through the use of 3 interchangeable flow cell assemblies. A delete f u n c t i o n , o n t h e C o n t r o l U n i t , subtracts eroneous readings to insure a c c u r a t e d a t a . The Control unit also supports a hard copy print out through the use of a printer accessory-. Section 2 General Description (See fig. la) The Gilibrator is comprised of the following basic components: Flow Cell Assembly, Control Unit (base), Battery Charger and Soap Solution. Different sized inter-changeable Flow Cell Assemblies are available for use as follows: Low Flow : 1 to 250 cc/min. S t a n d a r d F l o w : 2 0 cclmin t o 6 L P M High Flow : 2 to 30 LPM In addition to the basic components, an optional Printer Module is available. The printer provides a hard copy record of calibration data, however, identical data is displayed on the LCD of the Cilibrator Control Unit during calibration. 1. Flow Cell Assembly (See fig. lb) The Flow Cell Assembly consists of a Bubble Generator and Sensor Block. Each Bubble Generator is sized to produce a bubble film stretched across the diameter of the flow cell tube which is carried by airflow from the bottom to top of the tube. A s t h e b u b b l e t r a v e r s e s p a s t t w o i n f r a r e d sensors, each sensor transmits a signal to the Control Unit (base) indicat i n g t h e p a s s a g e o f t h e f i l m . The Flow Cell Assembly incorporates a manual bubble initiation push button which starts the film on its travel up the tube. A. Bubble Generator 1) Flow Ranges Low Flow : 1 t o 2 5 0 cclmin. S t a n d a r d F l o w : 2 0 cc/min t o 6 L P M I High Flow : 2 to 30 LPM 2) Pulsation Damper (2) - a built-in damper smoothes out any pulsation’ within the airflow and reduces occilation of the bubble film assuring maximum accuracy. 3) Bu bble Initiate Button (22) - T h i s p u s h b u t t o n Generator Ring (21) into the soap solution releasing the button, the ring lifts out of the a film bubble is generated across the opening (241. 2 lowers the Bubble reservoir. Upon soap solution and of the flow tube 4 ) B u b b l e B r e a k e r ( 4 ) - The Bubble Breaker is a secondary chamber in the upper chamber which provides the soap film a rapid expansion path which is instrumental in breaking the bubble. ‘This prevents excessive wall wetting by the soap film and allows it to flow back into the cell. 5) Storage Tubing (25) - T h i s a n t i - s p i l l t u b i n g c o n n e c t s u p p e r a n d lower cell chambers and prevents the soap solution from evaporating which may cause the solution concentration to change.’ CAUTION: If transporting by plane, be sure to disconnect this hosing from upper or lower Flow Cell Chamber Bosses (23 & 26) to prevent pressurization and possible rupture within the Bubble Generator. 8. Sensor Block (8) S u r r o u n d i n g t h e f l o w t u b e (24),and s e c u r e d b e t w e e n t h e u p p e r a n d lower chamber of the bubble generator, is the Sensor Block (8). The blockincorporates lower and upper sensors for time start and time stop. Thesensors consist of an infrared emitter and detector p a i r s w h o s e s e n s i t i v i t y a n d a c c u r a c y i s c o n t r o l l e d b y a “columnating slot”. This block is secured to the Bubble Generator Assembly (1) by means of two Locking Screws ((7) and allows easy removal to facilitate cleaning. 1) Electrical Interface - The Electrical Interface provides power to the sensing system as well as transmits timing information to the Control Unit. 2. The Control Unit (base) (See fig. la) The Control Unit (14) contains a crystal controlled timing system, a micro processor control system, and an LCD readout for displaying flow and messages. The Control Unit also contains switches for Reset (17), D e l e t e ( 1 6 ) a n d A u t o - A v e r a g i n g ( 1 5 ) f u n c t i o n s a s w e l l a s a n Printer Jack (18) interface port for direct connection to a hard copy printer. LED indicators are provided to note Charging (11) and Run calibration (20) operation. a ) Power ( 1 2 ) - s w i t c h t u r n s t h e C o n t r o l U n i t s p o w e r o n a n d o f f . b) Charge Indicator LED into the Charging Jack c) Printer Jack d) Reset themicro (11) - lights when the charger is plugged (18) - provides interface for auxillary printer. (17) - p u s h b u t t o n d e l e t e s a l l c u r r e n t i n f o r m a t i o n processor in order to initiate a new sequence. for e) Delete (16) - push button automatically deletes false information from the average and will reset the average and sample number When a printer is in line, this will to the previous reading. indicate a minus symbol and the average will return to the previous value. 