Download Pump Switchboard

Transcript

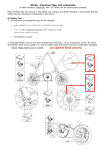

UNIVERSAL PUMP SWITCHBOARD USER MANUAL V 001.05 - JUNE 2012 © COPYRIGHT 2012, NETAFIM NO PARTS OF THIS PUBLICATION MAY BE REPRODUCED, STORED IN AN AUTOMATED DATA FILE OR MADE PUBLIC IN ANY FORM OR BY ANY MEANS, WHETHER ELECTRONIC, MECHANICAL, BY PHOTOCOPYING, RECORDING OR IN ANY OTHER MANNER WITHOUT PRIOR WRITTEN PERMISSION OF THE PUBLISHER. ALTHOUGH NETAFIM TAKES THE GREATEST POSSIBLE CARE IN DESIGNING AND PRODUCING BOTH ITS PRODUCTS AND THE ASSOCIATED DOCUMENTATION, THEY MAY STILL INCLUDE FAULTS. NETAFIM WILL NOT ACCEPT RESPONSIBILITY FOR DAMAGE RESULTING FROM THE USE OF NETAFIM'S PRODUCTS OR THE USE OF THIS MANUAL. NETAFIM RESERVES THE RIGHT TO MAKE CHANGES AND IMPROVEMENTS TO ITS PRODUCTS AND/OR THE ASSOCIATED DOCUMENTATION WITHOUT PRIOR NOTICE. CONTENTS Use of symbols 4 Safety instructions 4 Description Functionality Modularity and flexibility Reliability Easy and accessible maintenance How to identify your switchboard Data sheet General description PG list Switchboard environment of operation Switchboard block diagram The TeSys LU 5 5 5 5 6 6 7 7 8 8 9 Electrical circuits Control diagram Guidelines for connections Electrical symbols - Legend Power connection - 3-phase Terminal and wire specifications - 3-phase Power connection - 1-phase Terminal and wire specifications - 1-phase 11 12 12 13 14 15 16 Troublehooting Switchboard warning light No automatic start of the pump The controller does not turn on LU malfunction 17 17 17 17 List of spare parts 18 Warranty 19 SWITCHBOARD USER MANUAL 3 Use of symbols The symbols used in this manual refer to the following: WARNING The following text contains instructions aimed at preventing injury or direct damage to the crops, the product and/or the infrastructure. CAUTION The following text contains instructions aimed at preventing unwanted system operation, installation or conditions that, if not followed, might void the warranty. ATTENTION The following text contains instructions aimed at enhancing the efficiency of usage of the instructions in the manual. NOTE The following text contains instructions aimed at emphasizing certain aspect of the operation of the system or installation. ELECTRICAL HAZARD The following text contains instructions aimed at preventing death or injury by electrocution or direct damage to the product and/or the infrastructure. SAFETY FOOTWEAR The following text contains instructions aimed at preventing foot injury. Safety instructions WARNING In agricultural environment - always wear protective footwear. DANGER Hazard of electric shock, explosion, or arc flash. Disconnect all power before servicing equipment. Failure to follow these instructions will result in death or serious injury. CAUTION Only qualified electricians are permitted to perform electrical installations and repairs! WARNING The Universal Pump Switchboard does NOT provide protection against electrocution since it does not include an earth-leakage circuit breaker. The following items must be provided in the infrastructure: • A readily accessible circuit breaker, rated according to the total rated power of the load, certified as branch circuit over current protector compliant with the national code and requirements, • Grounding connection: ≤ 10 Ω. • All safety regulations must be applied. • The electrical installation must comply with the local safety standards and regulations. • Protection provided by the equipment may be impaired if the equipment is used in a manner other than that specified by the manufacturer. IP code: IP54 4 SWITCHBOARD USER MANUAL DESCRIPTION