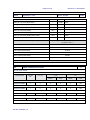

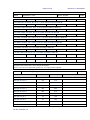

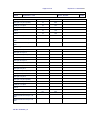

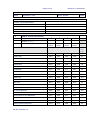

Download P1173 X1273 CB report SK

Transcript