3 f) Average (15) - p u s h b u t t o n w h e n p u s h e d a n d h e l d w i l l d i s p l a y the average of the previous sequence of readings. When released will display the last actual reading and when re-pushed and held, w i l l s h o w t h e numbe,r o f s a m p l e s i n t h e s e q u e n c e w i t h d i s p l a y information (S=sample #). Releasing the button will automatically bring the display back to the last reading. g) Sequence Run Indicator LED (20) - indicates bubble sequence by lighting as the bubble passes between the two sensors. The LCD (19) will be blank. The Run signal will also light when turning on the Control Unit and will extinguish after unit has finished it’s initial sequence check. h) Low Battery - w i l l i n d i c a t e o n t h e L C D d i s p l a y ( 1 9 ) i f i n s u f f i cient battery voltage is available to operate the unit properly. Since power for all Control Unit functions is derived from the r e c h a r g e a b l e ‘NiCad b a t t e r y , t h e b a t t e r i e s m u s t b e f u l l y c h a r g e d f o r p r o p e r o p e r a t i o n . A “Low B a t t e r y ” i n d i c a t i o n w i l l a l s o a p p e a r initially when turning the Control Unit ON as a sequence check of the unit’s electronics. i) C a b l e A s s e m b l y (5) - m a t e s w i t h t h e C o n n e c t i n g J a c k ( 6 ) i n t h e back of the Sensor Block. It provides power for the sensing system, information regarding cell size , and control of the timing information to the micro processor. j) T i m i n g S y s t e m - T h e q u a r t z c o n t r o l l e d t i m i n g ‘ s y s t e m c o n t r o l s i n f r a - r e d s e n s o r a c t i v a t i o n t o a s s u r e m a x i m u m c a l c u l a t i o n accuraCY. k) Micro Processor - controls the timing and mathematical data processing to provide optimum flow measurement characteristics. This programmable micro processor can be upgraded as new programs become available. 3. Battery Charger Standard wall operated 120V charger to charge Gilibrator Control U n i t f o r 1 4 h o u r s p r i o r t o o p e r a t i o n . The Charging LED on the Control U n i t w i l l b e i l l u m i n a t e d w h i l e ,charging i s i n p r o g r e s s . 4. Soap Solution This specially compounded low residue soap is specifically designed to provide high film strength and compatibility with the materials used within the Flow Cell Assembly. The Gilibrator System The Gilibrator Nomenclature 1. 2. 3. :: 6. 7. 6. 9. Bubble Generator Assembly Damper Plate 2a. Pulsation Damper 2b. “0” Ring Spacer Plate, Bubble Breaker Cable Assembly Sensor Block Connecting Jack Sensor Block Locking Screw Sensor Block 10. 11. 12. 13. 14. 15. 16. 17. 16. 19. 20. 21. 22. 23. 24. 25. 26. Figure la The Gilibrator System The Flow Cell Assembly Nomenclature 1. 2. 3. 4. 7. a. 9. 21. 22. 23. 24. 25. 26. 27. I I Bubble Generator Assembly Damper Plate 2a. P u l s a t i o n D a m p e r 2 b . “0” R i n g Spacer Plate, Bubble Breaker Sensor Block Locking Screw Sensor Block Base Plate Assembly 9a. “0” R i n g Bubble Generator Ring Bubble Initiate Button Air Inlet Boss Flow Tube Storage Tubing Air Outlet Boss Safety Tape a--- Figure lb 6 w Section 3 Theory of Operation 1. Primary Airflow Standard To be a primary standard, all values must be absolute and measured as absolute. A primary standard airflow measurement is a volume divided by a time interval as performed by the Control Unit of the Gilibrator. The volume, V, is measured volume of space between two infrared sensors. The time is that interval needed for a soap film bubble to traverse between the two sensors which bound the volume. T h e r e f o r e , V/t, t h e v o l u m e p e r u n i t o f time, becomes the airflow and is prime because all measurements are basic... volume and time. In today’s technology, time is measured by an electronic clock whose accuracy exceeds that of volume measurements by orders of magnitude, hence, the control accuracy volume resides solely with volume measurements. 