Functionality The Universal Pump Switchboard is designed to activate the pump at a command from the controller, provided there is sufficient water pressure in the mainline. If the water pressure in the mainline is too low, a low-pressure signal is transmitted to the controller. The controller may deactivate the pump. The pump can be activated/deactivated manually via a manual override. ATTENTION If the pump is activated manually via a manual override, low-pressure protection is not active, since it is also overridden. It is also possible to disconnect the pump manually. The Universal Pump Switchboard is equipped with 6 double-level terminals enabling the connection of the command lines to the solenoides of the dosing channels in addition to the pump command line. When connecting an external controller, use an 8-wire cable between the switchboard and the controller. Modularity and flexibility The switchboard is designed to operate with a large variety of: Pumps: • Single-phase pumps (0.5 kW to 2.2 kW) • Three-phase pumps (0.75 kW to 15 kW) Mains • 1 x 100-250V • 3 x 200-480V Controllers • 100-250V connected between phase and neutral • 100-250V connected between two phases • 100-250V from an external source Reliability • The switchboard is built of high quality components from internationally recognized manufacturers. • The core of the switchboard is the TELEMECANIQUE's universal breaker TeSys U starter-controller, also known as "LU". Easy and accessible maintenance • The switchboard's straightforward design enables easy and accessible maintenance. • All its components are available locally in almost any place on the globe. SWITCHBOARD USER MANUAL 5 DESCRIPTION How to identify your switchboard To identify the type of your switchboard check the imprint on the LU control unit. LUC C 12 B Switchboard assortment Control unit inscription LUCC12B LUCB18B LUCB12B LUCB32B Combination string FSA-SWITCHBOARD-LUB12+LUCC12B-1PHASE FSA-SWITCHBOARD-LUB32+LUCB18B-3PHASE FSA-SWITCHBOARD-LUB12+LUCB12B-3PHASE FSA-SWITCHBOARD-LUB32+LUCB32B-3PHASE Switchboard Cat. No. 33230-500000 33230-500100 33230-500200 33230-500300 Data sheet General features Outputs Feed to the controller voltage range Feed to the controller current range Fault signal Dosing channel command Inputs Pump command Dosing channel command Low-pressure signal Low-voltage supply Safety / Protection IP54 Short circuit or overload in the controller feed Short circuit or overload in the pump feed Phase imbalance Red indication lamp General features Dimensions wxdxh Weight 6 SWITCHBOARD USER MANUAL 1 X 100V to 1 X 250V (Jumper selection) up to 1A Dry contact N.O. when low water pressure or trip signal occurs Up to 6 channels 24VAC 1 pump command 24VAC from the controller Up to 6 channels 24VAC from the controller Dry contact N.C. from an external pressure switch 24VAC 400mA from the controller for the control circuit 2 fuses of 1A each. There are 2 fuses in order to allow connection of the controller between two phases Overload protection setting is adjustable in the LU control unit within the current range Applicable for 3-phase units Lights in case of too low pressure or trip 27.6 x 18.1 x 32.5 cm (10.9" x 7.13" x 12.8") 4.5 kg (10 lb) DESCRIPTION General description Q1 HF RP RF SM Terminals S0 1 2 3 2 3 4 5 6 PG list PG Cables 1 Mains 2 Mains to controller 3 Feed to pump and dosing channels 4 Dosing channel solenoide command cables + multi-wire command cable + pressure switch cable 5 6 1 4 5 6 SWITCHBOARD USER MANUAL 7 DESCRIPTION Switchboard environment of operation Low voltage power supply for control circuit (24VAC) LEGEND