2. Bubble Generation and measurement a) The Gilibrator consists of two elements, the Flow Cell Assembly and the Control Unit (base). T h e f u n c t i o n o f t h e F l o w C e l l A s s e m b l y -is to generate a clean consistent bubble which traverses up the flow tube. Measurement of the traverse time is done by infrared sensor pairs which are m o u n t e d a t t h e b o t t o m a n d t h e t o p o f t h e S e n s o r B l o c k . The volume bound by these sensors is specifically adjusted to a volume standard by allowing the upper sensor blocks to move in unison so as to enable this calibration to be set accurately to a primary volume standard, A second function of the sensor block provides the interfacing code to define the cell volume as well as sensitivity adjustments for the optical sensor systems. b) A s t h e b u b b l e t r a v e r s e s b e t w e e n t h e s a n s o r s , f i r s t o n e a n d t h e n t h e second, sensors are tripped thereby providing the time for the bubble This timing information is sent to the micro processor of the traverse. control base which in turn provides the crystal control time base for the T h e t i m i n g i n f o r m a t i o n a l o n g w i t h t h e volu,me i n f o r m a t i o n a r e t h e n system. sent to the micro processor which in turn does the necessary mathematical calculations which allow the flow to be displayed directly on the LCD readout. In order to insure the highest accuracy possible, a Delete and Average function are provided on the Control Unit. The Delete allows for subtracting out an obvious malformed bubble and the average allows the user to obtain average information without pencil or paper. A printer interface allows connection of a Printer Module so that hard copy can be produced. Section 4 Operating Procedures 1. Initial Set-up This covers all steps necessary to bring the Gilibrator into This includes charging, cell mounting, installing operating status. soap solution, connecting the printer (optional) and connecting the sampling source. A) Charging the Gilibrator 1. Prior to operation, plug the 120V charger into the wall and connect to the Charging Jack (13) on the right side of the Control Unit. The unit’s Charging LED (11) will light indicating that the unit is charging properly. Allow the battery system to charge for 14 hours prior to operation. B) M o u n t i n g t h e F l o w C e l l A s s e m b l y ( S e e f i g . 2 ) 1. Select the Flow Cell Assembly to cover the flow range required. 2. The bottom of the Flow Cell Assembly employs a quick mount feature. The base of the Flow Cell Assembly is positioned onto the mounting plate (10) of the Control Unit (14). Figure 2 M O ‘unting late Cell Assembly (bottom) Control Unit J a 3. Engage the pin of the cell assembly base into the mounting plate of the Control Unit. When the Flow Cell Assembly is properly engaged, the base of the cell will be flush to the mounting plate and the cell assembly will face towards either the right or left side. (See fig. 3) Figure 3 I I I I I I F l o w C e l l Assembly- ‘Mounti Control I Unit/ Cell Assembly Mounted 4 . G r a s p t h e b o t t o m c e l l c h a m b e r and r o t a t e t h e c e l l u n t i l i t clicks in. CAUTION: Always engage E disengage the cell by grasping and rotating 09 the bottom cell chamber. The cell assembly will now face forward. (see Fig. 4) Figure 4 Flow Cell Assembly Firmly twist cell into the locking position Control Unit 5 . Insert t h e C o n t r o l U n i t ’ s C a b l e A s s e m b l y ( 5 ) i n t o t h e S e n s o r Block Connecting Jack (6) located on the back of the Sensor Block (8). ( S e e f i g . 5 ) Figure 5 0 . . . . . . . . . Sensor Block Connecting Jack Control Unit Interface Plug Cl Adding Connecting the Control Unit’s Interface Plug to the Sensor Block’s Connecting Jack. the Gilibrator Soap Solution 1. Remove the Storage Tubing (25) from the upper Outlet Boss 26) of the upper cell. Fill the dispenser bottle provided with Cilibrator soap solution. Using the rubber Storage Tubing as a funnel, slowly add soap solution from the dispenser. 2. The amount of soap needed is determined by depressing the Bubble Initiate Button (22) and holding it down in the lower position. Continue to add enough soap solution until the angled edge at the bottom of the Bubble Generator Ring (21) is immersed in the solution. Do Not Overfill! (See fig. 6) 3. After filling is completed, the rubber Storage Tubing (25) may be removed completely. Recap the soap dispenser bottle for later u s e . N O T E : If the Flow Cell Assembly is not going to be used for a prolonged period of time, reinstall the rubber Storage Tubing between the inlet and outlet bosses (23 t 26). This will p&vent evaporation from occurring which may cause the solution’s concentrations to alter. D) Printer Connection (if applicable) 1. Connect printer cable to Printer Jack connector (18) on the left side of the Control Unit. Be sure to properly match up connectors before engaging. 10 Bubble Initiate Bubble Gel Solution Res E) C o n n e c t the Sampler 1. Connect the air sampler to be calibrated to the Upper Outlet B o s s ( 2 6 ) o f t h e F l o w C e l l A s s e m b l y w i t h l/4@’ ID tubing. NOTE: An auxillary liquid trap between sampler and flow cell is recommended to prevent moisture carry over into the sampler during continuous calibration periods. 2 . Operation A) Conditioning the Flow Tube 1. Turn on the sampler. Depress the Bubble Initiate Button (22) several times to wet the inner walls of the flow tube (24). You will not be able to initiate a timing bubble without first “Priming”the f l o w t u b e . T h e o p e r a t o r w i l l d e v e l o p a f e e l f o r b u b b l e generat i o n w i t h p r a c t i c e . B) P o w e r U p 2. After the Flow Tube walls have been “primed”, turn on the Power Switch (12) of the Cilibrator Control Unit (base) and the Printer M o d u l e i f o n e i s b e i n g u s e d . Wait approximately 10 seconds while the system runs through it’s check sequence. The Run LED (20) will light at this time as well as a Lo Battery indication and a series of five dashes displayed on the LCD Readout (19). Do not operate the Cilibrator until the Run LED signal extinguishes. Ready operation is indicated by a series of 4 dashes. C) Bubble Generation depress the Bubble Initiate 1. For optimum bubble generation, Button (22) and hold to initiate 1 bubble up the flow tube. Release the button to initiate a second bubble up the flow tube. This will be the standard procedure to making clean, consistent bubbles at High and Medium flow ranges. 11 2 . A s t h e b u b b l e r i s e s u p t h e F l o w T u b e (24). i t w i l l i n i t i a t e a timing sequence when it passes the lower sensor (Run LED will light) and culminate the timing sequence upon passing the upper sensors (Run LED will extinguish). The timing information is then transmitted to the control unit which will perform all the necessary calculation. A flow reading will instantaneously appear on the LCD display (19). However, if a bubble breaks before the time sequence is completed, timing will continue until another bubble is generated to trip the second sensors. This will cause an erroneous reading and should be subtracted from the average by hitting the Delete Button (16). If a Printer Module is used, be sure Led i t ’ s p r i n t i n g s e q u e n c e b e f o r e p r e s s i n g the Delete Button is activated, a negative ed on the LCD of the Control Unit and a’line showing this subtraction. t h e p r i n t e r h a s complethe Delete Button. When symbol will be displaythe printer will initiate D) Flow Readout With Printer Option - T h e p r i n t e r w i l l p r i n t i n s e q u e n c e t h e f l o w , average and sample number of each successive bubble reading. Without Printer Option - T h e C o n t r o l U n i t w i l l d i s p l a y t h e a c t u a l flow for each sample and will accumulate and average each successive reading. 1 . A v e r a g e ( 1 5 ) - In order to display average and number of samples, depress and hold the Average Button. Releasing the button will display the last flow reading. Repressing the button will display the number of samples accumulated for that averaging sequence and releasing will once again display the last flow reading. Additional pressing and holding will repeat this sequence. 2. Delete (16) - To delete obvious false readings, push the Delete Button which will automatically delete the false information from the average and reset the average and sample number back to the previous reading. 3. Reset (17) - To reinitiate the sequence for additional pumps, h i t t h e R e s e t B u t t o n . This will zero out all sample and average registers within the Control Unit and will cause the printer to i n d e x oneline and reprint sequence headings. This denotes the start of a new sequence. The Reset Button is also used if a malformed bubble is generated and has not been been subtracted f r o m t h e a v e r a g e byuse o f t h e D e l e t e F u n c t i o n . 12 Section 5 Storage t Maintenance 1. Storage A. Take Down Turn OFF the Control [if applicable). Unit, the sampler and the Printer Module B. For Daily Use If Cilibrator is to be used daily, it is recommended that the air sampler be removed and the Storage Tubing be replaced between the upper Plug in the Charger and connect into the and lower cell chambers. Control Unit Charging Jack (13). Recharge overnight for next day usage. C. Long Term Storage If the Cilibrator is not to be used for long periods of time, the following steps should be taken to keep the unit in proper working order. 