Mains Low voltage (24VAC) Command line Mains Pump command Controller Universal pump switchboard Power supply Fault signal Pump Dosing channel command Dosing channel command Dosing channel Low pressure signal Irrigation water main line Pressure switch NOTE If there is no controller, an external 24 VAC power supply must be provided. Switchboard block diagram Dosing valve command Dosing valve command Dosing valves Terminal Controller Manual pump command - ON Selector OFF Auto pump command SM Fuse LU Control unit LU auxiliary contact Pump command Low voltage power supply for control circuit (24VAC) Fault signal Trip signal or Low pressure signal HF Fault indication lamp LEGEND Mains Low voltage (24VAC) Command line Scope of delivery 8 SWITCHBOARD USER MANUAL Q1 LU base Pump power Pump supply Trip signal Relay RF Relay RP Low pressure signal Pressure switch Main switch S0 Mains DESCRIPTION The TeSys LU The TeSys U at the heart of the Universal Pump Switchboard replaces conventional components in a smaller space • The TeSys U starter-controller incorporates all the conventionally associated functions: circuit breaker + contactor + thermal relay. • It considerably reduces wiring time. • The electircal coordination of the components is intrisically ensured. Equivalent to Advantages • Space-saving • Time-saving • Safety The TeSys LU is composed of the following modules: • LUB power base This power base incorporates the power components: thermal blocks, switching mechanism and power contacts. It also incorporates the auxiliary contacts (terminal block not included). • LUC supervisable control unit Detection / tripping / measurement. LUB LUC • LUA signalling contacts Indicates that the protective device has tripped. LUA The TeSys LU - Combinations for the operation of the pump Power base LUB 12 (Up to 12A) LUB 32 (Up to 32A) Control Command unit voltage 1-phase 24VAC LUCC12B 3-phase 24VAC LUCB12B 3-phase 24VAC LUCB18B 3-phase 24VAC LUCB32B Current range 3–12A 3–12A 4.5–18A 8–32A Voltage range 1 X 100V to 1 X 250V 3 X 200V to 3 X 480V 3 X 200V to 3 X 480V 3 X 200V to 3 X 480V Overload motor protection 1.1kW 2.2kW at 1 X 100-115V at 1 X 200-250V 3.5kW 7kW at 3 X 200-220V at 3 X 400-480V 5kW 9kW at 3 X 200-220V at 3 X 400-480V 9kW 15kW at 3 X 200-220V at 3 X 400-480V *For other combinations, call Netafim. SWITCHBOARD USER MANUAL 9 DESCRIPTION Control and diagnostic unit • LUCB - Class 10 - 3-phase • LUCC - Class 10 - 1-phase • Protection against overloads and short-circuits. • Protection against phase failure and phase imbalance. • Earth fault protection (equipment protection only). WARNING The Universal Pump Switchboard does NOT provide protection against electrocution since it does not include an earth-leakage circuit breaker. The following items must be provided in the infrastructure: • A readily accessible circuit breaker, rated according to the total rated power of the load, certified as branch circuit over current protector compliant with the national code and requirements, • Grounding connection: ≤ 10 Ω. • Manual reset. • Fault differentiation with manual reset. • Thermal overload alarm. Test trip Test trip magnetic fault Test trip thermal overload fault Test trip thermal overload fault by energized LUC For full documentation on the TeSys LU, see www.schneider-electric.com 10 SWITCHBOARD USER MANUAL ELECTRICAL CIRCUITS Control diagram 800FP-SM32 “0” Auto Man. 3 3 SM 4 11 11 Q1 97 LUA1C20 RP RF 14 98 14 N24 P24 A1 Power supply Analog input 24 A2 X1 Fault indication X2 lamp Red HF DO1 COM COM COM V4 V5 V6 V1 V2 V3 V4 V5 V6 DO2 DO3 DO4 DO5 Digital output 24VAC EC(AI1) pH(AI2) DO6 DO7 