1. Disconnect the Cable Assembly on t h e F l o w C e l l A s s e m b l y . from the back of the Sensor Block 2. Remove the Flow Cell Assembly from the Control Unit (base). Remove the Cell from the base in the reverse order in which it was mounted. 3. Pour soap solution out of the Bubble Generator through the L o w e r I n l e t B o s s (23) B y h o l d i n g B u b b l e G e n e r a t o r h o r i z o n t a l l y a n d with the inlet boss facing down, tilt at a 45 degree angle. Continue until all of soap solution has poured out. (See fig. 7) Figure 7 13 4. Flushing the Bubble Generator Clean - There are 2 methods in which to cleanse the Bubble Generator. a. The unit may be flushed clean by connecting Storage Tubing to the Upper Outlet Boss and continuously running water through the generator until water runs clear. Maintain a horizontal position with cell bosses facing down and flush Then remove tubing and rock the for 15 - 30 seconds. cell in a see-saw fashion to empty out all excess water. Replace Seal Tubing between the Upper and Lower Cell bosses. (See fig. 8) Flow Cell Assembly 1 1 1 water clears. 1 1 Figure 8 I~FIOW I Cell Assembly; Rock the Flow Cell Assembly in a see saw fashion. or (see Figure 9) b. Remove the Sensor Block Assembly by loosening the 2 holding screwsand sliding the block out from between the Upper & lower cell chambers. Remove Safety Tape. Using a small flat blade screw driver, lift off the Damper Plate (2) using the notch between the upper chamber and the lid. Remove the Spacer (3) and then the Bubble Breaker Plate (4). This gives completeaccess to the interior of the Flow Cell Tube. Continue to run clear water through the cell until Rock cell to empty out all excess water. water runs clear. Replace the Bubble Breaker Plate (4) and center the Air Outlet Boss (26) with the plates largest hole. Next insert the spacer. To replace the Damper Plate assembly, moisten the O-ring (2b) w i t h s o a p s o l u t i o n a n d t h e n p r e s s t h e D a m p e r Plate into the top of the Upper Cell Chamber.Use fingers and firmly sqeeze p l a t e i n t o u p p e r f l o w c e l l c h a m b e r . 14 Figure 9 g-&J, Flush 1 -Doer F l o w C e l l Chlamber 1 Screws Do Not exert your body weight on the Bubble Generator to press plate into place. Excessive weight on the flow cell may result in breakage. Replace the Seal Tubing between the Upper and Lower cell bosses for storage. r Damper Plate Upper Flow Cell #sembly 1 Reposit ior! D a m p e r P l a t e A s s e m b l y into Upper F l o w C e l l C h a m b e r and press firmly into place. hamber Bubble Generator Assembly L 15 2. Maintenance The Cilibrator is designed so that little maintenance is required. The area which may need replacement is the Damper Diaphragm assembly. If the diaphragm becomes ruptured or worn please use the following procedure for its replacement. a. Removing and Replacing Damper Plate Diaphragm First, remove flexible Safety Tape (27) from around the lip of the 1) Using a small flat blade screwdriver, remove Damper Plate assembly. the Damper Plate (2) from the Upper Cell Chamber using the notch provided. R e m o v e t h e l a r g e O - r i n g (2b) a n d t h e P u l s a t i o n D a m p e r d i a p h r a g m (2aI. ( S e e f i g . 1 0 ) CA\ Damper Plate Assembly Figure 11 [A !r F l o w C e l l C h a m b e r Insert a Fiathead Screwdriver between the Damper Plate Assembly the Iip of the Upper Flow Cell a m b e r . Gently pry apart the two twisting the screwdriver. f3 Q 0 b-4 F i g u r e 1 0 Damper Plate Bubble Generator Assembly 2) To replace, center new diaphragm over Damper Plate aperture and roll O-ring over diaphragm and into the O-ring groove. If wrinkles occur, repeat the procedure to achieve a smooth placement. (See fig. 11) 16 Reposition Damper Plate Assembly into Upper Flow Cell Chamber D a m p e r P l a t e Asss bly- Upper Flow Cell Ch lber - Figure 12 Bubble Generator Assembly . 3) Wet 1@088-ring of Damper Plate Chamber firmly. (see Fig. 12) 4) Replace Safety cell chamber. Tape around & press into the Upper Cell lip of plate and the upper flow b . L e a k a g e C h e c k - T h e s y s t e m s h o u l d b e l e a k c h e c k e d a t 6” H20 by connecting a manometer to the outlet boss and evacuate the inlet No leakage should be observed. t o 6” H 2 0 . c. Cleaning - To clean the exterior mild detergent and warm water. NEVER OTHER HARSH CLEANERS TO CLEAN of the Bubble Generator use a USE ALCOHOL, ACETONE OR ANY THE BUBBLE GENERATOR. d. Transportation - When transporting the Gilibrator, especially by air, it is important that one side of the seal tube which connects the inlet and outlet boss, be removed thereby allowing f o r equalizing internal pressure within the generator. Do Not transport unit with soap solution or storage tubing in place. CAUTION: D o N o t P r e s s u r i z e t h e F l o w C e l l ! E x c e s s i v e p r e s s u r e m a y cause cell to rupture resulting in personal injury. 17 Printer Section 6 Module Operation Part # C-800274 1. Introduct ion The Cilibrator Printer provides a hardcopy record of all calibration data, identical to data calculated and displayed on the LCD readout of the Gil ibrator Control Unit (base). a. b. c. d. e. f. Handling Precautions Do not use where the temperature is extremely hot or cold. Do not leave in direct sunlight or where it is dusty. Do not operate near liquids or beverage. Do not operate without the heat sensitive roll paper loaded. Use only specified Cilian Replacement Roll Paper (A-400681). Do not attempt to disassemble the unit. NOTE: The printer should 0% b e u s e d w i t h t h e C i l i a n I n t e r c o n n e c t Cable providedwhich supplies the *power for the printer. Use of this printer with any other cable may cause permanent damage to the printer and to the equipment from which the cable is connected. The use of a non-shielded interface cable with the printer is prohibited. 2. G e n e r a l D e s c r i p t i o n ( S e e f i g . 13) The Printer is comprised of the following basic components: The Printer M o d u l e (l), I n t e r c o n n e c t C a b l e ( 2 ) a n d t h e T h e r m a l R o l l P a p e r . A b r i e f description is provided of their use and operation. The Gil ibrator System The Printer Module Assembly Nomenclature 1. Printer Module 2. Printer Interconnect Cable 3. Thermal Paper Cover 4. Paper Cutter 5. Paper Feed 6. Power (On-Off) 7. Parallel Interface Connect0 18 a) Printer Module 1 .Power (6) - T h i s s w i t c h a c t i v a t e s o p e r a t i o n o f t h e p r i n t e r f r o m the Control Unit’s power source. The printer will initially print a heading line upon activation. 2.Paper F e e d ( 5 ) - T h i s s w i t c h i s u s e d t o f e e d t h e T h e r m a l P a p e r continuously. P r e s s i t l i g h t l y . N o t e : Use the Paper Feed switch to feed out the paper. If paper is pulled out by hand, always feed it one line with the Paper Feed Switch before starting printing. 3.Paper C u t t e r ( 4 ) - T h i s i s u s e d t o t e a r o f t h e p a p e r . T e a r o f f by pulling it in the arrow direction only. b) Thermal Paper printer head. A specially treated paper which is activated by the .c) Interconnect Cable (2) - T h e i n t e r c o n n e c t c a b l e p r o v i d e s e l e c t r i c a l connection between the printer (1) and the Gilibrator Control Unit The printer operates from the same power source as the control (14). unit. 3. Theory of Operation The Printer Module is powered and interfaced to the Control Unit pf t h e C i l i b r a t o r b y m e a n s o f a n I n t e r c o n n e c t C a b l e . During a test series, the Control Unit transfers the sum of calculations of a given calibration bubble and provides the flow rate, the sample number and an average of the successive flow rates determined in that calibration series. The buttons on the Control Unit are used in conjunction with the Printer module during calculation. Delete, Auto Average and Reset buttons are provided to subtract false readings and to initiate new calibration sequences. Calculations are automatically provided by the Control Unit and transferred to the printer for a hardcopy readout. This is printed onto a thermal sensitive roll paper which advances a single line after printing out each successive reading. These hard copy calculations are retained for calibration records. 4. Operation Procedures a) Initial set-up 1 .Connect ing the Printer a) While the Gilibrator Control Unit is in the OFF mode, connect the large end of the Interconnect Cable (2) to the Printer Modules Parrallel Interface Connector and snap holding clips in place. Connect the smaller end to the Control Unit’s Printer connect port. Power is supplied to the printer from the Control Unit’s battery system. 2. Turn ON the Control Unit and the Printer Module. 