COM Fault to controller AL1 COM AL2 6 V3 5 COM 4 V2 3 COM 2 V1 103 102 101 N.C. Low pressure protection (presostat) 21 Dosing channels Pump command from controller 24 VAC Power supply from controller to switchboard 24 VAC P24 N24 Fuse 1A RF A1 LU9BN11 1 Fuse 1A 24 RF IN2 COM RP 21 4 A1 Q1 LUC***BL A2 A2 RP Digital input Controller P24 EC N24 EC/pH transducer pH LEGEND Scope of delivery WARNING The low voltage lines (24 VAC) must come from the same controller that issues the command for the pump. WARNING The polarity of the low voltage lines (24 VAC) must be observed - N24 = common from controller. SWITCHBOARD USER MANUAL 11 ELECTRICAL CIRCUITS Guidelines for connections All the commands to the switchboard are 24 VAC If the Universal Pump Switchboard is supplied factory-installed in a dosing unit, the dosing channels are already connected. If the Universal Pump Switchboard is supplied separately, connect the dosing channels as shown in the Control Diagram, page 11. COM When connecting the "Fault to controller" command line, make sure to program in the controller so that upon receiving a pump deactivation command from the switchboard, the controller deactivates the pump with a delay of a few seconds (see the Controller Manual). V NOTE When multiple dosing units are operated by a single controller (as typical of the NMC XL), the dosing channel solenoides are connected via a relay, as shown. SSR DO COM Dosing channel LEGEND Scope of delivery Electrical symbols - Legend Relay Q1 Main switch A1 5/L3 3/L2 1/T1 LUB unit 0 1 R A2 97 98 Dosing solenoid 2 4 6 Booster pump 6/T3 4/T2 2/T1 U V W 12 SWITCHBOARD USER MANUAL P Modular terminal Double level terminal Selector V LUC***B Fuse terminal 1 3 5 SM Terminal “0” Man. 3 4 Auto 3 4 220/110V Transformer 24VAC Internal wire External wire Related contact ELECTRICAL CIRCUITS Power connection 2 0 1 6 8 5/L3 Q1 10 97 98 5 7 See power L connection 1 options L 2 L 3 L L/N 4 5 Main supply 9 Feed to controller 6 LUC***B L L/N 7 8 Power supply to controller 6/T3 3 4/T2 1 2/T1 SO 5 X 25A 4 3/L2 1/T1 3-phase U V W 0 P Power connection options Pump WARNING When connecting the mains and the controller to the switchboard power terminals, make sure the jumpers are placed correctly according to the mains and the controller voltage. A jumper incorrectly connected might damage the controller! NOTE The switchboad exits the factory with a jumper connecting L3 to L4, as in option A. 3 X 400 V Option A Option B Option C V Controller 230 V 3 X 440 Mains Controller Mains Controller Controller 3 X 220 Mains V 3 X 220 V 3 X 220 V 230 V 3 X 400-480 230 V 3 X 200-240 230 V 3 X 400-480 V Controller - external Controller 230 V V Controller 115 V V 0r 230 V / 115 V 3 X 200-240 V 115 V 3 X 200-240 V 115 V No jumper External controller - No jumper L L L L L/N L L L L L/N 1 2 3 4 5 6 1 2 3 4 5 6 L L L L L/N 1 2 3 4 5 6 L1 L2 L3 N Jumper position 3-4 L1 L2 L3 L1 L2 L3 L L/N Jumper position 3-4 / 2-5 NOTE Option C - In some cases the controller is fed by an external source, usually in the USA, Mexico, Central America (some areas),and India (some areas). SWITCHBOARD USER MANUAL 13 ELECTRICAL CIRCUITS Terminal and wire specifications Voltage 220 - 440 V 110 - 220 V 110 - 220 V GND 220 - 440 V GND 24 VAC 24 VAC 24 VAC 24 VAC 24 VAC 24 VAC 14 SWITCHBOARD USER MANUAL Terminal symbol L1. L2. L3 L4 L/N U. V. W P24 N24 101 - 103 AL1 - AL2 V1 - V6 COM V1 V2 V3 V4 V5 V6 COM COM COM COM COM COM Dos. channel 1 Dos. channel 2 Dos. channel 3 Dos. channel 4 Dos. channel 5 Dos. channel 6 Pressostat (pressure switch) Booster pump command Fault to controller From controller 24VAC Pump 4 