19 1 3. Remove the heat sensitive roll paper cover. Installing the Thermal Paper (See fig. 14) a . SI i d e b a c k a n d r e m o v e the Thermal Paper Cover (3) from the printer section. (see Fig. 14) b . U s e t h e s p e c i a l Cilian heat sensitive roll paper (A-400681). 2) Cut the end of the heat sensitive paper a shown below. n n c. Cut the end of the paper in a half circle or triangular shape. d. While inserting the end of the paper, press the Paper Feed Switch (5) until the paper is fed Replace protective out. paper cover. (see Fig. 15) Figure 14 (3) While inserting the end of the tieat sensitive roll paper in the direction of the arrow, press and hold the paper feed switch until the paper is fed out. Since the outside of the heat rensitive roll paper is coated with a heat sensitive agent,‘pay careful attention to the front and back of the paper. Figure 15 b) Operation 1. Start Sequence a. Turn the Control Unit ON. out an identification heading test. The program version is t ion line for future reference. The Printer Module will print for the current calibration i n d i c a t e d a f t e r t h e identificaSee sample below. b. Initiate a bubble up the Flow Tube:and observe the reading on the Control unit and also on the Printer Module. The Printer will print in sequence the flow, average and sample number after each successive reading. NOTE : If you do not need a hard copy printout from the Printer Module, turn it OFF. This will preserve the battery life of the Gilibrator as the printer is powered by same. 2 . T h e A v e r a g e , R e s e t a n d D e l e t e b u t t o n s o n t h e C o n t r o l U n i t are used in conjunction with the printer during calibration. They are as follows: a) Average - In order to display average and number of samples, depress and hold average button. Releasing the button will display the last reading. Repressing will display the number of samples accumulated for that averaging sequence. Releasing the button will once again display the last flow reading. Additional pressing and holding will repeat this sequence. b. Reset - To reinitiate the sequence for additional pumps,hit the Reset Button. T h i s w i l l z e r o o u t s a m p l e a n d a v e r a g e r e g i s ters within the Control Unit and will cause the printer to index one line and reprint headings. This denotes the start of a new sequence. The Reset Button may also be used if a malformed bubble is generated and has not been been subtracted from the average by use of the Delete Function. c.Delete - To delete obvious false readings, press the Delete Button and subtract the false reading from the average. This resets the average and sample number back to the previous reading. 5. Storage E Maintenance a) Storage (Daily Take Down) 1. Turn the Power of the Printer Module OFF. All data stored in the printer cannot be reviewed once this is done. 2. Turn off the Power of the Control Unit. 3. Turn off the Power of the Sampler being calibrated. b) Storage (Long Term) - I f t h e P r i n t e r M o d u l e i s n o t t o b e u s e d f o r long periods of time, the following steps should be taken to keep the unit in proper working order. Disconnect the interconnect cable from the Control Unit and 1. from the Printer Module. 2. Store in original packaging or carrying case. c) Cleaning - Use a damp cloth with warm ACETONE or any other harsh cleaners. water. Never use ALCOHOL, Specifications Flow CelC Section 7 for the Gilibrator System Assembly Ranges Available 1 High Flow Cell 2 - 30 LPM S t a n d a r d F l o w C e l l 2 0 cclmin. - 6 L P M Low Flow Cell 1 - 2 5 0 cc/min. Operational Features D i r e c t F l o w R e a d i n g s - The easy to read LCD read-out on the Control Unit (base) instantly displays flow readings. Auto Averaging - A switch on the Control Unit provides Auto-Averaging of the successive flow readings. Flow Delete Function - A Flow Delete switch allows the user to delete erroneous flow readings from the Auto-Averaging function. For example, if a double bubble or other obvious malfunction is observed, that reading can be subtracted from the auto-average and will automatically reset the average to it’s previous value. Programmable Update - The micro-processor electronic design allows programmable updates to assure a long useful service life. Mechanical Features Pulsation Damper - The pulsation damper removes pulsation from the flow source for higher accuracy sampling as well as eliminating pulsations back into the flow source during bubble generation. i Ring Bubble Generator - The Ring Bubble Generator lifts an even soap film from the soap reservoir and provides consistent bubble generation. . Bubble Breaker - The Bubble Breaker design allows the soap film to be drawn away form the end of the flow tube before bursting. This improves flow m e a s u r e m e n t a c c u r a c y b y m i n i m i z i n g f i l m r e s i d u e Svithin t h e f l o w t u b e . Programmable Update - The electronics assure a long, useful service life. Accuracy 22 - Better than 0.5% design allows programmable updates to S e c t i o n 7 (cont’d) Gilibrator Printer Module Printing Thermal Specifications System dot matrix Character 2 dots Spacing Character Font 7x5 dot matrix Character Size 2.4 (vertical) x 1.1 (horizontal) mm Character Set 159 Alphabetic (upper and lower case), numeric, Kana, symbols Paper Thermal Paper width 80 + lmm, roll diameter 40mm reo;der Cilian T h e r m a l P a p e r (3 rolls A-400681) Printing Direction Left - right Printing Speed 0.6 line/second Number of Columns 40 columns/line Section 8 Parts List (2-30 LPM) H i g h F l o w Kit( S t a n d a r d F l o w K i t (2Occ - 6 L P M ) ( l - 2 5 0 cclmin) Low Flow Kit Deluxe H i g h F l o w C e l l A s s e m b l y only Standard Flow Cell Assembly ‘only Low Flow Cell only, Safety Tape (10 ft.) Control Unit (base) Printer Module Printer paper (3 rolls) B a t t e r y C h a r g e r (120~) Flow Cell Soap Soap bottle dispenser Tubing Carrying Case Part # D-800270 D-800271 D-800272 D-800275 D-800265 D-800266 D-800267 B-800331 D-800268 C-800274 A-400681 B-400674 A-400450 A-400667 B-800269 D-800273 23 Section 9 Warranty The Seller warrants to the Purchaser that any equipment manufactured by it and bearing its nameplate to be free from defects in material or workmanIf, at any time ship, under proper and normal use and service as follows: within 90 days from the date of sale, the Purchaser notifies the Seller that in his opinion the equipment is defective, and returns the equipment to the Seller’s originating factory prepaid, and the Seller’s inspection finds the equipment to be defective in material or workmanship, the Seller will promptly correct it by either, at its option, repairing any defective part or material or replacing it free of charge and returned shipped lowest cost transportation prepaid (if Purchaser requests premium transportation, Purchaser will be billed for difference in transportation costs). If inspection by the Seller does not disclose any defect in material or workmanship, the Seller’s regular charges will apply. This warranty shall be effective only if installation and maintenance is in accordance with our instructions and written notice of a defect is given to the seller within such period. This warranty is exclusive and is in lieu of any other w a r r a n t i e s , w r i t t e n , oral or implied; specifically , without limitation, there is no warranty of merchantability or fitness for any purpose. The liability of the Seller shall be limited to the repair or replacement of materials or parts as above set forth. Limitat’ion of Liability The Seller shall not be liable for any claim for consequential or special loss or damage arising or alleged to have arisen from any delay in delivery or malfunction or failure of the equipment. The Seller’s liability for any other loss or damage arising out of or connected with the manufacture, sale or use of the equipment sold, including damage due to negligence, shall not in any event exceed the price of the equipment supplied by us. Service Policy F o r a m i n i m u m f e e o f $95.00, Gilian Instrument Corp. will overhaul, repair and/or replace minor components, and recalibrate one Cilibrator. Gilian r e s e r v e s t h e r i g h t t o p r o c e e d w i t h a d d i t i o n a l r e p a i r s u p t o a m a x i m u m If major c o s t o f $13O.CtO p e r G i l i b r a t o r w i t h o u t n o t i f y i n g t h e c u s t o m e r . c o m p o n e n t s m u s t b e r e p l a c e d , Gilian w i l l n o t i f y t h e c u s t o m e r b e f o r e p r o c e e d ing with repairs. When the instrument(s) is returned, please include a purchase order marked “Repair Cost not to Exceed $100. Without Customer Authorization”. Also include company name, return shipping address, contact name and phone number, serial number(s) of calibrators, date of purchase and description of problem. Return to: Gilian Instrument Corp. 35 Fairfield Place W. Caldwell, NJ 07006-6206 Att: Gilibrator Repairs Dept. 24