5 6 7 8 Terminal block Modular Modular Modular Ground Modular Ground With LED fuse With LED fuse Double-level Double-level Double-level Double-level L L/N U V W To controller 1 2 3 External supply (optional) L L/N Main supply L L L P24 N24 102 101 103 AL2 AL1 3-phase Terminal color Gray Black Black Yellow + green Gray Yellow + green Black Black Gray Gray Gray Gray Wire color Brown Black Black Yellow + green Brown Yellow + green White Gray White White White Gray Terminal section 4 mm ELECTRICAL CIRCUITS Power connection 2 0 1 4 6 5/L3 3/L2 1/T1 1-phase Q1 8 97 98 5 See power L L/N connection 1 2 options Main supply 7 L L/N 3 4 Feed to controller 5 L 6 LUC***B N 7 Power supply to controller L 8 Power connection options 6/T3 3 4/T2 1 2/T1 SO 5 X 25A L/N 9 10 P Pump WARNING When connecting the mains and the controller to the switchboard power terminals, make sure the jumpers are placed correctly according to the mains and the controller voltage. A jumper incorrectly connected might damage the controller! NOTE The switchboad exits the factory with jumpers connecting L1 to L3 and L/N2 to L/N4, as in option A. 1 X 220 V Option A Option B Controller 230 V 2 X 440 V Mains Controller Mains Controller 2 X 220 V 2 X 220 V 230 V 1 X 200-250 230 V 1 X 100-250 V Controller 230 VV Controller - external 0r 2302 VX /200-240 115 V V X 200-240 V 230 V 115 V 2 X2220 V No jumper External controller - No jumper 1 X 100-115 115 V Controller 115 VV L L/N 1 2 L L/N 3 4 5 L L/N 1 2 L L/N L L/N 3 4 5 L L/N L L/N Jumper position 1-3 / 2-4 NOTE Option B - In some cases the controller is fed by an external source, usually in the USA, Mexico, Central America (some areas),and India (some areas). SWITCHBOARD USER MANUAL 15 ELECTRICAL CIRCUITS Terminal and wire specifications Terminal block Modular Modular Modular Modular Ground With LED fuse With LED fuse Double-level Double-level Double-level Double-level Voltage Terminal symbol 110 - 220 V L1, L3 110 - 220 V L/N External voltage L6, L8 External voltage L/N GND 24 VAC P24 24 VAC N24 24 VAC 101 - 103 24 VAC AL1 - AL2 24 VAC V1 - V6 24 VAC COM 16 SWITCHBOARD USER MANUAL V1 V2 V3 V4 V5 V6 COM COM COM COM COM COM Dos. channel 1 Dos. channel 2 Dos. channel 3 Dos. channel 4 Dos. channel 5 Dos. channel 6 8 9 10 Pressostat (pressure switch) Booster pump command Fault to controller L L/N From controller 24VAC To controller 3 4 5 6 7 External supply (optional) Main supply 1 2 L L/N Pump L L/N L L/N P24 N24 102 101 103 AL2 AL1 1-phase Terminal color Gray Blue Black Black Yellow + green Black Black Gray Gray Gray Gray Wire color Brown Blue Black Black Yellow + green White Gray White White White Gray Terminal section 4 mm TROUBLESHOOTING Switchboard warning light • The switchboard warning light is on (whether the dosing booster is running or not). Action 1) Check if the pressure on the main line is too low: If YES, restore the original main line pressure. 2) Check if the overload protection breaker is ON. Toggle it OFF and ON again. If the switchboard warning light is still on or the overload protection breaker trips (turns to OFF) again, have a qualified electrician check that the dosing booster is in working order (see the Dosing Booster Manual) and check for irregularities in the mains. 3) Check if the overload protection setting of the LU is set according to the pump consumption. If after implementing all the above steps, the malfunction is still not fixed - consult your Netafim representative. No automatic start of the pump • Automatic activation of the pump does not function. Action 1) Set the selector switch (SM) to MANUAL. If the pump still does not function, check the fuses (See List of Spare Parts, page 18) and replace if necessary. 2) If the pump still does not function, check whether: a) The main switch (SO) is set to MANUAL. b) The selector switch (SM) is not set to AUTO. c) The LU circuit breaker is set to OFF. d) The cable to the controller is disconnected or defective. e) The low voltage (24 VAC) from the controller to the switchboard is inversely connected (N to P) if necessary, reverse it . f) There is a malfunction of the controller (see the Controller Manual). If after implementing all the above steps the malfunction is still not fixed - consult your Netafim representative. The controller does not turn on • The controller does not receive power supply from the mains. Action 1) Make sure the jumpers are placed correctly according to the mains and the controller voltage. (For 3-phase installation see page 13, for 1-phase installation see page 15). WARNING A jumper incorrectly connected may damage the controller! LU malfunction • If after implementing all the actions regarding any of the malfunctions above, the malfunction is still not fixed, it is possible that the reason is a malfunction of the LU (for full documentation on the TeSys LU, see www.schneider-electric.com). SWITCHBOARD USER MANUAL 17 LIST OF SPARE PARTS Suitable Type/model for Technical data Cat. number Manufacturer 1-phase 194L-E16-1754 4 X 16A On request Allen Bradley 3-phase 194L-E25-1755 5 X 25A On request Allen Bradley On request Telemecanique Both LUB 12 or LUB 32 12 A Both LUA1C20 N.O. 32 A Accessory Symbol Main switch Main switch Telemecanique 3-12A, 1 X 100-250V Command 24 VAC 3-12A, 3 X 200-480V 77100-013600 LUCB 12B Command 24 VAC or 4.5-18A, 3 X 200-480V LU control 77100-013620 Telemecanique 3-phase LUCB 18B Command 24 VAC unit or 8-32A, 3 X 200-480V LUCB 32B On request Command 24 VAC Selector Both 800 FP - SM32 6A On request Allen Bradley switch Both 40.52 24 VAC 77100-001460 Finder Relay Both 40.52 24 VAC 77100-001460 Finder Relay Terminal Phoenix with LED Both UK5 - HESI 1A On request contact fuse Indicator Both PL16-22D LED - 24 VAC On request lamp Electrical Both 276 X 154 X 181 mm On request Hi box board Spare Both 179 020.1 Glass 5 X 20 mm - 1AF 77100-000470 Siba fuse 1-phase LUCC 12B 18 SWITCHBOARD USER MANUAL S0 LU base Fault aux. contact + terminal LU control 77100-013640 Telemecanique unit On request S0 Q1 SM RP RF Fuse HF WARRANTY Netafim warrants all the components of the switchboard to be free of defects in material and workmanship for 1 (one) year from the date of installation, provided the installation has been reported to Netafim within 30 days of installation. If the installation was not reported or was reported later than 30 days from the date of installation, Netafim will warrant the product for a period of 18 months from the date of production, according to its serial number. If a defect is discovered during the applicable warranty period, Netafim will repair or replace, at its discretion, the product or the defective part. This warranty does not extend to repairs, adjustments or replacements of a switchboard or part that results from misuse, negligence, alteration, force majeure, lightning, power surge, improper installation or improper maintenance. If a defect arises in your Netafim product during the warranty period, contact your Netafim supplier. Limited warranty This warranty is subject to the conditions in Netafim's official warranty statement. (For the full text of Netafim's official warranty statement, please contact Netafim). SWITCHBOARD USER MANUAL 19 20 SWITCHBOARD USER MANUAL GROW MORE WITH LESS WWW.NETAFIM.COM